Processing at Sea and Factory Ships

M O G E N S JUL

Danish M e a t Products Laboratory, Copenhagen, Denmark and Danish M e a t Research Institute, Roskilde, Denmark

I. Introduction 437 A. Perishability of Seafoods 437

B. Triple Purpose of Fishing Craft 439 II. Preserving and Processing the Catch on Board 440

III. Technical Considerations 441 A. Working Space 441 B. Carrying Capacity 441 C. Fishing Factory Ships 443 D. Capacity of the Processing Equipment 443

E. Water Supply 444 F. Ice Supply 444 G. Operating in a Rough Sea 444

H. Transfer of Catch on the High Sea 445

I. Unloading 447 J. Maintenance 447 K. Quality of Product 447

L. Speed 449 IV. Some Economic and Social Considerations 449

A. Wages and Accommodations 449 B. Working Conditions 450 C. Future Operations 450 D. Factory Ships or Shore Bases 451

V. Experience in Preservation and Processing at Sea 451

A. Salting Aboard 451 B. Floating Canneries 453 C. Freezing at Sea 456 D. Utilization of Waste Fish and By-products Aboard 466

VI. Summary 467 References 470 I. Introduction

A. P E R I S H A B I L I T Y O F S E A F O O D S

As was pointed out b y A. W . Anderson at the first Interna

tional F i s h i n g G e a r Congress (Kristjonsson, 1 9 5 9 ) , fish and other sea

foods are a m o n g the most perishable of all foodstuffs. This is a matter of minor concern to the fishermen in inshore fisheries, w h e n the fish is

437

4 3 8 M O G E N S J U L

kept aboard for only a few hours or, at the utmost, for a few days and where the catch m a y b e preserved in ice until the craft has returned to port.

Efforts to improve this means of preservation, b y the use of chilled sea water, nitrite, antibiotics, etc., h a v e not succeeded in bringing about any substantial extension o f the keeping time of fresh fish aboard ships, and there are today several types of fishery where this system of preserva

tion aboard is insufficient. S o m e are listed below.

1. No Shore Facilities

In many parts of the world, e.g., the Antarctic, Greenland, and the North Pacific, fishing m a y b e carried out close to shores w h e r e no process

ing facilities exist. E v e n where they exist, they m a y b e far away from population centers and the processed product must b e carried long distances to consuming centers.

2. Short Seasons

M a n y types of fishery, e.g., the Alaskan salmon industry and herring fishing in the North Atlantic, are so highly seasonal that it is difficult to make a shore installation profitable b e c a u s e of the short period of e a c h year in which it can b e kept in operation.

3. Operations on the High Seas

A fishery m a y often b e conducted far from any shore and therefore necessitate transport over considerable distances. This is the case, for instance, in t h e traditional British distant-water trawling industry. H e r e trips m a y b e up to 2 4 0 0 miles to and from the fishing grounds and the trawlers spend about 9 days running b a c k and forth and only 9 days fishing.

4. Depleted Stocks, etc.

Fishing communities in E n g l a n d , N e w E n g l a n d , and J a p a n experience difficulties b e c a u s e stocks in nearby waters have b e c o m e depleted, so fishing can b e extended only b y exploiting grounds far from the h o m e ports. S o m e countries, such as G r e e c e , Italy, Japan, Spain, the Soviet Union, the United Kingdom, and the United States, have a n e e d for fish that greatly exceeds even the m a x i m u m supply from n e a r b y waters. Fish, then, must b e obtained b y imports or b y fishing operations far from the h o m e ports.

I n all these instances, there is considerable interest in means of pre

serving the catch in a nonperishable form aboard.

One other solution exists, of course, in that the fish m a y b e kept aboard alive. I n most fisheries, this is not possible b e c a u s e the fish are

dead w h e n taken a b o a r d or have b e e n fished at such depths that they cannot survive the c h a n g e in pressure. Besides, live tank storage is space- consuming and m a y affect the stability of the craft. Y e t F r a n c e in 1 9 6 0 h a d a total of 8 3 boats with live tanks ( F A O , 1 9 6 1 ) .

I n r e c e n t years, further interest in processing a b o a r d has existed b e cause an increasing share of the world's c a t c h is b e i n g processed anyway.

F A O ( 1 9 6 3 ) indicates that direct consumption o f fresh fish increased from 12.2 million tons in 1 9 5 5 to 16.0 million tons in 1 9 6 2 . I n the same period, the amount of fresh fish used for preservation or other processing increased from 14.1 million tons to 28.7 million tons. I f the fish is to b e processed anyway, this m i g h t as well, in m a n y instances, take p l a c e on the fishing grounds.

B . T R I P L E P U R P O S E O F F I S H I N G C R A F T

I n traditional fishing operations, the fishing craft serves three pur

poses, ( 1 ) c a t c h i n g fish, ( 2 ) carrying the crew and the catching equip

m e n t to and from the fishing grounds, and ( 3 ) transporting the c a t c h to port. This means that the craft must have substantial fish-carrying capacity and, even though i c e is generally used for preserving t h e catch, must b e fast in order to b r i n g the fish b a c k to port in a reasonably fresh condition. T h i s implies that the design of the craft is a compromise b e t w e e n these functions, w h i c h often results in considerable adjustments.

T h e n e e d for a q u i c k return to port with the c a t c h has greatly influenced the design of craft, especially trawlers; for example, some of the latter are equipped with double the p o w e r n e e d e d to handle the trawl. E v e n then, a return to port m a y often b e necessary before the holds are full in order that the c a t c h m a y b e delivered while still in good condition.

T h e r e is, therefore, in some fisheries a considerable interest in separat

ing these functions, i.e., m a k i n g fishing craft that will b e efficient catch

ing craft and fish-transport vessels to carry the c a t c h and supplies b e tween the fishing grounds and the port. Another solution lies in preserving the c a t c h at sea in order that fishing m a y continue until the holds are full.

T h e former solution was e m p l o y e d when, m a n y years ago, use was m a d e in E n g l a n d of a fish-transport service to and from trawlers operat

ing in the North Sea. T h e vessel transported supplies to t h e trawlers and fish from them. This method, referred to as "fleeting," was standard use for trawlers fishing out of Hull, E n g l a n d , up to about 1930. ( S e e also V o l u m e I I , C h a p t e r 1, pp. 2 1 - 2 2 . ) Similarly, t h e J a p a n e s e sometimes use three vessels in pair trawling operations. T h e y are rotated in such a fashion that two are constantly fishing while t h e third is on its w a y to and from port.

4 4 0 M O G E N S J U L

C o m p l e t e separation of functions occurs in Antarctic whaling expedi

tions w h e r e the whalers are catching ships exclusively, while a mother- ship, i.e., the whale factory ship, supplies the whalers and does all the processing and most of the transporting of the catch. Besides, c o m m e r c i a l freighters carry fuel and other supplies to the factory ship and w h a l e oil and meal b a c k to port, while the factory ship remains on the whaling grounds for the full season.

II. Preserving and Processing the Catch on Board

T h e above indicates that in m a n y fisheries there exists a great n e e d for preserving or processing the c a t c h aboard. Traditionally, this has b e e n done for centuries in the North Atlantic ground fishing and the I c e l a n d i c herring fisheries. Ships from F r a n c e , Portugal, and Spain have salted the catch of cod-like species obtained off Newfoundland and Greenland

FIG. 1. Diagram of the various arrangements for fishing and fish processing.

1: Fishing vessels. 2: Long-distance trawlers equipped for freezing the catch. 3:

Motherships operating under their own power on the high seas. 4: Motherships installed on scows, etc., not able to navigate on the high seas. 5: Transport vessels equipped for serving a fishing fleet by taking the iced catch to a not too distant harbor. 6: Transport vessel for taking a processed catch from a mothership to a port.

7: Ordinary transport vessel. 8: Shore bases. 9: Fishing ports. 10: Rail cars (may be refrigerated). 11: Trucks. (After Pavlov, 1956.)

aboard. T o d a y , further development has taken p l a c e in this field and large-scale long-distance fishing m a y soon rely entirely on processing the c a t c h aboard.

Several approaches to the problem have b e e n outlined b y Pavlov ( 1 9 5 6 ) . T h e various arrangements for fishing and handling are illustrated in F i g . 1.

