CHAPTER 4

Tuna Canning and the Preservation of the Raw Material through Brine Refrigeration

S V E N LASSEN

Van C a m p Laboratories, Terminal Island, California

I. Identification and Resources 207

II. Fishing Methods 2 09

III. The Development of the Tuna Fishing Industry 209 IV. The Preservation of Raw Tuna by Brine Refrigeration 211

A. The Brine Circulation System 213 B. The Bait Water Circulation System 215 C. The Ammonia Refrigeration System 215

D. The Fishing 218 E. Stowing and Chilling 219

F. Packing and "Topping Off" 219

G. Brining 219 H. Freezing 220 I. Drying Up and Holding in Dry Storage 220

J. Thawing of Brine-Frozen Tuna 221

K. Unloading 222 L. Quality Evaluation of Raw Tuna 222

V. The Butchering 225 VI. Precooking and Cooling 225 VII. Cleaning, Cutting, and Canning 229

VIII. Retorting 231 IX. Standards and Quality Specifications 235

X. Quality Control of Canned Tuna 242

XI. Concluding Remarks 243

References 243

I. Identification and Resources

Tuna is a generic term applied to a group of two or more families of fish which, in the zoological system, are classified under the order of Scomberformes. The tunas are of considerable importance because of the role they have played through the ages as a food for man. Archeo- logical evidence (Corwin, 1930) indicates that tuna was used as a food by early civilizations thousands of years before the herring, the cod, and the salmon attained similar status (Fig. 1).

Tunas are generally large and migratory in habits. They are carnivo

rous and voracious. They feed on planktonic crustaceans, argonauts, squids, jellyfish, etc. Generally speaking, it can be said that tuna feed

207

208 SVEN L A S S E N

on whatever small sea animals are most abundant and t h e easiest to c a t c h in the waters they visit. W h i l e tuna thus seemingly prefer live food, they are not adverse to taking dead, or even salted, fish ( N a k a m u r a , 1 9 5 2 ) . T h e y will even b i t e on artificial lures when tuna are moving in the surface waters. W h e n they take bait, they seem to attack it at high speed, after w h i c h they dive deep, turning obliquely to the rear. T u n a are predominantly pelagic fish. T h e i r distribution in the oceans of the world is still incompletely known. I t is known, however, that they inhabit mainly the equatorial and temperate zones of the ocean.

FIG. 1. Butchering of tuna in the 6th century B.C. (From an ancient Greek wine pitcher in the State Museum of Berlin, Germany.)

T h e Pacific O c e a n has for m a n y years b e e n the center of large-scale tuna-fishing operations. T h e Atlantic O c e a n supports minor commercial tuna-fishing activity along the east coast of the United States, and some

what larger operations along the E u r o p e a n west coast from Norway to Spain. T h e South Atlantic O c e a n , considered a potentially rich tuna- fishing area, is as yet largely unexplored and unexploited ( M o l t e n o , 1 9 4 8 ) . Smaller tuna-fishing operations are established in many areas of the Mediterranean Sea, the C a r i b b e a n S e a , the Indian O c e a n , and in waters bordering the Australian south and east coast (Anonymous, 1 9 5 6 ) . Little is known about the spawning and growth of tuna. According to a report on J a p a n e s e fisheries (Nat. Resources Sect. Rept. No. 104, 1 9 4 8 ) , certain species of tuna, including the commercially important

4 . T U N A CANNING AND P R E S E R V A T I O N O F R A W M A T E R I A L 2 0 9

yellowfin, spawn in the waters surrounding J a p a n , T a i w a n , and t h e Philippine Islands, b u t very little is k n o w n o f t h e larvae immediately after hatching. Similar studies h a v e b e e n m a d e on the distribution of tuna larvae in t h e eastern part of the Pacific O c e a n . T h e s e studies indicate t h e p r e s e n c e o f a t least three p r o m i n e n t spawning areas, o n e off the west coast of M e x i c o , another off the west coast of C e n t r a l A m e r i c a , and a third b e l i e v e d to b e in the vicinity of the Galapagos Islands. T h e s e studies, a n d others c o n c e r n e d with t h e geographical distribution of tuna a n d their population relationships have, during r e c e n t years, a d d e d m u c h n e e d e d information of i m p o r t a n c e to t h e orderly c o m m e r c i a l utilization o f t h e t u n a resources o f t h e eastern Pacific O c e a n . T h e m a i n contributors to these valuable investigations h a v e b e e n the Inter- American T r o p i c a l T u n a Commission ( 1 9 5 7 ) , the California F i s h and G a m e Division, and the United States F i s h and Wildlife Service ( S h a p i r o , 1948; Powell and Hildebrand, 1 9 4 9 ; G r a h a m , 1957; Schaefer, 1 9 5 6 ) .

II. Fishing Methods

T h e methods of fishing for tuna vary greatly in the different tuna- fishing countries. F i s h i n g with gill nets, encircling nets, or drift nets is p r a c t i c e d in m a n y fishing areas. I n other areas, stationary fish nets ending in a trap are strung out at a right angle to t h e coastline to c a t c h migrating tuna moving inshore along the coast. T h e most important c o m m e r c i a l fish

ing methods in use, however, are t h e pole-and-line fishing method, the long-line fishing method, and the purse-seining method. T h e pole-and-line m e t h o d and purse seining are used for surface fishing, while the long-line fishing m e t h o d , developed to a h i g h d e g r e e o f perfection b y t h e J a p a n e s e , is for below-surface fishing. F o r a m o r e detailed description of tuna fishing gear, a n d methods of fishing, t h e r e a d e r m a y consult the several publications on t h e s u b j e c t b y t h e U . S. F i s h a n d W i l d l i f e Service, in particular, Fishing Leaflet No. 297 ( 1 9 4 8 ) .

III. The Development of the Tuna Fishing Industry

J a p a n has played a major role in t h e development of the tuna-fishing industry. U n t i l 1 9 1 2 , J a p a n s tuna-fishing operations w e r e on a relatively small scale limited to coastal waters. W i t h t h e introduction o f motor- driven vessels into their fishing fleet, in t h e years immediately prior to W o r l d W a r I, t h e J a p a n e s e w e r e a b l e to exploit m o r e fully the rich tuna-fishing areas surrounding their islands. W h e n the tuna c a t c h in t h e coastal a n d offshore h o m e waters o f t h e J a p a n e s e Islands h a d r e a c h e d its m a x i m u m in the early thirties, t h e J a p a n e s e b e g a n to explore the overseas tuna-fishing areas in t h e mid-Pacific O c e a n , and beyond. I n the m e a n t i m e , the Americans w e r e developing a tuna-fishing

2 1 0 SVEN L A S S E N

industry along the coast of California, w h i c h eventually was to extend to the larger fishing areas in the eastern parts of the Pacific O c e a n . W h i l e the J a p a n e s e tuna-fishing industry was to a large extent b a s e d upon supplying fresh or frozen tuna to the consumer, the American tuna in

dustry was b a s e d from its beginning upon the production of c a n n e d tuna.

T h e first tuna canning in the U n i t e d States was started in 1 9 0 3 , w h e n the sardine c a t c h failed ( T r e s s l e r and L e m o n , 1 9 5 1 ) . D u r i n g t h e first year, 7 0 0 cases of tuna w e r e produced ( 1 case = 4 8 ^ - l b . c a n s ) . T h e supply of tuna for the canning industry w h i c h developed in S a n Pedro and S a n D i e g o c a m e from the coastal waters of California, w h i c h for m a n y years were able to satisfy the growing demands of the local tuna- canning industry. As the years w e n t on, and the d e m a n d for c a n n e d tuna expanded, the tuna-fishing boats extended their operations b e y o n d the California coastal waters. T h i s expansion extended the tuna-fishing activ

ities into the Pacific O c e a n in a southward direction toward the equator and beyond. T h e extension of tuna-fishing activities to areas sometimes m o r e than 2,000 miles from h o m e port c r e a t e d some very difficult technological and e c o n o m i c a l problems. T h e s e problems involved, a m o n g others, the design and development of the right type and size of fishing vessel, w h i c h would b e suitable for long-distance fishing and able to stay at sea over a period of 3 to 4 months. A type of fishing vessel called the "tuna clipper" finally e m e r g e d as an answer to these problems. T h e tuna clipper soon b e c a m e very popular and, as a result, today dominates tuna-fishing operations in the eastern Pacific O c e a n .

