Fish Canning

C. J. H. V A N D E N BROEK1

Utrecht, The Netherlands

I. Introduction 1^7 II. General Issues in Canning 128

A. Bacteriological Principles I2 8

B. Practical Implications 132

III. Historical Notes 1 35

IV. Fish Canning Procedures 1 38

A. The Cannery 1 38

B. The Raw Material 1 39

C. The Can 1 49

D. The Canning Operation l ^3

V. The Canned Product 1 66

A. Nutritive Aspects 166 B. Discolorations and Appearance 166

C. Microbial Spoilage 177

VI. Examination of Canned Fish I8 0

A. General I8 0

B. Sampling I8 0

C. Direct Examination l8^

D. Bacteriological Examination I8 3

E. Examining Can and Filling I8?

F. Interpretation of Results i 9l

References I9 4

I. Introduction

In this chapter "canning" is taken in a narrow sense, m e a n i n g the m e t h o d of preservation in w h i c h spoilage is averted principally b y killing microorganisms through heat, although certain additives m a y e n h a n c e the preservation. T h e type of container m a y also have some influence on the final o u t c o m e of the h e a t processing. O t h e r ways of preservation applied to fish in cans are:

( a ) T h o s e in w h i c h salt is the main or c o m m o n preservative (salt and sugar in "delicatessen" or "gaffelbitar," salt and oil in "Seelachs,"

salt and smoke constituents in c a n n e d smoked fish). T h e s e categories of products are discussed in V o l u m e I I I , Chapters 6 and 7.

1 Present address: Laboratory of Histology, University of Utrecht, Utrecht, The Netherlands.

127

( b ) T h o s e in which acid ( v i n e g a r ) is the typical ingredient ( m a r i n a d e s ) . F o r these, see V o l u m e I I I , C h a p t e r 5.

Canning in this narrow sense covers a range of practices, beginning with pretreatment of the fish as well as preparation of the can; the filling and closure of the can and the crucial techniques of heating the filled cans to such a degree that a d e q u a t e killing of microorganisms is attained without undue d a m a g e to the fish; and finally the cooling, cleaning, and storage of the product. R e l a t e d problems are the preserva

tion of the fish prior to canning, control of the entire operation, and proper examination of the can and its contents.

II. General Issues in Canning

A . B A C T E R I O L O G I C A L P R I N C I P L E S

Strictly speaking, canning is not a sterilization. Since "sterility" has an absolute meaning, the canning process m a y not b e called a steriliza

tion b e c a u s e of the obvious practical difficulty of ascertaining the com

plete a b s e n c e of b a c t e r i a in the entire contents of a can or a canned lot. Moreover, it has b e e n found m a n y times that viable microorganisms m a y b e present in adequately c a n n e d products ( R o w a n , 1 9 5 6 ) . T h e noncommittal E n g l i s h verb "processing" is therefore rather m o r e ade

q u a t e for the heating procedure than the term "sterilizing" as used in certain other languages.

T h e kind of sterility considered desirable in canning might in most cases b e called a "statistical sterility," m e a n i n g that no viable m i c r o organisms can b e found when a sufficiently large n u m b e r of cans from a given lot is carefully investigated. T h e r e is then statistically a high probability that similar conditions prevail throughout the entire lot.

E v e n such "statistical sterility" cannot always b e attained b e c a u s e the heat, besides attacking microorganisms, also brings about undesirable changes in the fish. T h e canner must try to strike a b a l a n c e b e t w e e n wholesomeness of the product on the one hand, and possible presence of living b a c t e r i a on the other ( R i e m a n n , 1 9 5 7 ) .

It appears that spore-forming and even asporogenous b a c t e r i a ( s t a p h y l o c o c c i ) can b e present in canned fish without causing spoilage.

This so-called "dormancy" is often favored b y the presence of fat, as in oil-packed fish ( L a n g , 1 9 3 5 ) , w h e r e b a c t e r i a can b e encapsulated and rendered m o r e insensitive to heat b u t inactivated. So long as such a product is in good condition and free of pathogens it can b e considered hygienically a c c e p t a b l e ( B a l l , 1 9 5 5 ) .

This has led to the c o n c e p t of "commercial sterility" ( B a u m g a r t n e r , 1 9 5 6 ) or rather, as R i e m a n n ( 1 9 5 7 ) justly puts it, "commercial stability."

This implies no true sterility, but merely that a c a n n e d food is free of pathogens and will keep for about two years under normal circumstances.

A canning process m a y b e considered successful if only 1 can in 10,000 runs the risk of spoiling (Gillespy, 1 9 5 1 ) .

1. Fundamentals

Only with these points in mind m a y the laws governing the killing of bacteria b y h e a t b e applied. T h e s e laws will not b e dealt with here, since they are treated explicitly and fully in m a n y well-known textbooks on canning ( T a n n e r , 1944; J a c o b s , 1 9 5 1 ; Baumgartner, 1 9 5 6 ; Ball and Olson, 1 9 5 7 ) . I t is well known that the killing of microorganisms b y heat proceeds logarithmically; this means that for any unit of time during w h i c h a lethal temperature is applied, a certain proportion of any particular microorganism is killed, the higher the temperature the higher the proportion. This also means that a large initial number of bacteria needs a longer time a n d / o r a higher temperature of processing.

Temperatures b e l o w 6 0 ° C . ( 1 4 0 ° F . ) are not considered lethal for asporogenous b a c t e r i a or those b e l o w 1 0 0 ° C . ( 2 1 2 ° F . ) for spores.

E v e r y microorganism has a characteristic susceptibility to heat, the non-spore-forming b a c t e r i a b e i n g very m u c h alike in this respect and the most susceptible. W h e n oysters w e r e inoculated with staphylococci, p a c k e d in cans, and stored with inadequate or no retorting, Williams ( 1 9 5 6 ) found very few spoiled cans. W i t h initial loads of 10 million salmonellae or staphylococci per gram, however, Angelotti et al. ( 1 9 6 1 ) calculated that heating for 12 min. at 6 5 . 6 ° C . ( 1 5 0 ° F . ) was n e e d e d to reduce these to nondetectable levels.

T h e most important thermoresistant spores seem to b e mesophilic anaerobes (Clostridium sporogenes, CI. putrejaciens) producing putrid swelling, and mesophilic aerobes (Bacillus spp.) producing changes in color, flavor, texture, and sometimes swelling ( B a u m g a r t n e r , 1 9 5 6 ) . Thermophilic bacilli producing "flat sour" have b e e n recorded (Jarvis, 1 9 4 3 ) , b u t obligate thermophilic "flat sour" organisms seem to b e rare in canned fish ( R i e m a n n , 1 9 5 7 ) .

R a n g a s w a m i and Venkatesan ( 1 9 6 0 ) , in subjecting Bacillus licheni- formis, B. circulans, and B. coagulans to h e a t treatment, observed a death rate in three stages, ( 1 ) a destruction of a major part o f the population in a short period, ( 2 ) a rapid logarithmic destruction, and ( 3 ) a decreasing death rate. B. brevis, B. subtilis, Clostridium histolyticum, and Lactobacillus fermenti were destroyed according to a rather uniform pattern.

Although for m a n y b a c t e r i a liable to occur in fish to b e canned, thermal death times have b e e n established experimentally, it is not

possible to ascertain the amount of heating necessary for any one batch.

This is b e c a u s e in practice the canner is confronted b y m a n y unknown factors, the most important of which are ( a ) number and kind of b a c teria in the raw material, ( b ) temperature gradient in the can, and ( c ) environmental factors acting on the microorganisms.

2. Number and Kind of Bacteria in Raw Material

Since it is hardly possible to predict which species of heat-resistant bacteria will b e present in a food, it is safest to carry out processing so that the most dangerous of the pathogenic spore-formers, Clostridum botulinum, is destroyed. This is a microorganism liable to develop in nonacid protein-rich foods, such as fish ( p H 6 - 7 ) , and to form a potent toxin. T h e r m a l death curves for various strains ( A - C ) of this organism w e r e worked out on p u r e cultures b y E s t y and M e y e r ( 1 9 2 2 ) ; thermal treatment of the entire can contents must b e at least equivalent to 4 min. at 1 2 0 ° C . ( 2 4 6 ° F . ) or 1 0 min. at 1 1 5 ° C . ( 2 3 6 ° F . ) in order to kill the most heat-resistant strain, even in large numbers ( B a l l , 1 9 5 5 ) .

