Materials 2021, 14, 4880. https://doi.org/10.3390/ma14174880 www.mdpi.com/journal/materials

Supplementary Information

M(II)Al 4 Type Layered Double Hydroxides—Preparation Using Mechanochemical Route, Structural Characterization and

Catalytic Application

Márton Szabados

1,2, Adél Anna Ádám

2, Zsolt Kása

2, Kornélia Baán

3, Róbert Mucsi

3, András Sápi

3, Zoltán Kónya

3,4, Ákos Kukovecz

3and Pál Sipos

2,5,*

1 Department of Organic Chemistry, University of Szeged, Dóm tér 8, H-6720 Szeged, Hungary;

szabados.marton@chem.u-szeged.hu

2 Material and Solution Structure Research Group, Institute of Chemistry, University of Szeged, Aradi Vértanúk tere 1, H-6720 Szeged, Hungary; adeladam@chem.u-szeged.hu (A.A.Á.);

kasa.zsolt@chem.u-szeged.hu (Z.K.)

3 Department of Applied and Environmental Chemistry, University of Szeged, Rerrich B. tér 1, H-6720 Szeged, Hungary; kornelia.baan@chem.u-szeged.hu (K.B.); muule93@gmail.com (R.M.);

sapia@chem.u-szeged.hu (A.S.); konya@chem.u-szeged.hu (Z.K.); kakos@chem.u-szeged.hu (Á.K.)

4 MTA-SZTE Reaction Kinetics and Surface Chemistry Research Group, Rerrich B tér 1, H-6720 Szeged, Hungary

5 Department of Inorganic and Analytical Chemistry, University of Szeged, Dóm tér 7, H-6720 Szeged, Hungary

* Correspondence: sipos@chem.u-szeged.hu

10 20 30 40 50 60

γ-Al(OH)3

1:3.5 CuCl2:Al(OH)3 Cu2(OH)3Cl

{7.5Å} - LDH

1:4 CuCl2:Al(OH)3

1:3 CuCl2:Al(OH)3

1:2 CuCl2:Al(OH)3 1:1 CuCl2:Al(OH)3

2 θ ( ° )

In tensity (a. u.)

Figure S1. XRD patterns of the CuAl4–Cl−–LDH solids obtained using different initial Cu:Al molar ratios (reaction conditions: 96 h stirring, 90 °C, 6 h pre-milling). The basal spacing is shown in curly brackets.

10 20 30 40 50 60 {7.7Å} - LDH Al3O4Br

1:3.5 CuBr2:Al(OH)3 Cu2(OH)3Br

1:4 CuBr2:Al(OH)3

1:1 CuBr2:Al(OH)3 1:2 CuBr2:Al(OH)3 1:3 CuBr2:Al(OH)3

Intensit y (a. u. )

2 θ ( ° )

Figure S2. XRD patterns of the CuAl4–Br−–LDH solids obtained using different initial Cu:Al molar ratios (reaction conditions: 96 h stirring, 90 °C, 6 h pre-milling). The basal spacing is shown in curly brackets.

4000 3500 3000 2500 2000 1500 1000

Absorbance (a.u.)

Wavenumber (cm

−1)

LDH-ClO4−LDH-NO3−

1630 3465

3575

930 700

1085

620

1350

1050 820

Figure S3. Infrared spectra of the CuAl4–LDHs, prepared with nitrate and perchlorate interlayer anions.

10 20 30 40 50 60 {8.5Å} - LTH

0.125:1:1 Ni(NO3)2:Cu(NO3)2:Al(OH)3

1:1:1 Ni(NO3)2:Cu(NO3)2:Al(OH)3 0.25:1:1 Ni(NO3)2:Cu(NO3)2:Al(OH)3 0.2:1:1 Ni(NO3)2:Cu(NO3)2:Al(OH)3 0.17:1:1 Ni(NO3)2:Cu(NO3)2:Al(OH)3

0.5:1:1 Ni(NO3)2:Cu(NO3)2:Al(OH)3 (3 nm)

(3 nm) (4 nm)

(6 nm) (8 nm) (12 nm)

Intensit y (a. u. )

2 θ ( ° )

Figure S4. X-ray diffraction traces of the NiCuAl4–NO3−–LTH solids, with various initial Ni:Cu mo- lar ratios (gradual decrease of the added Ni(II) amount, crystallite thicknesses shown in nm, reaction conditions: 96 h stirring period, 90 °C, 6 h pre-milling). The basal spacing is shown in curly brackets.