All of the a b o v e m e n t i o n e d solutions are used. I t appears that the main possibilities lie in the fields of self-contained fish-processing ships and in motherships operating with a fleet of fishing boats, b o t h at times supported b y transport vessels.

Over the years, m u c h interest has b e e n shown in schemes for process

ing the c a t c h at sea. Yet, until recently, few fisheries were b a s e d on processing at sea. This is due to the fact that such processes generally are difficult to operate, especially w h e n they require a large processing crew and expensive processing installations. Therefore, m u c h experi

mentation and experience are n e e d e d b e f o r e such an operation can b e c o m e efficient. In the years following W o r l d W a r I I , m u c h progress has b e e n m a d e in some of these fields, and referred to at the S e c o n d W o r l d F i s h i n g G e a r Congress, London, 1 9 6 3 . Considerable information on the subject is also given in V o l u m e I I , C h a p t e r 19, Section V I .

Problems in factory ship operations have b e e n discussed b y Anderson ( 1 9 5 1 ) , Birkhoff ( 1 9 5 6 ) , H a r d y ( 1 9 4 7 ) , J u l ( 1 9 5 4 ) , Kuprianoff ( 1 9 5 6 ) , Nickum ( 1 9 5 5 ) , Pavlov ( 1 9 5 6 ) , R a n k e n ( 1 9 6 1 ) , and T r a u n g ( 1 9 5 5 , 1 9 6 0 ) . Considerable information on the subject has b e e n assembled b y the F o o d and Agriculture Organization of the United Nations and pre

sented at the First and S e c o n d International F i s h i n g B o a t Congresses, Paris and M i a m i , 1 9 5 3 , and R o m e , 1 9 5 9 .

III. Technical Considerations

A. W O R K I N G S P A C E

A difficulty in designing a floating fish factory is that of getting sufficient space. S p a c e is required for processing machinery, insulation of refrigerated holds, quarters for factory personnel, etc., as well as for storage of fish and materials before and during processing. In the earliest Soviet freezer motherships ( F i g . 2 ) m u c h space was set apart for inci

dental storage during processing, one of the factors often overlooked.

B . C A R R Y I N G C A P A C I T Y

In processing at sea the fish m a y b e dressed or filleted aboard, thus saving storage space. M a n y years ago attempts w e r e m a d e in N e w E n g l a n d to increase the catching capacity of trawlers b y filleting and

2 Ο Ο Μ 2 el FIG. 2. "Neveljsk," one of the earlier-type Soviet fish-freezing motherships. 9: Air-blast freezer tunnel with tracks for freezer trucks. 10: Air circulation fan. 11: Freezer coils. 12 and 15: Fish dressing and filleting sections. (After Pavlov, 1956.) Only call- outs that involve fish processing have been identified. Length of the ship is scaled in meters.

icing the c a t c h aboard. T h e system proved i m p r a c t i c a b l e b e c a u s e the ship would h a v e to stay at sea so long that the early part of the c a t c h would not keep.

T o use the extra space, the c a t c h must, therefore, b e preserved.

Processing facilities, insulation, etc., may, however, take up so m u c h space that storage capacity is little increased. W h e n a large N e w E n g l a n d trawler, the "Cormorant," was converted into the freezer trawler " O c e a n - life" it was found that the vessel w h i c h previously would carry about 2 5 0 tons of i c e d fish would carry only about 9 0 tons of frozen fillets, cor

responding to about 2 7 0 tons of fresh fish, after conversion ( T r a u n g , 1 9 5 5 ) .

T o d a y , the improved processing m a c h i n e r y and the increasing use of ships originally designed for factory ship operations have helped to solve this problem. I t should also b e k e p t in m i n d that wet-fish ships often m a y not utilize their full carrying capacity b e c a u s e of the n e e d for a q u i c k return to port.

C . F I S H I N G F A C T O R Y S H I P S

W h e n a ship is to b e used for fish-processing purposes, it is generally necessary to have m o r e covered space in the upper parts of the ship than on ordinary fishing craft. T h i s is difficult without reducing its value as a fishing ship. I n one attempt to o v e r c o m e this, the G e r m a n trawler

"Hans P i c k e n p a c k " was built with a half shelter deck on the port side.

T h i s leaves enough space for handling the trawl. W i t h a full shelter deck, handling t h e trawl was previously considered difficult, b u t experi

e n c e with the G e r m a n research vessel "Anton D o h r n " indicates that it is b y no means impossible. G o o d results on F r e n c h trawlers equipped with an almost full shelter d e c k are reported b y Gueroult ( T r a u n g , 1 9 6 0 ) .

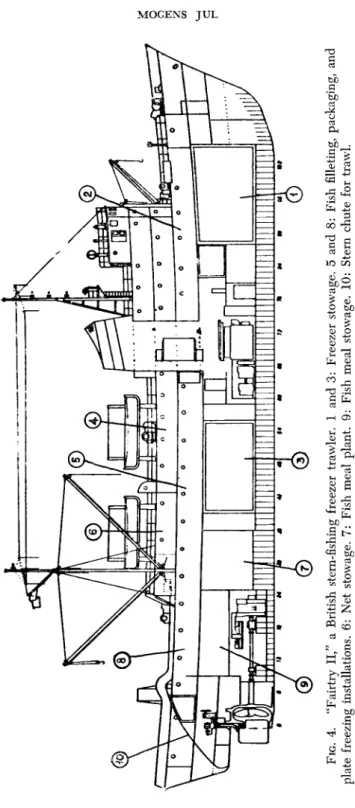

Since a fishing craft is generally very efficiently adjusted to the use to w h i c h it is put, any shift of its functions, e.g., from effective c a t c h e r and fast transport to fishing and freezing, is likely to require radical changes in design, as with t h e stern-fishing freezer trawlers o f the

"Fairtry" type d e s c r i b e d below. An exception is, o f course, the case w h e r e the processing is extremely simple and little or no extra space is required for it. This is the c a s e in the tuna clipper and purse seiner operations described below.

D . C A P A C I T Y O F T H E P R O C E S S I N G E Q U I P M E N T

British trawler operations have b e e n m u c h studied in connection with schemes for processing fish at sea. A British trawler catches up to 6 tons of fish per drag. O n an ordinary trawler, it would b e practically im-

4 4 4 M O G E N S J U L

possible to provide for processing machinery and a processing crew that would b e able to handle the m a x i m u m average catch. Unless entirely n e w designs are employed, it is therefore necessary to have buffer storage facilities for fish p a c k e d in i c e for 1-3 days' catch. T h e n processing capacity n e e d b e only 0.5 ton of fish per hour. T h u s , it is not always possible to process the fish immediately after it is taken aboard. A c c o r d ing to the W h i t e F i s h Authority ( 1 9 5 7 ) and E d d i e ( 1 9 5 9 ) , this extra storage involves little extra handling and the freezer hands generally have time left for this work. Most stern-fishing freezer trawlers of W e s t e r n G e r m a n y are equipped for freezing only part of the catch, the remainder b e i n g iced in refrigerated holds.

E . W A T E R S U P P L Y

W a t e r supply used to b e an important problem for processing-at-sea operations. Canning, in particular, requires large amounts of fresh water.

T h e first freezing aboard operations w e r e used in Russia in 1 8 8 0 w h e n freezing e q u i p m e n t was installed in barges on the Volga. T h e y probably used river w a t e r for processing. S o m e United States floating canneries obtain fresh w a t e r from the coast on special barges and are thus in

capable of operating on the high seas.

Today, most factory ships rely on e q u i p m e n t for distilling sea water.

Thus, a . S o v i e t fish-canning ship, the "Andrei Zakharov" described b y Vershinin ( 1 9 6 1 ) , carries two v a c u u m condensers with an output of 9 tons per hour w h e n working in series and 12 tons per hour w h e n working in parallel. E v e n then, the ship relies on air cooling of the heat-processed cans. This is not always desirable since it m a y result in slow cooling and overcooking o f the product. T h e "Vitus B e r i n g " referred to b e l o w has equipment for producing 2 0 tons of fresh water a day from sea water.

