Supplementary Materials: Ultrasound-Assisted

Hydrazine Reduction Method for the Preparation of Nickel Nanoparticles, Physicochemical

Characterization and Catalytic Application in Suzuki- Miyaura Cross-Coupling Reaction

Adél Anna Ádám 1,2, Márton Szabados 1,2, Gábor Varga 1,2, Ádám Papp 2, Katalin Musza 1,2, Zoltán Kónya 3,4, Ákos Kukovecz 3, Pál Sipos 2,5 and István Pálinkó 1,2,*

1 Department of Organic Chemistry, University of Szeged, Dóm tér 8, Szeged, H-6720 Hungary, lee- daa@hotmail.com (A.A.A.); szabados12m@gmail.com (M.S.); gaborvarga1988@gmail.com (G.V.);

musza.katalin@chem.u-szeged.hu (K.M.).

2 Material and Solution Structure Research Group, and Interdisciplinary Excellence Centre, Institute of Chemistry, University of Szeged, Aradi Vértanúk tere 1, Szeged, H-6720 Hungary, papy97@gmail.com (A.P.);

sipos@chem.u-szeged.hu (P.S.).

3 Department of Applied and Environmental Chemistry, University of Szeged, Rerrich B. tér 1, Szeged, H-6720 Hungary, konya@chem.u-szeged.hu (Z.K.); kakos@chem.u-szeged.hu (A.K.).

4 MTA-SZTE Reaction Kinetics and Surface Chemistry Research Group, Rerrich B tér 1, Szeged, H-6720 Hungary

5 Department of Inorganic and Analytical Chemistry, University of Szeged, Dóm tér 7, Szeged, H-6720 Hungary

* Correspondence: palinko@chem.u-szeged.hu

10 20 30 40 50 60 70 80

metallic nickel 8 nm

8 nm

7 nm

7 nm 100%

80%

60%

40%

220

200

111

Intensity (a.u.)

2

20%

7 nm

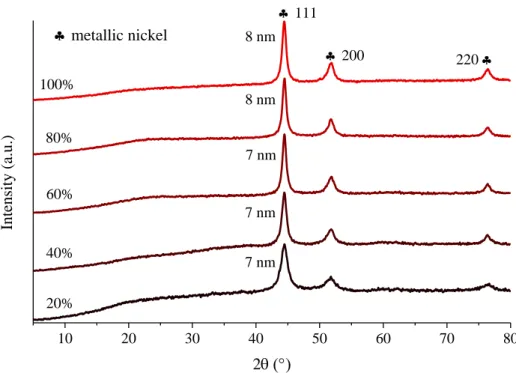

Figure S1. XRD patterns of the nickel nanoparticles prepared under ultrasound treatment with various ultrasound emission periodicities (duration of treatment: 4 h, temperature of treatment: 25 °C).

10 20 30 40 50 60 70 80

mechanical stirring 30 W

8 nm 14 nm

metallic nickel

10 nm 9 nm 8 nm

12 nm

220

200

111

Intensity (a.u.)

120 W 90 W 60 W

non-strirred

Figure S2. XRD patterns of the nickel nanoparticles prepared with mechanical stirring, without stirring or under ultrasonic treatment at various output power values (duration of treatment: 4 h, temperature of treatment: 25 °C).

10 20 30 40 50 60 70 80

metallic nickel

nickel(II) hydroxide

Intensity (a.u.)

2

a b c d

d: 5°C, non-stirred, 4 h c: 5°C, 30 W 100%, 8 h b: 5°C, 30 W 100%, 6 h a: 5°C, 30 W 100%, 4 h

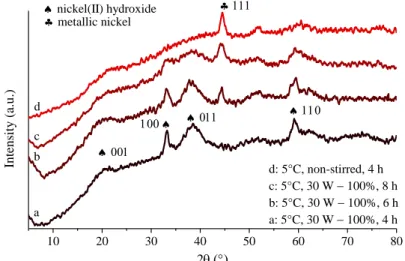

Figure S3. XRD patterns of the solid materials formed on ultrasound treatment (30 W − 100%) at 5 °C with 4 h, 6 h or 8 h treatments or without stirring at 5 °C after 4 h.

10 20 30 40 50 60 70 80

nickel(II) hydroxide

nickel-hydrazine-iodide complex mechanical stirring

nickel hydroxide mechanical stirring nickel hydroxide ultrasound treatment

nickel-hydrazine-iodide complex ultrasound treatment

Intensity (a.u.)

