RHEOLOGICAL PROPERTIES O F ASPHALTS R. N. J. Saal and J. W . A. Labout

I. I n t r o d u c t i o n 363 I I . R h e o l o g i c a l Properties of Pure Asphalts 366

1. D e s c r i p t i o n of R h e o l o g i c a l Properties 366 2. R h e o l o g i c a l Properties of Asphalts 369

a. Influence of T y p e on T i m e D e p e n d e n c e of Stiffness 369

b. D e v i a t i o n s from L i n e a r i t y ; C o n s t i t u t i o n 371 c. M e c h a n i c a l M o d e l S y s t e m of V a r i o u s T y p e s of Asphalts 374

d. Influence of Hardness on T i m e D e p e n d e n c e of Stiffness 377

e. Influence of T e m p e r a t u r e on Stiffness 377 / . Influence of Pressure on R h e o l o g i c a l Properties 380

g. Breaking Strength 381 3. R o u t i n e Analyses 382

a. P e n e t r a t i o n 382 b. Softening P o i n t R i n g and Ball 386

I I I . Asphalt-Mineral A g g r e g a t e M i x t u r e s 388

1. I n t r o d u c t i o n 388 a. M e t h o d s 389 2. R h e o l o g i c a l Properties of Asphalt-Mineral A g g r e g a t e M i x t u r e s 391

a. Influence of the Mineral A g g r e g a t e C o n c e n t r a t i o n 391 (1) D y n a m i c Investigation at Short L o a d i n g T i m e s 391 (2) Static Investigation at L o n g L o a d i n g T i m e s 393 b. R e l a t i o n between the R h e o l o g i c a l Properties of the M i x t u r e and

T h o s e of the A s p h a l t C o m p o n e n t 397

c. Breaking Strength 399

N o m e n c l a t u r e 400 I. Introduction

Asphalt is the highly viscous residue of certain kinds of petroleum o b - tained b y merely removing m o s t of their volatile c o m p o n e n t s . T h i s process is sometimes c o m b i n e d with a chemical treatment t o obtain a larger quan- tity of highly viscous residue or t o p r o d u c e asphalts with special rheological properties. In other cases the viscosity of the natural p r o d u c t is already so high that it need n o t b e artificially increased (native asphalts).

Asphalts are mainly used as a binding material and in protective coat- ings, taking b o t h forms of application in a v e r y general sense. Their suita- bility for these uses is largely dependent on their mechanical properties, in particular on those relating t o r h e o l o g y . F o r a correct j u d g m e n t of this

363

364 R . N . J . S A A L A N D J . W . A . L A B O U T

suitability, therefore, a thorough k n o w l e d g e of these properties is indis- pensable.

T h e c o m p o s i t i o n of petroleum varies w i d e l y with its origin. In fact, not all types are suitable base materials for asphalt, a n d those which are still differ so m u c h from one another that o n l y b y choosing the right processing conditions can the asphalts p r o d u c e d from t h e m b e m a d e t o meet the same quality requirements. Research into the manufacture of asphalts also c o m - prises rheological studies, which aim at gaining m o r e k n o w l e d g e on the structure of the material.

These t w o aspects of rheological w o r k , viz., applicational and manufac- turing research, require a different approach.

In the numerous applications of asphalt the mechanical conditions, such as magnitude of stresses and time of loading, cannot b e given with a high degree of precision. H e n c e k n o w l e d g e of the rheological properties of the asphalt need n o t b e so v e r y accurate either, b u t m a y b e restricted t o the primary effects, and the relation between stress and deformation m a y b e considered linear.

In the study of the structure of asphalts the understanding of any effect m a y contribute toward a deepening of insight. H e n c e , in this case m o r e exact knowledge is necessary and the study also comprises secondary ef- fects, such as small deviations from linearity, thixotropy, etc.

T h e various types of application of asphalt m a y b e divided into those using the asphalt in the pure state or m i x e d with only small quantities of fillers, and those e m p l o y i n g the asphalt in mixtures with other materials in a comparatively l o w concentration. In the latter case, the rheological be- havior of the asphalt composition will b e largely determined b y that of the other c o m p o n e n t s . Therefore, a discussion of the rheology of asphalt has t o be divided into t w o parts, one dealing with the pure asphalt (Part I ) , the other with mixtures p o o r in asphalt (Part I I ) .

M o s t asphalts are colloidal systems; t h e y contain high-molecular c o m - p o n e n t s ("asphaltenes"), which m a y b e precipitated as a solid b y diluting the asphalt with low-boiling saturated hydrocarbons. T h e remaining part is a highly viscous oil of the N e w t o n i a n t y p e ("maltenes"). It has been found that at n o t t o o high temperatures the disperse-colloidal phase of the asphalt system consists of the asphaltenes together with a proportion of the maltenes varying with the temperature. T h e continuous phase is a N e w t o n i a n oil of lower viscosity than the maltenes.

T h e rheological characterization of asphalts is, as a rule, based on t w o properties: penetration and softening p o i n t R i n g and Ball. T h e penetra- tion indicates the distance, in tenths of a millimeter, a needle will penetrate into the asphalt under standardized conditions of loading and time. T h e softening point R i n g and Ball ( t e m p . R & B ) is the temperature at which

the consistency of the asphalt is such that a steel ball placed on a disk of asphalt in a brass ring will cause a certain deformation of the disk, also under accurately specified conditions.

In accordance with these analytical m e t h o d s asphalts have been classified according t o " h a r d n e s s " and t o " t y p e . " Asphalts differ in t y p e when the distance between their t e m p . R & Β and the temperature corresponding with a certain penetration is different. T h e y are said t o differ in hardness when at equal t y p e the t e m p . R & Β differs (Fig. 1 ) .

W h e n expressed in this w a y the differences in hardness between the as- phalts used in actual practice m a y b e as high as a b o u t 100° C . T y p e s m a y v a r y so widely that the distance between t e m p . R & Β and the tempera- ture corresponding with a given penetration m a y v a r y b y a factor of 4.

Various systems h a v e been d e v e l o p e d t o describe the t y p e of an asphalt.

In the following, use will b e m a d e of the "penetration i n d e x " ( P . I . ) ; it repre- sents the a b o v e - m e n t i o n e d distance between the t e m p . R & Β and the temperature at a given penetration in the form of an index number. In this system a P . I . of —2.5 applies t o asphalts with a small difference and a P . I . of a b o u t 6 t o asphalts with a large difference between these t w o tempera- tures. T h e majority of asphalts h a v e penetration indexes lying between these t w o values.

It has been found that the penetration index is closely related t o the ex- tent t o which various asphalts, on deformation, show deviations from N e w - t o n ' s law. In static measurements at n o t t o o short loading times asphalts with a l o w index number ( — 2 or lower) o b e y N e w t o n ' s law. A higher index ( > — 2) goes with visco-elastic properties, the latter being m o r e p r o n o u n c e d

366 R . N . J . S A A L A N D J . W . A . L A B O T J T

according as the index is higher, and at a penetration index higher than ca.

+ 2 thixotropic phenomena m a y be observed.

F o r a more detailed description of this subject matter reference m a y b e m a d e t o " T h e Properties of Asphaltic B i t u m e n " b y J. P. Pfeiffer.1

II. R h e o l o g i c a l P r o p e r t i e s o f Pure A s p h a l t s 1. DE S C R I P T I O N O F RH E O L O G I C A L PR O P E R T I E S

T h e object of an investigation into the rheological behavior of asphalts is t o find the relation between deformation, stress, time of loading and tem- perature.

