CHAPTER 5

The Canning of the Sardine, Clupeo pilchardus Walbaum

HENRI CHEFTEL

Research Laboratories, J.-J. Carnaud et Forges de Basse-lndre, Paris, France

I. Gastronomic Characteristics of the Sardine C. pilchardus 247

II. Handling of Raw Fish 249 III. Preparation for Canning 250

A. Preparation for Cooking Prior to Filling 251 B. Preparation for Cooking in the Can 252

IV. Cooking 253 A. Cooking on Trays 254

B. Cooking in the Can 256

V. Filling 257 A. Trimming 258 B. Packing into Cans 258 VI. Adding Oil, or Sauce 258 VII. Seaming of the Cans; Type and Sizes of Cans 258

VIII. Washing of the Cans 260

IX. Processing 260 X. Cooling of the Cans 261

XI. Casing; Types of Cases; Warehousing 261

XII. Regulations 261 References 262

I. Gastronomic Characteristics of the Sardine C. pilchardus

I n most countries w h e r e the sardine C. pilchardus has traditionally b e e n c a u g h t a n d c a n n e d for m o r e than a century, this species is t h e only one entitled to b e described as a sardine. T h e same rule applies not only in Spain, Portugal, M o r o c c o , Tunisia, Italy, a n d t h e U n i t e d Kingdom, b u t also in certain countries w h e r e t h e sardine is very rarely c a u g h t or canned, e.g., B e l g i u m and G e r m a n y . T h i s particular species is not caught in North A m e r i c a n waters; any small fish of the clupeid family may, how

ever, b e l a b e l e d sardines w h e n c a n n e d .

H e r e is not t h e p l a c e to enter o n c e m o r e into this controversy, and to d e c i d e if describing a sprat or a herring as a sardine is or is n o t an unfair trade practice. I t is felt, however, that the differences b e t w e e n the sardine and t h e other species from t h e s a m e zoological family need to b e stressed, in order to understand t h e reasons for certain technical details in the canning operations.

247

I n F r a n c e , both at the ports and in the retail market, the genuine sardine gets a price w h i c h is five to six times the price paid for sprats or herrings. T h e r e must b e a reason for this, all t h e m o r e as the catch of sprats is m u c h smaller than the c a t c h of sardines.

T h e first peculiarity of the sardine is to b e found in t h e softness of its scales, w h i c h are never removed; moreover all precautions are taken to k e e p t h e m in place. I n this respect t h e old type of fishing net, in which the sardines w e r e caught b y the gills, was particularly appreciated, since the fish was killed at o n c e and prevented from losing part of its scales, as happens w h e n it struggles in a seine net.

T h e skin itself is thin and soft, easily torn; this is a good reason for keeping the scales on, and also for paying particular attention to the method of handling. T h e belly wall bursts open under slight pressure, especially if the fish is not of prime freshness.

As with other species, the fat content varies according to t h e season;

but the limits, 1 to 2 0 % , are greater than with most fishes. T h e best sardines for canning contain 1 0 - 1 5 % fat; this probably explains, at least in part, the reputation of t h e sardines from Brittany, w h e r e the fishing season occurs mainly during the autumn months w h e n the fat content is at its optimum level.

T h e sardine has relatively large viscera, w h i c h n e e d to b e removed;

simple beheading, as p r a c t i c e d with the sprat, would not b e satisfactory, even if the fish w e r e kept fasting before butchering. I t is even consid

ered essential b y most specialists that the digestive t u b e b e removed down to the last traces, an operation w h i c h requires b o t h care and skill when performed manually. Only recently was it possible to accomplish this mechanically in a satisfactory way.

T h e above remarks will show that the sardine C. pilchardus W . has indeed a n u m b e r of distinctive characteristics. As regards flavor, too, it is quite different from other fishes of t h e same family: less watery than the sprat, b u t not as strong in flavor as the herring, it occupies a p l a c e similar to t h e one held b y white m e a t tuna in the tuna-fish family.

Sardines are mostly c a n n e d in oil. Olive or peanut oil is used ex

clusively for this p a c k in F r a n c e , Portugal, Spain, and North Africa, b u t in Italy only olive oil is used.