2

Figure S4. XRD patterns of the nickel hydroxide and complex intermediates obtained under mechanical stirring or sonication (30 W − 100%) at 75 °C, after 4 h treatment.

100 200 300 400 500 60

65 70 75 80 85 90 95 100

6 5 4 3 2 1 0

Mass (%)

-Ni(OH)2

Endothermic Exothermic

Heatflow (V) DTG (mg/min)

Furnace temperature (°C)

-0.5 -0.4 -0.3 -0.2 -0.1 0.0 0.1 0.2 90

260 85

260

200 400 600 800 1000

90 92 94 96 98 100 102 104

non-stirred

90 240

370

375

Endothermic Exothermic

Heatflow (V) DTG (mg/min)

Mass (%)

Furnace temperature (°C)

12 10 8 6 4 2

-0.06 -0.04 -0.02 0.00 0.02 0.04 0.06 0.08 0.10

200 400 600 800 1000

94 96 98 100 102 104 106 108 110 112 114

265

Heatflow (V) DTG (mg/min)

Mass (%)

Furnace temperature (°C) 375

370

100

Endothermic Exothermic

mechanical stirring

12 10 8 6 4 2

-0.05 0.00 0.05 0.10 0.15 0.20 0.25

200 400 600 800 1000

92 94 96 98 100 102 104 106

120 W 100% ultrasound treatment 60

Endothermic Exothermic

Furnace temperature (°C)

Heatflow (V) DTG (mg/min)

Mass (%)

370 380

55

255

9 8 7 6 5 4 3

-0.06 -0.04 -0.02 0.00 0.02 0.04 0.06 0.08 0.10

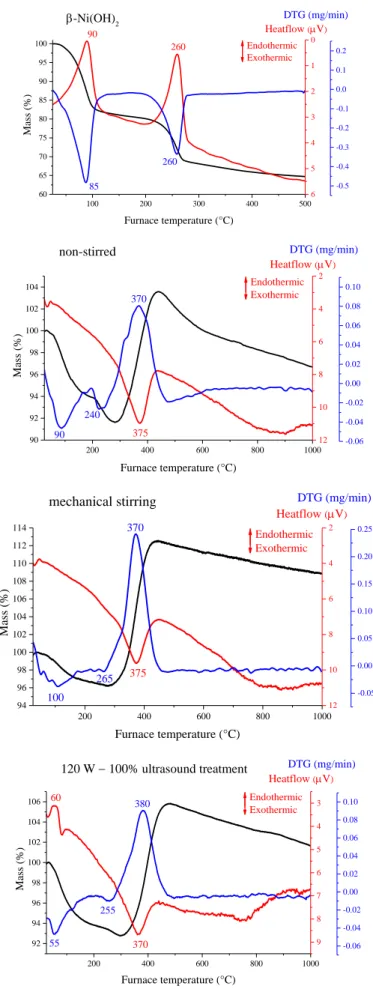

Figure S5. Thermogravimetric curves of the β-Ni(OH)2 and the NiNPs prepared without stirring, with mechanical stirring or under ultrasound treatment (120 W − 100%).

10 20 30 40 50 60 70 80

nickel(II) oxide

Intensity (a.u.)

2

100% 30 W ultrasonic mechanical stirring non-stirred

100%120 W ultrasonic 20%30 W ultrasonic

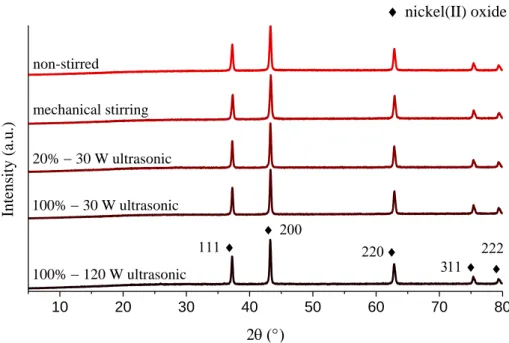

Figure S6. X-ray patterns of the thermogravimetric residues of the nanoparticles.