On deformation m o s t asphalts display visco-elastic properties. F o r a given asphalt the ratio of the elastic t o the permanent part of the deforma- tion depends on stress, time of loading, and temperature. A t slight defor- mations and short times of loading the deformation is predominantly elastic ; at considerable deformations and long loading times viscous deforma- tion dominates. In m o s t cases elastic deformation consists of an ideally elastic part and a p a r t showing retarded elasticity.

A t small deformations the relation between deformation and stress is linear; at considerable deformations and long loading times deviations from linearity m a y occur in certain cases. T h e y are secondary effects and will be left out of consideration for the time being.

T h e resistance t o deformation of materials which o b e y H o o k e ' s or N e w - ton's law can be described b y means of t w o primary quantities, v i z . :

(a) the modulus of elasticity, E, which is defined as the ratio of the tensile stress, σ, t o the strain, e :

Ε = σ (1)

€

(b) the viscosity, η, which is defined as the ratio of the shearing stress, dy

τ , t o the rate of shear, — :

n = f (2) ay

dt

T h e modulus of elasticity, E, is usually determined at small deformations, the viscosity η, at deformations which are generally considerable. T h e latter quantity can, however, be expressed in terms of tensile stress and strain according t o

v = T - t = 1 .Z.t (3)

1 J. P . Pfeiffer, " T h e Properties of Asphaltic B i t u m e n with Special Reference t o Its T e c h n i c a l A p p l i c a t i o n . " Elsevier, H o u s t o n , T e x . , 1950.

where m is Poisson's constant. F o r asphalts this constant is a b o u t 2, from which it follows t h a t

V a n der P o e l ,2 in describing the resistance t o deformation of viscoelastic materials, w h i c h include asphalt, uses the ratio σ/e as a function of the time of loading, t, and temperature, T. T h i s ratio σ/β is called "stiffness," S, and will also b e used here t o describe the rheological behavior of asphalts.

O n l y in those cases where measurements based o n direct shear are difficult t o express in terms of elongation will the rheological behavior b e given in terms of viscosity.

In general, the relation between stiffness and time at a given temperature is, for viscoelastic materials, represented b y a curve of the shape illustrated in Fig. 2 .

T h e left-hand (horizontal) part of the curve refers t o loading times which are so short that the deformation is mainly elastic; the stiffness is then iden- tical with Y o u n g ' s modulus. T h e right-hand part of the curve, which makes an angle of 45 deg. with the time axis, refers t o long loading times, at which the deformation has a predominantly viscous character and hence is p r o - portional t o time. A t intermediate times the deformation slowly increases and from elastic gradually b e c o m e s viscous.

In measuring the stiffness as a function of time t w o m e t h o d s of loading can b e distinguished, v i z . , static and d y n a m i c .

In the static m e t h o d a constant load is applied t o the material and the deformation is measured as a function of time. B e l o w the t e m p . R & Β use is m a d e of strain and bending tests on asphalt specimens and of rotational viscometers of the t y p e described b y C o u e t t e .3 A b o v e t e m p . R & Β capil- lary viscometers are c o m m o n l y used; the stiffness can then b e calculated from the viscosity according t o equation ( 4 ) . These m e t h o d s are suitable for deformation times longer t h a n 1 sec.

T h e d y n a m i c m e t h o d applies an alternating load t o a rod of the material under test, which is suspended freely or is held fixed on one end. T h e load varies sinusoidally with t i m e ; the stress at a n y m o m e n t can be expressed b y

T h e amplitude of the deformation also varies sinusoidally with the same frequency and can, at any m o m e n t , b e represented b y

(4)

€

σ = σ sin œt (5)

e = e sin (œt — φ) (6)

2 C . V a n der P o e l , Proc. 2nd Intern. Rheol. Congr., Oxford p . 331 (1953); Appl.

Chem. (London) 4, 221 (1954).

3M . C o u e t t e , Ann. chim. et phys. [6] 21, 433 (1890); J. phys. [2] 9 , 566 (1890).

R . N . J . S A A L A N D J . W . A . L A B O U T

LOG S

Ε

Ν

HG T

F I G . 2 . General picture of the relation between stiffness and time at constant temperature for viscoelastic materials.

where ω = angular frequency and Φ = the difference in phase between stress and deformation.

T h e stiffness is calculated from the resonance frequency as related t o the dimensions of the specimen.

T h e d y n a m i c m e t h o d is used for measurements at n o t t o o high tempera- tures and short loading times ( < 1 s e c ) .

F o r a graphic representation of the relation between stiffness and time V a n der P o e l2 uses the same time scale for the t w o types of loading; for the static m e t h o d log time and for the d y n a m i c m e t h o d log ( l / ω ) is plotted on the abscissa, using the same scale.

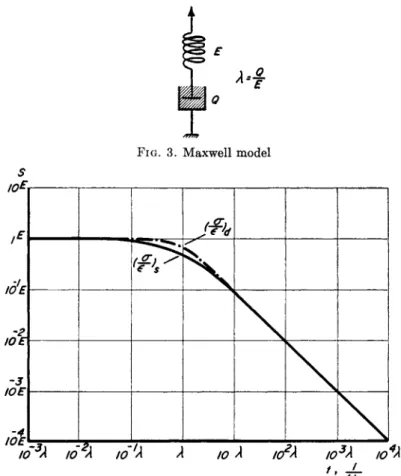

T h e correctness of this method of plotting has been tested b y means of a mechanical model consisting of an elastic and a viscous element.

F o r the M a x w e l l element of Fig. 3, σ/e determined b y the static m e t h o d can be calculated from the equation

(7)

σ / ' e determined b y the d y n a m i c method follows f r o m :

(8)

In these equations the s y m b o l λ = Q/E = relaxation time, and Q = c o - efficient of viscous traction (according t o T r o u t o n ) .

In Fig. 4 log ( σ /e )s and log ( σ / ί ) ^ have been plotted in one diagram against the same time scale.

I t will b e seen that the t w o curves practically coincide except in a small area of transition. F o r a first approximation, however, the t w o w a y s of representation m a y b e used side b y side without making a distinction b e - tween d y n a m i c and static m e t h o d .

2 . RH E O L O G I C A L PR O P E R T I E S O F AS P H A L T S

a. Influence of Type on Time Dependence of Stiffness

T h e relation between stiffness and time of loading at constant tempera- ture ( 2 5 ° C . ) is represented in F i g . 5 for different types of asphalt. I t will be seen that the differences in rheological character show u p as differences in time dependence of the stiffness.

F I G . 3. M a x w e l l m o d e l

iö'e\

- J

10 E\

to 3χ ιό2λ Ί^λ λ ~!ο~λ Ί/λ Ίο^χ 7ο4λ t, J-

ω

FIG. 4. Comparison of static and dynamic stiffness moduli for Maxwell model

370 R . N . J . S A A L A N D J . W . A . L A B O U T

ASPHALT Q b c PEN./25 °C 3 15 13 TEMP R a Bt°C 66 67 120 P.I. -2.4 -Q2 + 55 ASPHALTENES, % 3 20 34

Asphalt α is a material with a v e r y low asphaltene content, which has been prepared from a B o r n e o base material b y distillation ( P . I . = —2.4). A t short loading times the asphalt displays an almost purely elastic, at long loading times a purely viscous behavior. T h i s asphalt shows hardly any effects of retarded elasticity and hence n o partial recovery after removal of the load. T h e transition from the elastic t o the viscous part of the curve is fairly sharp.

