ContentslistsavailableatScienceDirect

Internet of Things

journalhomepage:www.elsevier.com/locate/iot

Research article

Reliability-as-a-Service for bearing risk assessment investigated with advanced mathematical models

Jan-M. Brandt

a,∗, Márton Benedek

b,c, Jeffrey S. Guerin

a, Jörg Fliege

da300 Wellington Street, Suite 104 (Bathurst Entrance), London, Ontario, N6B 2L5, Canada

bDept. of Differential Equations, Inst. of Mathematics, Budapest University of Technology and Economics, Egry József u. 1., Budapest, 1111, Hungary

cCentre for Economic and Regional Studies, Tóth Kálmán u. 4., Budapest, 1097, Hungary

dMathematical Sciences, University of Southampton, Southampton, SO17 1BJ, United Kingdom

a r t i c l e i n f o

Article history:

Received 2 September 2019 Revised 27 January 2020 Accepted 10 February 2020 Available online 18 February 2020 Keywords:

Classification

Support vector machines Industrial analytics Reliability Bearing tribology

a b s t r a c t

Asakeyplayerinbearingservicelife,the lubricantchemistryhasaprofoundeffecton bearingreliability.To increasethereliabilityofbearings,an IndustrialAnalytics solution isproposedforproactiveconditionmonitoringandthisisdeliveredviaaReliability-as-a- Serviceapplication.Theperformancepredictionsofbearingsrelyoncustomizedalgorithms withthemainfocusondigitalizinglubricantchemistry;theprinciplesbehindthesepro- cessesareoutlinedinthisstudy.Subsequently,independenttestingisperformedtocon- firmtheabilityofthepresentedIndustrialAnalyticssolutionforsuchpredictions.Byde- cipheringthechemical compoundsoflubricantsandcharacteristics ofthe interface,the IndustrialAnalyticssolutiondeliversaprecisebearingreliabilityassessmentaprioritopre- dictservicelifeoftheoperation.Bearingtestshaveshownthattheclassificationsystemof thisIndustrialAnalyticssolutionisabletopredict12outof13bearingfailures(92%).The describedapproachprovidesaproactivebearingriskclassificationthatallowstheoperator totakeimmediateactioninreducingthefailurepotentialduringsmoothoperation-pre- ventinganypotentialdamagefromoccurring.Forthispurpose,amathematicalmodelis introducedthatderivesasetofclassificationrulesforoillubricants,basedonlinearbinary classifiers(supportvectormachines)thatareappliedtothechemicalcompound’smixture data.

© 2020TheAuthor(s).PublishedbyElsevierB.V.

ThisisanopenaccessarticleundertheCCBYlicense.

(http://creativecommons.org/licenses/by/4.0/)

1. Introduction

Digitalizationofprocessesplay adominantroleinnearly all aspectsoflife. Thishasledtothedevelopmentofanew wayonhow humansandtechnologyinteract,mostfrequentlyreferredtoastheInternet-of-Things(IoT);inindustrialap- plicationsitisoftenreferred toasIndustrial IoT(IIoT)andispartofthe4th IndustrialRevolution(Industry4.0)[1].Thus,

List of abbrevations used in the paper: SVM , support vector machine; IIoT , Industrial IoT (Internet-of-Things); RaaS , Reliability-as-a-Service; WEC , white- etching crack; XFA , X-ray fluorescence analysis; IR , infrared techniques; SRR , slip-roll-ratio; k 4LF, dimensionless risk factor; SIF , surface-induced failure; SCC , stress corrosion cracking; CCI , chemical compound interaction; QP , quadratic program; ANN , artificial neural networks.

∗ Corresponding author.

E-mail address: jan.m.brandt@4linesfusion.com (J.-M. Brandt).

https://doi.org/10.1016/j.iot.2020.100178

2542-6605/© 2020 The Author(s). Published by Elsevier B.V. This is an open access article under the CC BY license.

( http://creativecommons.org/licenses/by/4.0/ )

thereisan ever-increasingpushtodigitalizeapplicationsandknowledge withthegoaltocreateavatars/digitaltwinsthat enhanceglobaleconomicgrowth,productivity,andcompetitivenessforfinancialbenefits.Inessence,thefuturebelongsto thosewhocancombineexistingknowledgewithdigitaltoolstostrategicallytransformdataintoaction.

AtthecoreofIIoTapplications,algorithmsarecreated,utilized,andinterconnectedinordertoincreasesystemefficiency throughpredictions andfurther providingactions;thesetypesofdigitalsolutionsare partoftherapidlygrowingmarket, referred to asIndustrialAnalytics;it isthe process ofcollecting, analyzing,andusingdatagenerated fromindustrialop- erationswiththesimultaneousgoalofincreasingcost savingsandenhancingreliability. Thisprocessishighlyvaluableto a wide range of asset-intensive applications in orderto better understand their industrial operationsandensuring their economic viability. As of recent [2], it is expectedthat the globalIndustrial Analytics market willgrow from USD 11.29 billion in2017toUSD 25.51billion by2022, ataCAGR of17.7%.IndustrialAnalytics canincludesoftware solutions,such asoperationalandrisk monitoringandanalyticsforvariousindustrialverticals.Thus, itcomesasnosurprisethat predic- tivemaintenance isanintegralpartofIndustrialAnalyticstoreduceoperationaldowntime,productioncosts,andincrease systemreliability[3];in 2018,thepredictive maintenancemarket wasvaluedatUSD3.3billion andisexpectedtoreach USD 23.50 billionby 2024,ata CAGRof39% between2018and2024, whereasmuchof thegrowthisanticipatedinIIoT applications[4].

Increasingbearing reliability is an essential part of enhancing the servicelife of moving machine elements. The per- formance ofbearings islargely governed by the tribologicalbehaviour within theapplication; tribologyis the scienceof friction,lubrication,andwear,andhasledtolarge costsavingssince itsintroductionduringthe1960’s[5].Consequently, themain parameters affectingthetribology ofmachineelements(i.e.,the tribosystem)isdefinedby theinteractions be- tween the mating surfaces(e.g.,material, roughness, etc.), the characteristics ofthe lubricatingmedium (e.g., type ofoil andadditives,viscosity,oxidation,etc.), theadjacentenvironment(e.g.,temperature, contamination,etc.), andtheapplied mechanicalfactors(e.g.,loadandmotion)[6].

Thetypeofbearingusedinanapplicationplaysamajorrole onthelongevityofmachineelements.Inparticular,roller bearingsare widelyused toallow theoperationofmachine elementsbeingusedinawide rangeofareassuch astrans- portation,windandmarineapplications.Duringthedesignphaseofmachineelements,theservicelifeofarollerbearingis estimatedbyassessingthemostrelevantstandard(DINISO281)thatdefinesthemethodsofcalculatingthebasicdynamic load ratingofrolling bearings within a givensize range. Further,DIN ISO 281provides guidance tothe design engineer oncalculatingthe basicratinglife -whichisthelife associatedwitha90%reliability consideringmanyofthepreviously mentionedsystemparameters[7].Oncetheestimatedbearinglifeisexhausted,thebearingsusuallyfailduetomaterialfa- tigue,referredtoasrolling-contactfatigue.Ofparticularinterestarethebearingfailuresthatoccurirregularlyandsuddenly whichare thenassociatedwithmassiveoperationalandmaintenancecosts duetorepairsnot beingable tobescheduled effectively.