Boneless, and b o n e - and skin-less, sardines, in olive oil, constitute a fancy p a c k of very limited volume. Contrary to t h e general impression, the boneless sardine, with its skin ( a n d scales) on, is t h e most difficult to prepare; it requires not only great skill, b u t also fish in perfect con

dition and perfectly fried.

O t h e r fancy packs are sardines in oil "aux achards" ( s p i c e d ) , a n a m e apparently derived from the Indian word "Achia" or "Achiar" for pickled

5. CANNING T H E SARDINE Clupea pilchardus W A L B A U M 2 4 9

b a m b o o ; and "a la ravigote," a sauce m a d e with egg yolk, olive oil, vine

gar, and various herbs.

A m o r e sizable p a c k consists of sardines in oil and tomato sauce, for which, as a rule, second-grade fish are used: those with bruised skins, or off-season, extra-large specimens, etc.

Hereafter, only the usual kind of plain sardines in oil will b e con

sidered, inasmuch as other types of packs do not show any important differences in the preparation.

Sardines in oil are p a c k e d as a rule h e a d to tail in rectangular-shaped cans. Since the belly of the sardine is white and the b a c k is blue-black, the fish m a y b e put into the c a n in such a w a y that, on opening, all bellies are uppermost, w h e n t h e contents of t h e c a n will appear silvery white; or with the dorsal part up, and they will appear steel blue. O w i n g to the already mentioned fragility of the b e l l y wall of the sardine, only fish absolutely fresh a n d in perfect condition will admit packing bellies up ("au b l a n c " ) ; sardines "ä Thuile d'olive" p a c k e d "au b l a n c " represent thus t h e finest quality of c a n n e d sardines, and it will b e appreciated that the difference in t h e style of p a c k just mentioned is not simply a m a t t e r of appearance.

II. Handling of Raw Fish

Contrary to w h a t appears to b e a rule in California, for instance, W e s t e r n E u r o p e a n or North African sardine canning factories are seldom situated right b y the sea. Moreover, the fact that the fish are sold at auction stands in the w a y of a direct delivery from b o a t to cannery.

D e s p i t e these difficulties, t h e operations might b e improved, and even

tually will, especially w h e n b e t t e r means of refrigerating and keeping t h e sardines on b o a r d the fishing boats will result in t h e use of larger boats and b i g g e r catches. Although so far it does not appear possible to p u m p sardines without damaging them—various trials h a v e b e e n made, especially in M o r o c c o — c a r r y i n g the fish b y hand from the b o a t to the trucks in wooden trays of about 1 0 kg. ( 2 1 l b . ) , or selling t h e m b y the thousand as still practiced in some F r e n c h ports, are procedures w h i c h could b e a b a n d o n e d with advantage.

B r o u g h t to the cannery b y truck, mostly in wooden cases of 2 0 - 2 5 kg.

( 4 2 - 5 0 l b . ) , t h e fish are usually c h e c k weighed, and stacked in the court

yard or at t h e entrance of the factory, waiting to b e treated. As a rule the sardines have already b e e n inspected, sorted b y size, and sprinkled with salt on t h e boat, before b e i n g stowed a w a y in ice. As regards freshness and fitness for food, all fish are examined on landing b y official inspectors.

I f the sardines have to

wait

m o r e than a few hours upon arrival atthe factory they should b e put under refrigeration, depending to some extent on t h e external temperature. I n this respect too, however, the sardine is particularly difficult to handle. F r o m the m a n y experiments w h i c h h a v e b e e n m a d e at times, it seems hopeless t o try either to freeze sardines without first b e h e a d i n g and gutting them, or to k e e p t h e m m o r e than about 12 hr. around 0 ° C . ( 3 2 ° F . ) . E v e n rapid cooling in refriger

ated brine, followed b y storage at 0 ° C . ( 3 2 ° F . ) in air, or in light brine, has not proved successful. R e c e n t investigations appear to indicate that a prerequisite should b e the rapid brine cooling of the fish as soon as it is taken out of the sea. F i s h w h i c h h a v e b e e n i c e d in the traditional w a y remain at too high a temperature during transportation, and it is too late to cool t h e m down w h e n at the cannery.

Similar difficulties have b e e n m e t with the California pilchard and the M a i n e herring, despite the fact that b o t h these fishes are less delicate than the sardine. A review of these experiments is available ( M a c C a l l u m et al, 1 9 5 6 ) .