Such thermal values are often related to an "F-value," which is the time in minutes during w h i c h the product is maintained at 2 5 0 ° F . ( 1 2 1 ° C ) . S u c h values are valid only under the assumption that the entire can content is raised almost instantaneously to this temperature level and subsequently cooled equally rapidly to a sublethal temperature (Gillespy, 1 9 5 1 ) .

Some bacteria are even more thermoresistant than CI. botulinum, e.g., CI. sporogenes and m a n y thermophilic bacteria. T h e i r F-values are 2 and 5 - 6 times as high, respectively, as for Cl. botulinum. Processing which would kill these species would highly impair the organoleptic properties of the fish. T h e only solution thus far seems to b e to avoid contamination with such organisms b y operating under strictly hygienic conditions.

3. Temperature Gradients in a Can

T h e required F-value of course is most difficult to establish in the inner portion of a filled can. I f the can contains a free flowing liquid, during processing the heat will b e transferred inside the can b y convection. B u t when the contents move along the can walls very slowly or not at all, the heat reaches the interior only b y conduction, a very m u c h slower process. Almost all fish packs consist of a mixture of solid parts with a relatively small quantity of free flowing liquid.

Thus the heat transfer inside the can is restricted.

F o r every product and every c a n size, t h e temperature gradients developing inside the can must b e established through experiment (for

methods employed in such measurements see Alstrand and Ecklund, 1952; B a l l and Olson, 1957; Powers et al., 1 9 6 2 ) . Salmon pastes have b e e n studied in this respect b y Patashnik ( 1 9 5 3 ) . A special device, t h e thermoresistometer, for testing heating efficiency was introduced b y Stumbo ( s e e W i l b u r , 1 9 5 1 ) . S o m e authors (e.g., Hicks, 1 9 5 1 , 1 9 5 2 ) are of the opinion that sterilization values obtained b y the classical methods of Ball and others are too high, b e c a u s e the coldest parts of the can contents need not b e those with the highest bacterial load.

B o a r d et al. ( 1 9 6 0 ) experimentally determined the F-values for the cooling phase of processing for a n u m b e r of packs. W h e n the can was immersed in cooling water immediately after the steam was cut off, the F-value varied b e t w e e n that obtained b y Gillespy's method as an upper limit and a less well-defined lower limit approaching the value calculated b y Ball's method. I n 3 8 of 3 9 experiments, however, the F-value e x c e e d e d twice that of Ball. Values close to Gillespy's estimate w e r e often obtained b y careful pressure cooling. Any delay b e t w e e n cutting off steam and immersion in cooling water increased the lethal value of the cooling process substantially. T h e latter is thought to b e a major source of the F-values in industrial processing. I n judging the bacteriological effect of processing, the resulting bacterial count of the total can, rather than that of the coldest part, should b e deter

m i n e d if at all feasible. Hicks thus defined a "survival n u m b e r for the can."

Finally, it is important to take into account the initial temperature of the can. R i e m a n n ( 1 9 5 7 ) records an instance w h e r e an otherwise adequate processsing proved i n a d e q u a t e for shrimps cooled in the cans prior to processing.

4. Environmental Factors

Survival of b a c t e r i a and germination of spores inside a can are in

fluenced b y the kind of substrate provided b y the food. Primarily the microbial growth depends on available water (Kefford, 1 9 5 7 ) .

Salt and other soluble substances increase t h e osmotic pressure, and m a y thereby reduce bacterial growth. M a n y foods, particularly those of animal origin, m a y contain small amounts of bactericidal com

pounds. S u c h substances m a y also b e added. T h e addition of antibiotics in order to r e d u c e processing and thereby improve p r o d u c t quality is n o w b e i n g investigated. T h e importance of oil in promoting "dormancy"

was mentioned above.

T h e r e are, on t h e other hand, indications that sublethal heating of bacterial spores m a y give rise to activation processes leading to germina

tion ( D e s r o s i e r and Heiligman, 1 9 5 6 ) . T h e manifold uncertainties should

b e taken into account whenever calculations are m a d e in canning proces

ses, and an appropriate safety factor should b e included ( H i c k s , 1 9 6 1 ) . Although there is a tendency to have certain processing data enforced b y law ( R i e m a n n , 1 9 5 7 ) , it seems that every canner must establish the proper processing time of his particular products and keep them under constant control through routine examination.

B . P R A C T I C A L I M P L I C A T I O N S

1. Preservation of the Raw Material

I t follows from the logarithmic action of heat on the destruction of microorganisms that in large numbers they require a more intense thermal process. H e n c e it is very important that the bacterial number in food prior to canning b e kept as low as possible. F i s h b e i n g a highly perishable commodity, its proper preservation is of p r i m e interest to the canner and often presents special problems ( H e s s , 1 9 5 6 ; see also Chapter 1, this v o l u m e ) .

O n c e the raw material is received in good bacteriological condition, the general policy is to operate either under a cold or a hot ( a b o v e 6 0 ° C , 1 4 0 ° F . ) schedule, and avoid leaving the fish at medium tempera

tures for any length of time. M a n y variations of cooling and freezing are b e i n g or have b e e n specially adapted to m e e t the requirements of the fish canner ( s e e Section I V , B , 1 ) . W i t h o u t proper application of these, microorganisms would multiply ( 1 ) in the food before canning or ( 2 ) in the filled cans i f these are not immediately processed. I n such cases an otherwise adequate processing m a y suddenly turn out an entire b a t c h of spoiled cans ( R i e m a n n , 1 9 5 7 ) .

A potential danger lies also in the remains of fish left on operational tables or equipment, through inefficient cleaning. Such refuse, if left overnight, will contain many millions of potentially thermoresistant bacteria and m a y seriously contaminate the next day's pack. F o r similar reasons, even slightly deteriorated parts of fish, such as intestinal viscera, belly flaps, etc., should always b e carefully trimmed off and discarded.

T h e y should never b e p a c k e d under the erroneous belief that they will b e "sterilized anyhow" ( E l d e r and Stevenson, 1 9 5 1 ) .

2. Prevention of Contamination

L i v e fish flesh is supposed to b e practically free of b a c t e r i a ( s e e Chapter 14, Vol. I ) . I n gutting and trimming, it will b e c o m e con

taminated b y microorganisms naturally present on the skin or in the intestines.

T h e s e microbes do not as a rule belong to pathogenic genera and m a n y strains are psychrophilic and offer little resistance to heating.

Pathogenic and thermoresistant spore-formers present the major hazard to the canner. T h e s e m a y b e taken up from soil, or from spices and other additives. Careful investigation of the latter and rigorously maintained sanitation can keep such contamination at a low level.

H e n c e any food material that has fallen on the floor should b e dis

carded; tables, machinery, and other equipment should b e easy to clean.

Stainless steel is outstanding in this respect. Workers should wear clean clothing.

As the d e m a n d for good organoleptic properties of canned fish products increases, the canner will tend to minimize processing time and temperature as m u c h as possible, and the necessity of strict hygiene will b e c o m e increasingly imperative.

3. Quick Heating and Cooling

In accordance with the rule that food for canning should b e kept either cool or a b o v e 6 0 ° C , the trend is to heat and cool cans as quickly as possible in processing in order to shorten the period the food is held at a medium temperature, and also to increase output.

H e a t transfer b e t w e e n the heating or cooling medium and t h e can contents is determined b y ( s e e Sellers, 1 9 5 5 ) :

( 1 ) H e a t capacity and m o v e m e n t of the heating medium ( l i q u i d ) , especially the flow of this medium along t h e c a n wall.

( 2 ) H e a t transfer through the can wall.

( 3 ) H e a t transfer inside the can b y convection a n d / o r conduction ( s e e a b o v e ) .

W i t h metal cans, ( 2 ) can b e disregarded and only ( 1 ) and ( 3 ) n e e d b e discussed:

( 1 ) : W h e n temperatures above 1 0 0 ° C . ( 2 1 2 ° F . ) can b e used without danger of scorching the outer layer of fish in the can, pure steam under pressure is the most economical in h e a t transfer because, in condensing along the cooler can wall, condensation heat will b e given off. W h e n , however, air is mixed with the steam, as occurs w h e n a retort is not carefully de-aerated before processing, the dew point is lowered and heat transfer will b e m u c h more inefficient b e c a u s e of the low heat capacity of gases. Also in that case there is no longer the direct relation

ship b e t w e e n pressure and temperature found in pure steam, so that temperatures can no longer b e simply read from the manometer.