0.0 0.2 0.4 0.6 0.8 1.0

5 10 15 20 25 30 35 40 45

Quantity adsorbed gas (cm3/g STP)

Adsorption Desorption

non-stirred

Relative pressure (p/p0)

10 100 1000

0.0000 0.0002 0.0004 0.0006 0.0008 0.0010 0.0012 0.0014

dV(r) cm3 /Å/g

non-stirred

Pore radius (Å)

0.0 0.2 0.4 0.6 0.8 1.0

5 10 15 20 25 30 35

Quantity adsorbed gas (cm3/g STP)

Adsorption Desorption

mechanical stirring

Relative pressure (p/p0)

10 100 1000

0.0000 0.0005 0.0010 0.0015 0.0020

mechanical stirring

dV(r) cm3 /Å/g

Pore radius (Å)

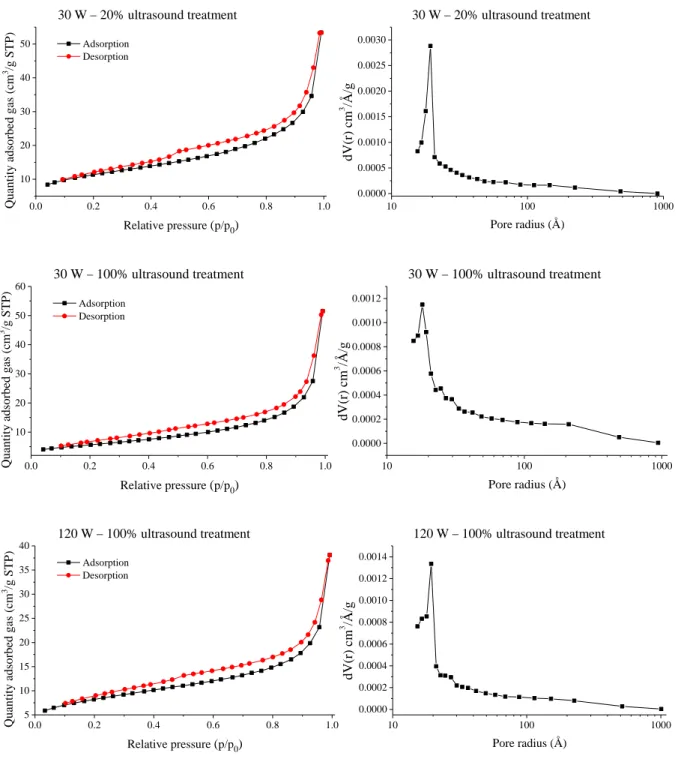

0.0 0.2 0.4 0.6 0.8 1.0 10

20 30 40 50

30 W 20% ultrasound treatment

Adsorption Desorption

Quantity adsorbed gas (cm3/g STP)

Relative pressure (p/p0)

10 100 1000

0.0000 0.0005 0.0010 0.0015 0.0020 0.0025 0.0030

30 W 20% ultrasound treatment

dV(r) cm3 /Å/g

Pore radius (Å)

0.0 0.2 0.4 0.6 0.8 1.0

10 20 30 40 50 60

30 W 100% ultrasound treatment

Quantity adsorbed gas (cm3/g STP)

Relative pressure (p/p0)

Adsorption Desorption

10 100 1000

0.0000 0.0002 0.0004 0.0006 0.0008 0.0010 0.0012

30 W 100% ultrasound treatment

dV(r) cm3 /Å/g

Pore radius (Å)

0.0 0.2 0.4 0.6 0.8 1.0

5 10 15 20 25 30 35 40

120 W 100% ultrasound treatment

Adsorption Desorption

Quantity adsorbed gas (cm3 /g STP)

Relative pressure (p/p0)

10 100 1000

0.0000 0.0002 0.0004 0.0006 0.0008 0.0010 0.0012 0.0014

dV(r) cm3 /Å/g

120 W 100% ultrasound treatment

Pore radius (Å)

Figure S7. N2 adsorption-desorption (left) and the pore size distribution (right) curves of the selected nickel nanoparticles.