F . I C E S U P P L Y

R a n k e n ( 1 9 6 1 ) feels that factory ships must carry their own ice- making plant. T o d a y , various kinds of scale i c e machines are used for this purpose. T h e y are well suited for making almost salt-free i c e from sea water: the i c e crystals are collected on the ice making cylinder and the salty nonfrozen water is discharged continuously. T h e "Vitus B e r i n g "

can produce 10 tons of ice a day from sea water on such equipment.

G. O P E R A T I N G I N A R O U G H S E A

M a n y machines are difficult to use in a rough sea. This is true of scales, m a n y installations for the manufacture of i c e , etc. Similarly, m u c h refrigeration equipment, e.g., direct-expansion contact plate freezers, does not operate well in a rolling sea. On the other hand, m u c h experience is

available today and even such c o m p l i c a t e d m a c h i n e r y as fish-filleting machines is n o w operated successfully up to wind of B e a u f o r t n u m b e r 8.

Often fear of the motion of the sea has b e e n exaggerated. In the above m e n t i o n e d "Oceanlife," extensive precautions like steel-mesh gloves were introduced to enable the workers to fillet in a rolling sea and to avoid cutting their hands. No special p r o b l e m appeared, however, when the ship b e g a n operating. This might have b e e n anticipated when it is considered that all the fish salted on ships in the North Atlantic are b e h e a d e d , split, etc., in all of t h e weather conditions encountered there.

H. T R A N S F E R O F C A T C H ON T H E H I G H S E A

W h e r e v e r motherships are considered, the problem of transfer at sea appears. I t is likely that motherships found extensive use in whaling operations b e c a u s e t h e transfer of the c a t c h in this case is an easy matter.

T h e w h a l e is simply t o w e d to the factory ship and hauled up through a slipway in the stern.

T h e G e r m a n mothership "Hamburg," which was designed to serve a n u m b e r of trawlers, experienced such difficulties in the transfer at sea that she h a d to stay inside sheltered parts of the Norwegian coast and could not operate at all on the high seas as anticipated.

N i c k u m ( 1 9 5 5 ) gives m a n y valuable suggestions with regard to this question. F l o a t i n g salmon canneries use the ships' normal gear for such operations, b u t generally operate inside sheltered waters off Alaska.

I t was then proposed that one m a k e use of the experience o f the whaling factories and that the trawler's c a t c h b e cleaned, gutted, and p l a c e d in a large net b a g to b e picked up later b y the mothership.

Birkhoff ( 1 9 5 7 , 1 9 5 8 , 1 9 5 9 ) suggested instead the use of special de

t a c h a b l e n e t bags ( t h e cod end and lower part of the t r a w l ) for deposit

ing the c a t c h in the high seas. T h e net b a g was to b e d e t a c h e d after e a c h haul and left in the sea with large r u b b e r floats easy to locate on the mothership's radar. A small automatic radio transmitter m a y also b e used.

This m e t h o d is similar to a principle used for m a n y years b y t h e J a p a n e s e , except that they generally tow the n e t b a g s to motherships inside sheltered waters. According to Birkhoff (Kristjonsson, 1 9 5 9 ) , the system has b e e n tested in the North Atlantic b y the G e r m a n research vessel

"Anton D o h m " and is b e i n g used nowadays b y British, German, and Soviet ships. Birkhoff ( T r a u n g , 1 9 6 0 ) states that even after 6 hours of drifting, the fish was in good condition. Extensive experiments b y the Torry R e s e a r c h Station proved the m e t h o d to b e entirely practicable, and such transfer "sausages" are n o w in frequent use. Motherships such as the "Vitus B e r i n g " even have a stern slip for taking the n e t b a g s aboard.

T h e bags are fitted with radar deflectors to aid in their location.

4 4 6 M O G E N S J U L

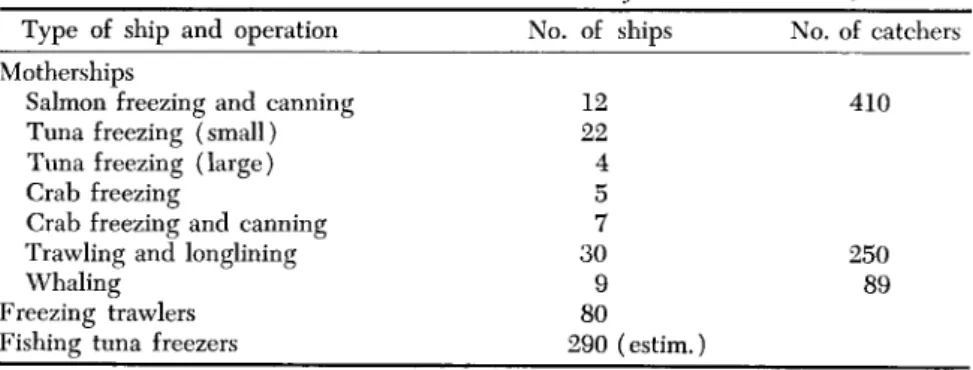

Type of ship and operation No. of ships No. of catchers Motherships

Salmon freezing and canning 1 2 4 1 0 Tuna freezing (small) 2 2

Tuna freezing (large) 4

Crab freezing 5

Crab freezing and canning 7

Trawling and longlining 3 0 2 5 0

Whaling 9 8 9

Freezing trawlers 8 0

Fishing tuna freezers 2 9 0 (estim.)

« After Sh. Takayama ( 1 9 6 2 ) .

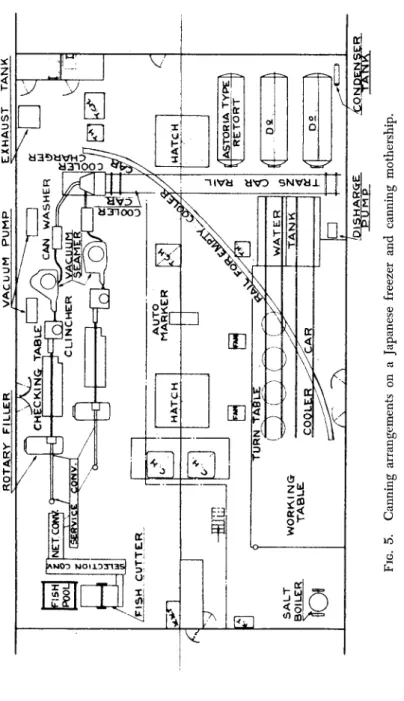

T a b l e I indicates the very extensive use in the J a p a n e s e fisheries o f mothership and catcher boats, all processing b e i n g b a s e d on transfer of the catch on the high seas. A J a p a n e s e mothership is shown in F i g . 3.

FIG. 3 . "Miyazima Maru," a Japanese freezer and canning mothership. 1: Salt stowage. 2 : Salted fish. 3 : Freezer stowage. 4 : Freezing rooms. 5 : Canning deck.

For layout of canning section, see Fig. 5 . (After Sato, 1 9 6 0 . )

I n the spring and summer, J a p a n e s e motherships operate with the salmon fleet in the North Pacific. H e r e about 3 0 catcher boats of about 50 gross tons serve each mothership. T h e y move in pairs into the leeway and are moored to the mothership. T h e c a t c h is then transferred in large baskets. T h e rest of the year some of these ships engage in similar operations with the tuna fleet, while others are in use as refrigerated transport vessels.

Problems of transfer at sea seem to have b e e n solved b y J a p a n and the Soviet Union.

TABLE I

USE OF MOTHERSHIPS AND PROCESSING AT SEA IN JAPANESE FISHERIES, 1 9 6 1 «

O n e other case w h e r e the difficulties involved in the transfer of the catch at sea have b e e n solved is the dory fishing operations described below.

Mothership schemes have m a n y advantages. O n e n e e d not design a vessel for both catching and processing and the vessel can rely on several catchers for the supply of fish, thus having a b e t t e r c h a n c e of always operating near full capacity. Nevertheless their use implies transfer of the catch at sea. Harper G o w (Fishing News, 1 9 5 9 ) indicates that at least Chr. Salvesen & Co. did not consider mothership operations an economic proposition for the U n i t e d Kingdom. Y e t t h e "Fairtry I F ( s e e F i g . 4 ) has operated with the conventional British trawler "Ross Hunter"

transferring the catch at sea. This was accomplished b y detachable cod ends.

I. U N L O A D I N G

M i n n e e ( 1 9 6 2 ) has called attention to the n e e d for provisions for mechanical unloading of factory ships. Systems for this h a v e b e e n in

corporated into two recently built stern trawlers, t h e D u t c h " E g m o n t "

and the British " L o r d Nelson."