T h e use of water has some advantages over steam: water has a m u c h higher heat capacity and, in working with water, there is no need to work under pressure, which makes the apparatus m u c h simpler. I t is, however, important that water have full access to all sides of the can. I n

some cases inefficient processing has b e e n caused b y placing flat oval pilchard cans with the flat sides towards e a c h other. W a t e r under pressure is applied in order to counteract inside pressure in the can which otherwise would cause bulging.

( 3 ) : H e a t penetration to the innermost portion of the can contents can b e accelerated b y :

( a ) Choosing a form and size of can with at least one of the dimensions as small as possible; the flat square can for sardines and the flat oval can for pilchards are advantageous.

( b ) Helping convection and conduction b y agitating the can during processing. End-over-end agitation as used for vegetable products

( C o n l e y et al., 1 9 5 1 ) could offer advantages in some cases, provided a head space promotes movement of the filling liquid. A reciprocated shak

ing motion might b e as effective as an end-over rotation and easy to establish ( F a r k a s , 1 9 6 2 ) .

( c ) Acceleration of cooling is usually done b y dipping the cans into or spraying with cold water. I t is almost unavoidable, however, in a mass produced product like a can, that tiny leaks are sometimes left in the seams or walls. Minute portions of cooling water m a y b e sucked into the can during cooling which m a y carry b a c t e r i a into the fish after processing. H e n c e it is obligatory that the cooling water have a bacterio

logical standard at least comparable to that of drinking water. I f this is not obtainable, the cooling water should b e chlorinated.

4. High Temperature-Short Time Processing (HTST) I t may in general b e said that the destruction of b a c t e r i a increases 10-fold for each 1 0 ° C . ( 1 8 ° F . ) temperature increase, while the chemical reactions, e.g., destruction of thiamine, responsible for product deteriora

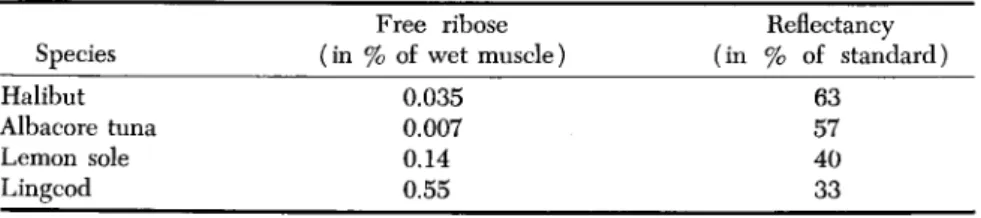

tion increase only 2-fold (Clifcorn, 1 9 5 8 ) . T h e so-called H T S T processing for some foods is an important step towards the proper b a l a n c e b e t w e e n bactericidal action and product deterioration. Unfortunately, with most canned fish, poor heat conduction severely limits the application of methods of this type, b e c a u s e the higher temperature needed for quicker heating would scorch t h e outer layers in the can. Aseptic canning can b e applied only for fluids or at least foods that can b e p u m p e d around ( l i q u i d and semisolid). This situation is the more unfortunate since m a n y fish products are especially adversely affected b y heat. T h e brownish color of m a n y fish products, due to Maillard reaction ( s e e Section V, B , 2 ) , is highly dependent upon the time and temperature of process

ing. I t m a y indicate that a product has b e e n oversterilized ( S p i l d e , 1 9 5 1 ) .

5. Alternative Methods

Heating problems will b e largely abolished if any of the n e w approaches to the sterilizing of foods should prove commercially practi

cable; such n e w methods are still largely or wholly in the experimental stage:

a. A D D I T I O N O F A N T I B I O T I C S

T h e use of antibiotics to reduce required processing times was mentioned. W h e r e a s certain antibiotics seem to b e very promising in the cold storage of fresh fish ( s e e Chapter 17, Vol. I ) , their use for canning appears dubious. Moreover, it remains to b e seen if the addition of antibiotics to food for this purpose will ever b e allowed, b e c a u s e of the danger to public health resulting from regular consumption and the risk of sensitization via residues.

b . D I E L E C T R I C H E A T I N G

This has proved useful for heating pieces of m e a t ( S l a t e r , 1 9 5 4 ) or for quick warming of deep-frozen dishes, b u t does not work inside a can since t h e electric field is conducted through the metal.

c. U L T R A S O N I C W A V E S ( S U P E R S O N I C S )

Microorganisms can b e killed quickly and efficiently b y ultrasound, b u t it does not yet seem useful for c a n n e d fish owing to the destructive action on t h e texture ( c a v i t a t i o n ) . I t might b e of use for sterilization of liquids ( R o s e , 1 9 5 4 ) .

d. U L T R A V I O L E T R A Y S

W a v e l e n g t h s of 2 5 4 - 2 6 5 πιμ have an especially strong lethal effect on microorganisms. T h e y are useful for destruction in air and on surfaces of empty cans, b u t on fish their use is not p r a c t i c a b l e b e c a u s e of their oxide absorption as well as strong oxidizing action, especially on fats and oils, which produces off-flavors.

e. S T E R I L I Z I N G B Y A T O M I C R A D I A T I O N

This is m u c h discussed; it can b e anticipated that increasing amounts of radioactive material will b e c o m e available as radiation sources at an economic r a t e ( B r o w n e l l , 1 9 5 3 ; see C h a p t e r 17, this v o l u m e ) .

III. Historical Notes

After Nicolas Appert in 1 8 0 9 won the prize offered b y the F r e n c h Government for a m e t h o d of preserving foods, the n e w technique was soon tried in E n g l a n d . L o b s t e r canning is reported from the United

Kingdom in 1817 ( D e w b e r r y , 1 9 5 7 ) and soon spread to the United States with lobster and salmon as early packs ( B o r g s t r o m , 1 9 6 5 ; for a detailed historical analysis of fish canning see the comprehensive study b y Cutting, 1 9 5 5 ) .

In early days "appertized" foods were mostly p a c k e d in glass con

tainers. About 1 8 2 0 tin plate containers, previously used for packing of smoked fish etc., were utilized with some hesitation. Around 1 8 4 9 D u r a n d invented the tin canister (from the G r e e k word kanistron) which soon was abbreviated to can. H e a t i n g was done in boiling water, the boiling temperature of which was increased b y adding salts ( N a C l , C a C l2, e t c . ) . T h e use of steam was introduced around 1840. B y then a sardine canning industry was already well established in F r a n c e ( B r i t t a n y ) . Various fish products were canned in E n g l a n d ; in A m e r i c a canned oysters found wide distribution and Atlantic salmon was just beginning.

In 1864 canning was started on the U.S. Pacific Coast ( D e w b e r r y , 1 9 5 4 ) , where an abundant supply of salmon gave rise to rapid expansion.

W h e n this led to exhaustion of the natural resources, canneries spread further north up into Alaska. Around 1 8 7 0 sardine canning in F r a n c e also expanded and spread to Portugal, Spain, and later to Morocco. W i t h the success of the sardine pack, the U.S. industry b e g a n to look for a similar product; this led to the canning of menhaden "sardines" around 1870 and finally the packing of California sardines, w h i c h started around 1890. This m a d e the United States chief producer of canned fish.

Almost throughout the nineteenth century canning remained a trial- and-error process. In many cases large lots had to b e c o n d e m n e d b e c a u s e of insufficient heating, and the bursting of cans b y inside pressure during processing was a common feature until after the pressure retort was patented b y Schriver in 1874.

T h e turn of the century coincided more or less with a n e w era in canning. Processing gradually b e c a m e founded on bacteriological knowl

edge. Manual handling was replaced b y mechanization, as in the form of the "iron chink" for gutting and butchering of salmon. T h e first quarter of the n e w century witnessed a tremendous increase in the n u m b e r of fish canneries and spread of the industry to various other countries. T h e conditions created b y the first world w a r lent some impetus to this development. N e w species were canned; tuna started in 1917 in Cali

fornia. In the following years, strong competition and increased demand for fine quality foods tended to eliminate a large n u m b e r of these can

neries.

At present, fish canning shows steady expansion in various realms:

( 1 ) T h e use of fish from more distant waters is m a d e possible b y increased use of cooling and freezing techniques ( s e e C h a p t e r 19,

Volume I I ; Chapters 1 and 9, this v o l u m e ) . A marked development in this respect was the construction of the "tuna clipper" in California, which freezes tuna on b o a r d and conducts defrosting prior to landing.

Such fish are used exclusively for canning. Similar methods have b e e n developed for salmon ( s e e further Chapter 4 , this v o l u m e ) .

( 2 ) T h e initiation and rapid development of canning in places where it did not exist previously. F i s h i n g of m o r e distant waters is nevertheless sometimes due to overfishing of adjacent resources.

