Supporting Information

Mechanochemical and wet chemical syntheses of CaIn-layered double hydroxide and its performance in a transesterification reaction compared to those of other Ca

2M(III) hydrocalumites (M: Al, Sc, V, Cr, Fe, Ga) and Mg(II)-, Ni(II)-, Co(II)- or Zn(II)-based hydrotalcites

Márton Szabados,

a,bAnna Adél Ádám

a,b, Péter Traj,

a,bSzabolcs Muráth,

c,dKornélia Baán

e, Péter Bélteky

e, Zoltán Kónya,

e,fÁkos Kukovecz,

ePál Sipos,

b,gand István Pálinkó

a,b*aDepartment of Organic Chemistry, University of Szeged, Dóm tér 8, Szeged, H-6720 Hungary

bMaterial and Solution Structure Research Group, Interdisciplinary Excellence Centre, Institute of Chemistry, University of Szeged, Aradi vértanúk tere 1, Szeged, H-6720 Hungary

cMTA-SZTE Biocolloids Research Group, Rerrich B. tér 1, Szeged, H-6720, Hungary

dInterdisciplinary Excellence Centre, Department of Physical Chemistry and Materials Science, University of Szeged, Rerrich B. tér 1, Szeged, H-6720, Hungary

eDepartment of Applied and Environmental Chemistry, University of Szeged, Rerrich B. tér 1, Szeged, H- 6720 Hungary

fMTA-SZTE Reaction Kinetics and Surface Chemistry Research Group, Rerrich B. tér 1, Szeged, H-6720 Hungary

gDepartment of Inorganic and Analytical Chemistry, University of Szeged, Dóm tér 7, Szeged, H-6720 Hungary

8 9 10 11 12 13 14

Norm. singal (a.u.)

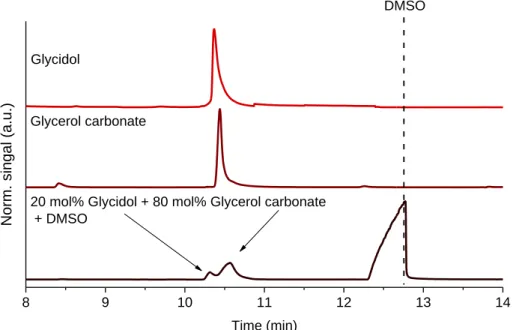

Time (min) Glycerol carbonate

Glycidol

20 mol% Glycidol + 80 mol% Glycerol carbonate + DMSO

DMSO

Fig. S1 The advantageous effect of DMSO on the separation of glycidol and glycerol carbonate.

Correponding author: István Pálinkó

E-mail address: palinko@chem.u-szeged.hu (I. Pálinkó)

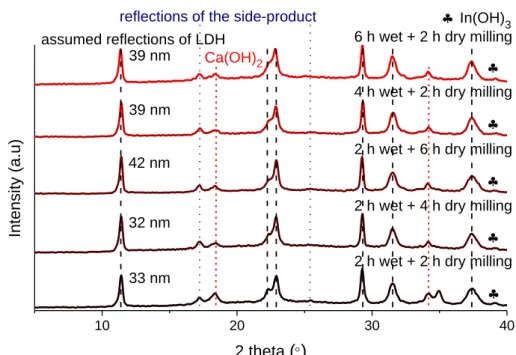

10 20 30 40 4 h wet + 2 h dry milling

2 h wet + 6 h dry milling

2 h wet + 4 h dry milling

2 h wet + 2 h dry milling 6 h wet + 2 h dry milling

39 nm 39 nm

32 nm 42 nm

33 nm

Intens ity (a.u)

2 theta (

)

assumed reflections of LDH

reflections of the side-product Ca(OH)2

In(OH)3

Fig. S2 X-ray powder diffraction patterns for the solids prepared with the purely mechanochemical technique at different wet and dry grinding times (400 l saturated NaCl solution).

10 20 30 40

800 l

600 l

500 l 400 l 900 l 42 nm

35 nm

38 nm 41 nm

33 nm

Ca(OH)2

Intens ity (a.u)

2 theta (

)

In(OH)3 LDH

side-product

Fig. S3 X-ray powder diffractogram patterns for the samples synthesized by the purely

mechanochemical technique at varied amounts of the saturated NaCl solutions (2 h dry and

2 h wet milling).

10 20 30 40

24 h stirring at 85C

12 h stirring at 85C

12 h stirring at 25C 32 nm

38 nm 39 nm

21 nm

side-product LDH

Intens ity (a.u)

2 theta (

)

Ca(OH)236 h stirring at 85C

In(OH)3

Fig. S4 X-ray powder diffraction patterns for the materials at varied stirring time and temperature prepared by the mechanochemically-aided route (2 h dry grinding, 5 ml 0.4 M NaCl solution).