T h e tuna clippers are large Diesel-motor-propelled ships equipped with all m o d e r n navigational aids, a b l e to hold from 1 0 0 to 5 0 0 tons of tuna in their fully refrigerated holds. T h e cost of this type of b o a t is high, and in order to amortize t h e investment over a reasonable period and m a k e a reasonable profit, t h r e e to four trips a year with a full load of tuna are necessary. T h e average trip to the fishing grounds and b a c k usually takes 6 0 - 7 0 days. T h e clippers are equipped only to fish with hook-and-line tackle and live bait. S o m e purse-seining boats are used for tuna fishing, b u t they a c c o u n t for only a minor part of the total c a t c h (Schaefer, 1 9 5 6 ) .

T h e seasonal run of a l b a c o r e and bluefin in California's coastal waters used to b e caught b y fishermen in smaller vessels resorting to hook-and-line gear. T h e s e vessels, due to the short distance they usually operate from h o m e port, often use crushed i c e for preserving the fish, and in some instances, a combination of crushed ice and ammonia re

frigeration. Since 1 9 5 8 there has b e e n a complete change in long-range fishing. T h e predominant method for tuna catching b y U.S. clippers is b y purse seiners.

4 . T U N A CANNING AND P R E S E R V A T I O N O F R A W M A T E R I A L 2 1 1

T h e quality of manufactured product depends to a large extent upon the quality of the raw materials entering into its manufacture. T h i s generalization applies, naturally, also to t h e manufacture of c a n n e d tuna. T h e m a n y ways in w h i c h the tuna raw material m a y b e affected b y the treatment it is subjected to on the tuna clipper while in transit would seem to b e sufficiently related to the manufacture of c a n n e d tuna to justify a discussion of these aspects of tuna canning in greater detail.

I n a s m u c h as the tuna clippers, as stated above, b r i n g in b y far the largest part of the tuna raw material, the discussion will b e limited to methods of preservation as used on b o a r d tuna clippers.

IV. The Preservation of Raw Tuna by Brine Refrigeration

T h e refrigeration system used in the tuna clipper is t h e brine im

mersion refrigeration system. T h i s m e t h o d of refrigeration dates b a c k to 1913 w h e n O t t e s e n was granted a patent involving t h e direct immersion of fish into eutectic brine. A modification of this system was selected in 1938 ( L a n g et al., 1 9 4 5 ) as the system o f choice after t h e p e r c e n t a g e of tuna rejects from boats using i c e for tuna preservation has assumed major proportions. T h i s crisis was caused b y t h e d e m a n d for m o r e tuna than could conveniently b e provided from the local offshore tuna-fishing area.

As a result, the fishing boats h a d to seek fishing areas further a w a y from h o m e port. I n so doing, the limit b e y o n d w h i c h i c e boats could safely b e used, without impairment to t h e quality of t h e i c e d tuna, was e x c e e d e d . A drastic reduction in rejects took p l a c e immediately following the introduction of t h e b r i n e freezing system, a n d this system of preservation has r e m a i n e d essentially u n c h a n g e d during t h e past twenty years. T h e use of b r i n e as a h e a t transfer m e d i u m b e t w e e n t h e tuna and the refrigerating coils offers m a n y advantages w h i c h are well understood b y engineers. A n advantage of t h e b r i n e system, equally important b u t perhaps less appreciated, is the inhibiting quality w h i c h salt ( N a C l ) in solution has on m i c r o b i a l life w h e n present in hypertonic concentration ( T a n n e r , 1 9 3 3 ) . T h e age-old m e t h o d o f preserving fish and meats b y salting or brining is, of course, b a s e d on that fact. T h e s e obvious ad

vantages may, in some instances, b e c o u n t e r b a l a n c e d b y the fact that brine solutions in c o n t a c t with fish, particularly, if extended over longer periods of time at temperatures a b o v e t h e freezing point of the brine, impart to the fish tissue qualities w h i c h m a y b e undesirable. I n this instance, there c a n b e a considerable penetration of salt into the tuna muscle. T h i s has a denaturing effect u p o n some of the m u s c l e protein, while another part of the m u s c l e content seems to dissolve. F u r t h e r m o r e , the remaining m u s c l e tissue c o m b i n e s with t h e salt in such a fashion that it cannot again b e r e m o v e d in subsequent canning operations ( L e w i s a n d

2 1 2 S V E N L A S S E N

Saroff, 1957; Saroff, 1 9 5 7 ) . Finally, brine in contact with the tuna has a tendency to draw moisture out of the fish, thereby causing a temporary or permanent loss in weight. T e m p e r a t u r e and p H of t h e brine, as well as its concentration, are factors w h i c h influence these changes t o a marked degree. A further study of t h e influence of sodium chloride brines upon tuna is badly needed. T h e use of sodium chloride brines as a freezing medium in a tuna clipper, if not used at all times at or near the eutectic temperature, can, therefore, not b e considered the ideal method of preservation, b u t must b e looked upon as a compromise b e t w e e n the advantages of brine refrigeration and its disadvantages, some of w h i c h have b e e n outlined in the above. T h e s e disadvantages m a y fortu

nately b e r e d u c e d to a reasonable minimum b y taking c a r e that the temperature of the brine w h e n in c o n t a c t with tuna is at all times kept at as low a temperature as proper operational p r a c t i c e will permit.

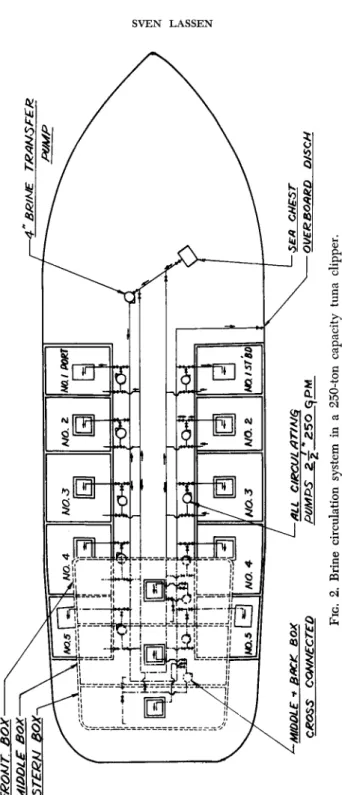

Any attempt to give a satisfactory description and illustration of the brine refrigeration system in a tuna clipper is complicated b y the fact that this system consists not only of a highly compartmentalized ammonia compression and expansion system, b u t also of a brine circulation system integrated into it for the purpose of transmitting, efficiently and fast, the heat from the highly perishable tuna to the heat-absorbing ammonia in the refrigeration coils. T h e periodic use of t h e freezing tanks ( w e l l s ) in a clipper for live bait, and in some instances for fuel during t h e first part of the voyage would further c o m p l i c a t e any attempt to incorporate all the m e c h a n i c a l features c o n n e c t e d with these uses into o n e composite description and illustration. I n view of this, and for the sake of clarity, the a m m o n i a refrigeration system is described and illustrated separately from t h e brine circulation system, and the b a i t circulation system also will b e treated as a separate entity. I t is h o p e d that t h e advantages gained b y such a representation will outweigh the obvious disadvantages of presenting interrelated systems as separate units. T h e descriptive and illustrative details to b e given have b e e n adopted to fit a situation such as one would find it in an average-size clipper of 2 5 0 tons capacity. T h e over-all specifications of such a b o a t would b e roughly as follows.

T h e b o a t is m a d e of steel, 1 2 1 ft. long, 28-ft. b e a m , 13-ft. draft, and will carry a fully refrigerated load of 2 5 0 tons of tuna. T h e b o a t is compartmentalized into ten wells, five on either side of the boat, and three b a i t boxes on the stern. T h e wells will average 8 0 0 c u b i c ft. or 6,000 U . S . gal. and hold about twenty tons of t u n a in e a c h well. T h e bait boxes will average 6 3 3 c u b i c ft. or 4 , 7 4 0 U . S . gal., or about sixteen tons of tuna each. All wells and boxes are usually insulated with a 5-in.

layer of fiber glass or other satisfactory insulation material.

