THE USE OF S T A T I S T I C A L DESIGN IN MISSILE P R O P U L S I O N STUDIES

C. A . O'Malley

A e r o j e t - G e n e r a l Corporation Liquid Rocket Plant Preliminary Design Department

Sacramento, California Abstract

It has been said by D r . Hafstead, Vice President for Research, General Motors, that one of the most powerful tools in the hands of the engineer today is statistical design.

Many industrial organizations are becoming increasingly aware of the usefulness of this tool and are taking steps to promote its use. L a r g e corporations in every field have e s tablished special sections to aid in the establishment and evaluation of design work and experimentation. Others are providing training for their engineers and scientists to enable them to more intelligently plan their work, and many are employing the services of consultants in this field.

Introduction

We are greatly indebted to the agricultural experimen

ters for much of the background development in experimental design. The application of statistical principles to industrial design and experimentation is a very recent development;

hence, few other than those specializing in the field have any great understanding of the techniques available and their power. The statistical courses given as part of mathematics programs in most schools provide useful background for the evaluation of results, but give little actual help in the initial designs; yet this is where most knowledge is needed.

Emphasis on Skill

It is frequently said that all the emphasis on skill needed to use statistical methods is ridiculous; that any good engineer with common sense can plan a program and get meaningful data. Yet the literature is filled with examples of poorly planned and poorly evaluated design and research, and hours are spent trying to bring sense to a hodge-podge

of engineering calculations and experimental data.

To use an example specifically directed toward l a b o r a tory r e s e a r c h e r s , in a 1957 talk before the Detroit section of the American Chemical Society, D r . W . J. Youden of the U . S . Bureau of Standards indicated the six steps that must be followed if you expect to get along without the use of statisti

cal design.

1. Take more c a r e - - I f the data collected will not correlate, probably it means bad technique and poor record taking.

2. Obtain new ins truments --If more care will not yield the results expected, the instruments must be at fault.

3. Samples must be bad--Obtain new samples and check and recheck.

4. Obtain many measurements to reduce chance of e r r o r (very quickly dropped as too laborious and time con

suming).

5. Measure another property--This permits a fresh start and repetition of the preceding steps.

6. If these steps fail, work on some other problem.

Obviously, such a course would be very wasteful of both time and money and it would be better to plan in advance a program which would acquire a maximum of useful informa

tion with less effort.

Requirements of Statistical Designs

What then are the requirements for such a program?

F i r s t , it should avoid bias. A good program must be com

pletely objective. Second, e r r o r s should be minimized, and at the same time a realistic estimate of those e r r o r s should be provided within the data collected. In research work, checks on the operation of the equipment used should be built into the program, and, specifically in design work, the num

ber of calculations should be reduced to the minimum needed to satisfy these requirements.

Characteristics of Good Designs

A good design will meet these requirements and s i m plify the entire program. It will face in advance the problem of data interpretation and present it in a usable form. The order of trial runs will be random to avoid bias and negate variations that may occur with time variations due to obso

lescence of available data. Sufficient replication will be in

cluded to permit e r r o r estimation, and the design work will be programed.

The investigation of the effects of varying a single f a c tor or making simple ne i t h e r - o rn choices is relatively simple.

However, in industrial work we frequently wish to investigate more complex relationships. There may be a relatively large number of independent v a r i a b l e s . The effects of the variables that we are able to control may not be independent of each other. O r there may be any number of variables over which we have little or no control and no way of even m e a s u r ing. Variables may be controlled, but only within a narrow range that will not significantly lower the criterion chosen for the evaluation of a given missile design. Because of these

restraints, the magnitudes of effects observed will usually be very small and may well be completely obscured by the errors involved in setting conditions and observing results and the effects produced by variations in conditions that are not con

trolled.

We can usually anticipate that the e r r o r of observations in industrial design or experimental work will be very l a r g e , and statistical tests of significance must be applied to each result to determine if it is real or caused by e r r o r . A l s o , if we are to ensure that any result be significant (i. e. , the a p parent effect significantly greater than the e r r o r in its deter

mination) we must either run a great number of tests (which may be expensive or too time consuming) or resort to special statistical designs that will permit us to derive the maximum of useful information from a minimum of actual tests.