A similar behavior can sometimes be observed with asphalts having a higher content of asphaltenes; in this case these asphalts also have a low penetration index ( — 2 or l o w e r ) .

Asphalt b has been prepared from Venezuelan base material b y distilla- tion. It displays retarded elasticity and shows partial recovery after longer loading times when the load is r e m o v e d . T h e transition from the elastic t o

the viscous part of the curve is not so sharp as that of asphalt a. Asphalts with a similar behavior are characterized b y a penetration index of from — 2 to ca. + 2 ; according as the P.I. is higher the transition area is larger.

Asphalt c has been prepared from Venezuelan base material by blowing (i.e., oxidation by air). This asphalt shows strongly retarded elasticity; its stiffness is little influenced b y the time of loading. In static measurements with short loading times the recovery after removal of the load is practi- cally complete. A t considerable deformations and long loading times thixo- tropy is observed and the relation between deformation and stress is no longer linear. This type of asphalts is characterized b y a penetration in- dex higher than + 2 , usually from + 4 to + 6 .

b. Deviations from Linearity; Constitution

T h e differences between various asphalts in the stiffness-time relation are linked up with differences in colloid-chemical structure.

As has been said in the Introduction, on deformation the continuous phase of the colloidal system behaves as a Newtonian liquid. T h e elastic effects shown b y most asphalts must therefore be attributed to the disperse phase, which, as has also been stated, consists of the asphaltenes and part of the maltenes. Asphalts which contain hardly any asphaltenes have a noncolloidal structure and consequently these asphalts behave as N e w - tonian liquids. A n example of this is asphalt a of Fig. 5. On deformation for not too short times this asphalt shows a purely viscous flow; only at very short times can ideally elastic effects be observed.

Some asphalts of high asphaltene content show a similar behavior, e.g., asphalts prepared from cracked base materials (i.e., base materials which b y exposure to high temperatures have thoroughly changed their composi- tion). T h e disperse phase of these asphalts must then consist of particles which, at the stresses prevailing during the measurements, d o not show elas- tic deformation.

M o s t asphalts containing asphaltenes display retarded elasticity. T w o types can be distinguished, of which asphalts b and c in Fig. 5 are represen- tatives. T h e differences found can be derived from Figs. 6 and 7, which con- tain more detailed data of two corresponding asphalts b' and c'.

Figure 6 refers to asphalt b'\ the stiffness derived from the total deforma- tion (St) and that calculated from the elastic part of the deformation (Se) have been plotted against the time of loading. T h e t w o curves d o not coin- cide; the difference is caused b y the resulting permanent deformation. For this asphalt the relation between deformation and stress is practically linear also at long times of loading, which appears from the fact that the values of St determined at different loads are equal.

For asphalt c' (Fig. 7) the values of St and Se coincide at loading times up to about 102 sec. Below this limit there is practically no permanent déforma-

372 R . N . J . S A A L A N D J . W . A . L A B O U T PROPERTIES OF ASPHALT

PEN./25°C 17 TEMP RSB =63°C

PL =Ό7 ASPHALT E NES = 25.3 % w t · (Γ 13.3 · ΙΟ 4 dynes/cm 2 Χ 0~ =6.60 · ΙΟ4

3 Ο CT 1.63 · ΙΟ4

STIFFNESS, dynes/cm2

Ό7\ 1 1 Γ

ιυ~ιο ΙΟ2 10 ^ ΙΟ4 ιο s LOADING TIME, SêC.

F I G . 6. Stiffness as a function of loading time and stress for asphalt bf at 35° C.

tion; a certain yield stress m a y be assumed. A t longer loading times there is permanent deformation; moreover, the relation between total deformation and stress is no longer linear, which appears from a spread of the curves for various loads. T h e fact that thixotropy occurs at higher loads can be derived from the slope of the log St curve in respect of the log time axis.

A t long times the curve makes an angle greater than 45 deg. with the axis, which means that the deformation increase with time is more than propor- tional. T h e rheological behavior of this type of asphalt points to its having a coherent structure which, at slight deformations for short times, is capable of complete elastic deformation and which, if the deformation is continued,

PROPERTIES OF ASPHALT PEN./25X 64 TEMPR3S 68·C

RI = t3.2 ASPHALTENES '25.0 % *

1 · or = 11.6 - tO4 dynes/cm2 2 x σ -- 574' ΙΟ4

3 ο (Γ * 1.41 - ΙΟ4 STIFFNESS, dynes/crrï

107χ 1

ΙΟ ΙΟ2 ΙΟ5 ΙΟ4 ΙΟ5

LOADING TIME, sec.

F I G . 7. Stiffness as a function of loading time and stress for asphalt c ' at 35° C

collapses. T h e colloidal character of this t y p e of asphalt is, therefore, that of a gel. T h e coherent structure is formed as a result of mutual attraction of the disperse particles; this idea is confirmed b y other investigations, in which, e.g., syneresis is observed.

Unlike asphalt c ' , asphalt V must h a v e such a structure that its disperse phase consists of free-moving elastic particles, and hence it has a sol char- acter.

T h e differences discussed are extremes; in general, intermediate forms also occur.

T h e extent t o w h i c h a coherent structure is formed in asphalts and the measure of elasticity of the disperse particles depend on the chemical c o m - position of the disperse and continuous phases.

A s will be seen from Figs. 6 and 7, the elastic deformation of either t y p e of asphalt o n deformation at long loading times does n o t proceed linearly

374 R . N . J . S A A L A N D J . W . A . L A B O U T

with time and stress; the recovery, ee, reaches a m a x i m u m and decreases again. This decrease is greater for a gel t y p e than for a sol t y p e . T h e rela- tion between this m a x i m u m and the load for a sol-type asphalt is repre- sented in Fig. 8. It can be described b y the following equation:

m a x i m u m values for ee e,

where b and k are constants (for sol-type asphalts k = 1 ) ; em represents the m a x i m u m elastic deformation at infinite time and stress (Fig. 8 ) .

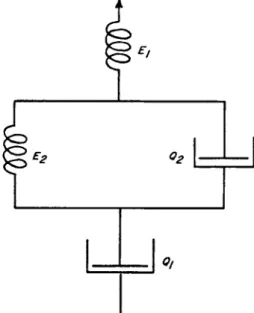

c. Mechanical Model System of Various Types of Asphalts

A mechanical m o d e l designed t o represent the rheological properties of asphalts at short loading times m a y consist of combinations of linear ele- ments, viz., an ideally elastic and a purely viscous element and one showing retarded elasticity. A simple representation of such a m o d e l is given in Fig.

9, which is a combination of a Maxwell and a V o i g t element. F o r this

/

MAX. VALUE OFee

10 \ Γ

F I G . 8. R e l a t i o n between m a x i m u m r e c o v e r y and stress for asphalt b'

model the following equation obtains for deformation at constant stress:

E\ Qi E2 ^ ) (10)

where Xr = — = retardation time.

H/2

Differences in rheological properties between asphalts can be represented in the model b y different values for the parameters.