4 . T U N A CANNING AND P R E S E R V A T I O N O F R A W M A T E R I A L 2 1 3

A. T H E B R I N E C I R C U L A T I O N S Y S T E M

In t h e b r i n e circulating system, b r i n e or sea water m a y b e circulated through t h e wells. T h e b r i n e in t h e course of its circulation c o m e s into contact with t h e a m m o n i a coils lining t h e inside surfaces of t h e wells, and will b e chilled b y the evaporating liquid a m m o n i a in t h e coils, t h e r e b y gradually causing a transfer of h e a t from any tuna stored in t h e wells. T h e evaporating a m m o n i a in t h e coils will flow to t h e a m m o n i a compressor w h e r e , after an adiabatic compression, it will b e freed of its heat, and liquefied in the condenser and r e t u r n e d t o the receiver for further use.

T h e b r i n e circulation system, as seen in F i g . 2 , comprises a 4 - i n . diameter sea suction m a i n line from t h e sea chest and a 4 - i n . drain dis

c h a r g e m a i n line c o n n e c t e d to e a c h well a n d box. T h e m a i n suction and main discharge lines are again interconnected, so that in c a s e of a b r e a k down of any of t h e circulating pumps, t h e transfer p u m p c a n take over.

T h e individual b r i n e circulating pumps, one for e a c h w e l l and b o x ( e x c e p t t h e b a c k b o x ) , are 2 % - i n . open impeller t y p e driven b y a 3 - H . P . , 2 2 0 - V , 3 - p h a s e A . C . motor, and a rating of 2 5 0 gal. p e r minute.

W i t h t h e proper valves c o n n e c t i n g t h e suction m a i n a n d t h e discharge main closed, e a c h well b e c o m e s a closed circuit taking suction from the b o t t o m of t h e well, b e t w e e n t h e bait screen, a n d discharging into t h e top of t h e well t h r o u g h t h e gooseneck in t h e coaming. E i t h e r t h e suction m a i n or t h e discharge m a i n m a y b e used to transfer b r i n e from one w e l l to another using any one of the t w e l v e circulating pumps. B o t h t h e suction m a i n a n d the discharge m a i n will b e used to transfer brine if the transfer b r i n e in the transfer is used. T h e transfer p u m p is usually a 4 - i n . diameter, 5 H . P . , 5 0 0 G . P . M . o p e n impeller type.

As c a n b e seen b y inspecting F i g . 2 , t h e b r i n e circulation system is r e m a r k a b l y flexible. B y handling t h e proper valves, any p u m p in the system c a n take suction not only from the main, b u t from any well or b o x a n d transfer or discharge its content, as required. S o m e of the disadvantages of this system are its complexity, and the fact that m a n y valves and m u c h piping are n e e d e d for its operation. As the valves a g e a n d corrode, opening a n d closing b e c o m e a laborious, time-con

suming operation. Another, perhaps m o r e important, disadvantage is that it is impossible to flush t h e system c o m p l e t e l y following t h e transfer, circulation, or discharge of t h e brine.

An effort to modify and simplify the b r i n e circulation system has recently b e e n m a d e b y a shipbuilding concern. I n their r e c e n t l y c o m missioned clippers, t h e b r i n e and b a i t circulation system are c o m b i n e d into one. T h i s eliminates m u c h piping and m a n y valves, t h e r e b y simpli-

FIG. 2. Brine circulation system in a 250-ton capacity tuna clipper.

214 SVEN LASSEN

4. T U N A CANNING AND P R E S E R V A T I O N O F R A W M A T E R I A L 2 1 5

fying the construction and helping to clear an already too-crowded shaft alley. Present day economics of tuna fishing makes these savings of particular interest. T h e wells and boxes ( e x c e p t the stern b o x ) have strung along their inside surfaces ly^-in. standard galvanized ammonia coils 8 in. on center.

B . T H E B A I T W A T E R C I R C U L A T I O N S Y S T E M

T h e b a i t circulation system is designed to satisfy the oxygen and food requirements of the large amount of live b a i t w h i c h present pole-and-line fishing methods m a k e it necessary to carry on a tuna clipper. T h e vessel illustrated in F i g . 3 carries as m u c h as 4,000 scoops of live b a i t at one time. This is equal to 2 0 tons of live bait. L i v e b a i t requires a large amount of oxygen, clean water, and food. T h e amount of food obtained from offshore "blue water" is probably inadequate for b a i t obtained from an inshore "green water" habitat, so the satisfactory feeding of bait, while in captivity, m a y b e as great a problem as is the supplying of the b a i t with a satisfactory amount of oxygen-containing o c e a n water. U n d e r favorable conditions, the major part of the bait, so indispensable to the fishing methods employed on b o a r d tuna clippers, m a y b e kept alive until they are used for "chumming."

T h e large axial flow bait pumps are calculated to provide sufficient water to completely c h a n g e the water in less t h a n 9 min. in all wells and boxes. However, freshly caught bait requires t h e highest flow rates. After the bait has b e e n in the wells for a few days and "settled down" the rate of flow m a y b e cut down considerably. T h e ability of some species of bait fish to survive b e t t e r than others is thought to b e due largely to their ability to better adapt themselves to abrupt and sometimes extreme temperature changes in the o c e a n w a t e r w h i c h m a y o c c u r w h e n the clipper in its search for tuna moves from one locality and temperature to another.

C . T H E A M M O N I A R E F R I G E R A T I O N S Y S T E M

T h e ammonia refrigeration system on a clipper ship ( F i g . 4 ) consists of the five elements indispensable to any a m m o n i a refrigeration system, namely, ( 1 ) compressor, ( 2 ) condenser, ( 3 ) receiver, ( 4 ) expansion valve, and ( 5 ) evaporating unit. I n the standard tuna clipper the refrigeration installation consists of three 6-in. X 6-in., 2-cylinder, ver

tical, single-acting compressors, turning at 3 6 0 r.p.m., giving a total refrigeration of 5 4 . 3 tons at 2 5 lb. p e r square i n c h on the suction side, and 185 lb. per square inch condenser pressure. T h e condenser will have 1,100 square ft. of cooling surface, with water circulating through the condenser at 2 5 0 gal. per minute. T h e twin a m m o n i a receivers hold

VALUES SHOW g Z5 MP Z2.Q IS 3 P#*S£ L/N£ S/ZES /.P.S. 4X//IL fi=LOUS ΛΟΟΟ qPM FIG. 3. Bait water circulation system in a 250-ton capacity tuna clipper.

216 SVEN LASSEN

4 . T U N A CANNING AND P R E S E R V A T I O N O F R A W M A T E R I A L 2 1 7

FIG. 4. Ammonia refrigeration system in a 250-ton capacity tuna clipper.

2 1 8 S V E N L A S S E N

1,200 l b . of a m m o n i a combined. F o r e a c h well and b o x ( e x c e p t the stern box, w h i c h usually has no refrigeration) b o t h automatically and manually operated expansion valves are provided. T h e evaporation system consists of 1%-in. standard galvanized ammonia coils, covering the inside surfaces of the wells. T h e coils are lined up 8 in. on center.

O n this basis, a 30-ton well has about 1,000 linear ft. of evaporator coils, which gives the well roughly 0.84 linear ft. of coil p e r c u b i c foot of space in the well. Besides this, the refrigeration system is provided with b a c k pressure regulators ( H u b b l e valves) on the three suction lines of the wells, pressure gauges, oil traps, safety controls, etc., as shown on sketch.

Refrigeration for the ship's stores is provided b y a separate 3-in. χ 3-in., two-cylinder, vertical, single-acting compressor w h i c h is rigged into the main a m m o n i a system as shown. T h e wells and boxes are all insulated, usually with a 5-in. layer of fiber glass. T h i s insulation has, in m a n y instances, proved inadequate, and other types of insulation are now b e i n g tested.