These are the problems that have lead the engineer to adopt methods originally developed by agricultural workers (who w e r e unable to control variations in weather, soil f e r tility, and other factors) and to develop other methods more suited to his problem.

Probably the most commonly used scheme of design, where more than one variable is involved, is the factorial

experiment originally developed during the 1920s and 1930s by R. A . Fisher and his colleagues at the Rothamstad E x p e r iment Station. Since it is f r o m this technique that other tech

niques have evolved, it would be well to discuss it in some detail.

The Classical Method and Factorial Design The classical method for design or experimental work is to hold all the independent variables constant but one. U n fortunately, this fails to detect any possible interactions b e tween variables. Thus, changing the value of factor A from a value, Αχ, to some other value, A2> might produce a given change in the criterion of evaluation with factor Β fixed at a value, B , , but a different change when factor Β is at B^.

Factorial design can detect this type and at the same time give the maximum amount of information about the problem under investigation for a given amount of work. In his

approach to experimentation, Fisher differed in two funda

mental aspects f r o m the classical "one variable at a time"

technique. F i r s t , he stressed the importance not necessarily of minimizing the magnitude of the experimental or design e r r o r , but rather of obtaining a reliable estimate of the exact magnitude of e r r o r . This knowledge is needed if exact tests of significance are to be applied. Secondly, he emphasized the advantages to be gained if as many as possible of the f a c tors under investigation can be included in the same design or experimental trial. These advantages are indicated as fol

lows :

Comparison of C l a s s i c a l and Factorial Design Methods

Classical Factorial 1. Each variable studied 1, A l l variables of inter-

individually, all others est studied simultane- held constant ously 2. A separate portion of the 2. A l l of the data used for

data used for each con- all conclusions elusion

3. No indication of inter- 3. Effect of interactions

actions detectable 4. No estimate of design 4. Estimate of design or

or experimental e r r o r experimental e r r o r possible unless indivi- possible without r e p e - dual tests are repeated tition of tests

several times

5. Conclusions drawn with- 5. Conclusions drawn out a known degree of within a known degree confidence of certainty

Factorial Design

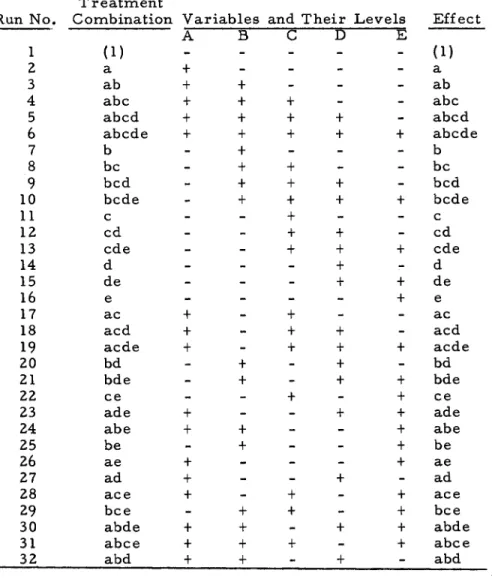

Let us assume that we wish to make a factorial design study involving five variables at two levels. The design trial would be set up as shown in Table 1. The plus and m i nus signs indicate the upper and lower levels of the variables,

respectively. The treatment combination indicates the p r o duct of all variables at their upper levels, and the effect o b tained, in the case of a complete factorial design trial, is synonymous with the grouping indicated for the treatment combination. Treatment combination (1) indicates all v a r i ables at their lower level.

Table 1. Complete 2 Factorial Design Level

Run N o . Treatment

Combination Variables and Their Levels Effect

A Β C D Ε

1 (1) - - - - (1)

2 a + - - - a

3 ab + + - - - ab

4 abc + + + - - abc

5 abed + + + + - abed

6 abede + + + + + abede

7 b + - - - b

8 be + + - - be

9 bed + + + - bed

10 bede + + + + bede

11 c - + - - c

12 cd - + + - cd

13 cde - + + + cde

14 d - - + - d

15 de - - + + de

16 e - - - + e

17 ac + + - - ac

18 acd + + + - acd

19 acde + + + + acde

20 bd + - + - bd

21 bde + - + + bde

22 ce - + - ce

23 ade + - + ade

24 abe + + - - + abe

25 be + -

-

+ be26 ae + - - + ae

27 ad + - + - ad

28 ace + + - + ace

29 bee + + - + bee

30 abde + + - + abde

31 abce + + + - + abce

32 abd + + - - abd

It will be noted that each column under variables A , B, C, D , and Ε contains 16 plus signs and 16 minus signs. In the complete type factorial design trial it is desirable to make the runs in a random o r d e r - - t o minimize design e r r o r - - i n stead of, for example, to make all runs containing A at the plus level first.