III. Preparation for Canning

T h e first operation w h i c h sardines undergo in the cannery consists of b e h e a d i n g and gutting. T h i s is usually done manually with the aid of a short knife: a cut is m a d e in the n e c k from the b a c k downward, just passing the b a c k b o n e b u t without biting into the esophagus; the h e a d is then pulled apart with a slight twist, dragging out the intestines as far as t h e small ones; these are then p i n c h e d a n d pulled further.

T h i s operation is generally carried out on tables, slightly tilted to

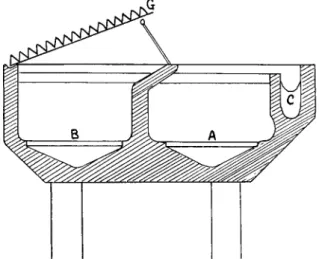

ward the operator and provided with a lower edging and with chutes to dispose of the trimmings. However, t h e b e s t arrangement is perhaps the one designed b y G. Masso of B u e u ( S p a i n ) and called the "canal": this is a large trough w h e r e the gutted fishes are thrown, while a smaller drain running alongside it receives the trimmings, w h i c h are carried a w a y b y a stream of w a t e r ( s e e F i g . 1 ) .

An experienced girl c a n handle about 1,000 sardines an hour, and, together with the difficulty of the operation, this high d e g r e e of manual efficiency is responsible for t h e fact that until r e c e n t years n o satisfactory automatic machinery was available to c o m p e t e with m a n u a l work, de

spite m a n y trials. T h e gutting machines generally used for herring are not adapted to handle properly such a small and delicate fish as t h e sardine. E v e n t u a l l y the M a t h e r & Piatt ( F r a n c e ) C o m p a n y developed a modified m a c h i n e o f t h e "Arenco" ( S w e d i s h ) type, w h i c h appears to work satisfactorily.

This m a c h i n e is said to handle 4 5 0 sardines p e r minute. I n most fac

tories, however, t h e gutting operation is still performed b y hand. Another

5. CANNING T H E SARDINE Clupea pUchatduS W A L B A U M 2 5 1 reason for this lies in the fact that manual labor is necessary for trimming the fish and for properly arranging it in the cans, and there is no purpose in mechanizing one operation too far if the subsequent step has to b e executed b y hand. T h e same t e a m of girls who perform the gutting moves next to the packing tables.

FIG. 1. Cutting and brining trough designed by Masso. A : receiving trough;

B: brining trough; C: flume for refuse; G: grill.

T h e succeeding operations follow from then on a different pattern according to w h e t h e r the fish are cooked prior to packing into the cans or cooked in the cans. W e shall b e g i n with a description of the first method, w h i c h is the traditional one.

A. P R E P A R A T I O N F O R C O O K I N G P R I O R T O F I L L I N G

1. Brining

T h e b e h e a d e d and gutted sardines are usually given a rapid wash in or under sprays of water, to remove most of the blood, then immersed in 2 5 % brine for a lapse of time from 4 to 15 min. according to the size of the fish. Brining is intended, first, to remove the blood, w h i c h the salt prevents from clotting, and, second, to salt the fish slightly.

Brining is carried out in wooden troughs, in tanks of concrete equipped with a system of pipes and pumps, or in the Masso "canals."

2. Arranging on Trays

As soon as the sardines are r e m o v e d from t h e brine, they are laid out n e c k down on special trays m a d e of tinned iron wire, w h e r e they are carefully arranged so that they do not touch one another ( t o prevent

their sticking together w h e n c o o k e d ) . T h e s e trays or grills, a large num

ber of w h i c h are n e e d e d in a factory, represent a b i g investment, and their cleaning, retinning, a n d regular replacement entail considerable expense. T h e tinning has to b e carried out with pure tin, kept free from contaminations b y foreign metals, especially lead, w h i c h m a y b e brought in b y other articles b e i n g tinned in the same baths.

3. Rinsing

T h e trays loaded with sardines are next given a rapid rinse under light sprays of water, usually on conveyors which carry them under and past the sprays. This operation is necessary to remove the b r i n e from the surface of the fish, w h e r e upon drying it would appear as salt crystals.