J . M A I N T E N A N C E

U p k e e p is a special problem on a factory ship since sea w a t e r and the high salt content of the air cause considerable corrosion. This is particularly true for ships operating in the tropics.

K. Q U A L I T Y O F P R O D U C T

I t is generally assumed that fish processed at sea is superior in quality to that processed ashore. However, a shore factory has available the total fish landings in the vicinity and m a y purchase exactly that part of it which is most suitable for processing. T h e floating factory, on the other hand, must use whatever has b e e n caught and has little choice with regard to the type of fish to b e processed. J a p a n e s e fish-freezing ships, however, m a y occasionally transfer the cheaper fish in the catch to reduction ships a c c o m p a n y i n g the fleet. J a p a n e s e ships operating off W e s t Africa also dispose of most of their c a t c h locally, while shipping frozen sea b r e a m to J a p a n w h e r e this fish commands high prices.

M a n y types of fishing factory ships use buffer storage in ice. T h i s m a y b e advantageous up to 1 2 hours for white fish. S o m e filleting machines have difficulties in working with pre-rigor fish. Pre-rigor freezing gives a fish of at least as good quality as post-rigor freezing except that w h e r e it is used for reprocessing ashore the defrosted flesh m a y have a slightly pinkish color to which the trade must first b e c o m e accustomed ( H a r p e r

FIG. 4. "Fairtry II," a British stern-fishing freezer trawler. 1 and 3: Freezer stowage. 5 and 8: Fish filleting, packaging, and plate freezing installations. 6: Net stowage. 7: Fish meal plant. 9: Fish meal stowage. 10: Stern chute for trawl.

448 MOGENS JUL

Gow, 1 9 5 9 ) . I t disappears in cooking. E d d i e ( 1 9 5 9 ) and Siavin ( T r a u n g , 1 9 6 0 ) agree that pre-rigor frozen fish is fully as a c c e p t a b l e as other fish.

However, E d d i e ( 1 9 5 9 ) is not c o n v i n c e d that pre-rigor frozen fish is suitable for direct retail sale. O n the other hand, such fish has b e e n frozen and exported from D e n m a r k as high-quality items for m a n y years. ( S e e further C h a p t e r 9, this v o l u m e . )

F r e e z i n g fish aboard in bulk originally caused some trade resistance.

B o t h F r e d Parkes and Heinsohn ( T r a u n g , 1 9 6 0 ) reported lower prices for such fish. On the other hand, such fish is preferred over the wet-fish in G r e e c e and the Soviet Union a n d consumer p a c k a g e d fish enjoys general popularity in most countries today w h e n distribution systems are adequate. Thus Chr. Salvesen & Co. originally filleted about 3 0 % of the c a t c h on t h e "Fairtry" series, b u t later switched t o filleting almost the whole c a t c h ( T r a u n g , 1 9 6 0 ) .

I n fact, problems of quality m a y very well necessitate processing at sea for m a n y fisheries in the future. It is likely that consumers will prefer sea-processed fish in the long run, even at an increased cost, over fish that has b e e n on ice for several days or even weeks prior to processing or cooking.

Reports from J a p a n e s e fish m e a l operations in the North Pacific stated that completely fresh herring gave a fluffy m e a l difficult to store. T h i s was remedied b y letting the fish remain on deck 2 4 hours prior to processing.

L . S P E E D

E d d i e (Kristjonsson, 1 9 5 9 ) discussed the possibility of decreasing the speed of factory trawlers w h e r e a q u i c k return to port is no longer required.

T h e saving in engine room could b e used for additional processing and freezing installations. This p r o b l e m is also discussed b y B o g u c k i and Swiecicki ( 1 9 6 1 ) . T h e y find that for Poland, at least, high speed is a great satisfaction for the crew and enables the vessel to r e a c h profitable fishing grounds ahead of other vessels, factors to which m u c h importance must b e attached.

IV. Some Economic and Social Considerations

A . W A G E S AND A C C O M M O D A T I O N S

Processing aboard a ship m a y involve considerable extra expense. T h e processing crew must b e paid from the time the craft leaves port until it returns, regardless of w h e t h e r there is fish to process or not. I n addition, quarters and meals must b e provided for the crew, also a high expense in comparison with shore operations. This means that factory ships have to rely very heavily either on fish-processing methods that are simple

4 5 0 M O G E N S J U L

and do not require m u c h hand labor, or on machines. This applies especially in areas with high labor costs. T h e remarkable development in recent years of fish-filleting machines, etc., some of w h i c h are described b y Schenck ( 1 9 5 8 ) and Kaufmann and T h i e r n e ( 1 9 5 8 ) , m a y contribute m u c h to improving the outlook for factory ship operations.

E x p e r i e n c e with having a large crew at sea for longer periods is reported from the operations of the "Fairtry" series. T h e s e ships make trips of up to 100 days' duration as opposed to 18 for the ordinary British distant-water trawler. S o m e fishermen reacted unfavorably to this com

paratively long stay at sea, although most soon b e c a m e accustomed to it and preferred the superior quarters and higher earning possibilities offered on the "Fairtry" (Fishing News, 1 9 5 9 ) . E v e n here, their stay away from home port is m u c h shorter than on many m e r c h a n t ships. F r i d m a n ( 1 9 5 9 ) states that, out of consideration for the crew, it is the opinion in the Soviet Union that a single fishing trip should not e x c e e d 9 0 days.

T o d a y many factory ship schemes exist w h e r e b y fishermen stay at sea for extended periods.

B . W O R K I N G C O N D I T I O N S

In long established fishing or processing-at-sea operations the crew m a y accept, out of habit and tradition, working conditions that m a y not otherwise seem acceptable. A case in point is dory fishing, especially where one-man dories are used as described below. Villiers ( 1 9 5 1 ) concludes, " I f fishing b y dory were a n e w industry there would b e no dory men."

C . F U T U R E O P E R A T I O N S

It is not unlikely, therefore, that the very considerations described above may, in the future, tend to encourage the use of processing at sea and factory ships. A fishery as described b y Villiers ( 1 9 5 1 ) seems so hazardous and hard that it cannot go on m u c h longer. Similarly, even on a modern trawler the crew m a y b e exposed to rough climate and some

times hazards during their work. It is likely that such ventures as the

"Fairtry," "Heinrich Meins," "Pushkin," and others described b e l o w will provide better working conditions. O n these, for instance, fishermen m a y set and haul the trawl with comparatively little hand labor. O n c e the catch is aboard, it is led down to the deck below. F r o m then on, all operations take place under shelter. T h e accommodations for the crew are as good as on modern commercial ships. O n t h e "Vitus Bering," one of a series of Soviet fish-freezing motherships recently built in Denmark, the crew accommodations are in every respect comparable to those on any modern commercial vessel.

A similar trend is seen, of course, in the development of ordinary fishing vessels, e.g., the latest trawlers and tuna purse seiners.

D . F A C T O R Y S H I P S O R S H O R E B A S E S

F r o m what has b e e n indicated above, it appears that shore processing is more e c o n o m i c than sea processing w h e n n e a r b y resources that are not too seasonal can b e used. M a n y fishing nations, therefore, endeavor to establish shore bases, e.g., J a p a n near British B o r n e o and m a n y other places in the Pacific, in the Indian O c e a n , on T i e r r a del F u e g o in the South Atlantic, in the C a r i b b e a n , in the C a n a r y Islands ( s e e V o l u m e I I , Chapter 19, Section V ) , the Soviet Union in t h e Kuril Islands, Poland b y renting a pier of the Cuxhaven fishing port, etc. O t h e r countries h a v e done similarly b y establishing shore bases in Alaska, Greenland, and Spitzbergen.

V. Experience in Preservation and Processing at Sea

S o m e fisheries l e n d themselves to processing at sea, such as salting cod at sea or tuna fishing; in others, sea processing has b e e n adopted after m a n y years of trial and error.

A. S A L T I N G A B O A R D

T h e p r a c t i c e of salting a b o a r d has b e e n followed for m a n y years.

Villiers ( 1 9 5 1 ) believes that the Portuguese salting-at-sea operations have b e e n carried out since before the discovery of America. I t is known that the Portuguese schooner owners formed a guild in 1 5 0 2 .