Referring to the above design trial it can be seen that each main effect is estimated f r o m the comparison of the averages of two sets of sixteen results rather than f r o m the

comparison of the averages of two sets of eight results as in the classical method. W e thus have doubled our accuracy- while running no more design trials.

The second big advantage of the factorial design is that it provides a means of estimating possible interactions b e tween the main effects.

It will be noted that in determining each main effect, and also in determining each interaction, the result of each of the 32 experiments has been used, while in the classical method only one result was used in all estimates, and each of the other results was used only once. To replicate the c l a s s ical set of experiments, at least half (16 runs) would have to be repeated to ascertain the magnitude of design e r r o r ; each would add only one effect to our knowledge, and tell us noth

ing of other effects or possible interactions.

Up to this point we have discussed only a five-factor design trial with all factors at two levels, or a 2^ factorial design. The method and principles can, however, be ex

tended to any number of variables, as long as for each v a r i a ble added we increase the exponent of 2 by 1. The number of runs necessary is then indicated by the value of the expres

sion; i . e . , a 2" experiment requires 64 runs. As additional factors are added, efficiency of the experiment improves, since with each additional factor, the accuracy of estimation of the effects is doubled. Similarly, with more variables it is possible to investigate higher order interactions, i . e . , interactions between three or more variables. It is observed, however, that as the number of factors is increased, the num

ber of experiments, which is increasing exponentially, soon becomes quite large. Fortunately, it can be demonstrated that in many cases the total number of tests to be run can be greatly reduced through the use of a technique known as f r a c tional replication without seriously affecting estimates of main effects and first- and second-order interactions. Higher- order interactions usually are negligible or nonexistant and need not be isolated.

In setting up one of the "partial factorial" design trials, two or more of the variables are "confounded" with a higher- order interaction; that is, their treatment combinations are made statistically equivalent to specific higher-order inter

actions, so that the effects observed for these particular runs may be due to the primary variables chosen for "confounding"

or the effects may be due to the higher-order interactions.

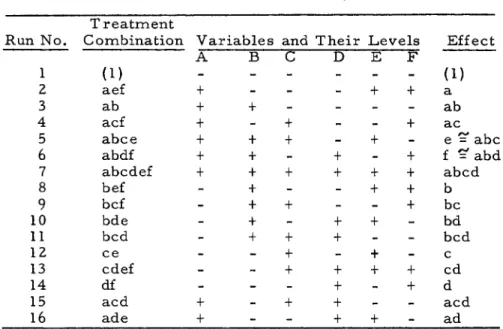

For example, in a hypothetical 2" design trial, if enough prior information is available to the designer to determine that variables A , B , C, and D have a much more radical effect upon missile range than do variables Ε and F , he can con

found Ε and F with a higher order interaction (above f i r s t - o r d e r ) . He sets Ε ~ ABC and F ^ A B D .

In the previously illustrated design trial, five v a r i a bles were considered. Let us add one more variable. This will be variable F . Now Ε will bear the sign of A B C and F will bear the sign of A B D . A l l of the important information that would normally be gained in 64 trials can now be gained from 16, because the higher-order interaction A B C and A B D are bound to be of little significance. The design trial a p pears in Table 2.