D . T H E F I S H I N G

W h e n a school of tuna is sighted, t h e fishermen take their positions in the especially designed m e t a l racks attached to the outside of the hull of the clipper, and the "chummer" starts throwing overboard the live bait, which m a y consist of anchovies, small pilchards or anchovettas, etc., to stimulate the tuna to bite. I n t h e m e a n t i m e , the fishermen start to fish with their pole and line gear provided with barbless hooks. T h e hooks are m a d e in the form of a lure called a "squid" or "jig." As soon as the tunas strike the hooks they are pulled on board, and in releasing the tension on the pole line as the tuna hits the deck, the barbless hook disengages automatically and the fisherman immediately throws out his line ready for another strike. I n this w a y fishing continues so long as the fish continue to strike or until there is a "rail full." A "rail full" describes the condition w h e n the tuna h a v e filled t h e stern, b a c k of the m e n in the racks, flush to the caprail. At this point there is no c h o i c e b u t to dis

continue fishing operations, and usually w a t e r chutes are rigged to flume the fish from t h e stern into t h e designated well. I n most instances the time the tuna spend on d e c k b e f o r e they are put into the well is of short duration. T h e r e are, however, situations where the tuna m a y have to spend several hours on d e c k before they c a n b e stored in the well.

T h e high temperature usually prevailing in the area w h e r e tuna are caught, and the fact that tuna, in spite of their presumed lack of a thermoregulatory b o d y mechanism, often have, w h e n landing on deck, a b o d y temperature of up to 1 4 ° F . a b o v e t h e surrounding ocean temperature, m a y m a k e the time on d e c k a very critical one. B y hosing down or watering

4 . T U N A CANNING AND P R E S E R V A T I O N O F R A W M A T E R I A L 2 1 9

the caught tuna occasionally, the internal temperatures of the fish can be lowered faster to that of the surrounding temperature. B y hosing down the tuna, the blood and vomit that are discharged from the tuna during the death struggle are also removed.

E . S T O W I N G AND C H I L L I N G

W h e n a well or b o x is expected to r e c e i v e tuna within the next 2 4 hr., the well is filled with sea water, if not already full, and the a m m o n i a coils in that well are cut into the refrigeration system, t h e r e b y lowering the temperature of the sea water. Sometimes, however, due to t h e unpredictable course that fishing often takes, the well is not ready w h e n tuna strike; at other times, fishing is so slow that it takes 2 to 3 weeks before a well is completely filled. I n such instances, some of the tuna in the well will h a v e b e e n kept for a long time at temperatures generally considered unfavorable for optimal preservation of quality.

T o o v e r c o m e difficulties of this type requires m u c h skill and good j u d g m e n t on the part of the tuna b o a t engineer.

F . P A C K I N G AND " T O P P I N G O F F "

W i t h the chilled sea w a t e r circulating in the well and the tuna b e i n g added as they are caught, the well finally arrives at a stage of fullness usually called "tails" or "tails up." At this stage no m o r e fish c a n b e added until some ( o r a l l ) of t h e sea w a t e r is p u m p e d out of the well.

Generally a well with "tails up" will hold about 2 0 to 2 5 % m o r e fish w h e n p u m p e d dry. T h e p r a c t i c e of settling t h e tuna in the well, t h e r e b y permitting 2 0 - 2 5 % m o r e fish to b e carried, is referred to as packing and

"topping off" and has b e e n used ever since brine immersion freezing was introduced into the tuna fleet. A closer study of the "packing" and

"topping off" p r a c t i c e revealed this p r a c t i c e to contain m a n y objection

a b l e features w h i c h will slow down fast, efficient, and uniform freezing of the tuna during the brine freezing w h i c h follows.

G. B R I N I N G

After a well is packed, a grating is secured low in the h a t c h c o a m i n g to prevent the fish from floating w h e n high-gravity b r i n e is added, or m a d e up in the well. T h e amount of salt required to m a k e up a b r i n e depends upon the lowest temperature to w h i c h the b r i n e is to b e taken during t h e freezing of t h e tuna in the well. I t is customary to add enough salt, progressively or in one lot, so that the freezing point of t h e b r i n e is 4 - 6 ° F . lower than the final temperature t h e b r i n e will have prior to its final discharge from the well. A rule-of-thumb m e a s u r e of the amount of salt to use in brining a well is to use one-half sack of salt ( o f 1 2 5 l b .

2 2 0 SVEN L A S S E N

n e t ) per estimated ton of tuna in t h e well. Sometimes the b r i n e used for the freezing of one well m a y b e reused for another well. T h i s procedure, however, does not extend b e y o n d the second well, b e c a u s e t h e b r i n e soon b e c o m e s "heavy" with organic matter. T h e most c o m m o n p r a c t i c e of brining a well is to m a k e up t h e brine in t h e coaming of t h e well containing the p a c k e d fish. W h e n the circulating sea w a t e r in t h e well has b e e n b r o u g h t down t o a b o u t 3 0 ° F . , the required a m o u n t o f salt is d u m p e d into t h e c o a m i n g on top of the grating, and the circulating water from the gooseneck inlet washes the salt down into the fish and ultimately dissolves the salt. S o m e engineers prefer the progressive salting methods, w h e r e b y t h e salinity of the sea w a t e r circulating in t h e well is pro

gressively b e i n g increased b y addition o f salt. T h e procedure followed in the brining of tuna is not very uniform, owing in part to very restricted space conditions, and the fact that t h e wells, besides serving to hold fish, must also serve as b a i t tanks and fuel tanks during a sea trip which, as mentioned above, often takes m o r e than 2 months.

H . F R E E Z I N G

W h e n the brine in a well has attained the required strength, the actual brine freezing begins. B y circulating the b r i n e in a downward direction the coils a t t a c h e d to t h e inside surface of t h e well absorb the heat of t h e b r i n e and of the tuna around w h i c h t h e b r i n e circulates. T h e time required to bring a well down to the desired temperature, usually b e t w e e n 1 5 and 2 0 ° F . , m a y vary from one to several days, but, in any case, after the desired low temperature has b e e n established, the well is not "dried up" for at least 7 2 hr. S i n c e q u i c k freezing is generally believed to b e less injurious to t h e fish m u s c l e t h a n slow freezing

( L u s e n a a n d Cook, 1 9 5 3 , 1 9 5 4 ; L u s e n a , 1 9 5 5 ) , the rate at w h i c h the temperature interval b e t w e e n 3 0 ° F . and 2 0 ° F . is traversed is of im

portance. D u r i n g this temperature interval, most of t h e h e a t of crystal

lization o f t h e i c e in t h e fish m u s c l e is given off. T h i s evolution o f h e a t slows down the rate of cooling of t h e b r i n e until most o f the tuna has frozen, after w h i c h the temperature again suddenly resumes its down

ward trend. T o bring t h e temperature of t h e tuna down through this interval fast c a n b e d o n e only w h e n t h e b r i n e is a b l e to circulate freely around t h e tuna in t h e well a n d t h e a m m o n i a coils. A tight p a c k i n g o f the tuna in t h e well is, therefore, not conducive to fast freezing and should b e avoided b y all means.

I . D R Y I N G U P AND H O L D I N G I N D R Y S T O R A G E

F o l l o w i n g t h e lowering o f t h e tuna in t h e b r i n e to t h e desired freezing temperature, t h e b r i n e is p u m p e d out o f t h e well. Refrigeration is

4 . T U N A CANNING AND P R E S E R V A T I O N O F R A W M A T E R I A L 2 2 1

usually stopped several hours b e f o r e t h e b r i n e in the w e l l is actually p u m p e d out to allow any coils that m a y b e i c e d and random pockets of i c e around t h e sides of t h e wall to t h a w out. T h i s makes it easier to thaw the well uniformly and unload the tuna later on upon arrival in port.

After t h e drainage period, t h e a m m o n i a coils a r e put into service again. T h e amount of refrigeration n e e d e d to maintain the temperature in the well will d e p e n d mainly upon the condition of t h e insulation of the well. I n c a s e of good insulation, very little refrigeration is n e e d e d to maintain t h e temperature. A further lowering o f the temperature of the frozen tuna w h i c h often takes p l a c e after the b r i n e has b e e n p u m p e d out is b o t h costly and undesirable.