( 3 ) T h e increased mechanization of all steps of the process, from unloading of fishing boats to fully automatized packing in crates of the sealed and labeled cans. A well-known example of a thoroughly mecha

nized cannery is V a n Camp's sardine canning plant in California (Anony

mous, 1 9 5 2 k ) and the L i e m p a j a canning factory ( s e e Orischitj, 1 9 5 8 ) may b e cited as an equivalent in the U.S.S.R. A large variety of machines is continuously put on the market (Anonymous, 1 9 6 0 a ) ( s e e Sections I V , C, 5 and I V , D , 5 - 7 ) . Not all canners are in a position to adopt such modern ways of production. Very expensive m a c h i n e r y would, through the seasonal character of the pack, lie idle for a lengthy period of time.

W h e n e v e r labor costs are high, mechanization opens the way to reduce production costs, besides increasing output.

( 4 ) A greater variety of pack. W h e n n e w waters are fished, n e w sites chosen for canneries, or increased competition initiates a search for n e w products, an increase in variety of canned fish products m a y b e expected.

Nevertheless, present output of c a n n e d fish still concentrates on a small n u m b e r o f species which h a v e proved suitable for canning, often improving their taste through seasoning. M a i n U n i t e d States products are still tuna, sardine, and salmon; shrimp, mackerel, and oysters rank second (Cutting, 1 9 5 5 ; Borgstrom, 1 9 6 1 b ) . In E u r o p e , sardines and brisling are the chief products with tuna, mature herring, and mackerels ranking second ( E m p e y , 1 9 5 3 a ) . In contrast to these fatty fish, nonfatty white fishes like cod and haddock are m o r e difficult to process, although this is done on quite a scale in the U.S.S.R. ( B o r g s t r o m , 1 9 6 1 a ) .

Quite a n u m b e r of species are labeled as sardines (Anonymous, 1952o;

Soudan, 1 9 5 3 ) . Several of the numerous other canned fish packs are:

sharks ( H a r d y , 1 9 5 3 c ) ; sturgeon (Anonymous, 1 9 5 2 c ) ; suckers (Anony

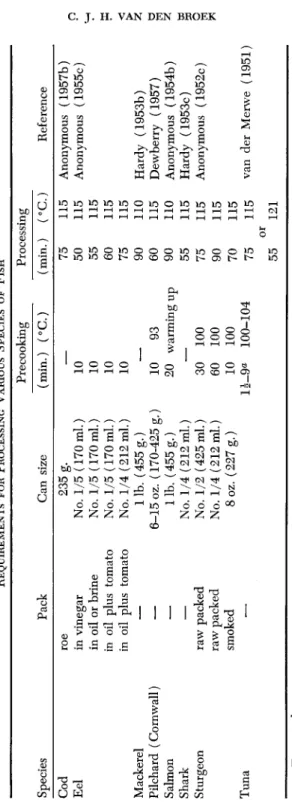

mous, 1 9 5 8 a ) ; saury (Cololabis sp.) (Anonymous, 1 9 5 7 d ) ; milkfish or bangos (Chanos chanos) (Sulit et ah, 1 9 5 7 ) ; eels, adult (Anonymous, 1 9 5 5 c ) and young ("civelles") ( B o u r y , 1 9 5 2 ) ; cod roe (Anonymous, 1 9 5 7 b ) . T h e canning of several other species has b e e n studied. As to shellfish canning, see Chapters 8A and 8 B , this volume.

Several ready-made fish dishes are manufactured and preserved through h e a t processing, e.g., smoked herring tidbits (Anonymous,

1 9 5 5 d ) , salmon (Anonymous, 1953d; Hastings, 1 9 5 5 ) , cod and related fish chowders (Anonymous, 1 9 5 3 c ) . Several Soviet packs are smoked or fried prior to canning. C o m b i n e d packs of fish and vegetables are available in the U.S.S.R. ( B o r g s t r o m , 1 9 6 1 a ) .

All in all, it has b e e n noted that consumption of c a n n e d fish dropped from 1 4 % to 6 % of the total of c a n n e d foods in the last two decades;

but this decrease is merely relative, and due rather to the great expansion of canning at large rather than to a drop in i m p o r t a n c e of fish canning.

O n the contrary, 6 0 0 , 0 0 0 tons were p a c k e d in 1 9 4 8 and 725,000 tons in 1952 ( C o m m o n w e a l t h E c o n o m i c Committee, 1 9 5 5 ; see also Chapter 19, V o l u m e I I ) .

I t is hoped that c a n n e d fish will find an outlet in countries where the very exacting transport of cooled and frozen foods is not yet available, but w h e r e the public taste will change, as in E u r o p e , from a preference for dried, smoked, and salted fish to more mildly flavored products. As predicted b y Cutting ( 1 9 5 5 ) , a cheap canning m e t h o d rendered efficient b y extensive mechanization could satisfy a market of sizable proportions in Africa, Asia, and South America.

IV. Fish Canning Procedures

A. T H E C A N N E R Y

W h e n canning developed in locations w h e r e fishing has b e e n prac

ticed a long time, t h e cannery usually forms a part of the industrial agglomeration around the fishing port. F i s h are obtained through the normal auction and transported to the canning plant b y motor vehicle. I n other places w h e r e c a n n i n g and fishing developed simultaneously, as on the North American west coast and in South Africa, canneries are often located on the waterfront so that fish can b e hauled directly from vessel to plant.

A still closer connection b e t w e e n fishing operations and canning is possible b y installing heat-processing lines on b o a r d the fishing vessels.

Owing to the technical difficulties and limited s p a c e as well as personnel problems, canning on board has thus far found only limited application.

F l o a t i n g canneries are employed whenever facilities on land are not ade

quately available or labor conditions permit this kind of operation.

British and Norwegian whalers have for some years c a n n e d w h a l e m e a t on board. A whaling factory can hardly b e c o m p a r e d in size with a fishing vessel. Partial canning of the catch, e.g., canning of cod and shellfish livers, has b e e n conducted on a n u m b e r of G e r m a n and Soviet trawlers.

F o r canneries on land, it seems that the old type multistoried building

in which production proceeds along a "gravity flow system" has b e c o m e obsolete ( W i e g a n d , 1 9 5 0 ) . One-story buildings are preferred; they are less expensive to build and maintain, and less floor space is lost b y the heavy supporting columns. Operations are easier to supervise; removal of dust, fumes, and offal is simplified, and inside transport is facilitated as there are no elevators.

A well-planned layout is essential in reducing operation costs. T h e flow of materials should preferably go in one direction from the receiving dock to the warehouse without bottlenecks or crisscrossings (Nelson, 1 9 5 8 ) . Handling of all material should b e restricted to a m i n i m u m and b e m e c h a n i z e d wherever possible. E q u i p m e n t must b e so arranged that it is accessible from all sides, but ample space left for fork trucks w h e r e necessary.

Floors can conveniently b e m a d e of concrete, preferably with s o m e r u b b e r or synthetic resin admixture, a n d should have a slight slope ( a b o u t 1:100 when w h e e l carts are used, 1:50 w h e n conveyor belts, etc.

are u s e d ) toward gutters. T h e latter should run parallel with the main flow of the operation. No section of the floor should b e m o r e than 6 meters ( 2 0 ft.) from a gutter. W h e r e v e r possible air, water, and steam mains should b e located in the floor to avoid dirty dripping pipes over

head.

A convenient height for tables and inspection belts is 9 0 cm. ( 3 5 . 4 i n c h e s ) ; e a c h worker should have some 8 0 cm. ( 3 1 i n c h e s ) width at his disposal. Workers should b e seated whenever possible. G r e a t care should b e taken to have the preparation and inspection tables sufficiently illuminated ( 3 0 - 5 0 foot-candles) and adequately shaded to avoid glare in the w o r k e r s face. O f course ventilation too is critically important in a cannery. S t e a m disposal m i g h t b e piped away from the retorts.

T h e actual course of operations naturally depends on the type of fish canned. Only general aspects will b e discussed here, m o r e specific details b e i n g presented in subsequent chapters. Sometimes handling of one type of fish is influenced b y the local p r a c t i c e for another type. T h u s , in California, m a c k e r e l is c a n n e d in m u c h the same w a y as sardines, w h i c h in turn is different from Atlantic Coast p r a c t i c e ( E m p e y , 1 9 5 3 c ) .

B . T H E R A W M A T E R I A L

I t is axiomatic that the quality of the c a n n e d product depends primarily upon that of the raw material, resulting from the natural characteristics of the fish and the handling prior to canning.