Table 2. 2 Factorial Design T r i a l

Run N o . Treatment

Combination Variables and Their Levels Effect

A Β C D Ε F

1 (1)

- - - - -

(1)2 aef

+ - - + +

a3 ab

+ + - - - - ab

4 acf

+ + - - +

ac5 abce

+ + + - + - e = abc

6 abdf

+ + - + - +

f = abd7 abcdef

+ + + + + +

abed8 bef

+ - - + +

b9 bcf

+ + - - +

be10 bde

+ - + + - bd

11 bed

+ + + - - bed

12 ce

- + - + -

c13 cdef

- + + + + cd

14 df

- - + - + d

15 acd

+ + +

_-

acd16 ade

+ - + + - ad

Analysis of the results of factorial design trials (or experiments) is made using a technique known as analysis of variance. When these methods are used the necessary calcu

lations and tests of significance become quite mechanical and easy to handle with the assistance of standard desk calcula

tors. Where available, an I B M 704 computer may be used to good advantage in l a r g e r design trials.

Unfortunately, factorial designs have one rather serious weakness. By themselves they are strongest only when inter

actions are not l a r g e , i. e. , effects are linear and additive or at best when it can be assumed that the effects can be d e scribed with a rather simple mathematical model.

The Box Method History and Description

A number of methods have been suggested for resolving

this difficulty, but none have proved so powerful as those a d vanced initially by G. E. P. Box and K. P. Wilson in 1951 and since further developed by Box and various others and now collectively known as the Box, Box-Wilson, or Box-Hunter method of experimentation. Descriptions of the method and various parts of it have appeared in a number of places, notably in the book Design and Analysis of Industrial E x p e r i ments, by Davie s (JY. To promote abetter understanding of this method, the Chemical Division of the American Society for Quality Control sponsored a series of short courses at various places about the country. They started in the Spring of 1956 and were conducted by D r . J. S. Hunter, Statistical Consultant for American Cyanamid Company and P r o f e s s o r at Princeton University, where he is a coworker of P r o f e s s o r Box. Another recent text that reviews the Box Method and other statistical methods especially useful to engineers is Applied Statistics for Engineers by Volk (2). This text is rather weak in many respects, but may be useful in conjunc

tion with the book by Davies.

The Box method makes much use of the factorial type of experiment, or design, described above, but makes one very important but very simple change. A new experimental point is added--the midpoint of the design--and it is replicated to gain an estimate of experimental or design e r r o r completely independent of the rest of the design. With this additional data much more information of the true nature of the response surface can be obtained. The Box method also makes great use of more simplified calculations based on experimental data available to the design engineer than can be found in standard texts on the subject of experimental design. Perhaps, though, the Box method might be better described as a philo

sophy rather than as a fixed technique.

Application of the Box Method, F i r s t Order

An application of the simplest factorial design where interactions and higher order terms are not of great i m p o r tance will be briefly described here, in reference to a hypo

thetical case where only the effects of "burning time" and

"percent inert binder in the solid propellant" upon missile range are considered. Figs 1 and 2.

It is evident that the surface is everywhere curved.

However, if we were to investigate only a small portion, it can be seen that a plane will very closely approximate the actual surface. This is one of the applications of the first- order design.

A second application is the determination of the opti

mum process conditions by use of a path of steepest ascents.

Actually this method is quite simple to apply. Once the

Missile Range

F i g . 1. Missile Range Response Surface Appears as a Ridge

% Inert Binder

200 nm

F i g . 2. Missile Range Response Plotted as a Contour Map

factorial design trial is completed and the constants of the equation determined, it is very easy to determine what

changes can be made in variable levels to approach maximum missile range along the shortest path, i . e . , that which is steepest. The process of experimentation can then be r e peated and a new approximation of the best path made. After only a few trials, the exact number depending on the size of changes and the direction, the best point will be discovered.

Obviously we could also add lines to the map which would also indicate the areas within which we would have to operate in order to ensure meeting imposed conditions such as maximum and minimum burning times consistent with the mission of the missile.

A third application is the screening of variables. F r e quently many variables are considered by the design engineer but only a very few will have a significant effect on the m i s sile range or other major design criteria. In this case, a fractional replicate of the factorial design would be used. In other words, instead of making the entire 2n runs (where η is the number of v a r i a b l e s ) necessary for the whole factorial, we would make a minimum of 2n"^ runs where 2n~^ is greater than the number of variables. The results would then permit us to eliminate those variables which did not show significant effects in the range under investigation. The U . S . Bureau of Standards has published a bulletin detailing fractional r e p licates of two-level factorial designs for f r o m 5 to 16 v a r i a bles in 16 to 256 runs (3).