Themostprominent,irregularandsuddenbearingfailureisthefailureduetowhite-etchingcracks(WECs).Thistypeof failureisassociatedwithavastfinancialburdenfortheoperatorasscheduled/calendar-basedmaintenanceprinciplesdonot apply [8–13].Thus, itisessentialto definepathwaysthat allowconditionmonitoringofthemostdetrimentalparameters that lead to WECs. Extensive research on WECs hasbeen conductedto date but thereis still a clear need forproactive conditionmonitoringaspartofpredictive maintenanceinitiativestodetectearlyandcriticalchangesintheoperation[8]. With such early-warningsystems,the operation andmaintenance manager wouldbe able take immediate action,before damageoccurs,toreturntheoperationbacktothespecificationasperdesign(i.e.,conductimmediateactionstoreturnthe operationbacktobearinglifeasperDINISO281).

Inthisstudy,a Software-as-a-Serviceapplicationispresentedtoprovidetheoperatorwithaclassificationalertsystem whenthereliabilityofrollerbearingapplicationdeviatesfromDINISO281lifeestimate.Bycombiningknowledgeinbearing tribology,lubricantchemistryandadvanceddataprocessing,variousmathematicalmodelshavebeensuccessfullyappliedto differentclassificationchallenges,suchasclusteringmethods,classifyingwiththeusageofcentralitymeasures,orsupport vectormachines(SVMs).Measurementsonperformanceandsystematicbehaviourofoillubricantstypicallyyieldcontinuous data(i.e.,datapointsintheEuclideanspaceRn)andtherefore,werelyonSVMs,asopposedtoclusteringanddatacoming fromadiscretespace.TheadvantageofusingSVMsisthattheyallowustoderivelinear(binary)classificationrules,thatare easy tointerpret,robustagainst outliersandthey carry sufficientdistinguishingpowerby maximizingthe gapa classifier hyperplaneyieldstowardstwosets ofdatapointstobeseparated(i.e.,trainingsets). Tothebestofourknowledge,thisis thefirstoccasionthatSVMsarebeingincorporatedintheclassificationofoillubricants.Subsequently,theprinciplesofthe proposed bearingrisk assessmentapproachareexplained,followed byan exampleonthe analyticalsteps performed,the bearingtestsconducted,aswellastheapplicationofSVMstoconfirmthepresentedriskclassificationsystem.

2. Methods

2.1. Reliability-as-a-Service(RaaS)

Inthe ageofIIoT,dataisusually collectedthroughsensors, storedin thecloud,andprocessedby algorithmsthat can be based onscientific knowledge andhuman expertiseto make processesmore reliableand thus,more efficient.In this study, this type of process is provided through proprietaryalgorithms of a Software-as-a-Service application tailored to bearingreliability(i.e.Reliability-as-a-Service(RaaS)).ThisRaaSapplicationtakesaholisticapproachontribologyandper-

mitsaproactiveapproachinassessingatribologicalapplicationduringsmoothoperationpriortoanydamageoccurring.In practicalterms, theoperation andmaintenance managercan take immediateaction,beforedamage occurs, to returnthe operationbacktothespecificationsasperdesign(i.e.,returntheoperationbacktobearinglifeasperDINISO281).Inthe following,thehigh-level principlesandprocessesusedintheRaaSapplication(SeerWorksTM Reliability,4LinesFusion,Inc., London,ON,Canada)areoutlined.

One of the greatest challenges inpredicting tribological events is to have fastalgorithms. Over the past decade, the approachesofacross-scale modeling initiatives have proposed methods that allowfaster computations.Coming from the molecularperspective withasize of10−9 metersit takesgreatcomputational powertointerpret effectson10−9 to 10−3 meters(e.g.,magnitudes of106 inlength scale). Theseacross-scaleeffects arecritical tounderstandandto modelasthe interactions of relevant parameters determine the reliability of contactsin relative motion(dry andlubricated). Consid- erable progress inmulti-scale modeling havebeen made in recentyears [14]; in order to use these multi-scale models itisnecessary tocreateinterfacialdescriptorsandpredictors toinvestigatesystemiceffects. Basically,predicatorsare ob- tainedby the propertiesofa molecule (e.g.,coming fromthechemical structure givenby thenature ofbonding, energy andsurface of the molecules). Exploring molecules by Quantitative Structure Property Relationship [15] andthe molec- ularproperties by the use ofdensity functional theory has become widely used [16]and some of thesepathways have been considered in the present study;here, the interactions of molecules with themselves and withsurfaces is part of molecular dynamics andab initio methods. The tribological behaviour of any lubricated contactis strongly governed by thechemical composition andmechanical characteristicsof the lubricantat the interface. Inthe following, theprinciple procedure that allows embedding molecular properties of lubricants into classical thermodynamics is introduced as an integral part ofthe applied tribological model forthe presentstudy. It is considered that thismodel is particularlyrel- evant to the type of bearing failure addressed inthis presentstudy asit is largely driven by the lubricantcomposition andits interactions withelectrical and electromagneticfields atthe interface. As part of thispresentmodel, the Arrhe- niusequation hasbeenconsideredto bea crucialcomponent;itprovidesinsighton howfastamolecular processmoves from A to B in a given environment. This process is affected by the presence of temperature changes and is generally expressedas:

k=M∗e−Ea

RT (1)

Eaisthe activationenergy(J/mol) fortheprocess ofshiftingthestate fromA to B; R isthegas constant(8.314 J/K∗mol) andTtheabsolutetemperature.The factorM dependsonhowoftenthemolecular speciecollidesandatwhichchemical orientation it occurs. The collisionsare assumedto be purely elastic; however,molecules,especially organic compounds, arenot rigidintheseelasticinteractions duetotheir inherent structureandtheir properties.Structuresofmolecules are expressedby their topology (i.e.,spatialarrangement ofmolecular bonding) andtheir movement ismainly expressedby thermalstress,pressureorshearing.Therelaxationtimeofsuchasystemisanimportantfactoronhowthecollisionsand stressescanbeuptakenandreleasedbythemolecules.Thus,anexpansionoftheunderstandingofthepre-exponentialfac- torMandtheactivationenergyEaispresentedbytheuseofdescriptorsderivedthroughmolecularmodeling.Transforming theArrheniusequationleadsto:

ln

kM

=−

EaRT

(2)

Wenowcomparethisrelationshipwiththechemicalpotential(i.e.,theenthalpyofacomponentinsolution).Thechemical potential(

μ

i)ofaconstituentiandthechemicalpotential(μ

j)ofacomponentjisgivenby:μ

i=μ

i(

0)

+RTln(

ai)

μ

j=μ

j(

0)

+RTln(

aj)

(3)Risthegasconstant,Ttheabsolutetemperatureandai,jtheactivityofthecomponentsiandjgivenastheactivitycoeffi- cienttimesthemolarconcentration.

Whileinequilibrium,thefactorDijiszero,expressingthatallchemicalpotentials

μ

i,μ

j,μ

k,... areequalto:Di j=

μ

j−μ

i=0 (4)Dijvalues >0reflecttheimbalance(i.e.,theinherententhalpynotinequilibrium).ThetemperatureindependentfactorDij isgivenbytheimbalanceofthesystemandmaybecomparedtotherelationshipEa/RT,meaningthat:

kM

=−

ajai

(5)

Ingeneralterms,itisthenassumedthattheprocessesfromAtoBaregovernedbytheactivityofthecomponentsi andj. TheexponentialfactorAtransformstheArrheniusequationandthiscanbeexpressedas:

Ea=−RTln

aiaj

(6)

Withinamolecularsystem,theactivityisattributedtoanattractionproperty,suchasdipolemomentsorpolarizability, byscalingitwiththemolecularmasstoamolecularproperty(i.e.,thespecificdipolemomentorthespecificpolarizability).