About 4 5 ships with 3 0 0 0 fishermen a b o a r d start out from L i s b o n around the b e g i n n i n g of April for fishing grounds on the G r a n d B a n k s and off Greenland. M o s t of the ships are sailing schooners with auxiliary engines.

T h e ships p r o c e e d first to Newfoundland, w h e r e they take on herring and other bait. F i s h i n g is carried out from dories—flat-bottomed one-man boats that can b e stacked six high on the decks of t h e schooners; a schooner normally carries about 6 0 such dories. T h e entire operation is extremely arduous as well as hazardous. As recently as the 1 9 5 8 season no less than five of the Portuguese motherships were lost in the Newfound

land operations.

W e a t h e r permitting, the dories are l a u n c h e d at dawn. E a c h m a n fishes all day from t h e dory. L a t e in the afternoon t h e y return to the schooner w h e r e the catch and t h e dories are taken a b o a r d and t h e fishermen b e g i n processing the fish.

T h e splitting and washing of the fish are carried out on the deck

4 5 2 M O G E N S J U L

where permanent tables are set up for that purpose, and small truck cars are used for transporting the fish to the salting barrels.

E a c h Portuguese schooner returns with 6 0 0 - 1 1 0 0 tons of salted cod, according to the size of the ship.

Operations similar to the Portuguese are carried out b y Spanish ships;

there are also Canadian and F r e n c h dory operations, b u t they generally rely on two-man dories. Villiers ( 1 9 5 1 ) indicates that in 1 9 5 0 t h e r e w e r e 13 motor ships from Newfoundland fishing with two-man dories on the G r a n d Banks. In general, however, the trend seems to b e to build salting trawlers as has b e e n done already b y m a n y countries, including Portugal.

T h e r e is some doubt as to w h e t h e r salting aboard will continue to the extent to which it has existed to the present. M a n y modern trawlers therefore are built so that conversion into wet-fish landing or even freezing is possible. As an indication of the present stage, it m a y b e mentioned ( F A O , 1 9 6 1 ) that in 1 9 6 0 F r a n c e h a d 3 1 salting trawlers, 1 4 6 1 wet-fish trawlers, and 2 freezer trawlers. R e c e n t F r e n c h freezer trawlers such as t h e "Colonel Pleven Π " are equipped for freezing one-third and salting two-thirds of the catch. T h e " M a r c e l i n a de Cirizia," a 297-ft. stern trawler, is e q u i p p e d mainly for salting.

Another matter is the salting of herring and herring-like species aboard. T h e y are highly perishable fishes and cannot b e i c e d for sub

sequent salting ashore w h e r e the trip b a c k to port lasts m o r e than about 1 day. F r e e z i n g herring is not desirable, and salting aboard will p r o b a b l y continue to b e important. T o d a y it is carried out especially b y the Netherlands and Sweden. T h e s e countries rely mainly on salting aboard the fishing vessel. M i n n e e ( 1 9 6 1 ) has described studies on D u t c h trawlers. T h e working procedure is somewhat time-consuming b u t space limitations on the deck hardly permit m u c h improvement. T h e solution m a y b e the adoption of a stern trawler of which a prototype is n o w b e i n g built in the Netherlands. I t is to b e equipped with a conveyor b e l t for transporting and sorting the catch.

F i s h i n g expeditions from the Soviet Union, in particular, rely mainly on motherships for herring-salting operations. I t is reported that in a recent year the Soviet Union h a d a thousand vessels e n g a g e d in herring operations on the banks off southwestern Norway. A m o n g t h e m w e r e a n u m b e r of motherships of which one, the "Iokhannes Vares," is reported to have operated there for 3 months, processing 1 7 0 0 metric tons of herring and servicing 1 0 0 fishing vessels. I t seems that the Soviet Union m a y switch to freezing part of this herring catch. ( B o r g s t r o m , 1 9 6 1 ) . In the beginning of 1 9 6 2 , 14 freezer trawlers from the Soviet Union were catching herring on Georges B a n k in the North Atlantic. T w o salting motherships, the "Kaszuby" and the "Pulaski," b o t h reconverted cargo

ships, w e r e in 1 9 6 2 operating with the Polish fishing fleet in the North Sea.

Staszewski ( 1 9 5 9 ) describes t h e "Sveyrodvinsk," w h i c h had just b e e n c o m p l e t e d in Poland for the Soviet Union. She is said to b e the world's first ship built as a mothership to service a fleet of herring-fishing craft. She has a c r e w of 2 6 0 persons and a total storage capacity of 10,000 cu. m. of refrigerated holds.

Terent'eva ( 1 9 5 8 ) describes a series of motherships for herring fishing under construction in the Soviet Union. T h e y are referred to in V o l u m e I I , Chapter 19, Section V I , E . I n addition, the Soviet Union is said to have ordered in Poland a herring mothership with a stern ramp for bringing aboard catches in detachable cod ends.

B . F L O A T I N G C A N N E R I E S

F l o a t i n g canneries are known mainly from the northern Pacific. Most of the n e w J a p a n e s e motherships referred to above are e q u i p p e d with salmon-canning lines ( F i g . 5 ) very similar to those in use in shore plants, e.g., in Alaska. I n recent years J a p a n is reported to have a total of 12 salmon-canning motherships operating in the area around the Aleutian Islands ( s e e also T a b l e I ) .

T h e Soviet Union has a substantial n u m b e r of floating canneries, m a n y of which are e n g a g e d in canning salmon and shrimp in the northern Pacific. All operate as motherships ( s e e further Borgstrom, 1959, 1961a, b ) .

T h r e e fish-canning ships were built in L e n i n g r a d in 1 9 6 0 - 1 9 6 2 as the first of a n e w series of floating canneries. T h e first, the "Andrei Zakharov,"

is described b y Vershinin ( 1 9 6 1 ) . It is equipped for staying at sea for 2.5 months and has a displacement of over 15,000 metric tons. F o r pre

serving the c a t c h prior to canning, it has a scale i c e plant with a capacity of 1 ton per hour and a refrigerating c a p a c i t y for chilling 1.5 tons of sea water and 4.5 tons of brisling per hour. T h e fish is taken a b o a r d b y conventional derricks. I t is said to b e able to carry 10 catcher boats on board to b e l a u n c h e d on the fishing grounds. F u r t h e r data are given in Volume I I , Chapter 19, Section V I , F .

T h e U n i t e d States has a few salmon-canning factory ships operating off Alaska and, in addition, some canning barges that depend on shore facilities.

Canning at sea places h e a v y requirements on specialized m a c h i n e r y and demands a large crew. Besides, as was mentioned, water supply is particularly difficult in canning operations; this m a y b e w h y several countries, especially J a p a n , the Soviet Union, and t h e U n i t e d States, rely more on freezing the raw material at sea for subsequent canning ashore.

^COTTAOtE

454 MOGENS JUL

FIG. 5. Canning arrangements on a Japanese freezer and canning mothership.

ROTARY FILLER VACUUM PUMP EXHAUST TANK X CHECKING TABLE' 1 ΛΛ 1 1 S I ' I 1 pen , Λ I lr—1 1 /Ο CAN WASHER 5 , FISH ζ NET CON^. Η h}j—| μ ΙΟΗ—4*=^-^II>==^L_ yg POOL 8 \ \\ I / CLINCHER WACUUM

Γ ^ΓΊω $ V

ί I I -I z I SERVICE CQNV. 1 ä J SEAM ERX

-'S V /FISH CUTTER J —/ I I * 1 · Γ ι AUTO F-rr, / ι 1 C „ V MARKER V [ J HATCH Π Γ \\ r& HATCH . zSLlL1 | j «ίν '

i /IASTORIA TYPE[\a Β Β .j^ g

βν

RETQRTt

1 <5 TURN TABLE : "<^xl I ^ κ( j ο ο OS »™* : ΕΞΞ 3

SALT WORKING ΤΑΝΚ Ζ BOILER TABLE /O * " < „ κ I'T V 7 ^

IP ^4 5 6 M O G E N S J U L

C. F R E E Z I N G A T S E A

T h e most spectacular development in recent years in factory ship operations has b e e n in the field of freezing aboard ships. F r e e z i n g m a y b e used for bulk products to b e defrosted and sold in the fresh state or used for processing such as canning, smoking, or freezing on land. Insofar as white fish is concerned, the trend seems to b e in the direction of freezing and p a c k i n g the product in consumer size packages on board.