10 20 30 40 50 60

Intensit y (a. u. )

{8.6Å} - LTH

1:0:1 Ni(NO3)2:Cu(NO3)2:Al(OH)3 1:8:1 Ni(NO3)2:Cu(NO3)2:Al(OH)3

2 θ ( ° )

1:2:1 Ni(NO3)2:Cu(NO3)2:Al(OH)3 1:4:1 Ni(NO3)2:Cu(NO3)2:Al(OH)3 1:5:1 Ni(NO3)2:Cu(NO3)2:Al(OH)3 1:6:1 Ni(NO3)2:Cu(NO3)2:Al(OH)3 Cu2(OH)3NO3

(12 nm) (9 nm) (7 nm) (12 nm) (13 nm) (11 nm)

Figure S5. XRD patterns of the NiCuAl4–NO3−–LTH materials, with different initial Ni:Cu molar ratios (gradual increase of the added Cu(II) concentration,crystallite thicknesses denoted in nm, reaction conditions: 96 h stirring period, 90 °C, 6 h pre-milling). The basal spacing is shown in curly brackets.

5 10 15 20 25 30 35 40 {8.7Å} - LDH

In tensit y (a.u.)

1:1 Co(NO3)2:Al(OH)3 AlO(OH)

1:1 Zn(NO3)2:Al(OH)3 4:1 Co(NO3)2:Al(OH)3

2 θ ( ° )

4:1 Zn(NO3)2:Al(OH)3 α-Al(OH)3

Figure S6. XRD curves of the CoAl4– and ZnAl4–NO3–LDHs, with different initial Co/Zn:Al molar ratios (reaction conditions: 96 h stirring period, 90 °C, 6 h pre-milling). The basal spacing is shown in curly brackets.

10 20 30 40

32:1 Mg(NO3)2:Al(OH)3 8 h premilling

32:1 Mg(NO3)2:Al(OH)3 6 h premilling

16:1 Mg(NO3)2:Al(OH)3 6 h premilling {8.5Å} - LDH

Intensit y (a. u. )

2 θ ( ° )

γ-Al(OH)3

32:1 Mg(NO3)2:Al(OH)3 12 h premilling

Figure S7. XRD patterns of the MgAl4–NO3−–LDH solids, with various milling times and initial Mg:Al molar ratios (reaction conditions: 96 h stirring period, 90 °C). The basal spacing is shown in curly brackets.

Table S1. The molar ratios of the incorporated metal ions into the gibbsite structure; the initial and the measured values in the formed LTHs/LMHs are shown with perchlorate interlamellar anions.

Samples (LDH-ClO4) Initial Molar Ratios1 Measured Molar Ratios Mg Ni Co Cu Zn Mg Ni Co Cu Zn

NiCu-Al - 2 - 2 - - 4.32 - 1 -

- 1 - 2 - - 2.51 - 1 - - 1 - 4 - - 1.48 - 1 -

NiCo-Al - 2 2 - - - 20.70 1 - -

NiZn-Al - 2 - - 2 - 15.16 - - 1

CoCu-Al - - 2 2 - - - 1 7.27 -

CuZn-Al - - - 2 2 - - - 5.63 1

NiCoCu-Al - 2 2 2 - - 20.89 1 8.27 -

NiCoCuZn-Al - 2 2 2 2 - 15.20 1 4.81 1.15

MgNiCoZnCu-Al 2 2 2 2 2 0.04 16.83 1 4.83 1.22

1 The initial molar ratio of the aluminum was at 1 in every case.

300 400 500 600 700 800 900

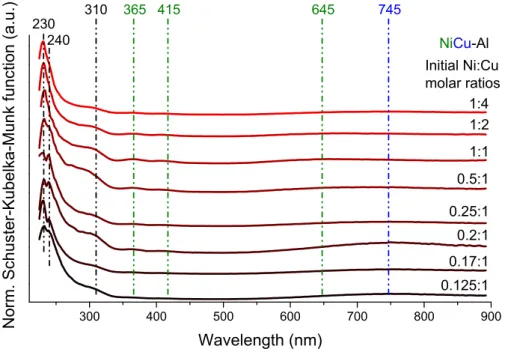

NiCu-Al Initial Ni:Cu molar ratios

0.17:1 0.2:1 0.25:1 0.5:1 1:1 1:2 1:4

0.125:1 240

Norm. Sch uster-Ku belka-Mun k function (a.u.)