10 20 30 40

25 nm 22 nm

Intens ity (a.u)

26 nm

19 nm

17 nm side-product

2 theta (

)

4 h

2 h 1 h 0.5 h 6 h LDH

Fig. S5 X-ray powder diffraction patterns for the samples at varying stirring time (room

temperature, 2:1 Ca:In initial molar ratio, 3 M base).

10 20 30 40 26 nm

Intens ity (a.u)

31 nm

22 nm

14 nm side-product

75C

50C

25C

5C

2 theta (

)

LDHFig. S6 XRD patterns for the materials prepared at various temperatures (2 h stirring, 2:1 Ca:In initial molar ratio, 3 M base).

4000 3500 3000 2500 2000 1500 1000

0 5

Absorbance (a.u.)

Wavenumber (cm-1) 1635

Fig. S7 Infrared spectrum of the CaCl

2×2H

2O starting reagent.

Fig. S8 TEM (the first), SEM (the second) and elemental map (the last four) images for the

CaIn-hydroxide-chloride side-product.

0.0 0.2 0.4 0.6 0.8 1.0 0

5 10 15 20 25 30

Quantity adsorbed gas (cm3/g STP)

Relative pressure (p/p0)

Adsorption Desorption CaAl-layered double hydroxide

1 10 100 1000

0.0000 0.0002 0.0004 0.0006

CaAl-layered double hydroxide

dV(r) cm3/nm/g

Pore diameter (nm)

0.0 0.2 0.4 0.6 0.8 1.0

0 50 100 150 200 250

Quantity adsorbed gas (cm3/g STP)

CaSc-layered double hydroxide Adsorption Desorption

Relative pressure (p/p0)

1 10 100

0.000 0.001 0.002

dV(r) cm3/nm/g

CaSc-layered double hydroxide

Pore diameter (nm)

0.0 0.2 0.4 0.6 0.8 1.0

0 5 10 15 20 25 30 35 40

CaV-layered double hydroxide

Quantity adsorbed gas (cm3/g STP)

Relative pressure (p/p0)

Adsorption Desorption

1 10 100 1000

0.0000 0.0004 0.0008

CaV-layered double hydroxide

dV(r) cm3/nm/g

Pore diameter (nm)

0.0 0.2 0.4 0.6 0.8 1.0

0 10 20 30 40 50 60 70 80

Relative pressure (p/p0) Quantity adsorbed gas (cm3/g STP)

CaCr-layered double hydroxide Adsorption Desorption

1 10 100 1000

0.0000 0.0004 0.0008 0.0012

dV(r) cm3/nm/g

Pore diameter (nm) CaCr-layered double hydroxide

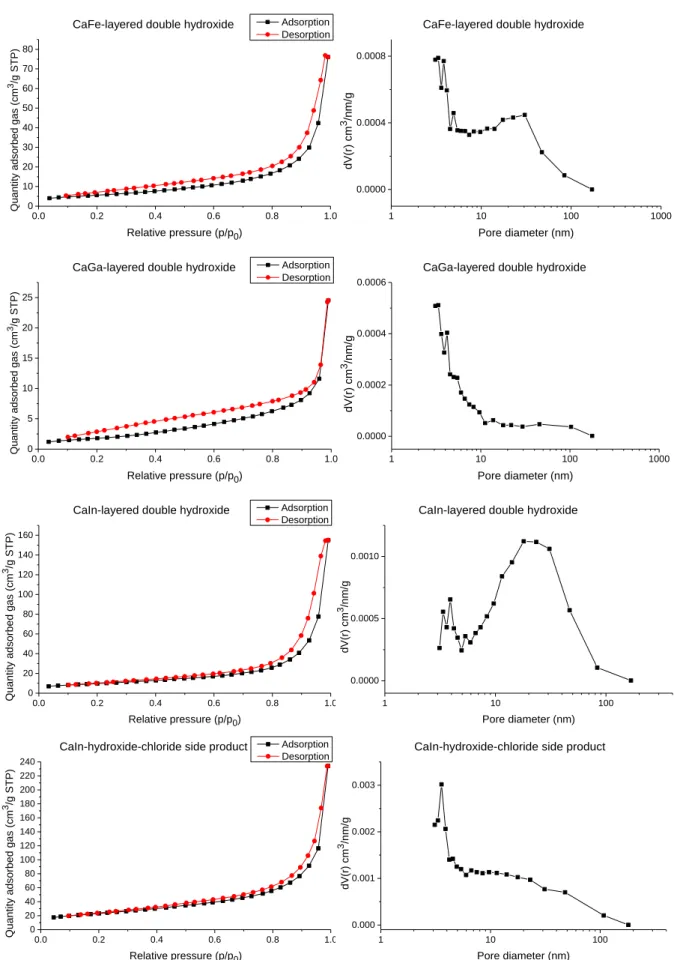

0.0 0.2 0.4 0.6 0.8 1.0 0

10 20 30 40 50 60 70 80

Adsorption Desorption CaFe-layered double hydroxide

Quantity adsorbed gas (cm3/g STP)