Thevolumeinthetribologicalcontactisalmostneverconstant;hence,thelubricantpassingthroughacontactisfrequently exposed tohighpressureasmatterofthereducedvolume.As thecontactareaapproacheszero,theactivationenergyEa increasesasthelubricantvolumedecreases:

Ea

(

j)

=−T∗(

cmi j+ln( ψ (

j))

VEa

(

j)

T =−1V

∗(

cmi j+ln( ψ (

j)))

, (7)wherecmijisrelatedtoaspecificmolecularpropertyofconstituentiorj,i.e.thespecificpolarizability,p;(cmi j=ln(pi/pj). ThereactionrateAtoBincreasesifthespatialdistributionofthej-thcomponentdecreases(e.g.,thej-thcomponentgets denser inthe givenvolume). As lubricants possesstheability tosolidifyin thecontactzone (i.e., createahigher spatial densityto decrease the activation energy),the transformation fromA to B isfacilitated andreaction rates are suggested to increase. The ability of molecules to self-order, expressed asa degeneration capability, is an important factor forthe lubricatedcontact.As thechangeofthevolume ina contactistransient,thelubricantcomponentsrequiresufficienttime forself-ordering;here, dipolemomentsact asrecognitionfunctionsbetweenmoleculesandpolarizabilityasarecognition functionforelectricalcharge.

The probability ofmoleculardegenerationin thecontactzone willincrease iftheaccessibilityof thefunction ishigh, bythe factthatthedensityatthesurfaceishighandthesymmetry gainisalsohigh(i.e.,thesymmetry increasesinthe degenerated state comparedto the non-degenerated state). All factors are molecular properties andshall be determined bymolecular modeling.Thedegenerationfactorishighifthemoleculespossesstheabilityforlong-rangecoupling.Under tribologicalconditions,theabilityofamolecularsystemtocreateself-assembliesisconsideredanimportantproperty;these propertiesarecloselyrelatedtothestructureoflubricantcomponentswherethedipolemomentsandthepolarizabilityare keyplayersinmolecularrecognition.

Comingtothereductionofenergydensity,itisalsoobviousthatthesepropertiesarecloselyrelatedtothedegeneration abilityofsuchsystemsandmayact assuitable descriptorsforlubricantsundertechnicalconditions.Thisisrelatedtothe electronpopulationinthehighestoccupiedmolecularstateandthedistancetothelowestunoccupiedstate.Onceexcited, themolecules completelyrelax overtime;thus, therelaxationtime isa measureofa molecularsystemto accommodate shearstressfrequency;iftherelaxationtimeisquick,themoleculesarecapabletouptakeahighershearfrequency,whereas iftherelaxationtimeisslower,themolecularsystemswilltendtoaccumulatemoreenergy.

Reactivity inatribosystemis accompaniedbyhighratesofcharge transfer(i.e.,shearing moleculesagainsteach other andthe creation/decayof electrical andelectromagneticfieldsduring atribologicalprocess. The response ofa molecular systemisdedicatedtothedipolemomentandtheinduceddipolemoments(i.e.,polarizability)asthemainpropertiesofa system.Thedrivingforceofatribologicalreactionisexplainedbythegainofenergyduringtheprocess(i.e.,thedifference ofthefreeenergyoftheeductsandtheproducts).Inatribosystem,thelubricantinvolvedmaybewrittenasavectorofall componentsandmoleculardigitsmayaddressthepropertiesoftheindividualcomponentsofthelubricant.Theindividual propertiesmaybe givenby the relaxationtime,the abilityto degenerate,the dipolemoment asa molecularrecognition digit, andthepolarizability asamolecular reactivitydigit that refers tothe abilityofthe molecule toreact via transient electricalfieldswithinthecontact.Thedipolemomentandpolarizabilityarekeyplayersinmolecularrecognitionandthese parametersarecloselyrelatedtothedegenerationabilityofsuchsystemsandmayactassuitabledescriptorsforlubricants undertribologicalconditions.

Observingbearingfailurethroughaclassicalview,thereliabilityisgivenbytheloadcapacityofthecomponent(e.g.,the bearing)andtheloading(i.e.,theforcespresentinthetribosystem)[7].Intheclassicalview,lubricantsactasasupporting element, that are mainly responsible for separating mating surfaces to reduce or eliminate friction and wear. Lubricant interactionsanditsdegradationcanhaveaprofoundeffectonmachineelements,alteringtheloadcapacity(e.g.,corrosion, stress-corrosioncracking, sludgebuild-up,andamorerecentphenomenon -WECs).Lookingmorespecifically atWECs,it may not be the lubricantitself actingon changes in loadcapacity butits sub-components (i.e., base oil andadditives), foreign elements(e.g.,water, detergents,etc.), andalsotheinteractions ofall oftheseconstituents thatpass throughthe interfaces.ChemicalstructuresandthecomplexityoftheirinteractionsrenderassessingWECriskdifficultforanend-userof aproduct.End-usersrelyonsendingoilsamplestoalabforanelementandchemicalanalysis.Unfortunately,labanalytics donotgo farenoughinassessingthecomplexitiesofthechemical interactions.Thisleavestheend-userlostinassessing complexissues,likeWECs,andthus,theyhavetomanagewiththeuncertaintyoffailures.

The aformentioned principlesandprocesses ofSeerWorksTM Reliability are applied to determineWEC risk classes.At the core, thisRaaSapplication deciphersthemain tribologicalparameters that define the bearingarticulation[17].More specifically, the physical,chemical anddynamicparameters of theinterface aredescribed indigital form;these parame- tersincludelubricantconstituentsli(li−1,...,li−n),the anisotropic,physicalpropertiesofthemating surfaces(si,sj),their inhereddynamics(dij),theinherentstructureofthematerialssurface(msi,msj),thebulkproperties(bi,...,bn),undercon- siderationsofintrinsicorimposedelectricalfields(ei,...,en).Theseparameterscomprisethetribosystemandserveasthe foundationofthealgorithms.Theirsecondderivativedescribesthemagnitudeofthecurvatureofthehyperplaneinspecific locationsthat indicate thelikelihood ofbearingfailure. The associatedunreliabilityof thetribologicalapplicationis then

Fig. 1. Schematic showing the process flow to generate an application/situation-specific dimensionless risk coefficient, k 4LF, that is then subjected to a classification system.

directlylinked totheextentofthediscontinuityinthehyperplane.Dimensionlessparametersdescribe,forevery givenin- cidentinthehyperplane,theconditionsthathaveshowntoleadtobearingfailureduetoWEC.Lubricantsaremixturesof functionalcomponentsthataremainly basedonorganicchemistry, andthus areextremelydifficultto describeinrespect totheirconjoint interactionsina tribosystem(e.g.,surfaces,viscosity, temperature,andothers).Asan integralpartofthe SeerWorksTMReliability,lubricantsaredefinedasacomponentvector;withinSeerWorksTMReliabilityeachlubricantcompo- nentismodeledinrespecttotheirtransientactivities,coveringtheirreactivityinadefinedtribosystem.Thesecalculations providevaluableinformationoflubricantcompounds,andthecombinationsthereof,thatcontributetobearingfailuresdue toWEC,amongotherbearingfailures.