Wavelength (nm)

645 745

415 365 230 310

Figure S8. UV-Vis diffuse reflection spectra of the NiCuAl–LTHs, prepared with various initial Ni:Cu molar ratios.

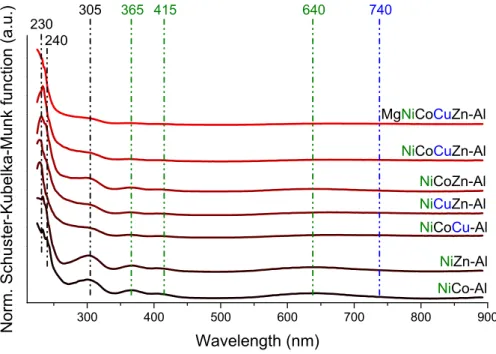

300 400 500 600 700 800 900

Norm. Schu ster-Kube lka-Munk function (a.u.)

NiCuZn-Al

Wavelength (nm)

NiCoCuZn-Al NiCoZn-Al NiCoCu-Al 240

640 415

230 305 365

MgNiCoCuZn-Al

NiZn-Al NiCo-Al 740

Figure S9. UV-Vis diffuse reflection spectra of nickel-containing LTHs/LMHs.

300 400 500 600 700 800 900

Norm. Schu ster-Kube lka-Munk function (a.u.)

255

MgCuZn-Al

Wavelength (nm)

MgCoCu-Al CoCuZn-Al CuZn-Al MgCu-Al

CoCu-Al Cu-Al 240

230 305 745

Figure S10. UV-Vis-DR spectra of copper-containing materials.

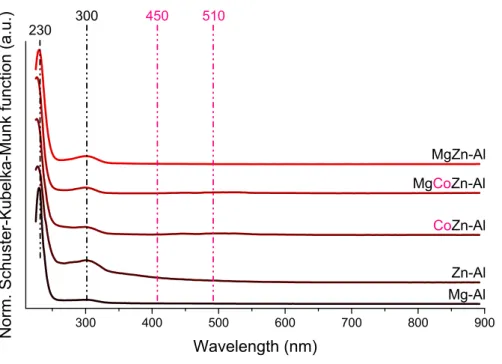

300 400 500 600 700 800 900

Norm. Schu ster-Kube lka-Munk function (a.u.)

Wavelength (nm)

Mg-Al Zn-Al CoZn-Al MgCoZn-Al MgZn-Al

230 300 450 510

Figure S11. UV-Vis diffuse reflection spectra of zinc-containing solids and the MgAl4–LDH.

300 400 500 600 700 800 900

Norm. Schuster-Kubelka-Munk function (a.u.)

*Unsuccesful LDH formation

Wavelength (nm)

Co-Al*

Co-Al MgCo-Al 255

240

230 305 450 510

625

Figure S12. UV-Vis-DR spectra of cobalt-containing samples; for the failed CoAl–LDH synthesis (marked with an asterisk), the reaction conditions were the following: 1:1 initial Co:Al molar ratio, 96 h stirring period, 90 °C, 6 h pre-milling.

Table S2. Optical properties of the prepared LDHs.

Samples Direct Band Gap (eV) Indirect Band Gap (eV)

6 h milled Al(OH)

35.30 5.11 NiAl

4–LDH 5.07 4.71 CuAl

4–LDH 4.79 3.93 CoAl

4–LDH 5.02 4.67 ZnAl

4–LDH 4.97 4.53 MgAl

4–LDH 5.17 4.89

Figure S13. SEM images of the ZnAl4– (A), MgAl4– (B) and CoAl4–LDH (C) prepared with nitrate interlamellar anions.

10 20 30 40 50 60 70 80

(511) (400)

(311) (440)

from NiCuAl8-LDH from ZnAl4-LDH

2 θ ( ° )

Inte nsity (a.u. )

from milled Al(OH)3 from MgAl4-LDH from CoAl4-LDH from NiAl4-LDH from CuAl4-LDH from NiCoAl8-LDH (220)

Figure S14. Powder X-ray diffraction patterns of the spent catalysts after long-term carbon monoxide oxidation at a 700 °C reaction temperature.