F o r asphalts of t y p e a in Fig. 5, which have practically n o retarded elas- ticity, the parameters E2 and Q2 are almost insignificant. Figure 5 shows that the rheological behavior of this t y p e of asphalt can almost completely be described b y Ex and Qi ( M a x w e l l m o d e l ) .

Asphalts of the elastic sol t y p e (b in Fig. 5 ) , which show ideal and retarded elasticity as well as viscous flow, can b e described b y the four elements of the model.

T h e rheological behavior of gel-type asphalts (c in Fig. 5 ) , which at not t o o high shearing stresses and at slight deformations d o not show perma- nent deformation, can be described b y means of the model, omitting the viscous element Qi .

Figure 9 gives, in its simplest form, the rheological character of different asphalts. Since, however, asphalts consist of a large number of c o m p o n e n t s differing in chemical character, molecular weight, and size of disperse par- ticles, their rheological properties will in general not allow of exact repre-

Q2

F I G . 9 . Simple m o d e l illustrating rheological b e h a v i o r of asphalts

376 Ε . Ν . J . S A A L A N D J . W . A . L A B O T J T

N° PEN/25°C TEMR RSBt°C RI.

1 3 2

4 64 16

82 67 575

0 0 0

STIFFNESS ^ dynês/cm2

LOADING TIME, sec.

FIG. 10. Stiffness as a function of loading time for asphalts of different hardness but of equal P . I .

sentation b y a simple model. A suitable model will have to contain a series of elements and the most adequate representation is b y an infinite series of Voigt elements with a continuous spectrum of retardation times from

\r = 0 to + oo.

The nonlinear functions at considerable deformations and long loading times are not described b y the model of Fig. 9. T h e representation of the maximum in the elastic recovery requires a nonlinear elastic model (as sug- gested b y Saal4) ; still more complicated models are necessary to represent

4 R . N . J. Saal, in " T h e Properties of Asphaltic Bitumen with Special Reference to Its Technical Application" (J. P. Pfeiffer, e d . ) , p . 52. Elsevier, Houston, Tex., 1950.

thixotropy of gel-type asphalts, as the structure of the material changes during deformation. T h i s matter will n o t b e discussed here.

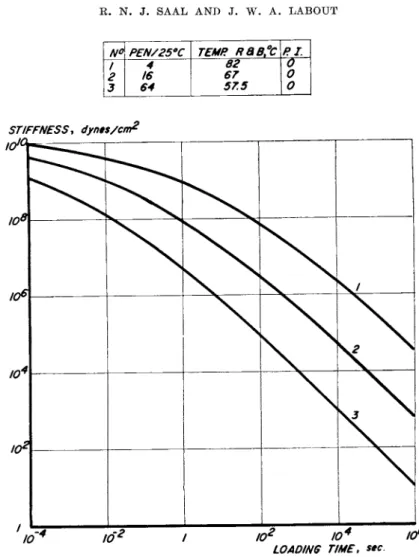

d. Influence of Hardness on Time Dependence of Stiffness

T h e relation between stiffness and time of loading at a given temperature is, for asphalts of the same rheological t y p e , dependent on the hardness of the asphalt, as can b e derived from measurements on asphalts with differ- ent penetrations at 25° C . and equal penetration indexes. T h e results of these measurements are represented in Fig. 10 for sol-type asphalts with penetrations at 25° C . of 4, 16, and 64 and a P . I . = 0.

T h i s figure shows that for asphalts of the same rheological t y p e b u t of different hardness the log stiffness—log time curves h a v e approximately the same shape. H e n c e , differences in hardness can manifest themselves in the curve being shifted along the log time axis. If the ratios between the hardnesses (penetrations) are equal, the curves are shifted over equal dis- tances.

e. Influence of Temperature on Stiffness

Asphalts are thermoplastic materials; their stiffness decreases consider- a b l y as the temperature is raised.

ST/FFA/ESS, dynes/cm2

F I G. 11. R e l a t i o n between stiffness and temperature for asphalts a, b, and c (Fig. 5) at l o a d i n g times of 10 s e c .

378 R . N . J . S A A L A N D J . W . A . L A B O U T

T h e relation between stiffness and temperature of the three above-men- tioned asphalts α, i>, and c at a constant loading time of 10 sec. is represented in Fig. 11.

A t low temperatures the deformation is predominantly elastic; at high temperatures it is mainly the viscous properties which determine the char- acter of the deformation. W h e n asphalts are arranged according t o tempera- ture dependence of the stiffness at equal times they are in the same order as when arranged according t o the time dependence at equal temperatures, as shown in Fig. 5 . T h e dependence of the stiffness on temperature grows with its dependence on time.

A change in temperature implies shifting of the log S— log t curves.

Curves which h a v e been determined at different temperatures can b e m a d e t o concide b y shifting along the log t axis (Fig. 1 2 ) ; log S — ( 1 / T ) curves which have been determined at different loading times can b e m a d e t o coin- cide b y shifting along the ( 1 / T ) axis (Fig. 13). F o r a limited temperature

PROPERTIES OF ASPHALT PEN/250C* 50 TEMP R a Θ*55Χ

PL * Ο 1 TEMP s Ο 0C 2 ,, *25*C 3 „ *50°C STIFFNESS, dynes/cm2

tn/L r

LOADING TIME, sec.

F I G . 12. Influence of temperature on the relation between stiffness and loading time

/ LOADING TIME *S-I0'4sec.

Ζ » » - 10 sec.

3 » * * 10 sec STIFFNESS, dynes/cm'

IOUi r

F I G . 1 3 . Relation between stiffness and temperature at different loading times for the asphalt of F i g . 1 2 .

range (below the t e m p . R & B ) this general principle can be approximately expressed b y the equation

where R is the gas constant, F an activation energy, and to a constant.5 T h i s relation can be introduced into the mechanical model b y assigning t o all the viscous elements the same value of F.

T h e shift of the log S — log t curve on the temperature being increased from Τι t o JP2 can, in the above-mentioned temperature range, b e repre- sented b v

5 C . V a n der P o e l , in " T h e R h e o l o g y of Building and R o a d M a k i n g M a t e r i a l s "

( M . Reiner, e d . ) , Chapter I X . N o r t h H o l l a n d P u b l . C o . , A m s t e r d a m , 1950.

380 R . N . J . S A A L A N D J . W . A . L A B O U T

F r o m this and from the experimental values, F can be calculated, which for most asphalts is of the order of a b o u t 50 k c a l . / m o l e .

On the whole, the log S — log t curves of an asphalt determined at differ- ent temperatures below the t e m p . R & Β have approximately the same shape ; at higher temperatures there m a y be deviations owing t o a change in the rheological character of the asphalt. F o r instance, in gel-type asphalts the gel structure is changed at high temperatures t o b e c o m e a sol structure.

It will be clear that this influences the relation between log S and log t, so that in this case curves determined at different temperatures cannot be m a d e t o coincide.

A t low temperatures and short loading times all asphalts show an ideal elastic behavior. T h e stiffness is then identical with Y o u n g ' s modulus Ε and has a value of ca. 2.5-3 Χ 1 010 d y n e s / c m .2, which holds for all asphalts.