SeerWorksTM Reliabilityalleviatestheuncertaintyoffailuresduetothelubricantandgivestheend-useranunderstand- ableriskassessmentandconcreterecommendationsforreducingtheriskofcomplexissues,likeWEC.Thisisaccomplished throughananalysisofthemedia(e.g.,lubricants,theirsub-components,foreignelements,thesystemcomponentsandthe entiretyoftheinteractionsbetweenalltheseconstituents).Startingwithinformationaboutthecurrentstateofthelubricant usingX-rayfluorescenceanalysis(XFA)andInfrared(IR)techniques,SeerWorksTM Reliabilityreducesthelubricantstotheir possiblebest-fitchemicalstructuresbyusingseveralmolecularmodelingsystems.Oncethepossiblechemicalstructuresare known,SeerWorksTMReliabilityvirtuallysimulatesthestructurespropertyrelationshipscombinedwiththeknowntechnical data.Morespecificallythesimulationslookatthemoleculesandtheirexposuretomechanicalenergy(e.g.,Slip-Roll-Ratio, SRR),electricalenergyand/oracombinationofthetwo.Furthermore,SeerWorksTM Reliabilityalsoconsidersthemechanical system’sactivityofagivensurface(fromlowroughnesstohighroughness)andphasedeviationsoftherotatingparts(i.e., in-phasemovementisrepresentedwithlowervaluesandout-of-phasemovementwithhighervalues).

Inprinciple,theknownparametersthatdefinethesystemserveastheinputintoSeerWorksTM Reliabilityandaresub- jectedtoalgorithmsthatarebasedonvariousprinciples(Fig.1).Theoutputisthedimensionlessriskfactor,k4LF;k4LFde- scribesattributesinrelationtotheinputparameters/componentsinanappliedsystem. WithrespecttoWECs,itisknown thatbothchemicalandmechanicalsystemsplayaroleinthereliabilityofasystem,thusSeerWorksTMReliabilitycreatesa dimensionlessk4LFriskcoefficientthatincorporateskeyparameters.

Togeneralize therisk assessment,SeerWorksTM Reliability takes the analysisand reducesit down to a simple set of generalizedclassesthatcanbeusedtomoreeasilyassesstheriskofthesystem.Inthepresentstudy,three(3)riskclasses havebeengeneralized:

– Class I indicates that the lubricant, its’ components and mixtures createa low risk with respect to mechanical and electricalexposure.Ifafailureoccurred,thenitisunlikelythatthefailurewasduetothelubricantasaprimecause.

– ClassIIindicatesthatthelubricantshowsapronouncedriskduetothesensitivityofthecomponentstowardmechanical (SRR) andelectrical impact. If theimpact is high, then thiswould be considered to be critical.Class II could lead to furtherissuesiftheend-userdoesnotreducetherisklevels(e.g.,stresscorrosioncracking(SCC),surface-inducedfailure (SIF)orwhite-etchingcracks(WECs).

– Class III indicates that the lubricant,its’ components,and/or foreign elements contribute to a highrisk of a system failure. It is mostlikely that therisk being observedis ofa WEC nature butthe risk could also lead toother failure modes(e.g.,SCC,SIF,orWECs).

Inareal-lifeenvironment,sparinglyavailabledatacanbegatheredandanalyzedwithrespecttothestructuresandtheir properties.Thereliabilityassessmentinthiscircumstancecanonlybe asaccurateasits inputsanddataasprovided.Even

Fig. 2. (a) A general FE-8 test rig schematic and (b) cylindrical roller bearing (adopted from [19] ) Table 1

Showing three possible variant structures of a determined lubricant consisting of base oil and additives ( C 1, . . . , C 8).

Chemical Variant Variant Variant

Compound Structure 1 (%) Structure 2 (%) Structure 3 (%)

C 1 0.37 0.00 0.00

C 2 0.00 0.67 0.67

C 3 0.35 0.00 0.00

C 4 0.00 0.64 0.64

C 5 0.08 0.08 0.08

C 6 0.28 0.00 0.00

C 7 0.00 0.31 0.00

C 8 0.00 0.00 0.44

Base Oil 98.92 98.29 98.16

withthemostadvancedsystemstheend-userisfacedwithalackofprecision duetothelackofinformationavailable for theassessment.SeerWorksTM Reliabilitybeginstoreducethisuncertaintyandforthefirsttimetheend-userhasareal-time assessmenttool.

2.2. SimplifiedAnalyticalSteps

A briefdescription ofthe analyticalsteps is provided inthe following.It is assumedthat the lubricantbeing usedis unknown(Note:wheninformationisunknownSeerWorksTMReliabilityperformsananalysisusingabest-fitapproachwhich canreducetheprecisionoftheriskanalysis).Asan example,theXFAbreakdownhasbeensuppliedthroughanoilsample analysis:

– Calcium=388ppm – Magnesium=229ppm – Phosphorus=3ppm – Sodium=53ppm – Sulfur=854ppm – Zinc=365ppm

SeerWorksTM Reliability uses the XFA data to render it into three (3) possible lubricant variants in terms of chemi- cal structures of each component (chemical structure components’ names are obfuscated; see Fig. 1, input parameters:

C1,C2,...,Cn),likelyoneofwhichisneartothetruecomposition lubricant(e.g.,fromtheaboveXFAdatawegetTable1).

Additional precisioncanbe addedwhenthelubricantbeingusedisprovided.Forthepurposeofthisstudy,SeerWorksTM Reliability isnotawareofthelubricantinuse.SeerWorksTM Reliabilitythenperforms analytics,throughvariousstatistical tools andproprietary algorithms, on each ofthe Chemical Compound Interactions (CCI) andthe known surfacematerial (Note:ifthesurfacematerial isnot known,thena non-stochiometricoxide,Fe-Fe3O4,isassumedasthedefaultmaterial).

SeerWorksTM Reliabilitythencreatesak4LFriskcoefficientandacorrespondingSRR(indicationofwherethethreatislikely to occur) foreach of the CCIs forphases 0.1through 0.9, reflecting thephase distortion between the moving parts and activity0.1 through0.9. For example,usingphase 0.1andactivity 0.1, theoutput forjustthe 1st variantfrom theabove

Table 2

Showing various combinations of a variant structures and their corresponding k 4LFand SRR.

Variant Structure 1

CCI k 4LF SRR

CC A CC B

C 1 C 5 0.96 3.09

C 1 C 6 .016 11.17

C 1 C 7 0.55 1.56

C 1 C 8 0.63 1.73

C 5 C 6 0.49 −1.35

C 5 C 7 0.31 0.73

C 5 C 8 0.84 −2.63

C 6 C 7 0.33 0.89

C 6 C 8 0.89 −2.84

C 7 C 8 1.26 5.19

Table 3

Showing Class categorization of each CCI for each of the three possible lubricant variants.