J . T H A W I N G O F B R I N E - F R O Z E N T U N A

B e f o r e the tuna in t h e wells o f a tuna clipper c a n b e unloaded, it is necessary that they b e partially or fully thawed. T h i s takes time, and that is w h y t h e tuna clipper engineer sometimes requires up to a week's notice b e f o r e h e c a n h a v e a well ready for unloading. Although there is a considerable variation in detail o f thawing methods, t h e general principle favored n o w seems to b e as follows: first, the ammonia refriger

ation on any well to b e t h a w e d is stopped. This, depending upon circumstances, is often done several days before thawing actually starts.

Next, sea w a t e r is introduced into the w e l l b y pumping the w a t e r from the sea chest through the well in an u p w a r d direction, allowing it to spill over t h e open coaming, or letting it e s c a p e through the bait circulation overboard discharge. I t is customary to start at least two wells at a time, one port w e l l and t h e corresponding starboard well, and t h e n p r o c e e d stepwise to t h e other wells as t h e y a r e needed. After approximately an hour, flow from t h e sea chest is stopped and the brine circulation p u m p takes over, reversing t h e flow through t h e well. Salt is then added, in amounts e q u a l to, or slightly in excess of, t h e amount originally used to freeze t h e tuna ( s e e Section I V , G ) . I f the temperature of t h e frozen tuna has b e e n lowered appreciably after t h e drying up of the well, additional salt will b e n e e d e d for rethawing. As soon as t h e brine circulation begins, an abrupt drop in temperature of the b r i n e occurs, due to t h e melting o f i c e in a n d around t h e tuna and t h e absorp

tion of h e a t resulting from this c h a n g e o f state. W h e n thawing comes to an end, after several days, the t e m p e r a t u r e of t h e tuna should b e around 2 8 ° F . , a n d t h e b r i n e is p u m p e d out. As m e n t i o n e d above, one reason for thawing t h e frozen tuna in a clipper w e l l is to bring t h e fish to a condition w h e r e it c a n b e unloaded. T h i s involves t h e separation of the individual fish, which, due to t h e freezing procedure, h a v e b e e n c e m e n t e d together in a matrix of i c e , w h i c h sometimes even fills the

2 2 2 SVEN L A S S E N

interstitial spaces b e t w e e n t h e fish. Another purpose of thawing is to bring the temperature of the tuna up to such a point that t h e fish upon landing will b e in a condition suitable for b u t c h e r i n g a n d precooking.

K. U N L O A D I N G

U p o n arrival at t h e dockside of t h e cannery, t h e t h a w e d t u n a are unloaded. T h e unloading procedure varies with the e q u i p m e n t available at the dockside. I n some instances, a m e t a l b u c k e t is lowered into the well, w h e r e it is filled b y the fishermen. I t is then hoisted up and b y a release m e c h a n i s m m a d e to discharge its content into a flume, which carries the tuna into the cannery. I n other instances, w h e r e fluming is impractical, w h e e l e d buckets are lowered into the wells, w h e r e they are filled b y the fishermen and hoisted over t h e side onto the dock, w h e r e they are rolled over the weighing scale into the cannery. I n some in

stances, t h e hoisting is done b y t h e clipper's own hoisting equipment;

in others, an electrically operated hoist located on the dock does all the hoisting, guided b y an operator stationed at the h a t c h opening. I n any event, the first step in landing of the tuna is, naturally, to weigh it, after which it is carried b y conveyor to t h e b u t c h e r i n g tables.

L . Q U A L I T Y E V A L U A T I O N O F R A W T U N A

T h e raw t h a w e d tuna, w h e n unloaded from the tuna clipper, reflects in its state of freshness the care it has b e e n given during the several weeks it usually has b e e n in transit from the fishing grounds. T h e most c o m m o n and practical m e t h o d for the determination of t h e state of freshness of the tuna, is t h e organoleptic test. T h i s is a test w h i c h relies for its execution exclusively upon t h e use of man's sensory faculties such as sense of sight, sense of smell, sense of touch, etc. S u c h a test fulfills one of the primary requirements at this point, namely, that t h e test b e practically instantaneous and fairly reliable. I n a subjective test such as this, absolute reliability is, of course, impossible. T h e organoleptic m e t h o d of evaluation has, here as in other b r a n c h e s of the food industry, stood the test of time and is therefore, generally a c c e p t e d b y t h e three parties involved here, namely, t h e tuna b o a t owner, the state cannery inspector, and the tuna canner. Several c h e m i c a l tests h a v e b e e n de

veloped for the purpose of putting t h e quality evaluation of raw tuna an a purely objective basis. T h e s e c h e m i c a l methods are generally b a s e d upon the isolation and c h e m i c a l determination o f one or several of the decomposition products w h i c h result from the deterioration and spoilage of fish, and w h i c h are not present in appreciable amounts in fresh fish.

O n e of the main requirements of such tests is that their use should enable the observer to detect spoilage long before the fish is in such a condition

4. T U N A CANNING AND P R E S E R V A T I O N O F R A W M A T E R I A L 2 2 3

that spoilage is obvious b y the organoleptic test. O f these c h e m i c a l tests, the most important seem to b e ( 1 ) volatile reducing substances ( V R S ) ,

( 2 ) total volatile bases, ( 3 ) t h e trimethylamine test, ( 4 ) total volatile acids.

W h i l e all of these c h e m i c a l methods are useful in the determination of incipient spoilage, t h e y h a v e found only a limited use for quality evaluation in r a w tuna, mainly d u e to t h e time element involved in their completion. I n cases of disagreement on quality b e t w e e n t h e parties involved, the c h e m i c a l tests may, however, serve a useful purpose as corroborative evidence. T h e organoleptic m e t h o d for quality evaluation in raw tuna remains, therefore, t h e primary method, and, in the hands of properly trained personnel, c a n give results of high a g r e e m e n t b e t w e e n individual observers.

Several attempts have b e e n m a d e to grade t h e r a w tuna into several classes, instead of b e i n g satisfied with only a rejection or a c c e p t a n c e pattern. N o n e of t h e s e attempts, however, has b e e n fully satisfactory.

An a t t e m p t e d organoleptic grade classification of raw tuna is given in T a b l e I.

I n this classification effort, four different grades have b e e n recognized.

I n these grades, six different physical characteristics, such as a p p e a r a n c e of gills, of eyes and skin, smell, and d e g r e e of physical d a m a g e to the tuna, h a v e b e e n used. All of these characteristics c a n b e recognized almost instantaneously. A quality classification is, therefore, a m a t t e r of seconds only. I n dividing up t h e total quality r a n g e into four different grades, t h e system used in other b r a n c h e s of t h e food industry has b e e n followed. I t is, o f course, possible to assign a numerical value to e a c h characteristic in e a c h quality class, and thus initiate a numerical scoring system w h i c h m a y have some practical application.

I n spite of the advantages that t h e use o f such a system m a y have, the score obtained does not define quality very concisely. I t will b e noticed that t h e grade classification does not contain any reference to t h e type of degradation of quality w h i c h is associated with adverse colors in the fish tissue u p o n cooking, and w h i c h sometimes is called b r o w n or green fish. Neither does the classification take into consideration any condition producing t h e so-called h o n e y c o m b e d fish. Another characteristic of t h a w e d raw t u n a that has proven difficult to incorporate into a classifi

cation is the adverse effect of salt penetration. Excessive salt penetration into the tuna m u s c l e makes t h e t u n a unsuitable for certain types of pack.