Contributing to this has b e e n the fact that fish handling, filleting, skinning, and freezing equipment has developed very rapidly and has b e c o m e very reliable even when operated in rough seas. A measure of the development m a y b e seen in the fact that the Soviet Union had, according to Rutov ( 1 9 5 9 ) , a total of over 3 0 0 freezer ships in 1 9 5 8 and her capacity for freezing at sea considerably e x c e e d e d that for freezing on land. Since then, m a n y freezer ships have b e e n added to the Soviet fleet (for further information see Borgstrom 1 9 5 9 , 1961a, b ; Hardy, 1 9 6 1 ; and Kassell, 1 9 6 1 ) . J a p a n reports having 8 0 freezer trawlers in 1 9 6 1 ( T a k a - yama, 1 9 6 2 ) . ( F o r m o r e recent developments, see also Borgstrom, 1964a, b . )

M u c h thought has b e e n given to the various methods of freezing at sea. Zimmerman ( 1 9 6 0 ) and R a n k e n ( 1 9 6 1 ) have compared the three methods of freezing fish at sea. Apart from tuna, w h i c h is discussed in detail below, it is the general impression that brine freezing m a y result in fish of somewhat inferior quality. C o n t a c t plate freezers o f the vertical kind, as developed in the United K i n g d o m and the Soviet Union, seem to b e more efficient for large gutted fish, while horizontal plate freezers are most readily adaptable to standard processing lines for filleting and packaging in consumer size packages. Air blast freezers are flexible b u t somewhat m o r e space-consuming. T h e y are used extensively on Soviet motherships.

R a n k e n stresses the importance of providing for efficient defrosting and special precautions such as precooling the fish, air-conditioning processing decks, etc., to prevent excessive frost formation. H e finds that even if freezing filleted fish requires less freezer hold capacity, m u c h of the space gained is taken up b y the filleting equipment.

Since the block-frozen fish produced on some o f the British factory ships is intended for processing ashore, the dielectric defrosting units introduced in several British fish-processing companies have b e e n a great improvement. I n these units it is possible to thaw the fish quickly and without raising its temperature more than a few degrees above the freezing point. In addition, the water logging that results from defrosting in water is eliminated. L a t e l y , efficient air defrosting machines have also b e e n built.

1. Conversion of Conventional Trawlers

Since both the United K i n g d o m and the United States have a substantial n u m b e r of large trawlers, considerable thought has b e e n given to means of converting them into freezer trawlers. M a n y of the solutions proposed have b e e n b a s e d on the assumption that wet-fish of reasonably high quality is preferred over frozen fish. Therefore some of the schemes have b e e n b a s e d on freezing only the earlier part of the catch.

Oldershaw and Siavin ( T r a u n g , 1 9 5 5 , 1 9 6 0 ) describe the U.S. experi

ment of converting the N e w E n g l a n d trawler "Delaware" into a freezer trawler. A system of wire-mesh baskets on a vertical chain that bring the fish into a refrigerated brine was adopted. Tests showed that the fish was of good quality when defrosted, filleted, and refrozen ashore, yet it is assumed that the brine freezing at times m a y have given some off-taste since tests w e r e carried out with freezing in glucose and similar solutions.

T h e United States fishing industry has not yet adopted the system. An economic study of its possibilities was carried out b y Rosen ( 1 9 5 8 ) .

Large-scale experiments w e r e carried out b y the W h i t e F i s h Authority and the Torry R e s e a r c h Station in the U n i t e d Kingdom. S o m e of these have b e e n described b y the W h i t e F i s h Authority ( 1 9 5 7 ) and E d d i e ( T r a u n g , 1 9 6 0 ) . F o r this purpose a special vertical plate freezer, the so-called Torry-Hall freezer, was designed. After beheading, gutting, and washing, the fish is p l a c e d b e t w e e n the plates and freezing begins. After about 4 hours, the refrigeration cycle is reversed until the surface of the fish is just defrosted. T h e n the blocks fall down and can b e placed in the holds of the ship. Since it would b e too space-consuming to freeze the whole catch immediately after it is taken out of the water, a refrigerated hold is provided for storing the catch until processing and for storage of the last part of the catch. Ships of this kind will b e able to stay 5 0 % longer at sea than ordinary trawlers of the same type. I t was found that reprocessing the fish ashore b y either filleting or smoking was c o m p a r a b l e in quality to products prepared from very fresh fish. T h e findings from this experiment were incorporated into the British stern trawler "Lord Nelson." Shipping World ( 1 9 6 1 ) indicates that she was originally con

ceived as a conventional stern trawler, but the plans were changed to provide for 16 Torry-Hall plate freezers, each of which produces 6 blocks, 4 inches thick and weighing 3 6 kg., every 4 hours. Only part of the catch is frozen; the rest is to b e landed as wet-fish.

On later British stern trawlers, i.e., the "Junella" and the "Ross Valiant," all fish are frozen in vertical plate freezers, and the "Ross Fighter," a side trawler, was converted for b l o c k freezing of the whole catch. Several of these r e c e n t ships, e.g., "Junella," have m u c h improved handling gear for very quick setting and hauling of the trawl.

4 5 8 M O G E N S J U L

Most of the stern trawlers constructed in G e r m a n y have adopted somewhat similar systems. S u c h ships as the "Bürgermeister Smidt,"

"Hessen," "Sirius," "Kiel," "Holstein," "Schleswig," and " L ü b e c k " all h a v e about 6 5 0 cu. m. of hold capacity of which 8 5 - 2 6 0 cu. m. are for freezer storage. T h e s e ships are equipped with conventional air blast freezers.

Some of the recent G e r m a n ships, e.g., the "Heinrich Meins," the "Sagita,"

and the "Heinrich Kern," carry filleting equipment. Heinsohn ( T r a u n g , 1 9 6 0 ) describes a number of these ships. L a t e r ships such as the " W i l h e l m Ladiges" freeze three-quarters of the catch. It is likely that W e s t e r n G e r m a n y too shall soon convert to all-freezer trawlers.

2. Tuna Clippers and Purse Seiners

T h e development of the American tuna clipper, as described b y Petrich ( T r a u n g , 1 9 5 5 ) , is an interesting aspect of processing fish at sea.

Around 1903, plants in California b e g a n to can tuna caught off the California coast. T h e product b e c a m e popular and boats soon h a d to go farther and farther away to obtain the fish. T o begin with, the fish was p a c k e d in ice in the holds of the boat. Soon the fishermen started to equip their boats with m e c h a n i c a l refrigeration and cooling coils under the deck and along the sides of the b o a t to offset the h e a t from the surroundings. Generally the boats also had tanks with circulating sea water in which live bait was stored. I t was quite natural for fishermen to use the bait tanks for storing iced tuna also. Since they w e r e already equipped for circulating sea water, the next step was to chill t h e sea water to cool the fish. This was very satisfactory and the boats soon h a d watertight holds where the fish was refrigerated b y chilled sea water.

T h e s e boats b e c a m e popular b e c a u s e it is extremely easy for the fisher

man to throw the fish in the holds after a day's work and just turn the chilled water on them. H e n e e d not go down in the holds and place the fish in ice. T h e next step was adding salt to the sea water and reducing the temperature so that the fish were actually frozen. Nowadays, the fish are generally chilled in refrigerated sea water; then a refrigerated brine is p u m p e d over to freeze them completely. W h e n this is accomplished, the brine is drained off the tanks and holds which are then used as dry holds until the ship is about to arrive in port. Ordinary sea water is then circulated through the holds, thus defrosting the fish so that they are ready for canning before port is reached. Generally some salt is added during defrosting to prevent freezing of the sea water.

Today, the use of nylon nets and power-operated blocks has m a d e the use of purse seiners more efficient than live-bait fishing, and most tuna clippers have b e e n converted to that system. T h e system for preserving the catch is, however, unaltered.

O n e important aspect of these tuna operations is that it is a type of processing at sea, w h e r e the work involved is actually less than that previously required when the fish was not processed at all.

E x p e r i e n c e in equipping large ships with similar freezing installations is of interest. T h e ships w e r e equipped to serve as motherships, especially for the large American tuna purse seiners operating off Central America.