Variant Structure 1 Variant Structure 2 Variant Structure 3

CCI Class CCI Class CCI Class

CC A CC B CC A CC B CC A CC B

C 1 C 5 I C 2 C 4 I C 2 C 3 I

C 1 C 6 I C 2 C 6 I C 2 C 6 I

C 1 C 7 I C 2 C 7 I C 2 C 7 I

C 1 C 8 I C 2 C 8 I C 2 C 8 I

C 5 C 6 I C 4 C 6 I C 3 C 6 I

C 5 C 7 I C 4 C 7 I C 3 C 7 I

C 5 C 8 I C 4 C 8 I C 3 C 8 I

C 6 C 7 I C 6 C 7 II C 6 C 7 I

C 6 C 8 I C 6 C 8 I C 6 C 8 I

C 7 C 8 II C 7 C 8 I C 7 C 8 I

lubricantvariantsisasinTable2.TheinformationsuppliedinTable2canbeusefultotheend-userbutweperformseveral simplificationstoassisttheend-userininterpretingtheir overallrisk.Tosimplifythecommunicationoftherisk,ageneral classificationsystemisused.AriskclassisassignedtoeachCCIineachofthethreevariants(itisimportanttounderstand thattheriskclassesaresoftrulesandnothardlinesofclassifyingtherisk.EachCCIriskshouldbeconsideredandreviewed carefully).Forexample,basedonthek4LFandSRRforeachCCIaboveisshowninTable3.Tofurthersimplifytherisklevel, thepredominantclassforallCCIs,withinavariant,dictatetheriskclassforthatvariant.However,ifthereisaCCIriskclass IIIidentifiedthenthevariantisautomaticallyassignedariskclassIII.Forexample,thepredominateCCIclassesfromabove areasfollows:

– Variant1=ClassI – Variant2=ClassI – Variant3=ClassI

Eachvariantwillthenhaveitsownriskclassasthevariantsareindependentofeachother.However,wecanreducethe complexityevenfurther.Thatis,ifallthreevariantshavethesameriskclassthenitissafetoassumethatthelubricant,no matterofthevariant,istheriskclassthat theyareall assigned.Forexample,all variantsaboveareriskclass I;therefore, thislubricantisariskclassI.However,ifthevariantsdifferinclassesthenonemustconsiderthemcarefully.Aconservative approachistoassumethatthehighestrisklevelacrossallthreevariantsistherisk classforthatlubricantbutitdoesnot necessarilyindicatethetruerisk. Although,iftheclientknowsthetruevariantbeingutilizedthentheproperriskcanbe assessedusingtheriskclassforthatvariant(SeerWorksTMReliabilitycanassistindeterminingthetruevariantifdetailson theadditivesandbaseoilsusedareprovided).AspartofSeerWorksTM Reliability,thefollowingassumptionsaremade:

• Riskisdefinedastheactivityatthesurfaceasacombinationoftheinterfacialmedium (e.g.,lubricant,allcomponents andtheirpermutations)andthesurface(e.g.,bearingmaterial)attributedtothelubricantanditsconstituents.

• RiskdoesnotcommentonSRRbutratherusesavirtualSRRasathresholdfordeterminingwhere,withintheconstruc- tion,theriskcomingfromthelubricantcouldplayasignificantrole.

• The Risk Classesare softrules forhelpingto determinethe magnitudeofrisk levels withrespectto eitherthe lubri- cant orthe construction. However, the detailed k4LF for all the compounds andvariance comparisons along with the correspondingSRRvaluesshouldbeconsideredcarefully.

• It is important to understand that the k4LF is calculated to give a simplified general risk based on the lubricant.

SeerWorksTM Reliability uses smallamounts of datato perform thesecalculations. However, with moreaccurate data fromtheend-userSeerWorksTMReliabilitycanbemoreprecisewithassessingtherisklevel.

• Typically,dataforphase 0.1andactivity 0.1are usedforthe generalclassification unlesstheconstruction model and surfaceroughnessareknown;surfacesthatslideintunewitheachotherareconsidered ofbeingin-phase(in-phase= 0andoutofphaseunequalzero).Thegreaterthephasethemoretheactivityisoutofphase.

• Eachchemicalcompoundinteraction(CCI)isratedusingthegeneralclasses.

• CountthenumberforeachclassacrosstheCCIsandthepredominateclassthendefinesthevariantclass.However,ifa classIIIisobservedinanyoftheCCIsthenthevariantisautomaticallyconsideredaclassIII(thismustbeperformedon eachofthethreepossiblelubricantvariants).

• IfallthreeVariantshavethesamerisk classthenthat definestheriskclassforthelubricant.However,ifthevariants differinclassesthenconservativelyonemustchoosethehighestriskclasstodefinetheriskforthelubricant.

2.3. BearingLifeTesting

Aspreviously mentioned,sudden,irregular bearingfailuresthat donotfollowclassical calculationsdefinedinDIN ISO 281[7],WECsinparticular, areofgreatinterestto manufacturersofbearingsandtheend-users. Inordertoevaluatethe performanceofbearingspriortotheiruseinthefield,bearinglifetestsarefrequentlyperformed.Oneofthemostfrequent testsistheFE-8bearingtestfollowingDIN51819-3[18].TheFE-8testisastandardizedbearingtestthatiswidelyusedin theindustrytoevaluatebearinglifeinthelaboratorysettingunderpredefinedconditions(Fig.2).

The bearings testedwere cylindricalroller bearings(type 81212,brass cageat

κ

< 1(explanation:κ

>>1 then full fluidfilmlubrication;κ

<<1mixed/boundarylubrication)ataspeedof750rpm,an axialforce 30– 60kN(1700– 2000 MPa),andtemperaturesetconstantto 90◦Cattheoilcircuittosimulateatypical WECfailure mode.Thelubricantsused consistedofthefollowingconstituentsandvariouscombinations:poly-α

-olefine, ISOVG46,ISOVG68,ISOVG100;zinc-/molybdenum-alkylphosphateasantiwearadditives;corrosionpreservativesonsulfonatebase,aminephosphates;boronic acidesters;VIimproversonPMMAbase;magnesiumsulfonate;antioxidantsonthebaseonalkylateddiphenylamines.This present test setup and lubricant compositions were selected to specifically createtest environments that are known to facilitatelubricant-mediatedWECs.

As partof theFE-8bearing test postanalysis, the bearingmaterials were assessed usingcommon metallurgicaltech- niquesto investigatewhethertheindicationsforWECswerepresent. Aftercuttingthesamplesperpendiculartotherace- way,thesurfacewasetchedwithnitalsolution(2%nitricacidinethanol)torevealthewhiteareastoconfirmthepresence ofWECs[20],[8],[10].Theracewaywasalsoassessedforwearusingscanningelectronmicroscopytodetermineearlysigns ofsurface-inducedfailure (SIF)andcracknetworksbelowthe raceway;SIFtogether withsurface-nearcracknetworksare knowntobeaprecursorofWECs.Inparticular,SIFsoccurinbearingsthathavebeentestedforextendedperiods(>>50h).

2.4. SupportVectorMachine(SVM)forBinaryLinearClassification

Letusstart bynotingthatthere arenumerousclassificationmethods onecanuse,such aslogistic regression,decision trees, randomforests,neural networksand SVMs. Themain driving force ofone beingmore suitable than theother lies in the natureof the considered applicationand theavailable data.We considered (binary andmulticlass) decisiontrees [21]asagoodstartingpoint,howeverthedataavailable(cf.Sections3.2and3.3)provedinsufficientforthesemethods,as theseprovidedoverlysimplisticclassificationrules.Accordingly,randomforest methodsseemexcessivefortheapplication considered,while regardingneuralnetworksonehastoworry aboutoverfitting.Ourattentionnaturallyfocusedon SVMs and, to some degree,logistic regression,therefore the remainder of thissection is devoted to very briefly introduce the methodologythatthemainconclusionsrelyon,followedbythepresentationoftheresults.