4 . Drying

The trays are now p l a c e d on m o b i l e racks, holding about 4 8 of them, which are w h e e l e d into t h e drying tunnel. T h i s is usually a wooden con

struction, some 1 5 m. ( 5 0 ft.) long, provided with two lateral doors on the same side, one for introducing and the other for taking out the racks. At one end of the tunnel a b i g fan sends a slow stream of air first through a steam radiator, w h e r e it is heated to 3 7 - 4 0 ° C . ( 9 8 - 1 0 4 ° F . ) , then over t h e fish. T h i s drying requires about 3 0 min., and has b u t a superficial effect; it is simply aimed at giving some firmness to the skin, so that it m a y b e t t e r withstand the frying in oil. Measurements have shown that the total water content of the fish remains practically un

c h a n g e d at this stage.

The sardines are n o w ready for frying.

It should b e noted that drying is carried out after cooking w h e n the fish are cooked in steam, and omitted altogether w h e n the cooking is performed in an oven.

B . P R E P A R A T I O N F O R C O O K I N G I N T H E C A N

1. Trimming

T r i m m i n g consists in properly squaring t h e cut at the collar and in cutting part of t h e tail. T h i s operation is carried out manually with scissors, and provides at the same time an opportunity for inspecting e a c h fish individually, and for discarding those w h i c h appear, mainly on account of bruises or improper gutting, unfit for canning.

2. Brining

T h e sardines are then brined as already described. T h e brine is, however, of a lower concentration, or the dip shorter, than in the tradi-

5. CANNING T H E SARDINE Clupea pilchardus W A L B A U M 2 5 3

tional procedure, since t h e fish usually receive an additional treatment in the can, w h e r e they are cooked with a certain amount of brine. T h e r e is no standard treatment, and slight differences are found from one can

nery to another. No rinsing is necessary. Adding a small amount ( 1 % ) of acetic acid to the brine has b e e n suggested in order to further firm the skin and to prevent the fish from sticking to one another, especially w h e n they h a v e lost their scales.

3. Filling of the Cans

T h e empty cans are generally sprayed inside with a small amount of oil, of the same kind and quality used later for oiling; this helps prevent the fish from sticking to the can. A small quantity of brine is then put into e a c h can, and the raw fish are arranged in the c a n in the m a n n e r described above.

IV. Cooking

Cooking the sardines prior to filling t h e cans has b e e n practiced tra

ditionally, it appears, since J o s e p h Colin in Nantes started sardine can

ning about 1 8 2 3 . B u t even w h e n the fish are p a c k e d raw, as done in recent years, it is necessary to cook and drain t h e m before closing the cans. T h i s is required in order to remove a certain amount of water, to render firmness to the flesh, and to avert excessive "fishy odor."

T w o experimental studies on the cooking of small fish of the sardine family should b e mentioned as outstanding. Beard's investigation ( 1 9 2 7 ) was aimed at finding the best w a y of making t h e oil frying superfluous.

As it was then performed, it was considered unsanitary and undoubtedly expensive. T h e second study was b y M e e s e m a e c k e r and Sohier ( 1 9 5 7 ) comparing various ways of cooking t h e sardine and trying to spot the essential factors and purposes of the cooking operation.

T h e s e investigations show that cooking is vital in removing tissue water, which, if not eliminated, will later appear in the c a n during the sterilization process, giving a watery, boiled-like fish into w h i c h t h e oil does not penetrate, and leaving large drops of water in the oil phase.

Meesemaecker's major conclusion is that the removal of water from t h e fish tissues is attained primarily b y h e a t coagulation and an ensuing shrinkage of the flesh proteins, b u t hardly through actual drying (i.e., as w a t e r v a p o r ) . I n fact, cooking at about 1 0 0 ° C . ( 2 1 2 ° F . ) in saturated steam is satisfactory for removing sufficient water, and whatever use is m a d e of higher temperatures or hot air mainly helps in carrying away from t h e surface of t h e fish the w a t e r w h i c h has b e e n expelled from the tissues. M . Beauvais, w h o developed in F r a n c e the "flash cooker" from t h e first type of sardine cooker designed b y E . Sanders of International

Machinery Corporation of B e l g i u m and b y t h e author, h a d r e a c h e d a similar conclusion: increasing the length of the steaming period m a d e it possible to reduce to a minimum the subsequent hot-air treatment, and thereby greatly to simplify the machine.