T h e y were first fitted with holds similar to the tuna clippers, b u t one great difficulty was soon found to b e that such a ship must remain in port until all the fish w e r e defrosted and used b y the canning plant. T h e special freezing process caused the fish to freeze together so that they could not b e separated in the frozen state. I f all w e r e defrosted at the same time, the capacity of the canneries was exceeded. T h e s e attempts have now b e e n given up, but provide good examples of the difficulties in adapting factory ship operations.

T h e system used in American tuna clippers and purse seiners has not spread greatly to other countries. J a p a n has a large fleet of tuna-fishing vessels all equipped with air blast freezers. I n recent years J a p a n has operated a total of about 9 0 such vessels in t h e Atlantic O c e a n . T h e y land the frozen fish in neighboring countries w h e r e fish- and meat-canning plants have benefited from this n e w supply of raw material.

3. Self-Contained Freezer Trawlers

As early as 1 9 2 8 a F r e n c h schooner, "Zazpiakbat," was equipped with machinery to freeze part of the c a t c h ( H a r d y , 1 9 4 7 ) . T h e ship was other

wise equipped for conventional salting of t h e catch aboard. Soon after an Italian trawler was similarly equipped. T h e y b o t h carried a brine freezer in which the fish was submerged b y a rotating drum. I n all of these instances, however, only small parts of the c a t c h w e r e frozen as is the case with m a n y modern trawlers. A revolutionary development was m a d e in Scotland about 1 9 5 0 with a converted mine sweeper, t h e " F a i r - free." I t was realized that since a factory ship requires considerable extra work space, it must have a higher freeboard than is possible under normal trawling operations. In addition, whaling experience showed that a more efficient way of handling the trawl might b e devised than that tradi

tionally used in the Atlantic trawling operations. Therefore the "Fairfree"

was equipped for setting and hauling the trawl over the stern, a m e t h o d previously used mainly on smaller Mediterranean and Pacific craft. T h e results, discussed b y L o c h r i d g e ( 1 9 5 0 ) , were so favorable that in 1953 the Chr. Salvesen & Co., L e i t h , launched a n e w ship, the "Fairtry," w h i c h is completely designed for this operation. T h e trawl is hauled in over the stern chute, and the fish is released onto the deck and from there goes down into insulated pounds w h e r e it is covered with scale ice until it

4 6 0 M O G E N S J U L

goes to processing. M a x i m u m holding time here is about 8 hours. T h e n the fish goes to filleting, mainly b y machines, and then to packaging lines and freezers. F r e e z i n g is either in contact plate freezers or in air blast tunnels.

T h e duration of each trip of the "Fairtry" is about 8 0 - 9 0 days, the ship remaining about 6 0 - 7 5 days on the fishing grounds. It carries about 6 0 0 tons o f frozen fish and can process 3 0 tons of fillets a day. T h e quality of the fish has b e e n good, and the company now operates two additional ships of the same type. T h e new ships are estimated at approximately $2.7 million ( U . S . ) each. A detailed description of the

"Fairtry" is given b y Hardy ( 1 9 5 3 ) . World Fishing ( 1 9 5 8 , 1 9 5 9 ) describes

"Fairtry I I " and " I I I . " Along with the design of the ships themselves went m u c h effort in improving the trawling operations and the gear. I t is estimated roughly, that the catch per year of such a ship is equal to the production of two large trawlers. T h e capital cost is about 4 times that of a trawler and the crew numbers 4 times as m a n y persons. In this latter figure it should b e r e m e m b e r e d that the product is fully processed and consumer packed.

One advantage of large stern-fishing freezer trawlers of this type is that they m a y b e able to fish in higher waves than conventional trawlers can. Thus, the dories in the North Atlantic have to give up fishing long before the trawlers. B i g trawlers may continue in weather that causes small trawlers to discontinue their operations, and the even bigger trawlers of the "Fairtry" type further extend the n u m b e r of days of active fishing operations.

Progress in this field, however, is not limited to factory ships. It is estimated that a modern side-fishing trawler m a y fish in weather up to force 7 on the Beaufort scale, while Heinsohn ( T r a u n g , 1 9 6 0 ) feels that the G e r m a n stern trawlers m a y fish in weather up to force 9. Others feel the stern chute m a y m a k e the ship less seaworthy. L . D . R o m y n (F i s h i n g News, 1 9 5 9 ) , who was captain on the "Fairtry," does not believe there is much difference in the severity of weather in which a stern trawler will work as compared to a large conventional trawler. In addition, operating the factory b e c o m e s difficult in heavy seas.

Fishing Gazette ( 1 9 6 1 ) describes the plans for a large modern freezer trawler to b e built in the United States to operate in the B e r i n g Sea. T h e vessel was projected to have 2 0 0 0 cu. m. of freezer storage space and 5 5 5 cu. m. of storage space for fish meal. T h e c a t c h will b e preserved in chilled sea water prior to processing. T h e ship is to b e equipped for m a c h i n e filleting, except for halibut w h i c h will b e cleaned, chilled, frozen, and glazed on lines specially designed for this purpose. As yet these plans have not b e e n carried out.

M u c h use has b e e n m a d e of the experience from the "Fairtry" in the Soviet Union. T h e first ships of this kind to b e operated there were the "Pushkin" and the "Gogol." B o i e ( 1 9 5 6 ) gives a summary of the results of their first fishing trips. I m p r o v e d gear handling is said to permit the "Gogol" to set and haul the trawl in 3 8 minutes. Special large strong nets have b e e n designed for these ships. Pomukhin ( 1 9 5 7 ) summarizes the general results of m o r e than 2 years of testing the first Soviet freezer trawlers of the "Pushkin" type b y stating that the annual total fishing period is 1 1 % longer than that of a salting vessel, and that the cost per kilogram of ready-for-sale fish is 1 9 % less. T h e production of fish per crew m e m b e r is 1 4 5 tons of round fish on a salting trawler b u t 1 9 0 tons on a freezer trawler of the "Pushkin" type. In comparison, the "Fairtry"

is expected to land fillets from approximately 8 0 tons of round fish per crew m e m b e r annually. After these favorable results, the Soviet Union h a d a considerable n u m b e r of these ships built in W e s t e r n G e r m a n y and ( 1 9 6 2 ) an additional n u m b e r on order.

L a t e r the Soviet Union designed an improved and somewhat larger trawler of this kind, the so-called "Mayakovski" class. T h e y w e r e built in the Soviet Union at B l a c k S e a ports. R e c e n t l y the Soviet Union has also obtained a n u m b e r of similar freezer stern trawlers from Poland o f the so-called B - 1 5 or "Leskov" class described b y Piltz ( 1 9 6 0 ) . T h e Polish fishing fleet had, 1964, eight factory trawlers of the B - 1 5 type, e.g., the " F e n i k s " and the "Kastor." M o r e ships of this type w e r e under construction. An interesting feature is that these trawlers are also used in the herring fisheries. Since they are e q u i p p e d with air blast freezers and often freeze whole fish, they m a y fill up considerably quicker than t h e "Fairtry" type that processes mainly filleted fish. In such cases they m a y transfer the c a t c h at sea to transport vessels and return to port only after a second full load has b e e n obtained.

As described b y Swiecicki ( T r a u n g , 1 9 6 0 ) , Poland is building a large n u m b e r of stern factory trawlers similar to the "Fairtry." W h i l e some h a v e b e e n delivered to the Soviet Union, some are in operation in Poland and it is e x p e c t e d that Poland will operate about 5 0 such ships in 1 9 7 5 .

Several other countries have recently built stern freezer trawlers of similar kind and size, such as the J a p a n e s e "Kaimon M a r u " and some Spanish trawlers. Yet, there seems to b e a trend toward the somewhat smaller trawlers, e.g., the Norwegian "Ronstad" with a c r e w of 2 3 , and

" L o n g v a " with a crew of 5 0 , and the Spanish " M a r Austral" with a crew of 3 4 . Spain has about 6 trawlers in this class, and 2 of the "Fairtry" class.

I n J a p a n there is a simultaneous trend b o t h towards larger—in excess of 3,000 and even 3,500 tons—as well as towards smaller units ( 1 0 0 - 2 0 0 gross tons) ( B o r g s t r o m , 1 9 6 4 a ) .