A s already said the deformation at high temperatures is predominantly viscous. T h e ideal elastic effects will certainly still exist, but they are largely or entirely obscured b y the m u c h more p r o n o u n c e d viscous effects. In this connection it is of interest t o point t o the relation with the compressibility of asphalts. F o r a number of asphalts with penetrations at 25° C . between 40 and 60 N e d e r b r a g t6 finds practically the same value for the compressibility at temperatures between 25 and 90° C . This value is of the order of 40 X 10~12 c m .2/ d y n e , which corresponds t o a bulk modulus Κ of 2.5 Χ 1 010 d y n e s / c m .2 A s the relation between Κ and Ε is given b y the equation

K = o , m 9s X E (12)

3(m — 2 )

and, in this case, m m a y be put ca. 3, there is a satisfactory agreement b e - tween the value of Ε calculated from the compressibility at high tempera- tures and the m a x i m u m value found for the stiffness at lower temperatures.

/. Influence of Pressure on Rheological Properties

T h e viscosity of liquids and hence their stiffness increases at increasing external pressure. T h e effect of a pressure increase on the stiffness of as- phalts, particularly of those with a low asphaltene content, m a y be v e r y considerable as is seen in T a b l e I (which gives the ratios between the stiffnesses at zero and at higher pressures for equal loading times and various asphalts at different temperatures).

T h e increase in stiffness produced b y a pressure increase is linked u p with a decrease of the "free v o l u m e " between the molecules. It has been said in Section 2e that the compressibilities of different asphalts are a b o u t

6 G . W . N e d e r b r a g t , in " T h e Properties of Asphaltic Bitumen w i t h Special Ref- erence t o Its T e c h n i c a l A p p l i c a t i o n " (J. P . Pfeiffer, e d . ) , p . 93. Elsevier, H o u s t o n , T e x . , 1950.

T A B L E I

I N F L U E N C E OF P R E S S U R E ON T H E S T I F F N E S S OF D I F F E R E N T A S P H A L T S A T T E M P E R A T U R E S B E T W E E N 20 A N D 60° C .

Asphalt Pressure P, kg/cm2

As- phal- tenes,

Me-

asur- 0 100 200 800

400

500 Origin Type Pen./25° C.

Temp.

R &

B, °C P.I.

As- phal- tenes,

ing temp.,

°C

stiffness at

D Λ. pressure Ρ Temp.

R &

B, °C

% wt.

ing temp.,

°C Ratio . stiffness at pressure Ρ =

0

B o r n e o N e w t o n - 47 47 - 2 . 2 1.2 25.0 1 4 . 0 13 45 167 597

ian 40.0 1

— —

20 59 170t y p e 49.0 1 2 . 2 5.8 15 37 90

California sol t y p e 54 48 - 1 . 8 5.1 20.0 1 2.5 6.6 17 44 115 40.0 1 2.1 4 . 5 9 . 2 19 40 49.4 1 1.8 3.7 7.1 14 27 Venezuela sol t y p e 44 55 - 0 . 3 15.5 20.9 1 2 . 2 4.9 11 24 54 30.0 1 2.0 4 . 2 8.5 18 36 40.0 1 1.9 3.6 7.0 14 26 50.0 1 1.8 3.1 5.5 10 19 Venezuela gel t y p e 35 86.5 + 4 . 4 28.9 60.0 1 1.7 3.0 5.2 9.1 16

(blown)

the same, w h i c h means that for these materials the decrease of the "free v o l u m e " caused b y pressure increase is a b o u t equal. T h e "free v o l u m e "

of high-molecular products is smaller than that of low-molecular sub- stances, so that at equal compressibility the decrease of this v o l u m e caused b y pressure is relatively greater in the former case. Consequently, the increase in stiffness of asphalts owing t o increase of pressure is greater as the molecular weight of the constituents of these asphalts increases.

T h e increase in stiffness of asphalts owing t o pressure must, in the first place, b e attributed t o an increase in viscosity of the continuous phase.

A t equal stiffnesses of the asphalts the viscosity of the continuous phase of asphalts with a l o w asphaltene content, i.e., with a l o w concentration of disperse particles, is higher than that of asphalts with a high asphaltene content. Consequently, the change in stiffness under increased pressure is greater for the first-mentioned t y p e of asphalts.

A s the "free v o l u m e " increases at rising temperature the effect of the higher pressure o n the stiffness is smaller as the temperature rises. T h i s is also illustrated b y T a b l e I.

g. Breaking Strength

Strictly speaking, breaking strength is n o t a rheological property. N e v e r -

382 R . N . J . S A A L A N D J . W . A . L A B O U T

theless, in the rheology of asphalts it is a v e r y important quantity for their practical application as it sets a limit t o the permissible stresses. Since in most applications the asphalt undergoes a certain deformation the resulting stress is determined b y the stiffness at the time of loading and the tem- perature in that particular case.

T h e breaking strength of asphalts is not a constant value but depends o n the time of loading and o n the temperature, although t o a m u c h smaller extent than does the stiffness. A t l o w temperatures and short times of loading the m a x i m u m value for the breaking strength of various asphalts is a b o u t 3 X 1 07 d y n e s / c m .2; this value decreases at longer loading t i m e s .2 A s the m a x i m u m value of the stiffness is 3 X 1 010 d y n e s / c m .2, there is n o risk of rupture at strains smaller than e = 10~3, i.e., 0.1 % . A t greater strains rupture does not necessarily occur, b u t m a y d o so depending on the stiffness and therefore also on the time of loading and the temperature.

3. RO U T I N E AN A L Y S E S

a. Penetration

In actual practice asphalts are classified according t o hardness on the strength of routine analyses, a m o n g which the determination of the pene- tration7 is one of the m o s t frequently used.

A s a rule, the penetration is determined b y applying a load of 100 g m . t o a standardized needle for a time of 5 s e c ; the distance of penetration is recorded in tenths of a millimeter.

If the asphalt adheres t o the needle shear occurs in the material. H e n c e , a given penetration represents a certain deformation under a certain load or, in other words, a certain stiffness during a certain t i m e .

F o r asphalts which d o n o t display retarded elasticity and which, in static measurements at not t o o short loading times, b e h a v e as N e w t o n i a n liquids, the relation between penetration and stiffness can be derived theoretically.

F o r this case the rate of penetration of the needle ^ ^e n* is proportional t o at

the load Ρ and inversely proportional t o the viscosity, hence t o S-t and, approximately, t o the penetration already reached, so that

d pen.

= C Ρ

or Q

=

2C Ptdt Q X pen. pen.2

or (13)

p e n /

the stiffness and the penetration being taken at the same time.

S = 2 C - ^ -2

7 Am. Soc. Testing Materials Standards D 5-25; I Ρ 49/46.

T h u s , for the above-mentioned asphalts the stiffness at the loading time in the penetration test is approximately inversely proportional t o pen.2 ( A n y influence of the point of the needle has here been neglected.)

T h e relation between penetration and stiffness of asphalts is complicated b y the fact that the penetration determination is carried out at decreasing stress, whereas the stiffness is defined at constant (or sinusoidally alternat- ing) stress. Consequently, the greater part of the deformation in the penetration test takes place in the v e r y beginning, so that the time at which the stiffness must be c o m p u t e d for comparison with penetration (the

" e q u i v a l e n t " loading time) is likely t o b e shorter than the actual penetra- tion time.