A . C O O K I N G ON T R A Y S

1. Frying in Oil

a. F R Y I N G

F r y i n g in oil is the traditional way of preparing sardines for can

ning and still is, in the author's opinion, the b e s t m e t h o d from the gastronomical point of view, provided the oil used is of good quality and renewed frequently.

Refined peanut oil is used almost exclusively for this purpose. T h e trays loaded with fish are immersed in the oil, held at 1 2 0 - 1 2 5 ° C . ( 2 4 8 - 2 5 7 ° F . ) , for about 4 min. T h e time is varied to some degree, depending on the size of the fish and also on their fat content; t h e length of the cook is considered satisfactory w h e n the fish b e g i n to leave the tray and float at the surface of the oil bath, and is judged also b y the appearance of the b a c k b o n e . This should b e very thin, almost threadlike, without side bones remaining apparent.

T h e standard apparatus for this operation is the Lagillardaie trough, in the improved design b y March'adour, who provided it with an auto

matic chain with variable speed drive to carry the trays all through the oil bath. T h e trays slide on rails, and the trough itself carries a layer of water at the b o t t o m and on top of it a layer, about 4 0 c m . ( 1 5 in.) deep, of oil, heated b y steam coils. T h e trough has a capacity of about 4 0 0 liters ( 1 1 0 gal.) of oil, w h i c h are used for frying from 3 to 7 tons of sardines. T h e smaller the quantity of fish fried in a b a t c h of oil, the better the quality; b u t no fixed rule c a n b e given, inasmuch as it depends on the fat content of the sardines. W h e n the latter are lean, m a n y more m a y b e cooked, since they do not give off fat; on t h e contrary they absorb oil, and fresh oil has to b e added to maintain t h e proper level.

O n the other hand, w h e n the sardines are rich in fat, the level in the oil b a t h rises, and the oil quickly b e c o m e s a mixture of fish and peanut oil, with a consequent lowering of the quality of the product. T h e amount of fish oil m a y e x c e e d 5 0 % if the operation is carried too far; at this point, the fish will not drain properly, and remain covered with a layer of fat, w h i c h tends to dry like a varnish on account of the unsaturated fatty acids present. S u c h a condition must, of course, b e avoided.

M e a n s have b e e n devised for purifying t h e oil, continuous centrifu- gation and "washing" with a stream of water b e i n g generally used. T h i s

5. CANNING T H E SARDINE Clupea pilcharduS W A L B A U M 2 5 5

treatment, however, while effective in removing solid matters from the oil, cannot separate fish oil from peanut oil. Emulsifying t h e mixed oils with water, followed b y centrifugation, allows recovery of the peanut oil, whose emulsion breaks easily ( C h e f t e l and M o c q u a r d , 1 9 3 9 ) , b u t the process is too expensive. T h e ordinary w a y to dispose of used frying oil is to sell it for soap manufacturing; the price obtained is around one- sixth that of the original oil.

b . D R A I N I N G

T h e trays coming from the frying b a t h are left to drain, usually overnight, on inclined tables lined with zinc or stainless steel. T h e oil is recovered, centrifuged, and returned to the bath. T h i s step of the operation is necessary, since t h e fish cannot b e handled unless they are cooled, w h e n they are less liable to b r e a k into pieces. F r o m the sani

tary point of view it is, however, unfortunate that the fish m a y not b e p a c k e d as soon as fried, since at this stage they are practically sterile ( L a n g , 1 9 3 5 ) .

2. Cooking in Steam

a. C O O K I N G

W h i l e frying in oil is t h e traditional w a y of preparing sardines in Brittany, cooking on trays in steam has b e e n t h e general practice until recent years on t h e southwest coast of F r a n c e , Spain, Portugal, and M o r o c c o ; and is still largely used except in M o r o c c o , w h e r e it has b e e n completely superseded b y cooking in t h e can.

T h e fish are prepared as described a b o v e ( S e c t i o n I I I , A, 1 - 3 ) fol

lowing the steps of brining, arranging on trays, and rinsing, b u t are not given any drying. T h e m o b i l e racks loaded with t h e trays of fish are introduced into iron chests, similar to the ones used in California for cooking tuna, w h e r e they are submitted to steam cooking at about 105 ° C . ( 2 2 1 ° F . ) for approximately 1 5 min. T h e fish give off water and oil, w h i c h are collected in tanks w h e r e the oil is separated and recovered.