Application of the Box Methods, Second Order

The more complex second-order equations could also be used for path-of-steepest-ascent optimization. However, the f i r s t - o r d e r approximation is usually adequate for such applications, although second-order models are helpful in response surface mapping and in the development of the the

ory concerning the process in question.

What is the Best Design?

Unfortunately there is none. It has been said that the only time a design can be properly planned is after it has been completed. Each situation calls for a different tech

nique and the dispatch with which the problem can be solved depends upon the tools the designer has at his disposal. We can, however, set forth certain principles that should be followed:

First, most design engineering is iterative. That is, the designer will first conceive an idea which he will then calculate through to a finished design. Based on the design

results, he will modify or change his first idea, developing a new idea which he will then test, continuing this cycle p r o - cess until the investigation is complete. Statistics can help at each step.

Each design must be chosen to provide the maximum of useful information for a minimum of effort. Preferably, this information should be in a f o r m useful in further investiga- tions. Statistical guidance is essential.

Each plan should be amenable to division into suffi- ciently small parts for frequent evaluation of progress and also minimization of confusions caused by obsolete data. This division is most successful when guided by statistical con- siderations, and statistics are essential to recombining the parts.

No plan should be so inflexible that it cannot be altered or even scrapped if it is found to suffer from serious defects.

Factorial Design Applied to a Prepackaged Liquid Propulsion System

Now let us turn to an application of factorial design, in a preliminary design problem involving a hypothetical a i r - to-surface missile.

F o r the sake of familiarity, the variables chosen w e r e three for which missile designers already have a good "feel."

They could have been new variables on which the designer has no or little prior knowledge.

Calculations are presented in which all missiles must fit the trajectory parameters for a 300-nm mission.

The variables investigated are:

Burning time Chamber pressure Propellant combination

The first two quantitative variables are investigated at two levels, and the qualitative variable "propellant combination"

is represented by two sets of storable liquid bypropellants on which unclassified data has been available for many y e a r s . Since the missile skin is subjected to rather severe aerody- namic heating, propellants w e r e chosen which can be safely temperature-cycled f r o m -65 to 160°F when stored under moderate pressure: I R F N A (22% N O J / U D M H and 0. 70 N - O ,

+ 0.30 N O / C1 0Hl 6. ù z 4

The criteria of evaluation for the missile design are:

Missile diameter Axial g-forces

O v e r - a l l missile weight

The most successful combination of variables is that which results in the lowest values for these three criteria.

The statistical evaluation will show the actual

significance of each variable with respect to each of these criteria.

Fixed Conditions and Assumptions

1 . The hypothetical mission is to deliver a 1 , 0 0 0 - l b warhead 3 0 0 nm f r o m the launch point. The launch aircraft will travel at M = 0 . 8 5 at 3 5 , 0 0 0 - f t altitude. The aircraft will launch the missile horizontally, and the missile will fly a ballistic trajectory, achieving a cutoff velocity of 7 , 4 5 4 . 1 0

ft/sec.

2 . Assume the aircraft cannot handle an external missile with outer diameter greater than 3 7 . 5 in. without ex

tensive modification.

3 . Assume the guidance section and structural m e m bers of the missile cannot handle in excess of 1 5 - g axial acceleration forces.

4 . Designs will incorporate bell-shaped nozzles, equivalent in performance to the longer 1 5 ° half-angle conical nozzles.

5 . Gimbaled engine will be used for thrust-vector control.

6 . Inside case diameter, D = 3 7 . 0 in.

7 . A r e a ratio, £ = 1 6 .

8 . Combustion chamber diameter - throat diameter, Dt + 6 in.

9 . Characteristic length, L * - 6 0 i n . , (per Missile Engineering Handbook for HNO3 with J P - 3 . ) The propellants chosen will be assumed to have approximately the same L * .

1 0 . A s s u m e gas generator system and controls will add 1 5 % on to calculated length of tanks. This is a realistic value based upon past experience with this particular type of propulsion system.

1 1 . Propellant weight fraction, Wf/ W = 0 . 9 0 . This is predicated upon the increased use of fiberglass, plastic honeycomb, and ablative materials in thrust chambers and auxiliary structures.

1 2 . Ullage is neglected, for purpose of simplifica

tion.