It is v e r y difficult t o derive this equivalent loading time theoretically;

therefore an empirical approach has been used. It appears that if, for as- phalts of a different rheological character but with equal penetrations at 5 s e c , log S is plotted against log t1 the resulting curves intersect, on an average, at a time of a b o u t 0.4 sec. (see Fig. 14). T h i s means that different asphalts with equal penetrations at 5 sec. show the same stiffness deter- mined under constant stress at a loading time of 0.4 sec. T h i s time is used t o derive a general relation between stiffness and penetration. Figure 15 shows this relation between stiffness at t = 0.4 sec. and penetration at t = 5 sec. for different asphalts with P . I . between —2 and + 6 . A t high penetra- tions, hence, at considerable deformations, the quadratic relation between stiffness and penetration is approximated; however, at low penetrations, hence, at small deformations, the m a x i m u m value for the stiffness, as dealt with on page 380, cannot b e exceeded.

T h e same ratio between equivalent and actual loading time exists, if other penetration times are taken. T h i s follows from the fact that also the slopes of the log pen.-log time and the log stiffness-log time curves are closely related. T h i s is shown b y T a b l e I I , in which ^ Pe n- _ β a n (j

^Ί ^ ^ = Bf are given for a number of different asphalts and also the ratio a Jog t

Bf/B which always is approximately —2, the value which according t o formula (13) must apply t o asphalts without retarded elastic effects.

T h e a b o v e relationships i m p l y that the influence of temperature u p o n penetration and stiffness are also closely related.

A c c o r d i n g t o the empirical relation8

log pen. = Β log t + AT + C (14)

8 M . C . Siegmann, in " T h e Properties of A s p h a l t i c B i t u m e n with Special Reference t o Its T e c h n i c a l A p p l i c a t i o n, , (J. P . Pfeiffer, e d . ) , p p . 160-66. Elsevier, H o u s t o n , T e x . , 1950.

384 R . N . J. S A A L A N D J. W . A . L A B O U T

No PEN/25°C P.I.

1 30 -2 2 30 0 3 30 t2 4 30 + 4 5 30 + 6

e

250 -2

7 250 0 β 250 t2 STIFFNESS, dynes/cm

2ΙΟ

10·

IO

cI06

10 <

10

4I

χ .10 -2 10

e10' /0

eLOADING TIME, sec.

F I G . 1 4 . Stiffness as a function of loading time at 2 5 ° C . for asphalts with pene- trations at 2 5 ° C . of 3 0 and 2 5 0 and different P. I .

equal penetrations are obtained at constant Β log t + AT, hence at 1 dt _ _ 9 Q A

tdf~ 6 Β 1

A c c o r d i n g t o equation (11) equal stiffnesses are obtained at constant

1η

Τ

0-Έτ'

L e-

a tld£ = F_

t dT RT2

F r o m this it follows that A Β

which value is in satisfactory agreement with experimental data ( T a b l e I I ) . 0 . 4 3 ^ = 0.12 at 25°C.

STIFFNESS 1*0.4" . dynes/cm*

tot-

to*

\

\

\

•:\.

\

i

>

\ \

\ \ -+—TEMP RS Β

^

-+—TEMP RS Β

PENETRATION / 5"

F I G. 15. R e l a t i o n between stiffness a t t = 0.4 s e c . and penetration a t t = 5 s e c . for different asphalts with P . I . between —2 and + 6 .

In the technical applications of asphalts it is usual t o express the tem- perature dependence of t h e penetration as t h e change of log pen. with temperature a t a constant time. T h i s change depends u p o n the slope of the log pen.-log time curve, i.e., u p o n the value of B. A c c o r d i n g as Β has a lower value for a given change in temperature a smaller change of log pen. is found. T h e description of the temperature dependence of log pen. at a con- stant time is thus, in fact, mainly a representation of t h e rheological character of the asphalt, as expressed b y B. Since the ratio A/B is practi- cally constant ( T a b l e I I ) , t h e rheological character of the asphalt is ex- pressed t o the same extent in the constant A. N o w the latter has been

386 R . N . J . S A A L A N D J . W . A . L A B O U T

T A B L E I I

V A L U E S OF S O M E C O N S T A N T S FOR D I F F E R E N T A S P H A L T S R E F E R R I N G TO S T I F F N E S S AND P E N E T R A T I O N

Pen.15" at 25° C. P.I. B' Β B'/B A

ΑΙ

Β17 96 207 30

- 2 . 0 0 . 0 + 2 . 0 + 4 . 0 + 6 . 0 + 0 . 1 + 0 . 1 + 0 . 6

1.00 0.70 0.53 0.38 0.29 0.60 0.77

•0.80

0.50 0.37 0.26 0.19 0.15 0.30 0.39 0.37

2 . 0 1.9 2 . 0 2 . 0 1.9 2 . 0 2 . 0 2 . 2

0.055 0.040 0.030 0.023 0.018 0.039 0.039 0.037

0.11 0.11 0.11 0.12 0.12 0.13 0.10 0.10

taken as the basis of the penetration i n d e x :9 20 - P.I. 1_

10 + P.I. ' 50 (15)

Hence, the penetration index strongly reflects the rheological character of the asphalt. It will n o w be clear that the relation between stiffness and time, which is governed b y the rheological character of the asphalt, m a y be related t o the penetration index.

b. Softening Point Ring and Ball

Asphalt cannot be said t o have a precise melting point in the strict sense of the term; on heating its stiffness gradually decreases. T h e softening point refers t o an arbitrary point on the stiffness-temperature curve of the as- phalt. This point is entirely dependent on the conditions of determination.

In the R i n g and Ball m e t h o d10 a " d i s k " of asphalt in a c o p p e r ring is loaded with a steel ball of 3.5 g m . T h e assembly is heated in a water bath at a rate of 4 - 5 ° C . per min. until the asphalt, under the weight of the ball, has sunk through a distance of 1 in. T h e temperature at which this takes place is the softening point R i n g and Ball ( t e m p . R & B ) .

T h e softening point R & Β can b e conceived as a point on the log S — 1/T curve at a given time of loading. T h i s time must be v e r y m u c h shorter than the total time in which the R & Β determination is carried out as the great- est deformation takes place in a short time immediately preceding the m o m e n t at which the recorded temperature is reached.

F o r an approximation of the " e q u i v a l e n t " loading time in the R & Β test, use can be m a d e of a theoretical deduction showing that for a material satisfying the equation

9 J. P . Pfeiffer and P . M . van D o o r m a a l , J. Inst. Petroleum Technol. 22, 414 (1936).

10 Am. Soc. Testing Materials Standards D 36-26; Ε 28-42; I Ρ 58/46, S = f(t-eAT)

under isothermal conditions, an analogous equation

5 = / ( < ' · eA'T) (16)

holds, if tf = l/pAr and the material has been subjected t o a constant tem- perature rise of p° C . per second over a sufficiently long t i m e ; Τ being in this case the final temperature.11

A t the t e m p . R & B , A' appears t o a m o u n t t o a b o u t 0.2 reciprocal degree for all asphalts, whereas in the test a value of ρ = 5 ° / 6 0 sec. is prescribed, so that l/pAr = 60 sec. T h i s value has t o be corrected, because in the R & Β test the temperature of the asphalt is somewhat lower than that of the liquid bath. T h i s temperature difference can be deduced from R & Β determinations at various rates of heating.