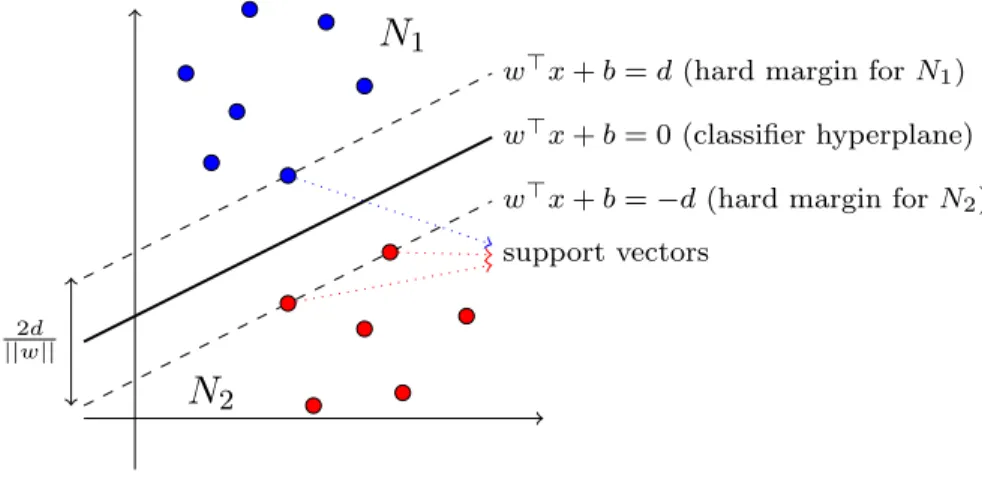

Among theabovementioned andingeneral,one ofthemostwidespreadmathematical toolsforbinarylinearclassifi- cationis thesupportvector machine(SVM) ([22],[23],[24]).Ata givendatasetofndata pointsx1,x2,...,xn∈X,all of them belong to a m-dimensional vector spaceX⊆Rm. Thisis the caseofn measurements on a systemdescribedby m characteristicswereperformed.Supposethatforeachofthenmeasurementsxi,i=1,...n,thereisacorrespondingbinary indicatoryi∈

{

−1,1}

(e.g.indicatingsuccess(1)orfailure(−1)).Iftheconvexhullsof

{

xi:yi=1}

and{

xi:yi=−1}

aredisjointed,thenthereexistsalinearbinaryclassifierdefinedby w∈Rmandb∈R:wxi+b>0 ⇐⇒ yi=1.Inordertofindtheseparatinghyperplanethat carriesthelargestdiscrimina- torypowerwedefinebsuchthatd:=minyi=1wxi+b=maxy

i=−1wxi+b.

Withthechoiceofdwehavewxi+b≥dforallyi=1andwxi+b≤ −dforallyi=−1,determiningtwohyperplanes, calledthehardmargin,aroundtheclassifier,thehyperplanelyinginbetweenthesetsequidistantlyfromtheirconvexhulls.

Thesehyperplanesaresupported by datapointsthatare locatedexactlyon them,calledsupportvectors (hencethename SVM),asshowninFig.3.

Themethodisindicativeofhowitiscomputedaswell:maximizingthedistance,definedby2d/||w||,subjecttokeeping thepointsonthecorrectsidewithatleastagivendistance.Sinceforagiveninstancedisfixed,wemaximizethedistance byminimizing||w||.Correctclassificationisforcedbylinearconstraints

yi

wxi+b≥d

∀

xi∈N, (8)Fig. 3. SVM hard margin

whileminimizing||w||over(8)isaconvexquadraticprogram(QP)thatcanbesolvedefficiently.

However,iftheconvexhullsarenotlinearlyseparable,thehardmargin doesnotexistandthepossibilitiesareembed- dingthe dataintoalarger dimensionalspace(atthe expenseoflesstractablecomputations), orconsiderthesoft margin balancing,throughparameter

μ

,themaximumdistance||w||andmisclassificationerrorszi:=max(0,d−yi(wxi+b)),the smallestnon-negativenumbersatisfyingyiwxi+b

≥d−zi.Consequently,thesoftmarginclassifiercanbecomputedus- ingtheconvexQP

min n

i=1zi+

μ||

w||

s.t. yi

wxi+b

+ zi ≥d

∀

xi∈N z ≥0(9)

3. Results 3.1. BearingTests

TheXFAandIRdataof24differentoillubricantswereanalyzedindependentlyusingSeerWorksTMReliabilitytobeable toidentifywhichlubricantswouldlead tobearingswithWECsorSIF.Outofthe 24oils, 13oilswere testedontheFE-8 bearingtest rigandeach testwassuspended ifthemaximumtest periodof 1000 hwasreached- regardlessofbearing survival status. The SeerWorksTM Reliability risk classifications performedprior to the FE-8 tests were compared to the actualresultsfromthe13FE-8tests;12outofthe13testsmatchedtotheirresults(Table4).

3.2.k4LFandSRR

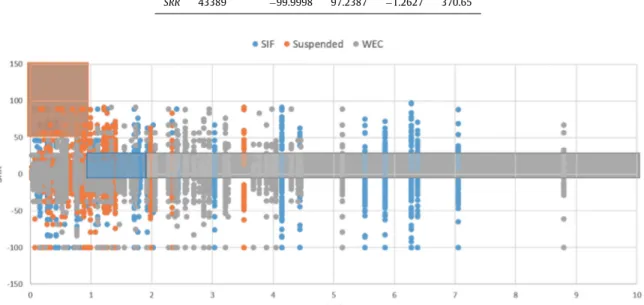

Anexperimental datasetcovering 24lubricantscollectedina samplesizeofmore than43,000 wasavailableforthis study.Thedatasamplewasfocusedon twoparameters thatwere virtuallyexpressed bytheSeerWorksTM Reliability: the WEC coefficientk4LF andtheslip-roll-ratioSRR. Wealso usedthe risk classassessment bySeerWorksTM Reliability asan exante classificationfor13lubricants outof24asinTable4,theremaining11beingunclassified,usingthegeneralrules ofriskclassification asabove.Interms oftheparametervalues,thismeansthe following:ifk4LF> 2and0< SRR<30, thenthecorrespondingsamplerecordlikelyleadstoWEC;if1<k4LF<2and0<SRR<30,thenSIF;whilek4LF<1and SRR> 30typicallyleadstonobreakdown.Table5andFig.4show thedistributionofthesampledata,withtheempirical classificationrulesdepictedonthelatterasrectangularareasinthek4LF/SRRspace.

Thefirst things that can be notedfromTable 5 andon Fig.4 isthe sizeable classificationerror betweenthe exante classificationandtheempiricalrules,aswellasthesignificantnoiseintheSRRvalues.Itisapparent thatthesampledata interms ofthe latteris notsuitable todeduce classificationrules from, andas fortheformer, classifyingthe samplein termsofthe k4LF valuesrathersimply justbygroupingthem basedon shapeof thedataset, wecan alreadyreduce the errorby1.5% comparedto theclassificationprovided. Inanycase, thereisroom forimprovement,thereforewefocus on thecomponentsofthetestedlubricantsinordertoderiveclassificationrules.