F i n a l l y there is the important question of size of tuna, w h i c h has a strong influence upon yield, texture, taste, etc., o f the c a n n e d product and w h i c h it has not b e e n possible to include in T a b l e I nor in any quality grading chart k n o w n to t h e writer. I t is, therefore, obvious that t h e p r o b l e m of

TABLE I GRADE CLASSIFICATION FOR RAW TUNA Characteristics Class I Prime Class II Commercial Class III Marginal Class IV Rejectable Gills Bright bloody red Pale red to brown red Dark brown to yellow brown Yellow-white, slimy Eyes Clear, bright, and protruding Sunken, cloudy-white or reddish Sunken, dull-white, smashed, red Missing Skin Normal luster, color clear and bright Color dull—no apparent slime Normal color and luster gone—some muscle structure visible

Gross discoloration, skin in abnormal state of decomposition Odor Fresh: typical of freshly caught fish Flat to slightly fishy odor Slightly stale or rancid odor but not sour or putrid

Sour, putrid (stinkers), or definite off or foreign odor REIECTED Physical damage No mutilation or deformity Slight deformities or mutilation—no splitting

Some splitting of fish— slightly broken or smashed

Badly split, smashed, or mutilated, and/or 20% of flesh exposed REJECTED Degree of firmness of muscle and belly

Firm and elastic Firm, no elasticity Soft Very soft and mushy 224 SVEN LASSEN

4 . T U N A CANNING AND P R E S E R V A T I O N O F R A W M A T E R I A L 2 2 5

devising a quality grading chart w h i c h takes into a c c o u n t all, or even most, of t h e m a n y factors that constitute quality is a very difficult task.

T h e pigments responsible for the d e v e l o p m e n t of off-colors in tuna upon cooking h a v e b e e n the subject of m u c h speculation in the past. R e c e n t work on this p r o b l e m seems to h a v e established that t h e p i g m e n t responsible for t h e characteristic pink color of c a n n e d tuna m e a t is a h e m o c h r o m e , and that this pink h e m o c h r o m e p i g m e n t upon oxidation changes into t h e less desirable tan h e m o c h r o m e . T h i s would indicate that reducing conditions, if maintained during canning operations, should produce a m o r e attractive c a n n e d product of good color quality ( B r o w n and T a p p e l , 1 9 5 7 ) .

V. The Butchering

T h e b u t c h e r i n g t a b l e is a long, w i d e t a b l e , in the m i d d l e of w h i c h runs a slow-moving, wide b e l t conveyor, level with t h e t a b l e top, which carries the tuna d o w n the length of t h e table. T h e b u t c h e r i n g crew, standing b y the tables, slit t h e b e l l y of the tuna open with one stroke of their b u t c h e r i n g knives, while with the left h a n d they pull out the viscera. T h e n , with another stroke of the knife, t h e y m a k e an incision b e l o w the gills o f t h e tuna, t h e r e b y severing the visceral connection with the head, a n d with a third stroke of t h e knife t h e y sever the visceral connection with the vent. T h e viscera, w h i c h amount to from 3 to 8 % of the total w e i g h t of t h e tuna, is used for fish-meal manufacture. D u e to their high content of vitamins A and D , t h e tuna livers often are sepa

rated from t h e rest of t h e viscera for vitamin extraction. T h e S t a t e B o a r d of H e a l t h in California maintains a c a n n e r y inspection service, and inspectors or other representatives of this service are always present to see to it that no tuna passes t h e b u t c h e r i n g t a b l e w h i c h will not fully c o m p l y with their standards of suitability for h u m a n food. After the visceral cavity has b e e n rinsed with water, t h e tuna are transferred to wire baskets and p l a c e d in w h e e l e d racks holding about 7 0 0 l b . of fish, after w h i c h they are rolled into the cookers.

VI. Precooking and Cooling

T h e cookers used for precooking of tuna are large, rectangular-shaped steel c h a m b e r s provided with live steam inlets, outlets for condensate, and vents a n d relief valves. T h e relief valve is set so that the temperature in the cooker never exceeds 2 1 6 ° F . T h e c a p a c i t y of e a c h individual cooker m a y vary from 2 to 5 tons of b u t c h e r e d tuna, corresponding to 6 to 16 racks. After t h e cooker has b e e n filled, the door is closed and bolted, and steam is let into t h e cooker. D u r i n g cooking, the tuna suffers a consider

a b l e loss in weight. R a w tuna, in t h e condition it is received at the

2 2 6 SVEN L A S S E N

cannery, contains 6 8 - 7 6 % water. D u r i n g precooking, and coincidental with the heat coagulation of the fish protein, the w a t e r content drops to lower values ranging from 6 5 to 7 1 % . T h e subsequent sterilization cook of the c a n n e d tuna in t h e retort further lowers the w a t e r content of the tuna muscle to values ranging from 6 0 to 6 7 % .

As the cooking proceeds, water, and water-soluble proteinaceous material such as gelatin, nitrogen-containing extractives, and other sub

stances are l e a c h e d out of the fish and a c c u m u l a t e in the condensed steam w h i c h flows from the cooker continuously during the cooking operation. T h i s condensate also contains a certain amount of oil. T h e steam which, during t h e cooking, escapes through the steam vents contains certain volatile substances that are characteristic of raw fish odor ( a m i n e s ) . U n d e r the influence of heat, the protein in the tuna muscle will coagulate and shrink a w a y from the b o n y structure, thereby, making easier the subsequent cleaning and separation of the dorsal and ventral loins w h i c h are used for canning. T h e precooking of tuna is, therefore, a very important step in the over-all canning operation, as this step, perhaps m o r e than any other, influences not only yield b u t quality. I t is unfortunate that no studies on the cooking o f tuna have b e e n published, and as a result the precooking of tuna is still done on an empirical basis. I t is known, however, that in order to obtain a good cook, the temperature of the tuna, as measured along t h e upper part of the spinal column, in the thickest part of the fish, must b e brought up to approximately 1 4 0 - 1 5 0 ° F . F u r t h e r cooking b e y o n d this point is not only unnecessary b u t actually reduces b o t h yield and flavor of the tuna meat.

This reduction in yield and flavor is a c c o m p a n i e d b y a corresponding drop in w a t e r content of the tuna m u s c l e protein. F i g u r e 5 shows the relationship b e t w e e n t h e moisture content of tuna m u s c l e protein of precooked yellowfin tuna and the temperature attained in the c e n t e r of the tuna at the end of t h e precook period. I n a s m u c h as the temperature attained in the center of the tuna is directly related to the time of pre

cook, the moisture content-cooking time relationship m a y b e expressed b y a graph of similar slope.

T o obtain a good cook, it is also important that t h e tuna b e graded for uniform size, within very narrow limits. T h i s sometimes proves difficult w h e n the size distribution in a load of tuna is wide. Another important point to observe in connection with precooking of tuna is that all the tuna must have the same temperature w h e n entering the cooker. T u n a w h i c h has not b e e n fully thawed will n e e d m u c h m o r e h e a t b e f o r e a temperature rise takes p l a c e in t h e tuna than will a fully t h a w e d fish. T h e preferred size of tuna lies b e t w e e n 10 and 2 0 l b . Often, however, skipjack are received w h i c h w e i g h considerably less; at other times tuna weighing

4. TUNA CANNING AND PRESERVATION OF RAW MATERIAL 227

RELATION OF WATER CONTENT OF MUSCLE TO DEGREE OF COOK Temperature in °jF.in center ,of fish, at end of cpojk FIG. 5. Data from cooking of yellowfin tuna.

2 2 8 SVEN L A S S E N

from 5 0 to 1 0 0 l b . are received. S u c h large tuna do not give as fine a canned product as do the small tuna, and are, therefore, not used for

"fancy" grade pack.

T h e S t a t e of California F i s h and G a m e C o d e specifies that "No yellowfin tuna or bluefin tuna weighing less than 7^4 pounds m a y b e sold, purchased, or processed." F o r albacore, the c o d e states that "No albacore weighing less than 7 pounds m a y b e sold, purchased, or processed." F o r skipjack, the m i n i m u m weight is 4 l b . T h e c o d e permits these tuna to b e taken at all times of t h e year.

T h e cooking time for tuna varies with size. T a b l e I I gives a general idea of the cooking time used in some tuna canneries.

TABLE I I

T H E RELATIONSHIP BETWEEN AVERAGE COOKING T I M E AND SIZE OF TUNA

Size (lb.) Cooking time (hr.) Size (lb.) Cooking time (hr.)