Differences in the rate of heating give rise t o different final temperatures for the same deformation under the same load according t o

A'T1 A'T2

6 6 (17)

A'pi Afp2

so that an increase in the rate of heating b y a factor 2 results in an increase in t e m p . R & Β of 3 ° C . A c t u a l l y , differences in t e m p . R & Β are found as given in T a b l e I I I .8

It is evident that a large part of the differences in t e m p . R & Β can b e directly explained b y the influence of the rate of heating. T h e remainder is related t o heat transfer from bath t o bitumen, w h i c h requires a temperature difference proportional t o the rate of heating. T h i s difference, as calculated from the experimental data, is given in the last c o l u m n of the table.

Under the condition of the R & Β test (rate of heating 5 ° C . / m i n . ) the difference between the average temperature of the asphalt and that of the bath is a b o u t 3 ° C . Therefore, the time of 60 sec. calculated a b o v e obtains for a temperature 3° C . below the t e m p . R & B . T h i s time has t o be cor- rected b y a factor of e ~3 A' = 0.5, so that theoretically the " e q u i v a l e n t "

loading time in the R & Β test amounts t o a b o u t 30 seconds. F o r asphalts with a P . I. n o t exceeding + 2 the stiffness is found t o be on an average 1.5-103 d y n e s / c m .2 at this t i m e .2

A t the t e m p . R & Β the penetration in 5 sec. of asphalts is of the order of 800. A s in the penetration text the " e q u i v a l e n t " loading time has been deduced t o be 0.4 s e c , asphalts with a P . I. lower than + 2 should also show equal stiffnesses at the t e m p . R & Β and a time of 0.4 s e c T h i s is actually the case, as appears from Fig. 15, which also includes the stiffness at the t e m p . R & B . , viz. 9.104 d y n e s / c m .2 at 0.4 s e c T h i s figure is in agreement with direct viscosity measurements on various asphalts at the t e m p . R & B . carried out earlier12 giving a value of η = 1.2 · 1 04 P. F r o m the relation S = 3η/1 a stiffness of the same value as given a b o v e is calculated.

1 1 R . N . J. Saal, Proc. 4th World Petroleum Congr., Rome S e c t . V I / A , p . 29 (1955).

1 2 R . N . J. Saal, Proc. 2nd World Petroleum Congr., London p . 515 (1933).

388 R . N . J . S A A L A N D J . W . A . L A B O U T

T A B L E I I I

T E M P . R & Β AT D I F F E R E N T R A T E S OF H E A T I N G

Rate of heating Temp. R& B°C. Difference minus 3°C.

Temp. diff. between bath and asphalt

° C.I min.

Javanese asphalt Mexican asphalt Javanese asphalt Mexican asphalt

Temp. diff. between bath and asphalt

2.5 53 51

} ;· \

2 1.35 57.5 56

} ;·

J

2 . 5 2.710 62.5 61.5

J 2 J

2 . 5 5.3The fact that for asphalts with different values of the P . I. below + 2 at the t e m p . R & Β equal stiffnesses are found at a time of 30 sec. (S = 1.5· 103 d y n e s / c m .2) as well as at a time of 0.4 sec. (S = 9.104 d y n e s / c m .2) explains w h y penetrations at the t e m p . R & Β generally d o not show ap- preciable differences for asphalts of different P . I. T h i s is in agreement with the conclusion given at the end of section 3a, that P . I . figures based on one penetration and the t e m p . R & B . m a y describe the visco-elastic nature of an asphalt just as well as figures based o n t w o penetrations at different times and the same temperature.

III. A s p h a l t - M i n e r a l A g g r e g a t e M i x t u r e s

1. I N T R O D U C T I O N

In m a n y technical applications use is m a d e of mixtures of asphalt and mineral aggregate. D e p e n d e n t on the nature of the application the ratio between the quantities of asphalt and mineral aggregate and the nature of the mineral used m a y v a r y considerably. So-called protective coatings usually contain mixtures with a content of mineral material varying be- tween 0 and 20 % v o l u m e . In mastics this quantity varies between 45 and 7 0 % v o l u m e ; in so-called dense road carpets, such as sandsheet and as- phaltic concrete, between 70 and 8 5 % v o l u m e . In open graded mixtures even larger quantities m a y occur. T h e t w o first-mentioned mixtures h a v e no voids, dense road carpet mixtures a l o w percentage of v o i d s and open graded mixtures a voidage up t o , say, 2 0 % . T h e mineral aggregate used may v a r y from filler t o coarse stones. In mastic and sandsheet mixtures filler and sand are used, asphaltic concrete also contains coarser material.

The aggregate is m o s t l y applied in the form of a graded mixture.

T h i s chapter will not deal with all the types of mixtures enumerated a b o v e , but will be confined t o mastics and dense road carpet mixtures. A s b l o w n - t y p e asphalts are not used in road carpets they have not been dealt with either.

In applying these compositions it is the rheological properties of the mix- ture that count, which, naturally, are closely linked up with those of the

asphalt, b u t on which the mineral aggregate exerts a strong influence. T h e asphalt imparts visco-elastic properties t o the asphalt-mineral aggregate mixtures. A t small deformations and short loading times the relation b e - tween deformation and stress is a linear one. A g a i n , the rheological b e h a v i o r of the c o m p o s i t i o n in this area can b e c o m p l e t e l y described b y means of the ratio σ / e , i.e., b y the stiffness, which, like that of pure asphalts, depends on the time of loading and the temperature.

If long loading times and considerable deformations are applied the relation b e t w e e n shearing stress and shear is n o longer linear. T h i s is stated b y Lee and M a r k w i c h ,13 a m o n g others. A c c o r d i n g t o N i j b o e r14 a yield stress is found t o exist under these conditions.

a. Methods

F o r the examination of asphalt-mineral aggregate mixtures at small deformations and short loading times d y n a m i c m e t h o d s h a v e been applied.

V a n der P o e l5 uses the torsional vibration test t o determine stiffness. I n this test a vertical cylindrical r o d of c o m p o s i t i o n is fixed on one end, carry- ing a cylindrical mass, which is m a n y times that of the rod, at the t o p . A small electric m o t o r with eccentric weights on its shaft and fixed t o the mass on t o p of the rod sets u p torsional vibrations in the system around the longitudinal axis of the rod. F r o m the resonance frequency of the system the shear m o d u l u s τ/y is calculated and also the stiffness, according t o σ/e = a b o u t 3 τ / γ . In this m e t h o d stresses u p t o 107 d y n e s / c m .2 can b e applied.

F o r the study of rheological properties at considerable deformation and long loading times N i j b o e r14 uses the triaxial test, particularly on dense road carpet mixtures. A cylindrical test piece of the asphalt c o m p o s i t i o n is placed in a water-impermeable elastic j a c k e t surrounded b y a liquid (water) in a closed space. T h e test piece is axially loaded with a constant load so that a constant stress σχ is d e v e l o p e d . O w i n g t o the deformation caused in the test piece a stress develops in the surrounding liquid, which reaches a constant value σ3 and acts on the cylinder in a horizontal direction. Under these t w o stresses the test piece is in a state of equilibrium. B y repeating this procedure at various stresses σχ a c o m b i n a t i o n of different values for σι and σ3 is obtained. If these data are represented in the form of a M ö h r stress diagram, the relation between the normal stress σ and the shearing stress r can b e derived. A n example of this is given in Fig. 16. T h e tangent t o the M ö h r stress circles cuts off part of the ordinate. This value of r is considered as the yield stress of the material at zero pressure and is called the initial resistance re.

1 3 A . R . Lee and A . H . D . Markwieh, J. Soc. Chem. Ind. (London) 56, 146 (1937).