T h e natural characteristics of certain species render t h e m very suitable for canning, e.g., sardines, salmon, tuna, herring; others seldom give a c c e p t a b l e products unless m a d e up into special dishes, such as

nonfat white fish. Environmental factors and the life cycle often have an influence. Thus, salmon canned during the spawning season usually yield an inferior grade (Anonymous, 1 9 5 2 g ) . Also associated with the spawning season is the "mush" due to an infection b y a proteolytic protozoan ( s e e further Section V , B , 8 ) . O t h e r seasonal variations affect the composition of the fish, mainly the fat and water contents, and influence the flavor of the final product. Brisling m a y not b e canned in Norway until the fat content has r e a c h e d 7 % .

Storage conditions also greatly influence the quality of the final product. I f raw salmon is stored in a fish hold m a d e of wood treated with a phenol- or cresol-containing germicide, it m a y exhibit an un

pleasant phenol-like odor when canned. S u c h holds must b e washed thoroughly with an alkaline detergent solution and subsequently rinsed (Jones, 1 9 6 1 ) .

In J a p a n e s e experiments ( T a n i k a w a et al., 1 9 5 2 ) , mackerel was stored for 1 2 - 3 0 hours at 1 5 - 1 6 ° C . ( 6 0 ° F . ) before canning. Spoilage was accompanied b y marked increase in amino acid N, suggesting autolysis;

the increase in volatile basic Ν was less, b u t still indicative of spoilage. As soon as previous holding exceeded 12 hours ( a n d volatile b a s i c Ν ex

ceeded 2 0 m g . % ) , the canning results w e r e poor. O n e sign of inferior quality is the crumbling of the m e a t after canning, which was not observed w h e n fresh mackerel was c a n n e d ( T a n i k a w a et al., 1 9 5 2 ) . I n a later experiment the maximum permissible storage at 2 0 ° C . ( 6 8 ° F . ) was found to b e 15 days ( T a n i k a w a and Yagi, 1 9 5 4 a ) .

D e v e l o p m e n t of off-odors in salmon during storage prior to canning and determination of the odoriferous compounds indicative of incipient spoilage were studied b y T a n i k a w a ( 1 9 5 8 ) .

Prior to canning, the J a p a n e s e saury (Cololabis saira) could b e kept only 2 1 hours at 1 5 ° C . ( 6 0 ° F . ) and 12 hours at 2 0 ° C . ( 6 7 ° F . ) , at which time the volatile basic Ν exceeded 2 0 m g . % . If, however, the fish was canned in tomato sauce, a slightly longer storage period ( 2 8 and 17 hours, respectively) and a slightly higher volatile basic Ν content ( 2 5 m g . % ) could b e tolerated ( T a n i k a w a and Yagi, 1 9 5 4 b ) .

Tuna, if canned in an advanced state of decomposition, m a y on canning give rise to a pitted appearance known as "honeycombing"

(Hillig, 1956b; see further Section V , B , 7 ) . T h e stage of decomposition at time of canning can b e determined from the content of lower fatty acids, such as propionic and butyric (Hillig, 1 9 5 6 a ) .

I n salmon, prolonged storage prior to canning leads as a rule to heavier curd formation on the m e a t surface, this being the result of protein coagulation ( s e e Section V , B , 6 ) . Evidently other factors such as species, catching areas, etc. are also involved. T a n i k a w a et al.

( 1 9 5 2 ) , on the other hand, observed in experiments with mackerel that there was more curd formation from fresh than from stale fish.

1. Temporary Bulk Preservation

a. A D D E D C H E M I C A L S

If the time interval b e t w e e n catching and canning is not too long, some degree of preservation is obtained b y simple sprinkling of salt.

This may b e done on board, as with California sardines ( H a r t m a n , 1 9 5 5 ) , or in the cannery, whenever fish like herring must b e held until the next day before canning ( E m p e y , 1 9 5 2 ) . In Portugal, sardines are lightly salted even after b e i n g put on the cutting tables (Anonymous, 1 9 5 4 g ) . M a c C a l l u m et al. ( 1 9 5 6 ) report from their Yugoslavian experiments that sardines, after b e i n g sprinkled with salt, gave an inferior canned product.

T o suppress the off-odor that might a c c o m p a n y incipient decomposition, salmon is allowed to soak in 1 % solution of Sustane 1-F ( a mixture of 3-teri-butyl-4-hydroxyanisole and 2-teri-butyl-4-hydroxyanisole) before b e i n g canned or frozen for later canning ( T a n i k a w a , 1 9 5 8 ) .

In California, chlorine is used for the short-time preservation of sardines b y chlorinating the water used to p u m p the fish into the cannery.

Antibiotics have also b e e n employed in keeping salmon prior to canning ( S t e r n et al., 1 9 5 6 ) and w e r e considered superior to refrigerated brines held at 0 ° C , 4 . 5 ° C , and 1 0 ° C . ( 3 2 ° F . , 4 0 ° F . , and 5 0 ° F . ) .

b . C H I L L I N G

Chilling is of course the m e t h o d of choice whenever fish must b e kept for more than a few hours before canning. Canneries receive the raw material as a rule in great quantities and at irregular intervals. I t is therefore advantageous to have a special area in the cannery available for the storage and icing of these fish. I f the fish are received from an auction and arrive in wooden boxes with i c e , it is beneficial to wash the newly arrived fish in flowing cold water, thus removing the heavily contaminated i c e and slime. T h e n the fish are re-iced. T h e amount of ice to b e added will depend on temperature of the fish, temperature of the storage room, and length of storage until the fish are canned. Proper and uninterrupted chilling not only improves the quality of the canned product; it also gives the canner an opportunity to process larger lots with smaller manufacturing capacity. I n Norway, it was found that b y improving the methods of cooling the keeping time for sprats could b e extended from 4 to 6 days ( J u l , 1 9 5 1 ; see further Chapter 1, this volume, where the whole field of chilling is reviewed and additional methods, such as use of refrigerated sea water, are discussed).

T h e application of a chilled w e a k brine is called the T o c q u e r system ( T o c q u e r , 1 9 5 5 ) ; sardines or other fish are kept in circulated refrigerated b r i n e at 2 ° C . ( 3 5 ° F . ) in a holding tank, from w h i c h they are regularly fed into a highly m e c h a n i z e d canning line. I t should b e kept in m i n d that when fish are held at low temperatures until heat treatment begins, processing temperatures and times must b e adapted to such low initial temperatures.

Cooper found ( 1 9 5 7 ) that m a c h i n e gutting o f pilchards was less efficient at lower temperatures. H e found it advisable to w a r m up the chilled fish to about 1 3 ° C . ( 4 5 ° F . ) in order to facilitate handling.

c. F R E E Z I N G

W h e n e v e r the time lapse b e t w e e n catching and canning exceeds several days, bulk freezing is advisable for keeping the raw material in good condition. Intervals of months have to b e bridged w h e n canneries m a k e an effort to maintain production during off-season. I n Northern E u r o p e , large quantities of herring and brisling are frozen for this purpose. F r e e z i n g techniques are not essentially different from the freezing of fish for other purposes, except that b r i n e freezing, often favored for e c o n o m i c reasons, entails problems of salt uptake.

In large-sized fish like salmon or tuna the salt uptake is relatively small, especially after thawing in water ( M i y a u c h i and Heerdt, 1 9 5 4 ) when leaching m a y b e c o m e a factor. As always, good initial quality, quick freezing, good glazing, and low storage temperature are the principal factors governing the quality of the canned product (Anony

mous, 19521; Mathiesen, 1 9 5 4 ) .

Norwegian sprats must b e stored at — 3 0 to — 3 5 ° C . ( — 2 2 to — 3 2 ° F . ) if they are to b e canned after 8 - 1 0 weeks of frozen storage with a quality comparable to that of newly caught canned sprats. T u n a proved to b e a c c e p t a b l e for canning in Norway after 15 months of storage at — 2 0 ° C . ( — 4 ° F . ) , provided the fish were dipped in brine before freezing and defrosted in cold water (Anonymous, 1 9 5 2 i ) . M a c C a l l u m et al. ( 1 9 5 6 ) found that frozen Yugoslavian sardines are still suitable for canning after 3 months of storage at — 2 0 ° C . ( — 4 ° F . ) .

F r e e z i n g is also used to assure that the fish are in good condition when brought to the cannery from distant waters. O n b o a r d tuna vessels the fish are loaded into special wells immediately after catching, quickly cooled in refrigerated sea water, and subsequently frozen in brine. This frozen fish is kept at — 8 to — 1 0 ° C . ( 1 4 - 1 7 ° F . ) until defrosted prior to landing ( s e e further details in Chapter 4, this v o l u m e ) .