Cooking in steam, performed in t h e m a n n e r just described or in other ways, is particularly convenient for very fat sardines, on account of the defatting w h i c h takes place, rendering t h e fish m o r e digestible.

b . D R Y I N G

W h e n t h e cooking is finished, the racks are pulled out of the steam chests and left standing for draining and drying. I n dry weather, this superficial drying of t h e fish takes p l a c e spontaneously in a m a t t e r of a few hours; quite often, however, it is necessary to submit the fish to some artificial drying in a drying tunnel, in the m a n n e r already described ( S e c t i o n I I I , A, 4 ) .

3. Oven Cooking

Cooking in hot dry air, or b y means of radiant heat, has b e e n tried m a n y times for sardines, the hot-air oven b y Girodin ( o f Quimper, Brit

t a n y ) b e i n g probably the first effort. Electrically or gas-heated infrared ovens have also b e e n on the market, b u t with limited success. A general review of the various methods of cooking sardines was prepared b y L o p e z Capont ( 1 9 5 7 ) .

I n fact, the only oven for sardines w h i c h appears to have passed t h e prototype stage and is actually in use in a n u m b e r of canneries, mainly in Spain or Portugal, is the hot-air tunnel oven b y G. Masso. T h e loaded grills are pulled b y a chain through a tunnel, some 3 0 m. ( 1 0 0 ft.) long, in which circulates a stream of air at about 2 5 0 ° C . ( 4 8 2 ° F . ) . Facilities are provided for modifying the speed of the chain, the speed and tem

perature of the air, as well as the evacuation of the fumes and replace

m e n t b y a proportion of fresh air. This method has b e e n lately improved b y providing a section in which the fish are cooked in steam before b e i n g treated with hot air; this feature makes the process quite similar to the one applied in the F l a s h cooker b y M . Beauvais.

W h e n properly carried out, this m e t h o d of cooking gives excellent results; fine flavor of the fish, good appearance, and a b s e n c e of water in the cans. O n e disadvantage lies in the length of the oven, and another in the fact that the sardines have still to b e handled twice, the second time when cooked.

B . C O O K I N G I N T H E C A N

T h e first experiments on the cooking of sardines in the cans w e r e m a d e b y the author in 1947, and led to the construction, b y International M a c h i n e r y Corporation ( I . M . C . ) in B e l g i u m , of their first continuous sardine cooker. I n this machine, the cans, previously sprayed on the inside with edible oil and p a c k e d with fish, are successively filled with brine, drained, brined again, heated in steam for 10 min., drained, heated in air at 1 5 0 ° C . ( 3 0 2 ° F . ) for 2 0 min. in an inverted position, filled with hot oil and brought to the seamer, at a speed of 6 0 or 120 cans a minute.

Descriptions of this cooker are available (Cheftel, 1950; Roskis, 1 9 5 0 ) . Although this type of cooker requires careful control and was found rather difficult to run, the more so in factories where operations h a d so far b e e n performed mainly b y hand, it m e t with immediate success, especially in Morocco, on account of the considerable savings w h i c h it permitted. T h e advantages of the in-the-can cooking are, first, in the fact that the fish are handled only in the raw state, thereby avoiding losses through breaking into pieces and sparing m u c h hand labor; and secondly in a considerable economy of oil, due to the high closing tem

perature and the consequent smaller final volume and capacity of the

5. CANNING T H E SARDINE Clupea pilchardus W A L B A U M 2 5 7 cans, resulting from the fact that the ends of the can are drawn in b y the vacuum created in the retraction of the contents during cooling. T h e saving on the cost o f the finished product has b e e n estimated at some 2 0 to 2 5 % , and this situation practically compelled all canneries w h i c h did not operate an I . M . C . cooker to devise some system of raw packing.

Various manufacturers brought on the market hand-operated or semi

automatic cookers of the in-the-can type, and h o m e - m a d e devices w e r e put up in a n u m b e r of canneries. A description of several of these systems will b e found in the already mentioned paper b y L o p e z C a p o n t ( 1 9 5 7 ) .