1 3 . Weight fraction, unused propellant = 0 . 0 2 0 8 3

(based upon similar designs in the past).

1 4 . O v e r - a l l missile weight, W Q = 1 , 7 8 0 + W . Guidance section = 6 0 0 lb, propulsion controls = 1 8 0 l b . Delivery element = 1 , 0 0 0 l b .

1 5 . Nozzle discharge coefficient, C - Q = 0 . 9 7 1 5 — a

realistic value based upon past practice.

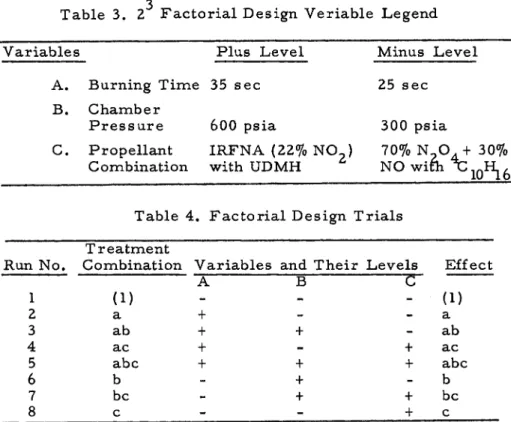

We will investigate three variables at two levels, as shown in Table 3 .

Table 3. 2 Factorial Design Veriable Legend

Variables Plus Level Minus Level

A . Burning Time 35 sec 25 sec B. Chamber

P r e s s u r e 600 psia 300 psia C. Propellant

Combination I R F N A (22% N O J with U D M H

70% Ν Ο + 30%

NO wifti I C^ H ^

Table 4. Factorial Design Trials

Run N o . Treatment

Combination Variables and Their Levels Effect

A Β C

1 (1) -

-

- (1)2 a

+

--

a3 ab

+ + -

ab4 ac

+

-+

ac5 abc

+ + +

abc6 b -

+

- b7 be -

+ +

be8 c - -

+

cStatistical C r i t e r i a of Evaluation - With Respect to Primary- Variables and Interactions

The worth of each design will be judged on the basis of:

1. De, exit diameter, as small as possible. Designs which exceed the 37 in. Dc will be considered unsatisfactory,

2. g-forces, as small as possible. Designs in which F ^ Q / W ^ Q exceeds 15 g will be considered unsatisfac

tory.

3. Gross weight, as small as possible. Since each design is made to fit the original equation of trajectory, it is assumed each will have approximately a 300-nm range.

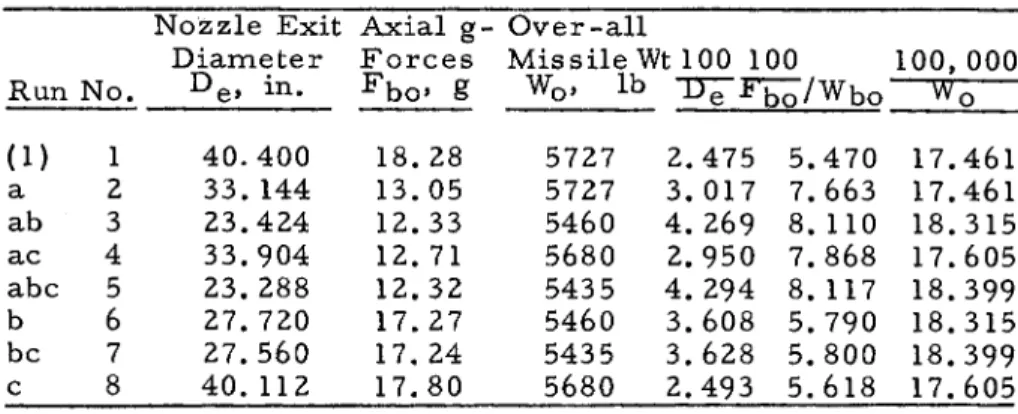

Tabulation of Results

Statistical criteria in a factorial design a r e applied in the analysis of variance to numerically evaluate the data. The results are easier to evaluate when they are direct functions of the desired criteria. In this case small values of De,

F J ^ / W ^ Q , and W Q are desired, so the criteria used will be reciprocals of these values.