4 WA 35

8 50

12 2 70 554

20 90 ey2

25 3y2

T o the cooking time shown in T a b l e I I must b e added the so-called

"coming-up time," w h i c h is the time it takes to bring the temperature up to 2 1 6 ° F . in the cooker. T h i s usually requires one-half hour to one hour, depending upon the size of the cooker, the temperature of t h e tuna w h e n entering the cooker, and the average size ot t h e fish. W h e n the precooking has b e e n completed, the steam is turned off, the cooker door opened, and the racks of steam-cooked tuna are rolled out and allowed to cool. T h e cooling often takes 1 2 - 1 8 hr., and is usually carried out in cooling rooms provided with good air circulation and screened for protection against insect infestation. D u r i n g t h e cooling period, the tuna undergo some very important changes. T h e weight of t h e cooked tuna is further r e d u c e d through evaporation from the hot fish. A general drying up of t h e surface area of the fish often takes place. T h e skin on the tuna, w h i c h during cooking has loosened from t h e muscle tissue and w h i c h at that point m a y b e peeled off, will, as a result of the drying during cooling, dehydrate and b e c o m e leathery and reattach itself to the cooked tuna muscle. S o m e of t h e oil contained in the tuna, w h i c h during cooking has a c c u m u l a t e d on t h e surface of the c o o k e d tuna, m a y b e c o m e oxidized as a result of the temperatures prevailing during the cooling, and the air circulation w h i c h characterizes a cooling room.

Finally, there is the problem of preventing microbial life from develop-

1/2

3 /

m

4 / 2

4 . T U N A CANNING AND P R E S E R V A T I O N O F R A W M A T E R I A L 2 2 9

ing on the surface of the tuna while it is cooling prior to b e i n g canned.

B y reducing the t i m e b e t w e e n cooking and canning to a minimum, the influence of microbial life on the surface of t h e tuna m a y b e r e d u c e d to during cooling is m u c h m o r e difficult to o v e r c o m e a n d has, as a m a t t e r inconsequential dimensions. T h e effect of dehydration and oxidation of fat, only b e e n overcome in part b y b e t t e r design of cooling rooms.

VII. Cleaning, Cutting, and Canning

T h e racks of cooled tuna are n o w rolled into the cleaning room, w h e r e a c r e w of cleaners (usually w o m e n ) , standing on b o t h sides of the cleaning table, start the task of separating skin, bones, fins, b l o o d meat, etc., from the light loin meat. T h e cleaning tables are long tables, usually covered with stainless steel, in t h e middle of w h i c h an elevated con

veyor belt, also of stainless steel, is provided to receive the loin m e a t and carry it to the cutting m a c h i n e on its w a y to the canning equipment.

U n d e r the cleaning t a b l e runs a steel conveyor b e l t which, through holes a n d chutes in t h e cleaning table, receives the offal from the tuna clean

ing, a n d transports it to a cart in w h i c h it is transported to the fish m e a l plant.

T h e previous cooking and cooling of the tuna have firmed the m u s c l e tissue to such a n extent that t h e fish c a n b e handled b y the cleaners without crumbling. T h e dorsal, ventral, a n d pectoral fins are first re

moved, after w h i c h the skin is scraped off the flesh ( o f the t u n a ) with a knife, without cutting too deeply into the m u s c l e meat. N e x t the tuna is cleaved b y h a n d into four longitudinal parts, e a c h containing one of t h e dorsal or ventral loin muscles w h i c h surround the spinal column of the fish from h e a d to tail and w h i c h form the m a i n substance of t h e tuna.

As the tuna is b r o k e n into these four sections, the m e a t falls readily a w a y from t h e b o n y structure, thus aiding in a c o m p l e t e separation of fish m u s c l e from t h e bones. T h e dark vascular b l o o d meat, w h i c h separates the dorsal and ventral loins and is in part e m b e d d e d in t h e m , is scraped off, and the c l e a n e d loins are p l a c e d on t h e conveyor b e l t w h i c h carries t h e m to t h e canning equipment. T h e procedure w h i c h is followed from h e r e on depends u p o n the style of p a c k w h i c h is desired. T h e T u n a Standards that h a v e recently b e e n set, w h i c h will b e discussed in m o r e detail later, recognize four styles of pack. T h e s e are ( 1 ) solid pack, ( 2 ) chunk pack, ( 3 ) flake pack, a n d ( 4 ) grated pack. T h e solid p a c k m a y b e p a c k e d b y h a n d or b y m a c h i n e . I n c a s e a h a n d p a c k is used, the tuna loin meat, u p o n leaving t h e cleaning tables, is passed through a guillotine

like cutting m a c h i n e w h i c h cuts t h e loins into proper lengths to fit the depth of t h e can. T h e individual loin pieces which, generally speaking, h a v e the shape of a sector, are p l a c e d neatly, side b y side, in the c a n b y

2 3 0 SVEN L A S S E N

the cannery worker until it is filled completely. After this, the c a n is placed b a c k on the moving conveyor line w h e r e the required amounts of salt, oil, or other flavoring ingredients are added automatically. F r o m there the cans m o v e either into an exhaust b o x before they finally enter the closing m a c h i n e , or, if an exhaust b o x is dispensed with, through a closing m a c h i n e provided with a steam-jet v a c u u m mechanism. T h e m o r e expensive hand packing is fast b e i n g replaced b y the m o r e practical m a c h i n e pack. T h e introduction of the modern closing m a c h i n e in w h i c h a v a c u u m is pulled on the filled can immediately before closing has largely eliminated the n e e d for exhaust boxes.

I f m a c h i n e packing is used for solid packs, the loin meat, on leaving the cleaning tables, is formed into a cylindrically shaped continuous ex

trusion, b y passing through a m a c h i n e called t h e pack-shaper. At the point w h e r e the e m p t y c a n passes the discharge end of the pack-shaper, the cylindrically shaped tuna loins are pushed into the can and cut b y a reciprocating knife, t h e r e b y filling t h e c a n with a solid plug of tuna meat. T h e c a n is subsequently passed through a tapping m a c h i n e which, b y means of a revolving, reciprocating plunger, presses the tuna m e a t further down in the can, t h e r e b y leaving room for the subsequent addi

tion of salt, oil, or other flavoring ingredients. F r o m there the can is sent to the v a c u u m closing m a c h i n e .

F o r chunk pack, the tuna loin m e a t is machine-cut into suitable pieces b y a cutting device similar to t h e o n e just m e n t i o n e d and passed through a so-called pack-former, an ingenious m a c h i n e w h i c h fills the cans loosely, and subsequently b y means of a tapping m a c h i n e presses the content of the loosely filled cans down to proper volume before the cans return to the line w h e r e salt, oil, or other ingredients are added, then on to the conventional v a c u u m closing m a c h i n e ( s e e further Anonymous, 1 9 3 9 ) . F l a k e p a c k is manufactured in a m a n n e r m u c h like chunk pack. T h e size of the individual pieces of tuna m e a t is m u c h smaller than chunk pack. T h e relative content of large and smaller pieces is regulated b y t h e standards covering this style of pack. T h e individual p i e c e of flake must, however, b e of such a size that "the muscular structure of the flesh is retained." T h e standards covering the manufacture of canned tuna will b e dealt with in m o r e detail later in this chapter.

T h e grated p a c k is produced b y passing t h e tuna m e a t from the cleaning tables through a grating m a c h i n e , in w h i c h the tuna m e a t is c h o p p e d up and passed through a screen to give a product of uniform size. I t is p a c k e d into the cans b y passing it through the pack-former, w h i c h is equally well suited for filling the cans with chunk, flake, or grated tuna. L e a v i n g the pack-former, the cans containing the grated tuna are passed through the tapping m a c h i n e , then b a c k to t h e packing

4. T U N A CANNING AND P R E S E R V A T I O N O F R A W M A T E R I A L 2 3 1

line to have salt, oil, and other optional flavoring ingredients added, after w h i c h they are closed in the steam-jet closing m a c h i n e .

After leaving the closing m a c h i n e , the tuna cans are usually passed through a m a c h i n e or device in w h i c h the cans are c l e a n e d of any oil or other organic matter w h i c h has stuck to t h e surface of the cans, before they are d u m p e d into cylindrical, perforated metal baskets in w h i c h they are transported to t h e retorts.