A B C

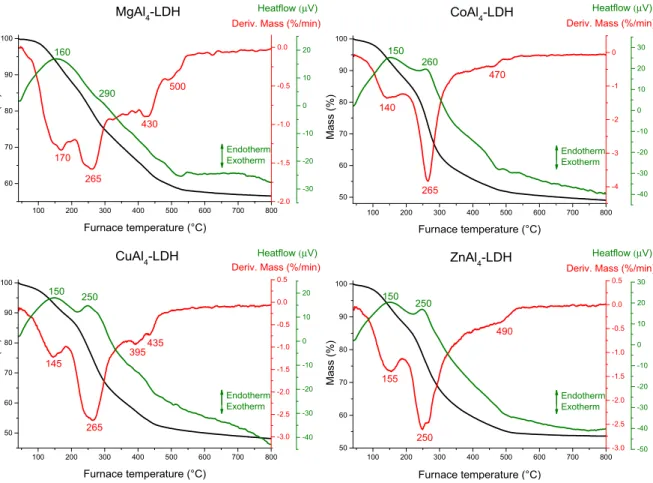

100 200 300 400 500 600 700 800 60

70 80 90 100

290

Mass (%)

Furnace temperature (°C)

Deriv. Mass (%/min) Heatflow (μV)

MgAl4-LDH

170 265

430 500 160

-2.0 -1.5 -1.0 -0.5 0.0

Endotherm Exotherm

-30 -20 -10 0 10 20

100 200 300 400 500 600 700 800

50 60 70 80 90 100

260 150

140

470

265

Furnace temperature (°C)

Heatflow (μV) Deriv. Mass (%/min)

CoAl4-LDH

Mass (%)

Endotherm Exotherm

-4 -3 -2 -1 0

-40 -30 -20 -10 0 10 20 30

100 200 300 400 500 600 700 800

50 60 70 80 90 100

Heatflow (μV) Deriv. Mass (%/min)

CuAl4-LDH

Furnace temperature (°C)

Mass (%)

Endotherm Exotherm

-3.0 -2.5 -2.0 -1.5 -1.0 -0.5 0.0 0.5

-40 -30 -20 -10 0 10 20

395 145

150 250

265

435

100 200 300 400 500 600 700 800

50 60 70 80 90 100

ZnAl4-LDH Heatflow (μV)

Deriv. Mass (%/min)

Mass (%)

Furnace temperature (°C)

Endotherm Exotherm 150 250

490

250 155

-3.0 -2.5 -2.0 -1.5 -1.0 -0.5 0.0 0.5

-50 -40 -30 -20 -10 0 10 20 30

Figure S15. Thermogravimetric, derivative thermogravimetric and differential thermal analysis curves of the magnesium-, cobalt-, copper- and zinc-containing LDHs prepared with nitrate interlamellar anions.

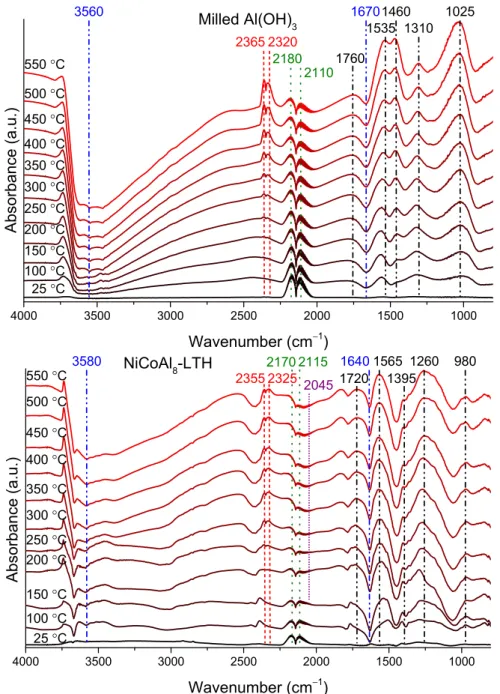

4000 3500 3000 2500 2000 1500 1000 2320

2365 21802110

1535 1310

500 °C 450 °C 400 °C 350 °C 300 °C 250 °C 200 °C 150 °C 100 °C 25 °C

Milled Al(OH)3

Absorbance (a.u.)

Wavenumber (cm−1) 550 °C

3560 1460 1025

1760 1670

4000 3500 3000 2500 2000 1500 1000

1565 1395

Absorbance (a.u.)

Wavenumber (cm−1) NiCoAl8-LTH

550 °C 500 °C 450 °C 400 °C 350 °C 300 °C 250 °C 200 °C 150 °C 100 °C 25 °C

2325 2045 2355

21702115

3580 1260 980

1720 1640

Figure S16. DRIFT spectra of the milled Al(OH)3 and NiCoAl8–LTH, heated up to 550 °C in the presence of a carbon monoxide–helium flow.