Relative pressure (p/p0)

1 10 100 1000

0.0000 0.0004 0.0008

dV(r) cm3/nm/g

CaFe-layered double hydroxide

Pore diameter (nm)

0.0 0.2 0.4 0.6 0.8 1.0

0 5 10 15 20 25

Quantity adsorbed gas (cm3/g STP)

CaGa-layered double hydroxide Adsorption Desorption

Relative pressure (p/p0)

1 10 100 1000

0.0000 0.0002 0.0004 0.0006

CaGa-layered double hydroxide

dV(r) cm3/nm/g

Pore diameter (nm)

0.0 0.2 0.4 0.6 0.8 1.0

0 20 40 60 80 100 120 140 160

Adsorption Desorption

Quantity adsorbed gas (cm3/g STP)

CaIn-layered double hydroxide

Relative pressure (p/p0)

1 10 100

0.0000 0.0005 0.0010

CaIn-layered double hydroxide

dV(r) cm3/nm/g

Pore diameter (nm)

0.0 0.2 0.4 0.6 0.8 1.0

0 20 40 60 80 100 120 140 160 180 200 220 240

Adsorption Desorption

Relative pressure (p/p0) Quantity adsorbed gas (cm3/g STP)

CaIn-hydroxide-chloride side product

1 10 100

0.000 0.001 0.002 0.003

CaIn-hydroxide-chloride side product

dV(r) cm3/nm/g

Pore diameter (nm)

Fig. S9 N

2adsorption-desorption isotherms (left) and the corresponding pore size distribution

plots (right) for the LDHs and the CaIn

-hydroxide-chloride side-product.

10 20 30 40 50 60 70

Intens ity (a.u)

2 theta (

)

Heat-treatedCaIn-layered double hydroxide

Heat-treated

CaIn-hydroxide-chloride side product

CaIn2

O

4 CaO

Fig. S10 X-ray powder diffraction patterns for the CaIn-LDH and the side-product after heat treatment at 900°C.

10 20 30 40 50 60 70

32 nm

after 1. use CaAl-LDH without DMSO after 2. use CaAl-LDH

after 1. use CaAl-LDH

initial CaAl-LDH after 3. use CaAl-LDH

Intens ity (a.u)

2 theta (

)

23 nm

10 20 30 40 50 60 70 17 nm

Intens ity (a.u)

2 theta (

)

after 2. use CaSc-LDH

after 1. use CaSc-LDH

initial CaSc-LDH after 3. use CaSc-LDH 15 nm

15 nm

16 nm

10 20 30 40 50 60 70

Intens ity (a.u)

2 theta (

)

after 2. use CaV-LDH

after 1. use CaV-LDH

initial CaV-LDH after 3. use CaV-LDH

6 nm

unknown reflections

10 20 30 40 50 60 70

Intens ity (a.u)

9 nm2 theta (

)

after 2. use CaCr-LDH

after 1. use CaCr-LDH

initial CaCr-LDH after 3. use CaCr-LDH

5 nm

10 20 30 40 50 60 70

Intens ity (a.u)

2 theta (

)

after 2. use CaFe-LDH

after 1. use CaFe-LDH

initial CaFe-LDH after 3. use CaFe-LDH

18 nm

10 20 30 40 50 60 70 26 nm

Intens ity (a.u)

2 theta (

)

after 2. use CaGa-LDH

after 1. use CaGa-LDH

initial CaGa-LDH after 3. use CaGa-LDH

10 20 30 40 50 60 70

20 nm

Intens ity (a.u)

2 theta (

)

after 2. use CaIn-LDH

after 1. use CaIn-LDH

initial CaIn-LDH after 3. use CaIn-LDH

20 nm 15 nm

10 20 30 40 50 60 70

Intens ity (a.u)

2 theta (

)

after 2. use Ca3In4-side-product

after 1. use Ca3In4-side-product

initial Ca3In4-side-product after 3. use Ca3In4-side-product

Fig. S11 X-ray powder diffraction curves of the initial, the used hydrocalumites and the

Ca

3In

4-side-product.

4000 3500 3000 2500 2000 1500 1000

after 1. use CaAl-LDH

Abs orba nc e (a.u.)