F u r t h e r experimentation b y M . Beauvais, then with I.M.C.-France, ended in the construction of the F l a s h cooker, a m u c h simplified version of the original m a c h i n e . Cookers of this type h a v e n o w b e e n in use for several years in a n u m b e r of canneries in F r a n c e , and various E u r o p e a n countries, and m a y b e said to represent at present the b e s t apparatus for sardine canning b y the raw-pack system ( B e a u v a i s , 1 9 5 4 ) .

The Flash Cooker

O n using the F l a s h cooker the fish should b e b r i n e d and rinsed before packing into t h e can; the filled cans are then submitted, in an inverted position, first to 3 0 min. cooking in steam, then to 15 min. drying b y air at 1 2 5 ° C . ( 2 5 7 ° F . ) with a volume of air amounting to 4 m .3 ( 1 4 1 cu. ft.) per J/4 c l u b can per hour. F i n a l l y the cans are oiled a n d carried on to the seamer. F e e d i n g and discharge are automatic. T h e cooker c a n handle all sizes of fish cans, square or oval; since it is built b y assembling standard elements, its capacity m a y b e adapted to a wide range of needs. T h e chain carrying the cans is automatically washed, brushed, and sprayed with oil. T h i s cooker is described in a paper b y M o u c h e t ( 1 9 5 6 ) .

V. Filling

T h i s operation, a rather simple one w h e n it is performed before cooking, i.e., on raw sardines, is m o r e difficult w h e n the fish are handled in the cooked state. T h e grills, coming either from t h e frying b a t h or from the steaming chests or hot air ovens, are carried to the packing tables after a cooling period. I n one of the most c o m m o n arrangements, e a c h packing post is provided with double swiveled racks m o u n t e d on a vertical shaft on w h i c h they c a n rotate; the grills are put on the racks, an empty grill b e i n g removed and r e p l a c e d with a loaded one while the sardines are taken from the other.

T h e girl w h o performs this operation has to trim, inspect, and separate the sardines into three classes: the perfect ones; those w h i c h are slightly bruised, h a v e lost part of their scales, or whose abdominal skin is lacerated; and finally, the broken ones, w h i c h are discarded. S h e then packs t h e fish in t h e cans.

A . T R I M M I N G

T h e operator is provided with a pair of scissors a n d taking t h e sardines one b y one from the grill she puts t h e m in front o f h e r u p o n the table and cuts the "collar" ( n e c k ) and the two points of t h e tail fin.

T h e performance of a skilled operator will vary m u c h according to the condition of the r a w fish and the care with w h i c h it has b e e n arranged on the grills. I f t h e sardines touch e a c h other and stick together on the grills, m a n y bruised skins will result; and if they are not in a prime state of freshness, they will easily b r e a k w h e n handled. O n an average, a skilled girl in Brittany trims and packs 1,000 to 1,200 sardines an hour.

B . P A C K I N G I N T O C A N S

T h e cans are handled on trays; t h e y are put either on t h e t a b l e or on a sort of drawer or b o a r d protruding from the table, on the left of the operator, w h o thus has to turn 9 0 ° to perform the packing operation.

VI. Adding Oil, or Sauce

T h e oil used for sardines is either olive or p e a n u t oil.

T h e traditional w a y of oiling the cans was to overflow them with oil, or even to immerse t h e m in oil; they w e r e then left overnight in order to allow the ( c o l d ) oil to completely fill the interstices. T h i s rather un

sanitary m e t h o d has b e e n now superseded b y m e c h a n i c a l oiling with the help of various types of machines; the oil is added hot.

Sauces, the most used of w h i c h is a mixture of tomato puree and 2 0 % peanut oil, are, on the contrary, put into the can before the fish. Sardines in oil-tomato sauce are definitely a second-class product, the best sardines b e i n g always p a c k e d in olive oil.

VII. Seaming of the Cans; Type and Sizes of Cans

T h e cans are closed on various types of seaming machines, from semi

automatic hand-fed ones of about 3 0 - 4 0 cans per minute to fully auto

m a t i c ones handling 2 5 0 cans per minute.