T h e canning operations and the e q u i p m e n t described here are illus

trative of methods and e q u i p m e n t used in t h e large tuna-canning centers located on the Pacific Coast of t h e U n i t e d States. I t is b e l i e v e d that the methods and the canning e q u i p m e n t used in other countries for similar purposes do not vary essentially in principle from those used in the United States. I n countries w h e r e labor costs are lower and skilled oper

ators harder to get, there will naturally b e less incentive to install the expensive and highly complicated packing machines, w h i c h in this coun

try have b e e n found so useful for high quality mass production; in that instance, hand-packing or semiautomatic packing is used ( s e e also Jarvis, 1944, 1 9 5 2 ) .

F o r a discussion of standards of identity, fill of container require- and other optional flavoring ingredients used in tuna canning operations, ments for c a n n e d tuna, and of quality specifications for salt, salad oil, the reader is referred to Section I X of this chapter.

VIII. Retorting

T h e retorting or autoclaving w h i c h follows the filling and closing of the tuna c a n consists of heating t h e c a n and its contents to such a tem

perature that all microbial life inside t h e c a n is destroyed. T h i s is t h e most critical step in t h e whole canning operation and has, therefore, b e e n the subject of considerable study. T h e minimum time required to destroy the spores of the most heat-resistant organisms at various temperatures must naturally b e k n o w n for any size and type of p a c k b e f o r e recom

mendations on retorting temperature and time can b e made. T h e funda

mental work b y B i g e l o w et al. ( 1 9 2 0 ) on h e a t penetration in processing canned food, and the establishment b y B i g e l o w ( 1 9 2 1 ) of the logarith

m i c nature of t h e thermal death-time curve for microorganisms did m u c h to advance safe canning practice. I n the study on the heat resistance of sixteen different botulinum strains, W e i s s e ( 1 9 2 1 ) found that under best conditions of survival, t h e most heat-resistant spores of Clostridium botu

linum w e r e destroyed in 5 hr. at 1 0 0 ° C , within 4 0 min. at 1 0 5 ° C , and within 6 min. at 1 2 0 ° C . E s t y and M e y e r ( 1 9 2 2 ) also m a d e extensive studies on the h e a t resistance of Clostridium botulinum. T h i s last work h a d a profound influence upon the formulation of t h e cannery code in

2 3 2 SVEN L A S S E N

California and elsewhere. A very comprehensive study of the bacteri

ology of the thermal processes for canned marine products has b e e n reported b y L a n g ( 1 9 3 5 ) .

O n the basis of carefully conducted studies on heat penetration and distribution in packs of a given style and fill, and the establishment of the thermal death time for spores of a heat-resistant organism (usually Clostridium botulinum) in a pack, it is possible to calculate the time and temperature at w h i c h a given c a n size containing a given style of p a c k must b e heated to obtain total destruction of microbial life inside the can. I t is on the basis of such measurements that t h e California Depart

ment of P u b l i c Health, B u r e a u of F o o d and D r u g Inspection, C a n n e r y Inspection Section issues instructions regarding the temperature and the time at w h i c h it must b e maintained during retorting (Natl. Canners' Assoc., 1 9 3 1 ) . F o r further details on process calculations of and general bacteriological and c h e m i c a l examination of c a n n e d food, the reader is referred to C a m e r o n and E s t y ( 1 9 2 6 ) and T o w n s e n d et al. ( 1 9 5 4 ) .

T h e retorts used in the tuna canning industry are, with a few excep

tions, batch-type retorts, consisting of long, horizontal, cylindrical pres

sure vessels, m a d e of j4 hi-? or thicker steel plate, with ends dished for safety. At one end is a hinged door of the same diameter as the shell.

T o secure a safe and airtight closure during retorting, the door is usually secured b y a large n u m b e r of eye-bolts, attached to the shell, which m a y b e swung into the recesses in the perimeter of t h e door, and secured b y nuts. I n some retorts, the so-called spider closure m e c h a n i s m is used for securing the retort door.

T h e retort is provided with a track w h i c h allows the cylindrical baskets filled with cans from the canning machines to b e rolled into the retort. I n a 4-ft.-diameter retort, the cylindrical baskets on wheels will have a 42-in. diameter so that at least a 3-in. c l e a r a n c e is left b e t w e e n the perforated m e t a l basket and t h e wall of the retort. W i t h a 32-in.

length of basket, a 24-ft.-long retort will b e a b l e to hold eight baskets of cans and still have ample room to spare for the important steam and water circulation. T h e retort has steam, water, and compressed air con

nections, and is provided with air vents, bleeders, a w a t e r and steam distribution system, relief valves, pressure gauges, temperature measur

ing and recording instruments, etc.

I n order to give the public m a x i m u m protection against t h e danger of inadequate retorting, the California State D e p a r t m e n t of Public Health has, as already mentioned, imposed upon the canners of California very strict specifications, with regard to the time and temperature at w h i c h c a n n e d tuna must b e held in the retort. I t also has issued specifications with regard to the design of the retorts to b e used. T h e s e r e c o m m e n d e d

4 . t u n a c a n n i n g a n d p r e s e r v a t i o n o f r a w m a t e r i a l 2 3 3

specifications on retort design pertain mainly to such m e c h a n i c a l features as t h e methods of introduction of steam a n d w a t e r into the retort, t h e n u m b e r o f vents, bleeders, thermometers, etc., all of w h i c h have for their purpose to secure proper and uniform heating, cooling, a n d venting of the retorts. Details of these specifications m a y b e found under the head

ing "Retort E q u i p m e n t and Operation," Sections 1 2 7 2 5 - 1 2 7 8 5 of Article 8, entitled " C a n n e r y Inspection Regulations," S u b c h a p t e r 2, C h a p t e r 5, T i t l e 17 ( P u b l i c H e a l t h of California Administrative C o d e ) . T h e follow

ing is a general description of the p r o c e d u r e followed during retorting operations in a tuna cannery.

After t h e retort has b e e n loaded, the retort door is closed and bolted, and a c h e c k is m a d e to see that all vents and bleeders are open, and drain and overflow closed. S t e a m is then admitted gradually through the steam control valve as well as through its by-pass valve, into t h e perfo

rated steam spreader w h i c h runs through t h e entire length along the inside b o t t o m o f t h e retort. W h e n t h e t e m p e r a t u r e has c o m e up close to t h e processing temperature, t h e by-pass valve is gradually closed and the temperature is b r o u g h t up to t h e final processing temperature b y the steam control valve alone. H a v i n g finally arrived at the processing tem

perature, t h e recording t h e r m o m e t e r and pressure g a u g e are c h e c k e d , and time, temperature, and pressure are entered in t h e production record. T h e t i m e it takes to b r i n g a retort up to t h e required processing temperature is t h e "lag" or "come-up time." D u r i n g the processing period, the tem

perature must b e k e p t constant, and frequent temperature checks must b e m a d e to m a k e certain that no fluctuation in temperature occurs. I t is important to see to it that all bleeders are k e p t open during the entire processing period. W h e n the processing t i m e has c o m e to an end, the steam is turned off, and all bleeders are closed, after w h i c h compressed air is introduced into t h e retort, increasing the pressure a b o u t 2 l b . p e r square i n c h a b o v e the processing pressure w h i c h existed in t h e retort during processing. W a t e r is n o w introduced into the retort through the perforated top inlet pipe w h i c h runs inside the retort along its entire length. A constant pressure is maintained in the retort during the intro

duction o f t h e cooling w a t e r b y manipulating the compressed air valve.

As t h e w a t e r level in t h e retort rises, the pressure in t h e retort should b e closely w a t c h e d and k e p t constant. W h e n t h e w a t e r level is n e a r the top o f t h e retort, t h e overflow or drain is o p e n e d slightly and then o p e n e d rapidly the m o m e n t t h e retort is filled with water, to avoid pressure fluctuations w h i c h m a y d a m a g e the cans in t h e retort. Cooling of the cans b y t h e w a t e r is n o w continued for some time, during w h i c h the pressure in t h e retort should b e k e p t up until t h e cans h a v e cooled down so that a lower pressure in t h e retort will not subject the c a n lids to