Italian canneries are provided mainly with tuna frozen on land.

F r e n c h experiments on canning of previously frozen tropical yellowfin

tuna gave good results (Anonymous, 1 9 5 5 b ) . F r o z e n transport in ships of a tuna clipper type is used for salmon in the North Pacific.

Although it has b e e n reported that the quality of a c a n n e d product m a d e from frozen fish is not different from that m a d e from the unfrozen material, e.g., m a c k e r e l ( H a r d y , 1 9 5 3 b ) , conclusions that differences do exist seem to predominate.

Occasionally the c h a n g e is for the better, e.g., w h e n through protein denaturation the fish flesh acquires a firmer texture, as seems to b e the experience of some herring canners. T h i s has b e e n established for salmon b y penetrometer readings ( C r a v e n and Dassow, 1 9 5 2 ) .

Usually, however, and in particular w h e n freezing is conducted b y less a d e q u a t e methods or w h e n the bulk frozen fish is held in storage for too long a time, undesirable changes take place. T h e a p p e a r a n c e of salmon m a y b e impaired b y formation of curd: a jellylike surface precipitate settling on the fish during h e a t processing. S u c h curd forma

tion can b e diminished b y increasing the water-binding properties of the fish muscle proteins through dipping in brine of other salt solutions

( S t a n s b y and Dassow, 1 9 5 1 ; Anonymous, 1 9 5 2 p ) . T h i s also prevents sticking o f the fish m e a t to the can wall ( s e e further Section V , B , 6 ) .

T h e a p p e a r a n c e can also suffer b y b r o w n i n g due to the breakdown of hemoglobin l e a c h e d from the blood vessels. T h i s kind of discoloration is normal for frozen fish and can b e prevented to some extent b y a b r i n e dip or b y freezing in brine (Anonymous, 1 9 5 2 i ) . M o s t other dis- colorations, such as b l e a c h i n g or yellowing through oxidation during frozen storage, are more specific for freezing than for canning (Anony

mous, 19521).

Normal flavor can b e largely preserved in tuna if the fish is dipped in chilled brine before freezing, kept at — 2 0 ° C . ( — 4 ° F . ) for no longer than 15 months, and defrosted in cold water (Anonymous, 19521). J a p a n e s e workers noted a particularly unpleasant odor in canned frozen salmon, and traced it in part to piperidine, formic acid, formaldehyde, and amino- valeraldehyde w h i c h m a y have b e e n formed through fat oxidation and hydrolysis, and to volatile nitrogen formed in decomposition of protein.

O t h e r flavor changes w e r e attributed to the absorption of odor from the cold storage warehouse. In this case ammonia, ethylene, formaldehyde, and acetaldehyde are the chief components. A limit to frozen storage of salmon to b e used for canning was put at 5 0 days b y T a n i k a w a et al. ( 1 9 5 6 ) . A typical "freezer" odor, noted upon opening cans of salmon preserved b y freezing, was found to b e due to fat oxi

dation. This appeared after about 5 0 days of normal frozen storage. This period can b e increased to about 8 0 days b y treatment with butylated hydroxyanisole as antioxidant ( T a n i k a w a and Motohiro, 1 9 5 9 ) .

Texture, instead of b e i n g improved b y freezing, can also b e impaired since toughness increases with longer frozen storage. A brine dip before freezing or even after thawing m a y lessen this kind of deterioration

(Anonymous, 1 9 5 2 p ) .

2. Treatment of Raw Material before Canning

a. D R E S S I N G

In all preparative techniques the dominating trend is for mechani

zation. Transport from the fishing craft to the canning plant is minimized by mooring the vessel close to the factory. F o r unloading, the hoist has been replaced b y pumps, some of which are c a p a b l e of handling 1 0 0 - 3 0 0 tons of small fish per hour. This requires only two workers for the whole operation. Manufacturers of the pumping systems claim they can handle fish up to approx. 9 0 cm. ( 3 5 i n c h e s ) in length. T h e m e t h o d has found wide application in the United States, on the west coast (for California p i l c h a r d ) as well as in the east ( M a i n e sardines) (Tjilflaat, 1 9 5 0 ) .

E q u a l l y labor saving is the transport of fish within the cannery b y fluming. Tanks m a y easily b e c o m b i n e d with the fluming system for receiving, storing, and cooling if needed (Anonymous, 1 9 5 2 k ) . I t can also b e used for floating off ice or for brining. Automatic weighing and sorting can b e inserted in the feeding line.

T h e scaling necessary for most herring-type fish is usually done in rotating mesh cylinders ( E m p e y , 1952; Anonymous, 1 9 5 6 c ) . F o r the de- sliming of salmon, a rotating table has b e e n described (Anonymous, 1 9 5 0 ) .

Further pretreatment of fish for canning differs widely between species; hardly any general features can b e mentioned except the trend toward mechanization (Anonymous, 1954b, g, h; D e w b e r r y , 1957; Hardy, 1 9 5 3 a ) .

Some species must b e stored alive to get rid of ingested food (sprats in N o r w a y ) .

Evisceration on board, however desirable from a bacteriological point of view, is seldom feasible for the smaller species mainly used for canning. Evisceration of tuna is not thought practicable on the U.S.

Pacific Coast, due to salt penetration during freezing on the tuna clippers ( s e e Section I I I ) . I n F r a n c e , tuna stored on i c e is always gutted on board ( E m p e y , 1 9 5 3 b ) .

F o r most small fish, dressing is restricted to scaling and removal of head and intestines; for larger fish like tuna and salmon, butchering goes as far as the removal of the b a c k b o n e and sorting out of various parts of the m e a t for different packs. According to T a n i k a w a et al ( 1 9 5 2 ) ,

removal of the b a c k b o n e shortens the precooking time for mackerel. I n m a n y special cases, mechanization is coupled with other stages of the process, e.g., b e h e a d i n g with placing sardines on rods for smoking prior to canning (Anonymous, 1952o and 1 9 5 6 c ) . I n other cases, small as well as larger-sized fish are m e c h a n i c a l l y cut and p a c k e d lengthwise in t h e can ( E m p e y , 1953c, for mackerel; Anonymous, 1954h, for s a l m o n ) .

B l e e d i n g is necessary for m a n y species. T u n a are h u n g after b e heading and gutting to drain off the blood ( s e e C h a p t e r 4, this v o l u m e ) ; sharks must b e b l e d immediately after catching ( H a r d y , 1 9 5 3 c ) .

Sometimes certain parts of the fish are excluded from the canned product. I n tuna and mackerel, the b r o w n lateral m e a t is reported to frequently give an inferior product. C h e m i c a l b l e a c h i n g was found un

successful, b e c a u s e it destroys flavor ( M a t h i e s e n , 1 9 5 4 ) .

E v e n if the fish has b e e n w a s h e d or flumed before entering t h e dressing line, it is sometimes useful to give the dressed pieces a final washing just before canning. Chlorination of the w a t e r has proved to b e very efficient in removing b a c t e r i a from the dressing line w h i c h otherwise m a y b e c o m e a dangerous source of contamination (Dussault, 1957;

Somers, 1 9 5 1 ) . I f chlorinated water is used to wash the fish before packing, the chlorine should b e washed off b y a dip in p u r e water.

Besides chlorination, ultraviolet irradiation has b e e n found useful for purifying small amounts o f water in canneries ( R o w a n , 1 9 5 7 a ) .

T h e last washing can b e c o m b i n e d with salting.

b . S A L T I N G

Although sometimes used to r e m o v e blood and slime or to improve flesh texture, t h e main o b j e c t of salting and brining is to stabilize t h e flavor of the c a n n e d product and to bring out its characteristic taste. As such it is an important step in the preparation for canning.

I n m a n y cases the fish is salted before canning either b y "rousing"

(i.e., mixing the fish with dry salt) or b y immersion in brine; this can b e c o m b i n e d with washing or precooking b y using brine in these steps. T h e main p r o b l e m in salting is to get the fish to take up enough salt, so that after all subsequent steps the most desirable concentration of 1 . 1 - 1 . 6 % salt remains. R o w a n ( 1 9 5 4 ) found, as expected, that its salt content is dependent on duration of immersion in brine, amount of fish per volume of brine, and to a lesser degree on temperature of the brine bath. H e observed, in canning South African pilchards, that 2 5 - 3 0 % of the absorbed salt m a y b e lost during subsequent precooking, while M e e s e - m a e c k e r and Sohier ( 1 9 5 6 ) report losses of 4 0 - 6 0 % for sardines c a n n e d in M o r o c c o .