4 6 2 M O G E N S J U L

As referred to above, W e s t e r n G e r m a n y has built several ships of similar design, also considerably smaller, which return with part of the catch in the iced state. W e s t e r n G e r m a n y has constructed a special air blast freezer to b e used on b o a r d such ships for freezing the fish at sea.

According to Commercial Fisheries Review ( 1 9 6 1 ) , the freezer consists of compartments formed b y aluminum plates pulled b y two continuous chains. F r o m the end the compartments are shaped as a square-cornered U. T h e compartments retain their shape after b e i n g filled until the fish is frozen: they open up when the chain runs over a round cogwheel, which causes the walls of the compartment to spread. H e r e the frozen fish fall out over a discharge. T h e compartments pass through a freezing tunnel 12 meters long and 1.5 meters high.

F o r herring freezing the compartments may b e divided into two sections each to contain about 5 kg. of herring. I t is expected particularly that factory ships with this kind of equipment will b e able to freeze herring on a large scale.

F r e e z i n g equipment somewhat similar to this has b e e n constructed in the Soviet Union, as described b y Pavlov ( 1 9 5 6 ) . H e r e the plates are attached to a shaft. T h e space b e t w e e n them is filled when they are in the top position. After freezing, a warm liquid is sent through the plates when they are in the lowest position, and the frozen blocks slide out.

O t h e r countries to follow this general trend are Italy and G r e e c e . A description of some of the freezer trawlers operated from there is given by Gianisi, Osti, and Costa ( T r a u n g , 1 9 6 0 ) . Most are conventional trawlers, but the G r e e k "Evangelistria I V " is a specially designed stern trawler with a freezing capacity of 1 ton per hour and a freezer hold capacity of 6 0 0 tons, i.e., similar to the size and capacity of the "Fairtry"

series.

E a s t e r n G e r m a n y has converted a b a n a n a carrier into a large factory ship ( c r e w 1 4 0 m e n ) , the "Martin Andersen Nex0." This vessel has since b e c o m e part of the distant fishing fleet, operating in the Northwest At

lantic, off W e s t Greenland and Newfoundland.

In this connection it might b e mentioned that a remarkable develop

m e n t has taken p l a c e in the Atlantic fisheries along the Canary Islands and west of Mauritania. I t is estimated that 11 Greek, 18 Japanese, and 15 Italian ships w e r e catching and freezing fish in that area in 1 9 6 1 . In the same period, Spain is reported to have had six freezer trawlers fishing hake off the shelf of W e s t Africa.

It is generally considered to b e easier to preserve fish from warm waters, the reason b e i n g that t h e bacterial flora in the slime of the fish and in the intestines is less psycrophilic than that of fish from cold waters.

W h i l e this m a y have some merit in the wet-fish trade, it is, however, a

matter of less concern for freezer ships, except w h e r e very high catching rates are encountered.

I t appears that the Soviet Union has a special program for operating freezer trawlers in tropical waters. Thus, the Soviet Union operates a considerable fleet of fish-processing vessels off W e s t Africa. S o m e of the catch is sold locally while the most desirable fish is taken b a c k to the Soviet Union. I t is estimated that in 1 9 6 1 - 1 9 6 2 about 2 0 stern freezer trawlers of the 2 0 0 0 - 3 0 0 0 - t o n class were engaged in this activity.

Zorzhova ( 1 9 6 0 ) describes the freezer trawler " Z u k o w s k f which has b e e n designed for catching and processing sardines in tropical waters.

T h e catch is either processed directly or stored in refrigerated sea water.

T h e trawler is equipped with air blast freezers w h i c h have a total capacity of 6 - 7 tons of raw fish. T h e trawler has also a fish m e a l plant and small installations for canning fish.

T h e Soviet Union has built the first of another series of factory ships for such purposes—the 80-m. long "Tropik" class. T h e "Tropik I " is designed for fishing with b o t h b o t t o m and midwater trawls for sardines, herring, and flatfish, and is equipped for tuna fishing with either live bait or long lines. I t has a fish p u m p for sardine fishing and two powered skiffs for purse seining. Soviet plans call for 6 0 freezer stern trawlers for fishing in the tropics to b e built during the years 1 9 6 1 - 1 9 6 5 .

M o s t of the sea-frozen fish is used in the Soviet Union for reprocessing ashore for either canning, smoking, or ready-made dishes ( B o r g s t r o m , 1 9 6 1 b ) .

4. Freezer Motherships

T h e extensive use of salmon-freezing motherships b y the J a p a n e s e in the Northwest Pacific is described above. According to Sato ( T r a u n g , 1 9 6 0 ) , these ships use contact plate freezers with horizontal shelves. Both salmon, w h i c h is a fairly flat fish, and whale m e a t adapt very well to this type of freezing. I n 1 9 6 1 J a p a n is said to have h a d 12 motherships with 4 1 0 catchers fishing for salmon in t h e North Pacific. T h e same ships are used later for freezing flat fish in the same area. J a p a n also reports a total of 17 portable-vessel-carrying tuna-freezing motherships used in various areas of the Pacific. T h e y are supported b y a large n u m b e r of catching vessels ( s e e T a b l e I ) .

E v e n in these factory ship operations on the high seas, a danger of overfishing is present. Certain agreements exist b e t w e e n J a p a n and the Soviet Union restricting mothership operations. J a p a n restricts the n u m b e r of portable tuna-fishing vessels per mothership to a few and the size of e a c h to 2 0 tons. In addition, the motherships cannot employ catcher vessels of over 2 0 0 tons.

4 6 4 M O G E N S J U L

T h e Soviet Union has a very large n u m b e r of freezer motherships.

Pavlov ( 1 9 5 6 ) describes some of them. A few are traditional fish-freezing factories put on barges and apparently to b e operated as motherships in sheltered waters. Others are ships of the "Refrigerator" series e q u i p p e d to operate on the high sea. O n e such ship is the "Neveljsk" ( s e e F i g . 2 ) . T h e first ship of this series was built in 1 9 3 3 . T h e y fish mainly in the Pacific O c e a n ( H a r d y , 1 9 4 7 ) .

T h e "Pervomaisk" series, which the Soviet Union had built in D e n mark, is equipped with air blast freezers in w h i c h the freezing pans are moved mechanically from station to station on the racks in the freezer tunnel. T h e y have a carrying capacity of 2 5 0 0 tons. So far, four ships of this series have b e e n built. In 1 9 6 2 this series was followed b y another, highly mechanized, version such as t h e "Vitus B e r i n g , " a d a p t e d for taking the catch aboard either over the side or, in d e t a c h a b l e cod ends, over a stern slip. O t h e r large motherships have b e e n purchased in Poland, e.g., the "Pionersk."

It is reported that one Soviet fleet operating in Bristol B a y in 1 9 6 1 consisted of six freezer motherships, two freezer trawlers of the "Pushkin"

type, and 7 6 medium trawlers. T h e freezer ships are supported b y freezer transport vessels.

Piskarev and Kaminarskaya ( 1 9 6 1 ) describe the system of freezing used on Soviet factory ships. T h e catch is generally placed on metal trays and air-blast frozen. M u c h work has gone into making the arrangement automatic, to steady trolleys and trays in heavy seas, and to prevent frost formation on doors, hatches, etc.

T h e United States uses a small n u m b e r of freezer ships in the salmon industry in Alaska. This industry has a short season and must have most of its workers flown up from the other Pacific States. F r e e z e r ships m a y move along the coast and thus b e used over a longer period and serve to extend the period of operation for shore canning plants.

In the beginning, it seemed logical to adopt a freezing system similar to that used on tuna clippers. I t turned out, however, that the salmon, as a smaller and flatter fish, tended to prevent an even brine circulation in the freezing tanks. In addition, since the salmon is p a c k e d raw in the cans with the skin on, any salt penetration from the brine m a y tend to give the fish an off-taste. T h e s e operations have therefore never b e c o m e very popular in the U . S . industry. Nowadays, t h e trend is toward preserving the c a t c h aboard in refrigerated sea water and processing in shore plants or mobile canning factories.

Spain has recently launched a mothership operation; the "Pescanova I " is a factory ship of 16,000 tons to b e followed b y 10 c o m b i n e d trawl,