3.3.LubricantComponentAnalysis

Inthepresentstudy,thecalculationswereappliedtothecomposition ofthe24oillubricants:altogetherthetestedlu- bricantsconsistedof18differentcomponents.Thatmeansforeachoilithereisanxi∈X⊆R18,describingthecomponents oftheoilsuchthatX=[0,1]18and18

j=1(xi)j=1,i.e.thej-thcoordinateofxi,(xi)jshowswhatistheratioofcomponent

Table 4

Risk class assessment using SeerWorks TM Reliability in relation to the outcome from physical laboratory tests.

Oil Lubricant Overall Lubricant FE-8 Results Variant b Risk Class (SIF, WEC; hours) a

2 I I I I No Failure ( > 1000)

3 II I III III Failure (SIF; 1000) c 4 III III III III Failure (SIF; 100)

7 III I I III Failure (WEC; 100) c

9 III III III III Failure (SIF; 100)

10 III I I III Failure (WEC) c

11 I I I I No Failure

13 I I I I Failure (SIF; 1000) d

15 III I I III Failure (SIF/WEC; 100)

16 I I I I No Failure (1000)

17 III III III III Failure (WEC; 100)

22 I I I I No Failure (1000)

24 III III III III Failure (WEC; 37.5)

a SIF = surface-induced failure; WEC = white-etching cracks; not match for oil number 13

bIf class III only present once in the list of variants, worst case of Class III is assumed for Overall Risk Class

c Risk level dependent on Lubricant variant (further study required)

dTest suspended at max hours and bearing failed late (Oil 13 was pre- dicted a “class I” and failed late but due to SIF).

Table 5

Experimental data summary of k 4LFand SRR parameters.

Sample size Min Max Mean Var

k 4LF 43484 0.0018 16.5607 1.2339 2.6848 SRR 43389 −99.9998 97.2387 −1.2627 370.65

Fig. 4. Sample data of oil lubricants ( k 4LF/ SRR dimension)

jinoili.Furthermore,thereareyWEC,ySIF,ySuspandyUnc in

{

−1,1}

,indicatingwithvalue1whethereachoilisclassifiedas WEC,SIF,SuspendedorotherwiseUnclassifiedintheexanteclassification(trainingset).UsingthecomponentdataasaninputfortheSVMs,classificationrulesarederivedfrommuchlessnoisysamplescom- paredtotheexperimentsabove,butthe18componentsmeansthat thedimension ofX isstillrelatively lowenoughthat allowedtheanalysisandinterpretationoftheresults.

As previously described,the SVM methodwasappliedto repeat thesameprocess withthe samexi,i=1,...,24 data pointsfinding4binaryclassifiersforeachyidentifier.StartingwithclassifiersforyWECandySIF,itwasfoundinbothcases that theWEC(SIF)lubricantscanbe clearlyseparatedbya (classifier)hyperplanefromthenon-WEC(non-SIF)lubricants, withcorrespondingdistancesofdWEC=0.000175anddSIF=3.5178∗10−6.TheseparatinghyperplanesweregivenbybWEC=

Table 6

Binary classifier hyperplane coefficients for WEC and SIF.

Comp. 129 130 131 132 133 134 135 136 137

w WEC −0 . 001 0.0019 0.0032 0.0034 0.0008 −10 −9 0.0004 0.0013 −10 −5 w SIF 0.0003 −10 −4 −10 −4 −10 −4 0.0006 −10 −6 0.0009 0.0004 0.0005

Comp. 138 141 142 143 144 145 146 154 155

w WEC 0.0008 0.0002 0.0009 0.001 −0 . 0069 −0 . 0 0 07 10 −4 −0 . 001 −0 . 003 w SIF −0 . 0 0 03 −10 −6 −10 −7 −0 . 0 0 02 0.0002 −10 −6 0.0003 −10 −5 −0 . 0 0 04

Fig. 5. Binary classifier hyperplane coefficients for WEC and SIF

Table 7

Binary classification consistency for each lubricant.

Lubricant Ex ante WEC SIF Suspended

2 Susp. ?

3 SIF SIF

4 SIF

7 WEC WEC

9 SIF SIF

10 WEC WEC

11 Susp.

13 SIF SIF

15 SIF SIF

16 Susp.

17 WEC WEC

22 Susp. ?

24 WEC WEC

0.000175,bSIF=3.5178∗10−6 andthecoefficientsofwWEC andwSIF foreachofthecomponentsare showninTable6and Fig.5.

Thesame testswere conductedforthe remaining ySusp andyUnc withtheonly differencethat inthesecases thedata pointswere notlinearlyseparable,henceit wasreliedonthesoftmargin formulation.Oncetheseparate binaryclassifier hyperplanesweredetermined,theirconsistencyneededtobeevaluated.Therefore,itwasinvestigatedwhetherthesetsof lubricantsclassifiedasWECandSIFweredisjointed,whileallofthembeingclassifiedasnon-Suspendedatthesametime (Table7).

AsshowninTable7,theblankcellsareclassifiedasnon-WEC(-SIF,-Suspended)fortheWEC(SIF,Suspended)classifier,

“?” denoteslubricants that violated(8) forthenon-separableySusp case, whilethe remaining11blankrowsof lubricants thatwerenotclassifiedexante(asinTable7)were omitted.Itcanbeseenthat thebinaryclassifiersthatweregenerated forWECandSIFwere consistentwitheach other andthe computedWECandSIFclassifyinghyperplanescanbe usedas stand-alonelubricantclassifiers,asaninputforlearningalgorithmsorforfurtheranalysis.Forthelatterpurposes,itisof

Table 8

Most influential components for WEC and SIF classifiers.

Component w WEC w SIF

130 0.0019

131 0.0032

132 0.0034

144 −0.0069 155 −0.003

133 0.0006

135 0.0009

Fig. 6. Multiclass decision tree for classification

particularinteresttohighlightthe(relatively)mostinfluentialcomponentsforeachclassifierinTable8.Foreachclassifying hyperplane,thesearethedefiningcoefficientswiththelargestabsolutevalue,relativetotheotherdefining coefficientsof thehyperplane.Therefore,thecoefficientshavenostand-alonemeaning,rathertheirmagnitudeindicatestheinfluenceeach lubricantcomponenthasintheclassificationprocess.Thus,ideally,fortheWECandSIFbinaryclassifiers,wewouldliketo finddifferentcomponents thataremostinfluential,thecomponentsmainlydeterminingwhetherthelubricantwillleadto WECornot,orwhetheritwillleadtoSIFornot.Indeed,theseformedtwodisjointedsetsofcomponents,indicatingthat thekeylubricantcomponentsthatareofincreasedriskforWECandSIFhavebeenidentified.

3.3.1. LogisticRegressionandDecisionTrees

Toprovideamorecompleteunderstandingofthequalityofthemethodused,theSVMmethodologywascomparedwith twootherclassificationapproaches, i.e.decisiontreesandlogisticregression.Duetothelackofsufficientdata,onlyoverly simplisticclassificationruleswereachievedfordecisiontrees(Fig.6)

Inthecaseoflogistic regression,parameterswere estimatedtoachievethe highestprobability ofcorrectclassification bymaximizingthelogarithmoftheoddsofcorrectclassification.Hence,weconsiderthetaskofamaximumlog-likelihood parameterestimationthat requiressolvinga non-linear,butunconstrainedoptimizationproblem.Sinceintheseproblems mostgradientsearchalgorithms donotconverge,Newton’smethodisusedtoobtaintheestimatedparameters,again, fo- cusingonobtaining binaryclassifiersforeachlubricantoutcomecategory(e.g.,WEC,SIF,etc.).Itisofnosurprisethatthe classificationusinglogisticregressioniscompletelyinlinewithwhatwasfoundusingSVMs(Table7). However,SVMsare notonlylesspronetooutliersthanlogisticregression,interpretingtheestimatedparametersinthelatterisfarlessstraight- forwardcomparedtothecaseofSVMswiththesoftandhardmargin (Fig.3)hyperplanes(coefficientsinTables6and8), becausetheseestimatedparameters(Table9)havenogeometricalmeaning1.