A second major p r o b l e m in salting is to obtain uniform salting

throughout large b a t c h e s of fish. A simple rousing or brine immersion is not satisfactory. V e r y uniform salting can b e obtained b y laying the fish on flakes to b e immersed, w h i c h is of course very time-consuming. In some South African canning plants the preferred procedure seems to b e to maintain a strong circulation in the brining tank. E l s e w h e r e sardines are washed in brine in rotation drums (Buffa, 1 9 5 5 ) .

Finally, salt pellets m a y b e added to the fish after it is p l a c e d in the cans and before processing. About 3 days later the salt has penetrated the fish fairly uniformly.

T h e purity of the salt used is important. S e a water has b e e n found unsuitable for brining; this is attributed to its calcium and magnesium sulfate contents w h i c h impart an unpleasant flavor to the fish (Aalderink, 1954; D e w b e r r y , 1 9 5 7 ) .

c. P R E C O O K I N G

W h e n fish flesh is heated, a fair amount of water is released from the proteins. T h e amount varies ( a b o u t 1 7 . 5 % for tuna, 1 9 - 3 4 % for sardines), depending on the fat content ( M e e s e m a e c k e r and Sohier, 1 9 5 6 ) . F u r t h e r release of water takes p l a c e during storage of the canned product

( W i t t e , 1 9 5 6 ) . I f all this water were to remain in the can a very un

attractive p a c k would result; sauces would b e diluted, oil would b e mixed with water, and the fish w h e n shrunken would not b e p a c k e d tightly enough to avoid damage. I t could also take on an unappetizing gray color. Finally, the ensuing salt solution might corrode the can (Nielsen and Rasmussen, 1 9 5 2 ) .

It is necessary, therefore, to cook the fish before it is retorted, either before or after packing it into the can. Precooking is a very critical process.

T h e fish should b e heated enough so that no further water is exuded in retorting. In some cases, however, a small quantity could b e absorbed b y adding sauce in concentrated form (Ludorff, 1 9 5 0 ) . T h e addition of carboxymethylcellulose ( C M C ) was advised b y Schoonens ( 1 9 5 2 ) and recently proved effective b y the Torry R e s e a r c h Station ( 1 9 5 8 ) , though the additive rendered the sauce tasteless. T h e addition of 1 % dry polyphosphate to herring fillets was found to reduce the exudate b y 2 0 - 4 0 % b y the same Station. I t is necessary in general that the w a t e r content of the fish b e reduced at least to 6 0 % (Nielsen and Rasmussen, 1 9 5 2 ) .

Sardines normally lose 2 0 - 3 0 % of their weight in cooking ( M e e s e m a e c k e r and Sohier, 1 9 5 9 ) . T h i s amount increases with temperature and duration of cooking and varies inversely with fat content of the fish.

H e n c e lean sardines require m u c h longer cooking than fat ones. Drying in hot air in addition to cooking has b e e n advocated, b u t is not required

if the sardines have b e e n correctly cooked. Air drying after steam cooking facilitates handling of the cooked fish and improves final a p p e a r a n c e of the product. Cooking does not in general appreciably decrease the fat content of sardine muscle, b u t the fish m a y lose about 1 0 % of their dry matter and 5 - 8 % of their caloric value in the procedure.

T h e practice of some canners of reducing weight losses of the fish b y minimizing the precooking should b e discouraged (Ludorff, 1 9 5 0 ) . Striking differences in weight of herring fillets in cans ( 8 7 - 1 5 3 g. in a 2 0 0 net weight c a n ) owing to indiscriminate precooking have b e e n reported b y W i t t e ( 1 9 5 6 ) . His experiments show that neither the type of s a u c e nor its amount has any influence on the weight loss of the herring, b u t only the degree of precooking. H e advises that descriptions on the can label b e written with due consideration for these weight losses.

In the U.S.S.R. various fresh water species are fried in oil before b e i n g c a n n e d with tomato sauce. T h e weight loss of the fish, due to the removal of moisture as a pretreatment, depends on the extent of frying and on the species. T h e kind of equilibrium attained b e t w e e n fish and sauce upon processing depends further on the quantities of fish and sauce and the size of the can. T h e correct procedure has therefore to b e found for every p a c k (Kalantarova, 1 9 5 8 ) .

Jarvis ( 1 9 5 2 ) showed that precooking "little tuna" (Euthynnus al- letteratus) at a lower temperature than in t h e normal Californian proce

dure resulted in a lighter color of the canned meat. F o r sardines, cooking time was found to depend on the fat content, lean fish needing m u c h longer cooking times ( M e e s e m a e c k e r and Sohier, 1 9 5 6 ) .

T h e classical m e t h o d of precooking is heating in brine. In F r a n c e , tuna is precooked mostly in 1 6 ° salinometer brine: 3 - 5 - l b . sections are boiled for 2 hr. in paper-lined crates to avoid contact with m e t a l surfaces.

Precooking in brine is more satisfactory than in steam or hot air ( E m p e y , 1 9 5 3 b ) .

Oil-packed fish like sardines can b e precooked b y immersion in heated oil. Peanut oil or Norwegian sild oil are used for frying and precooking of sild b y immersing the filled cans in the oil at 1 1 0 ° C . ( 2 3 0 ° F . ) for 2 - 3 min.

( E m p e y , 1 9 5 3 a ) . In general, however, this m e t h o d has b e e n replaced b y precooking in hot air (Buffa, 1 9 5 5 ) . T h e m e t h o d has b e e n m e c h a n i z e d in various ways, such as the circulating system of Sundry Co. (Anony

mous, 1 9 5 2 n ) , or a system in which the sardines in cans are subsequently heated b y steam and progressively hotter air currents, while the cans, closed b y a grid, are inverted at intervals to drain off the exuded water ( H a r t m a n , 1 9 5 5 ) . Another decanting system is the Bonnefon m a c h i n e (Castanie, 1 9 5 4 ) . M o s t of these systems are highly specialized for a

certain type of fish; further descriptions will therefore b e found in sub

sequent chapters.

d. D R Y I N G

In these precooking systems, decanting a n d / o r hot air currents are used to remove such moisture as is exuded in the cooking process. Steps to remove this moisture are inserted into most canning lines. T h e simplest way is to lay out the fish on grills or wire mesh to drain and additionally to dry in a cool air current. T u n a is laid out for 1 8 - 2 4 hr. for this purpose.

Such drying should take p l a c e in well-covered ventilated places, where the fish is protected from contamination. Special regulations are often in force to ensure good practices.

T h e removal of moisture b y means of centrifugation was tried out for tuna and gave best results with 5 0 0 - 6 0 0 r.p.m. for 15 min. (Buffa, 1 9 5 4 ) .

D r y i n g in hot air currents is a critical procedure b e c a u s e of excessive drying of the fish surface, b u t has proved successful in some cases, e.g., in the T o c q u e r system (Anonymous, 1 9 4 9 ) . M e e s e m a e c k e r and Sohier ( 1 9 5 6 ) report that drying in hot air noticeably increases the quantity of oil absorbed b y sardines. After using too high temperature, the organic matter of the fish m a y b e impaired and oil absorption decreased. E x cessive drying results in a tough texture.

A further effective m e t h o d of drying is b y applying vacuum. Harrison and R o a c h ( 1 9 5 2 ) and T a r r ( 1 9 5 4 b ) subjected retort loads of fish on trays or in unsealed cans to evacuation immediately upon precooking. T h i s resulted in immediate boiling off o f moisture and simultaneous removal of undesirable volatile substances, as well as rapid cooling. Since the evaporation does not depend upon h e a t conductivity, the rate of evacu

ation is limited only b y the danger of disrupting the fish flesh.

e. S M O K I N G

H o t air drying m a y b e accomplished b y smoking. This imparts a desir

able flavor to canned fish, in addition to removing moisture. I t is used par

ticularly for sardine-type fish. In these procedures, as described for E n g land (Anonymous, 1952o, 1 9 5 6 c ) , California (Anonymous, 1 9 5 2 k ) , and Norway ( E m p e y , 1 9 5 3 a ) , the fish are usually strung on rods and passed through a smoking tunnel, which m a y b e more or less automatized but w h i c h does not differ essentially from devices used for sole-purpose smok

ing ( s e e V o l u m e I I I , C h a p t e r 2 ) .