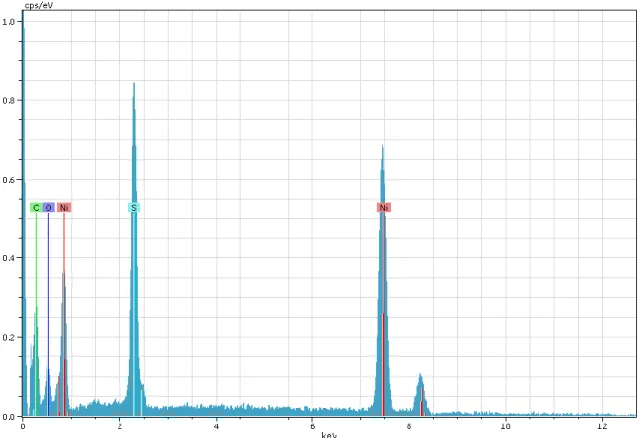

Figure S8. Energy dispersive X-ray analysis spectrum of NiNPs prepared at room temperature with ultrasound treatment of 30 W output power and 20% emission periodicity (signals of carbon, aluminum and phosphorous are from the adhesive tape/sample holder).

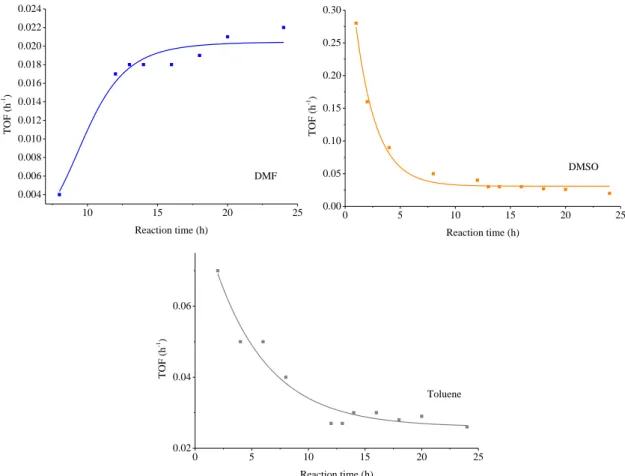

10 15 20 25

0.004 0.006 0.008 0.010 0.012 0.014 0.016 0.018 0.020 0.022 0.024

0 5 10 15 20 25

0.00 0.05 0.10 0.15 0.20 0.25 0.30

0 5 10 15 20 25

0.02 0.04 0.06 TOF (h-1)

Reaction time (h)

DMF DMSO

TOF (h-1 )

Reaction time (h)

Toluene TOF (h-1)

Reaction time (h)

Figure S9. Evolution of the turn over frequency (TOF) values of the ultrasonically synthesised nanoparticles (30 W, continuous sonication) during the cross-coupling reaction in DMF, DMSO and toluene solvents.

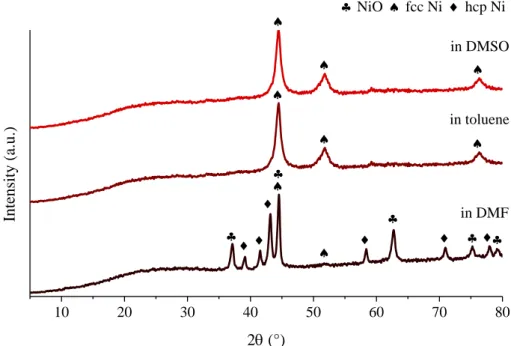

10 20 30 40 50 60 70 80

Intensity (a.u.)

2(°)

in DMF in toluene in DMSO

NiO fcc Ni hcp Ni

Figure S10. XRD patterns of the used nickel nanoparticle catalyst (30 W − 100%) after the first 24 h run in various media (fcc—face-centered, hcp—hexagonal close-packed).

10 20 30 40 50 60 70 80

* Unidentified • NiS NiO fcc Ni hcp Ni 30 W100% DMSO

mechanical stirringDMSO

30 W100%toluene

mechanical stirringtoluene

Intensity (a.u.)

2

•

• •

•

•

• •

• •

•

Figure S11. XRD patterns of NiNPs prepared by 30 W − 100% ultrasound treatment and mechanical stirring after the repeated run in toluene and DMSO solvents (fcc—face-centered, hcp—hexagonal close-packed).

Figure S12. Energy dispersive X-ray analysis spectrum of NiNPs prepared with ultrasound treatment (30 W − 100%), after using it as catalyst in DMSO solvent (signals of carbon and oxygen originate from the adhesive tape/sample holder, the Ni:S molar ratio ~1:1).

Figure S13. Energy dispersive X-ray analysis spectrum of NiNPs synthesized with mechanical stirring, after using it as catalyst in DMSO solvent (signs of the carbon, aluminium and the oxygen could originate from the adhesive tape/sample holder, the Ni:S molar ratio ~1:1).