14 L. W . Nijboer, "Plasticity as a Factor in the Design of Dense Bituminous R o a d Carpets." Elsevier, Houston, T e x . , 1948.

390 R . N . J . S A A L A N D J . W . A . L A B O U T

In the plane of shear, however, there is not only a shearing stress but also a normal stress. A t plastic deformation of the material this normal stress causes a frictional resistance between the aggregate particles. T h e b o u n d a r y condition for plastic flow can b e derived and m a y b e described as follows:

= (?±±Ξ! tan φ + r . ) c o s φ (18) where φ is related t o the coefficient of friction / between the particles ac-

cording t o φ = arc tan / , and is equal t o the slope of the tangent t o the M ö h r stress circles in Fig. 16.

T h e t w o factors re and φ refer t o the material in a state of equilibrium; n o allowance is m a d e for elastic effects.

T o determine the resistance at flow N i j b o e r withdraws, at a constant rate, a small quantity of the surrounding liquid. Consequently, the stress σζ is reduced and flow occurs in the material at a constant rate of shear. It appears that the stress Σ3 also remains constant at a lower level. B y re- peating this procedure, each time at higher loads, and b y analyzing the results in a M ö h r stress diagram, the resistance of the mixture at flow in relation t o the stress applied can be derived with the aid of the formula

dei 2 Γ Σ Ι — Σ3 / Σ Ι + Σ3 \

1

/ - Ι Γ ΛVm'-rr = 5 : — - — - I — „ — tan φ + re ) cos φ\ (19)

at 3 — s i n φ |_ 2 \ 2 / J

where r\m is a differential viscosity of the mixture.

T h e constants re, φ, and t\m, which are used for the description of the Τ

F I G . 1 6 . M o h r ' s diagram of stresses in triaxial shear test

rheological behavior of the asphalt compositions at plastic deformation, have been derived b y N i j b o e r at stresses σι > 5 Χ 1 06 d y n e s / c m .2.

In this system the material is considered t o be a B i n g h a m material with a yield stress dependent u p o n stress conditions. T h i s naturally implies a cer- tain idealization, so that the values of re and v\m are somewhat dependent u p o n experimental conditions. A s with m a n y other materials, the intro- duction of a yield stress, however, is a v e r y convenient form of description of the properties of the material, so that the m e t h o d can be considered suitable for engineering purposes and for obtaining a fundamental idea of the behavior of asphalt compositions at plastic deformations.

2. RH E O L O G I C A L PR O P E R T I E S O F AS P H A L T -MI N E R A L AG G R E G A T E MI X -

a. Influence of the Mineral Aggregate Concentration

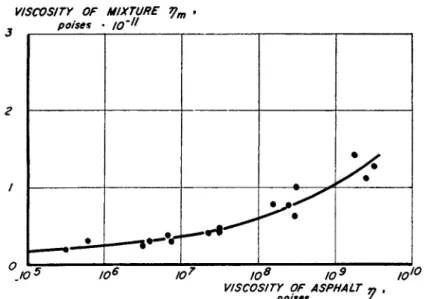

(1) Dynamic Investigation at Short Loading Times. T h e stiffness of as- phalt-mineral aggregate mixtures depends on the stiffness of the asphalt and the v o l u m e ratio of asphalt t o aggregate. W h e n considering mixtures in which the asphalts h a v e the same stiffness, the influence of the v o l u m e concentration of the aggregate can be derived from Fig. 17.

In this figure the stiffness of various mastics has been plotted as a func- tion of the concentration b y v o l u m e Cv of mineral aggregate. T h e s e mastics h a v e been prepared using t w o different asphalts and the measurements h a v e been carried out at such a temperature and time of loading that the t w o asphalts show the same stiffness, viz., 2 Χ 1 010 d y n e s / c m .2. T h e mineral aggregate consists of filler (particle size < 7 4 μ) and sand (particle size from 74 μ t o 2 m m . ) . It will be seen that the ratio b y v o l u m e of asphalt t o mineral aggregate is the only important factor. In these compositions the nature and the particle size of the mineral have n o influence on the stiffness of the mixture; in spite of the variations in particle size and grading of the mineral (filler, sand, and mixtures of these) all the points practically lie on a single curve. Only at high aggregate concentrations (ca. 8 0 % v o l u m e and higher) is some influence of the grading of the aggregate mixture and the corresponding variations in v o i d a g e observed. T h e stiffnesses m a y differ here b y a factor of 2.

F o r mineral aggregate concentrations u p t o a b o u t 25 % v o l u m e the rela- tion between stiffness and concentration m a y be expressed b y means of an empirical equation developed b y Eilers and V a n D i j c k :1 5

T U R E S

(20) where m and a refer t o mixture and asphalt, respectively.

*5 H . Eilers, Kolloid-Z. 97, 313 (1941).

392 R . N . J. S A A L A N D J. W . A . L A B O U T

MINERAL AGGREGATE ASPHALT MINERAL AGGREGATE PEN/25°C TEMP R8B PL

Δ

y

0

•

• •

QUARTZ FILLER 1 LIMESTONE FILLER. L SAND \ QUARTZ FILLER +

SAND

J3 "C

66 '2.3

Δ

y

0

•

• • SAND ] QUARTZ FILLER* >

SAND J 13 54 -2.6 STIFFNESS OF MIXTURE,

dynes /cm

2I I I EQJI8) i

Ο 02 0.4 06 0.8 I VOLUME CONCENTRATION OF

AGGREGATE, C

vF I G . 1 7 . R e l a t i o n between stiffness of mixture and v o l u m e c o n c e n t r a t i o n of min- eral a g g r e g a t e .5

F o r v e r y l o w concentrations this equation changes into Einstein's for- mula as follows:

^ = 1 + 2.5C, (21)

Va

A t high concentrations the stiffness of the mixture is limited b y the Y o u n g ' s m o d u l u s of the stone, which is of the order of 2 Χ 1 012 d y n e s /

2

c m . .

T h e influence of the temperature on the stiffness has been ascertained for dense sandsheet mixtures at a frequency of 60 c.p.s. T h i s is illustrated b y Fig. 18. T h e s e sandsheet mixtures contain either asphalts of the elastic

PROPERTIES OF ASPHALTS USED IN THE MIXTURES*

No PEN/25 °C TEMP RSB °C Ρ T.

1 2 3 4

64 20 32 113

46 67 61.5

46

-1.7 + 0.4 + 03 STIFFNESS OF MIXTURES

-ai

10

8 6

10s

* * * *

2 /

\

V \

\

\

\ \

\ «

γ

-40 -20 20 40

TEMPERATURE, 0C F I G. 18. Influence of temperature on stiffness at 60 c.p.s. of sandsheet mixtures containing different asphalts.5

sol t y p e or an asphalt without visco-elastic effects. T h e c o m p o s i t i o n of the mixtures under test is: 78 % weight of sand ( > 7 4 μ - 2 m m . ) , 13 % weight of limestone filler ( < 7 4 μ ) , 9 % weight of asphalt.

(2) Static Investigation at Long Loading Times. Asphalt-mineral aggregate mixtures also containing coarse particles h a v e been examined with the aid of the triaxial test. Using this t y p e of mixtures it is found that under the conditions of the test the concentration as well as the nature of the aggre- gate have an influence on the properties of the compositions. A s in this test,