1490Wavenumber (cm

-1)

initial CaAl-LDH after 1. use CaAl-LDH without DMSO after 3. use CaAl-LDH2935 2870 1775

1620, interlayer water, 780

10401105

1410

4000 3500 3000 2500 2000 1500 1000

1040

Wavenumber (cm

-1)

Abs orba nc e (a.u.)

initial CaSc-LDH after 1. use CaSc-LDH after 3. use CaSc-LDH

1500 1100

2935 2870 1780

1620, interlayer water, 730

1400

4000 3500 3000 2500 2000 1500 1000

Wavenumber (cm

-1)

Abs orba nc e (a.u.)

initial CaV-LDH after 1. use CaV-LDH after 3. use CaV-LDH

1480

2920 2860 1785

1630, interlayer water, 790

10451090

1410

4000 3500 3000 2500 2000 1500 1000

Wavenumber (cm

-1)

Abs orba nc e (a.u.)

initial CaCr-LDH after 1. use CaCr-LDH after 3. use CaCr-LDH

1500

2930 2865

1635, interlayer water, 775

10501105

1395

4000 3500 3000 2500 2000 1500 1000

Abs orba nc e (a.u.)

Wavenumber (cm

-1)

initial CaFe-LDH after 1. use CaFe-LDH after 3. use CaFe-LDH1480

2930 2850

1615, interlayer water, 750

1775 104011001400

4000 3500 3000 2500 2000 1500 1000

Wavenumber (cm

-1)

Abs orba nc e (a.u.)

initial CaGa-LDH after 1. use CaGa-LDH after 3. use CaGa-LDH

1480

2925 2850

1615, interlayer water, 785

1775 105011051405

4000 3500 3000 2500 2000 1500 1000

1470

after 3. use Ca3In4-side-product

after 3. use CaIn-LDH

Abs orba nc e (a.u.)

Wavenumber (cm

-1)

after 1. use CaIn-LDHafter 1. use Ca3In4-side-product

2925 2860 1780 105010951410

Fig. S12 Infrared spectra of the initial, the used hydrocalumites and the Ca

3In

4-side-product.

300 400 500 600 700 800

0 50 100

605

Sc hu ster-Kub elk a-Mu nk f un ction (a.u.)

Wavelenght (nm)

395Fig. S13 UV–Vis diffuse reflection spectrum of the CaV-LDH.

100 200 300 400 500 600 700 800 moderate

weak

CaIn-LDH CaGa-LDH

CaCr-LDH CaFe-LDH

CaV-LDH CaSc-LDH CaAl-LDH

No rm. sig na l ( a.u.)

Temperature (C)

Ca3In4-side-product strong basic sites

Fig. S14 CO

2-TPD profiles of the hydrocalumites and the Ca

3In

4-side-product.

10 20 30 40 50 60 70 7 nm

Intens ity (a.u)

9 nm4 nm

2 theta (

)

initial MgAl-LDH after 1. use MgAl-LDH after 2. use MgAl-LDH after 3. use MgAl-LDH

10 20 30 40 50 60 70

Intens ity (a.u)

6 nm2 theta (

)

initial MgCr-LDH after 1. use MgCr-LDH after 2. use MgCr-LDH after 3. use MgCr-LDH

10 20 30 40 50 60 70

Intens ity (a.u)

8 nm

initial MgFe-LDH after 1. use MgFe-LDH after 2. use MgFe-LDH after 3. use MgFe-LDH

2 theta (

)

10 20 30 40 50 60 70

4 nm

5 nm

5 nm

Intens ity (a.u)

4 nm

initial NiAl-LDH after 1. use NiAl-LDH after 2. use NiAl-LDH after 3. use NiAl-LDH

2 theta (

)

10 20 30 40 50 60 70

after 3. use NiCr-LDH

after 2. use NiCr-LDH

after 1. use NiCr-LDH

initial NiCr-LDH

3 nm

Intens ity (a.u)

2 theta (

)

10 20 30 40 50 60 70

4 nm

Intens ity (a.u)

2 theta (

)

initial NiFe-LDH after 1. use NiFe-LDH after 2. use NiFe-LDH

10 20 30 40 50 60 70

2 theta (

)

Intens ity (a.u)

after 3. use CoAl-LDH after 2. use CoAl-LDH after 1. use CoAl-LDH initial CoAl-LDH 12 nm

10 20 30 40 50 60 70

2 theta (

)

Intens ity (a.u)

5 nm

initial CoCr-LDH after 1. use CoCr-LDH after 2. use CoCr-LDH after 3. use CoCr-LDH

10 20 30 40 50 60 70

Intens ity (a.u)

10 nm

2 theta (

)

initial CoFe-LDH after 1. use CoFe-LDH after 2. use CoFe-LDH

10 20 30 40

10 nm 7 nm

ZnFe-LDH

ZnCr-LDH

ZnAl-LDH

Intens ity (a.u)

2 theta (

)

5 nm