O f particular interest for canning is the m e t h o d of electrostatic smoking. In this the fish, laid out on a wire-mesh b e l t or p a c k e d in cans, are transported through a c h a m b e r in w h i c h smoke particles positively charged b y a strong electric c h a r g e (e.g., 2 0 , 0 0 0 volts) are

attracted to the fish in a matter of seconds; the fish is grounded and h e n c e negatively charged (Anonymous, 1954f, k ) . E a r l y experiments b y H a m m and Rust ( 1 9 4 8 ) resulted in a satisfactory flavor b u t a less satisfactory color of the fish. T h e method was not immediately adopted b y the industry. Interest has b e e n revived in this procedure of late and electro

static smoking has b e e n adopted in several countries. Difficulties are encountered in obtaining uniform smoking: if the fish are laid on wire mesh this leaves marks and fish p a c k e d in cans are left unsmoked on the lower side. T h e saving of time, however, is considerable: a smoking process normally taking 8 - 1 6 hr. can b e replaced b y electrostatic smoking for 1 0 - 3 0 min. with a similar taste result (Anonymous, 1 9 5 7 a ) . H e n c e this method seems to offer possibilities of adding to the mechanized processes for canning.

C. T H E C A N

1. Normal Tin Plate

T i n plate is still the most widely used material throughout the canning industry for making cans. Essentially, tin plate is a thin steel sheet coated with a m u c h thinner layer of tin on b o t h sides. Its unique advantages lie in the combination of the strength of the steel with the protective properties and the gloss of the tin layer. Regarding its corrosion resistance and staining properties, the steel plate m a y b e considered to b e covered on both sides with 4 layers: alloy, tin, protec

tive oxide, and oil (Vaurio, 1 9 5 5 ) . H e n c e , corrosion resistance does not depend solely on thickness of the tin coating b u t also on the c h e m i c a l composition of the base steel; a thick coat may, under some circum

stances, offer less protection than a thinner one ( s e e further, Hoare, 1 9 5 0 ) .

Tin shortage during the second world war produced a trend towards reducing the tin coating. Electrolytic plating especially has b e e n devel

oped into a successful method. Such tin plate has in later years b e e n used for fish products. In many instances the tin layer can b e reduced to YZ-YA lb. ( 0 . 2 - 0 . 1 k g . ) per base box ( t h e unit area equal to 20.2 m .2) . Normally such thin coating must, however, b e reinforced b y special enamels or lacquers.

M a n y such protective lacquers have b e e n developed ( M i d w o o d , 1 9 5 4 ) . At present these can b e a d a p t e d to any type of canned food and to any canning procedure ( F l ü g g e , 1 9 5 1 ) . T h e can linings formerly w e r e applied to the tin plate sheets, b u t recently more and more cans are coated b y inside spraying, which is more expensive b u t avoids damaging of the coatings during manufacture of the can.

C a n n e d fish products normally belong to the nonacid types of food, so

that corrosion is not the main problem for the inside of the can. C a n n e d seafoods are sulfur-staining foods, in that they are liable to produce sulfur ions during processing. T h e s e sulfur ions r e a c t with the tin coating to form tin sulfide or, if the steel b a s e is exposed, b l a c k iron sulfide.

Neither of the two sulfides is detrimental to health b u t b o t h m a y seriously impair the appearance of the product. Therefore, the use of so-called sulfur-resistant coated ( S R - c o a t e d ) cans is indicated. T h i s lacquer is especially n e e d e d for fish species containing a large amount of T M A O (trimethylamine o x i d e ) (Anonymous, 1 9 5 3 a ) . It has b e e n observed that salmon p a c k e d in cans of electrolytic tin plate m a y exhibit an un

pleasant odor, in contrast to packs in cans of hot-dipped plate ( K o i z u m i and Nonaka, 1 9 5 8 - 1 9 5 9 ) . In the former case, m u c h more free H2S was found to b e present than in the latter; it was concluded that H2S is probably not absorbed or b o u n d b y Sn or F e in electrolytic tin plate owing to its resin-lacquer coating ( s e e further Section V , B , 3 ) .

Coating lacquers m a y b e subdivided into:

( 1 ) Inorganic types, such as the "Protecta-tin" process, w h i c h involves the use of N a3P 03, N a2C r204, and N a O H in a wetting agent like T e e p o l or Disperol ( D a v i s , 1 9 5 5 ) . Inorganic compounds, like zinc oxide, may b e added to organic coatings to absorb the sulfur b y forming white zinc sulfide ( B u c k , 1 9 5 2 ) .

( 2 ) O r g a n i c types, of w h i c h the main ones are:

( a ) Vinyls, especially polyvinyl chloride or copolymers of vinyl chloride and vinyl acetate; these have good c h e m i c a l resistance b u t b e c o m e soft on heating, w h i c h makes the fish stick to the can wall or causes the coating to loosen.

( b ) Phenolics or phenol-formaldehyde polymers; these are efficient sulfur-resistant lacquers and therefore useful for fish canning, but some m a y impart a phenolic taint to the pack. Phenolic ( b a k e l i t e ) type coat

ings are flexible only in very thin layers and h e n c e m a y crack.

( c ) Oleoresinous lacquers are the most widely used. T h e y combine good chemical resistance with tastelessness and low price. Moreover, b y addition of a variety of chemicals these lacquers c a n b e tailormade to m e e t almost any demand.

( d ) E p o x i d e lacquers are the latest addition to the list; they are b o t h acid- and sulfur-resistant and thus have a wide range of application, b u t the process of coating the tin plate is m u c h m o r e critical than with the oleoresinous lacquers and they are more expensive. T h e nontoxicity of can linings has b e e n stressed b y Ives and D a c k ( 1 9 5 7 ) .

F o r some fishery products, especially crustaceans, the cans are lined with a v e g e t a b l e p a r c h m e n t ( s e e further Chapter 8A, this v o l u m e ) . In canning kippers in the United Kingdom, paper is also p l a c e d b e t w e e n

each fish to prevent sticking and to improve t h e appearance of the p a c k ( E m p e y , 1 9 5 2 ) .

2. Black Phte and Other Substitutes

Besides electrolytic plating, shortages during the second world war stimulated the development of b l a c k plate and other substitutes ( s e e Brighton et al., 1 9 5 4 ) . In general, these materials h a v e proved to b e difficult to use for fish products. T h e so-called C M Q ( c a n making quality) b l a c k plate can b e m a d e sulfur-resistant b y means of lacquers, preferably of the oleoresinous type, b u t these are liable to c o m e off during processing. Furthermore, the side seam cannot b e soldered as well as with tin plate and may develop leaks during pressure cooking.

Steels coated with aluminum, zinc, nickel, or titanium or chemically treated ("bonderized") have all b e e n tried, b u t have found little appli

cation in the fish canning industry (Anonymous, 1 9 5 5 e ) . 3. Aluminum

Especially in the Scandinavian countries, tin plate has b e e n largely replaced b y aluminum in fish canning. T h e material is m u c h softer than steel plate and the use of the aluminum can m a y b e restricted to instances where very rough handling is avoided and to cans of small to medium size. T h e thickness of the aluminum plate should b e 3 0 - 4 0 % greater than that o f tin plate used for a similar purpose ( E i k e et al., 1 9 5 9 ) . Aluminum m a y b e reinforced b y the addition of M g , Mn, or Cr. After a variety of such materials had b e e n used in Norway for various fish products ( T a a r l a n d , 1 9 5 2 ) , a special A l - M g alloy was developed, the tensile strength of which almost equaled that of steel plate (Anonymous, 1 9 5 5 h ) .

T h e aluminum used in cans is submitted to an anticorrosion treatment, usually anodizing in dilute H2S 04, and thereafter can b e coated inside with a lacquer suitable for fish products (Nickelsen, 1 9 5 1 ) . A continuous anodizing process was developed in Norway in 1 9 3 9 , with some later improvements (Anonymous, 1 9 5 5 h ) . A fully automatic can production line for aluminum cans was set up in G e r m a n y in 1 9 5 6 (Anonymous, 1 9 5 7 c ) . Aluminum cans here r e a c h e d the point w h e r e they c o m p e t e d successfully with the tin can. T h e i r advantages are: ( 1 ) absence of sulfur blackening, ( 2 ) no metal dissolving into the food, ( 3 ) easy opening of the can, and ( 4 ) light weight.

4. Glass and Other Nonmetal Materials

H e a t processing of foods in flexible packages has b e e n tried recently, but principally for military purposes ( L e i n e n , 1 9 5 9 ) . A combination of