1Moreover, Newton’s method did not even converge to obtain a binary classifier for the ’Unclassified’ class.

Table 9

Logistic regression estimated parameters for WEC and SIF binary classifier.

Comp. - 129 130 131 132 133 134 135 136 137

WEC 8875 −89 5754 30176 −25228 −84 −97 900 −91 −73

SIF −517800 5183 12872 803 3015 5280 5118 13443 5143 5080

Comp. 138 141 142 143 144 145 146 154 155

WEC −128 10817 −3041 −1152 −136 −1222 −89 −79 −89

SIF 5694 41256 −4551 −3773 5342 −3098 5178 5235 5400

4. Discussion

Ithasbecomeincreasinglyimportanttopreserveenergyandmaterialresourcesaroundtheglobetoboostsustainability.

Aspartofindustrialanalytics,therapidlygrowingpredictivemaintenancemarkethasalreadyshowntoprovidevastsavings.

Theseconceptsarebeingusedinawiderangeofindustrialapplicationsbyreducingfailuresanddowntimewhileincreasing longevityofmachine elements.SeerWorksTM Reliability,asaRaaS application,hasproven toprovidethe userwithstress pointsofan applicationthat relatesto eventswhenthe presentlubricatedcontactis atrisk forvarious typesoffailures andWECsinparticular.Intoday’sdigitalworld,monitoringsensorsarebecomingincreasinglyconnectedaspartofIIoTand thecollecteddatacanthenbestoredandprocessedon-premise orinthecloud.SeerWorksTM Reliabilityprocessesdatain ahardenedprivatecloud (withthird-party penetrationtestinggradeof“exceedingbestpractices”)that hasbeencollected bysensors,orrelatedequipment,eitherinreal-timeoroffline.SeerWorksTMReliabilitysimulatesthelubricantinteractions withthetypeofbearingsurfacetoprovidesystemicriskassessmentofalubricatedcontact;therefore,theriskassessment isgovernedbythelubricantconstituents(i.e.,baseoilandadditives;lubricantchangesduetoe.g.,water,detergents,sump residueandotherdegradationcompounds),type ofbearingsurfacematerials,roughness,adjacentelectricityandtheinter- actionsthereof.ItneedstobenotedthatSeerWorksTMReliabilityprovidesariskassessmentforveryearlyWECfailurethat ismediatedbythelubricant;itdoesnotassessriskfactorsthatcanoriginatefrommaterialinclusionsorothersources[8]. SeerWorksTM Reliability, as a proactive condition monitoring application as part of predictive maintenance permits relationshipstoevolve – asinthecaseofreal-lifeapplicationsthatare characterizedbycascadingevents(e.g.,tribology).

While others teach machines based on data from past events, SeerWorksTM Reliability uses deterministic approaches forthese evolving/cascading events [25–28]. Thus, SeerWorksTM Reliability can be applied to any type of system where cascadingeventsplay a role asinmost real-worldsituations. SeerWorksTM Reliability can show significant abnormalities earlyon,i.e.ariskclassIlubricantchangingtoariskclassII/IIIlubricantasmachineoperatingtimeprogresses.Aspartof thisprocess,lubricantsamplesaredrawn,analyzedfollowingindustry-standard protocolsonan ongoingbasis wherethen SeerWorksTM Reliability uses thatstandard datato reportaboutsignificant abnormalities.ThisRaaS applicationdeciphers thechemicalcompoundsofthelubricantandthecharacteristicsoftheinterface toprovideproactiverecommendationsto guaranteemachinereliabilitylongbeforeanymajordamage/root-causeinitiates.

Bearinglife can be separated intotwo phases:the time frame when the applicationis in smooth operation and the time frame whendamage hasbeen initiated, progresses andeventually leadsto catastrophic failure;the latteris associ- atedwiththe highestoperationalandmaintenance cost asfailure isinevitable(e.g.,bearing replacementsin an offshore windturbinecancostmillionsofUSDandreduce itsavailabilitytogeneratepower). SeerWorksTM Reliabilitymanagesthe threatsinsmooth operationby reducing the uncertaintythrough recommendations that willeliminate damage initiation (Fig.7).

Thereareplenty ofmonitoring sensorsavailablethat areabletodetect damageandestimatetheremaining usefullife [29,30],e.g.includingindustry-standardlubricantanalyses,acoustic,vibration,andparticlecontaminationsensors.Therisk classesthatarecreatedwithinSeerWorkTM ReliabilityhaveshownhighlyeffectiveinprovidingproactiveWECalerts.There- fore,thispermitstheoperatortoperformevidence-basedratherthancalendar-basedmaintenanceandimplementcounter measuresthat willextendthe servicelife oftheoperation.Thegreaterchallenge istopredicthowthe applicationisper- formingduringsmooth operation,wherenodamage hasyetdeveloped,andthereliesthegreatestamountofuncertainty.

Thebesttimeforreducingthreatsofdamageexistsinthesmoothoperationperiod;thisiswhereproactiveconditionmon- itoringhasitsgreatestvalue.Basedontheholistictribologicalapproach,SeerWorksTMReliabilityprovidesariskassessment andrecommendationstoreducetheuncertainty,reducethreatsofdamage,prolongthesmoothoperationperiodandextend availability.

Among the most widely used classification methods, e.g. neural networks, random forests, decisiontrees, logistic re- gressionandSVMs,weapplied thelatterthreeandfound thatSVMsare themostsuitableforthelimitedamountofdata onecan gather onthe performance andeffect oflubricantoils onbearingfailure. The generalclassificationgeneratedby SeerWorksTM ReliabilityhasproventobeinlinewiththefindingsofFE-8labexperiments,asshownbyTable4.According to Table7, summarizing theclassification withthe binaryclassifiers generated by SVMs, it wasfound that theseclassi- fiersareconsistent witheach other:wheneveralubricantwasclassifiedasWEC(SIF)by theiraccordingclassifier,itwas classifiedasnon-SIF(non-WEC) bytheother correspondingclassifier,aswell asdistinctivelynot beingclassifiedwiththe lubricantteststhatweresuspended.Additionally,comparingTables4and7,itwasfoundthattheSVMclassifierswerein linewiththe findings ofSeerWorksTM Reliability andFE-8bearingtests. Therefore, itis worthwhile to lookinto theco- efficientsofthesebinaryclassifiers thatallowed usto identifythe keylubricantcompounds reliable forWEC andSIF,as

![Fig. 2. (a) A general FE-8 test rig schematic and (b) cylindrical roller bearing (adopted from [19] ) Table 1](https://thumb-eu.123doks.com/thumbv2/9dokorg/774028.34891/6.816.143.682.84.344/fig-general-schematic-cylindrical-roller-bearing-adopted-table.webp)