Table 5. Results Nozzle Exit Axial g- O v e r - a l l

Diameter F o r c e s Missile Wt 100 100 100,000 Run N o . De, in. Fb o > g WG, lb De F b o /wb o W0

( 1 ) 1 40.400 18. 28 5727 2.475 5.470 17.461

a 2 33.144 13. 05 5727 3, 017 7. 663 17.461 ab 3 23.424 12.33 5460 4. 269 8. 110 18.315 ac 4 33.904 12. 71 5680 2. 950 7.868 17.605 abc 5 23.288 12. 32 5435 4. 294 8. 117 18.399 b 6 27. 720 17. 27 5460 3. 608 5. 790 18.315 be 7 27. 560 17. 24 5435 3. 628 5.800 18.399 c 8 40. 112 17. 80 5680 2.493 5.618 17.605 Without resort to statistical evaluation it can be seen that Run 5 is the best of the eight runs, as far as low values of Dg, FD O/ WD O, a n (i Wo are concerned.

The statistical evaluation is then made to determine the primary effects and interactions of the variables. Tables are prepared showing the calculation of effects and mean squares by Yate!s method and also the analysis of variance for each of the criteria considered. These r a w data tables are not p r e sented in this report.

Within the limits of this study, the best design was achieved with:

35 sec burning time

600 psia chamber pressure

propellant combination of red-fuming nitric acid (22% NO^) with unsymmetrical dimethylhydra- zine

Conclusions on Designing for Low M i s s i l e Diameters

1. Chamber pressure is a highly significant variable.

2. Burning time is significant, but only about one- fourth as important as chamber p r e s s u r e s .

3. The choice between the propellant combinations investigated has no significant bearing upon missile diameter.

4. None of the variable interactions significantly affect missile diameter.

5. Increasing chamber pressure and burning time both had beneficial effects in decreasing missile diameter.

However, it is indicated that changing from the propellant combination mixed oxides of nitrogen with turpentine to r e d - fuming nitric acid with unsymmetrical dimethylhydrazine

actually caused a very minor increase in missile diameter.

Conclusions on Designing for Low Axial g-Forces

1. Burning time is a highly significant variable.

2. Chamber pressure is quite a significant variable, but only about one-fifth as significant as burning time.

3. The choice between the propellant combinations investigated has no significant bearing upon axial g-fore es.

4. None of the variable interactions significantly affect axial g-forces.

5. It is indicated that increased burning time and chamber pressure both had beneficial effects in decreasing axial g-forces. Changing from N2O4+NO with C j o^ l o t o I R F N A with U D M H also had a beneficial effect, although it was very minor.

Conclusion on Designing for Low M i s s i l e Weight

1. Burning time is not a significant variable, within the limits studied.

2. Chamber pressure is a highly significant variable.

3. The choice of propellant combination is signifi

cant, but only about one-fiftieth as significant as chamber p r e s s u r e .

4. None of the variable interactions significantly affect missile weight.

5. It is indicated that increasing chamber pressure and going to the propellant combination I R F N A with U D M H both had beneficial effects in decreasing o v e r - a l l missile weight. However, a slight interaction existed between these variables, which tended to raise missile weight to a minor degree.

O v e r - a l l Conclusions (within the limits and type of propel- lants studied):

1. Low missile diameter is most dependent upon achieving a high chamber p r e s s u r e .

2. Low axial g-forces are most dependent upon s e lecting a sufficiently high burning time.

3. Low o v e r - a l l missile weight is most dependent upon achieving a high chamber pressure (note that no change in propellant weight fraction was assumed necessary within Pc limits selected).

Conclusion

The general nature of the conclusions illustrates the advantage of using factorial experimental designs for a wide variety of missile propulsion design problems.

References

Owen L . Davies, The Design and Analysis of Industrial Experiments, Second Edition, Hafner Publishing Co, , New York, 1957.

William Volk, Applied Statistics for Engineers, F i r s t Edition, M c G r a w - H i l l Book C o . , N e w York, 1957.

Fractional Factorial Experiment Designs for Factors at Two Levels, Applied Math Series 48, Statistical Engineering Lab. , National Bureau of Standards, U . S . Government Printing Office, Washington, D . C. 15 A p r i l 1957.