N o v a c u u m seaming machines are used, and even steam exhausting before closing is seldom practiced, due to the fact that no m a c h i n e manufacturer ( e x c e p t i n g International M a c h i n e r y Corporation in its first m o d e l of sardine c o o k e r ) has put on the market an exhaust b o x w h i c h would prevent drops of condensed steam from falling into the cans. T h i s n e g l e c t of the process of exhausting has b e e n unfortunate, and has given rise at times to overfilling, with consequent flipping of the cans. T h e almost general adoption of hot oiling, however, has improved the situation, a n d the r a w packing m e t h o d has m a d e exhausting un-

5. CANNING T H E SARDINE Clupea pilchardus W A L B A U M 2 5 9

APPROVED CAN SIZES IN FRANCE

Inside dimensions Over-all height

inches inches Capacity Name mm. (approx.) mm. (approx.) ml.

1/15 Ρ 99x46 315x113 18.5 11/16 50

1/10 Ρ (club 20) 104x59.8 402x206 20 12/16 75

1/8 Ρ 95x60 312x206 24 15/16 94

1/6 Ρ 25 105x76 402x300 24 15/16 125

1/6 Ρ (club 30) 104x59.8 402x206 28.5 102 125

1/4 Ρ 30 105x76 402x300 31.5 104 187

1/3 Ρ 40 105x76 402x300 40 109 250

1/3 Ρ sardines 115.7x94.6 409x312 32 104 250 1/2 Ρ sardines 115.7X94.6 409x312 43.5 111 375 1/1 Ρ sardines 115.7x94.6 409x312 81 303 750 3/1 Ρ sardines 205.3X120.4 802 x412 104 402 2250 1/6 Ρ ovale poisson 105.2x64.7 402 X208 30.5 103 125

Practically all these cans are of the three-piece type, with soldered key-opening cover. S t a m p e d two-piece cans with scored cover are m a d e only in the smaller sizes, mainly in M o r o c c o , and in a limited quantity. T h e preference for t h e three-piece soldered c a n is not due only to tradition. No doubt this type of c a n lends itself b e t t e r than any other to easy opening without damaging the fish, a n d to easy removal of the contents without tearing it to pieces.

I t was thought at one time that this type of c a n was unsanitary, b e c a u s e of the contamination of the product b y the lead of the solder.

It is a fact that c a n n e d sardines from F r a n c e , Spain, and Portugal, about 2 5 years ago, often w e r e found to contain traces of lead in undesirable amounts ( a r o u n d 5 p . p . m . ) . Studies b y L a m p i t t and R o o k e ( 1 9 3 3 ) and b y Cheftel a n d Panouse-Pigeaud ( 1 9 3 8 ) have, however, shown that the grills, and t h e pipes and cocks used for the oil, and not the cans, w e r e responsible for this contamination, w h i c h has since b e e n avoided. As a consequence, no prejudice exists any longer against the three-piece soldered can, w h i c h is manufactured today b y automatic high-speed machinery.

M o s t sardine cans are lithographed around the b o d y and on the cover; they are usually not l a c q u e r e d inside, the traces of sulfide stain- necessary. H o m e - m a d e exhaust boxes are used in some factories for the largest cans.

T h e sizes of the cans are officially standardized in F r a n c e since 1 9 4 5 , and it is illegal to use sizes of cans w h i c h have not b e e n approved b y A F N O R (Association Frangaise de N o r m a l i s a t i o n ) . T h o s e used for sardines are listed in T a b l e I .

TABLE I

ing and of corrosion b e i n g considered negligible. I n later years, however, partly as a c o n s e q u e n c e of the advent of electrolytic tinplate, there is a tendency in favor of l a c q u e r e d cans.

In conformity with official regulations, all cans are provided, at the m o m e n t of closing, with a stamped or e m b o s s e d c o d e giving t h e n u m b e r of the factory and the date of packing.

VIII. Washing of the Cans

As a rule, the cans are washed before processing, especially in order to k e e p the retort free from oil, b u t also to recover the oil with w h i c h the cans are unavoidably smeared on the outside. T o this end, washing is done in various types of machines under sprays of hot w a t e r with no a d d e d detergent, a n d t h e oil is recovered b y setting a n d centrifuging.

T h e oil thus obtained amounts to about 1 g. ( 0 . 0 3 5 o z . ) p e r oil can, and is used for frying or sold to soap manufacturers.

IX. Processing

Twenty-five years ago, processing of sardines in oil took p l a c e in boiling water, and it must b e admitted that no serious accidents through underprocessing ever occurred, except with t h e large size ( 1 / 1 and 3 / 1 )

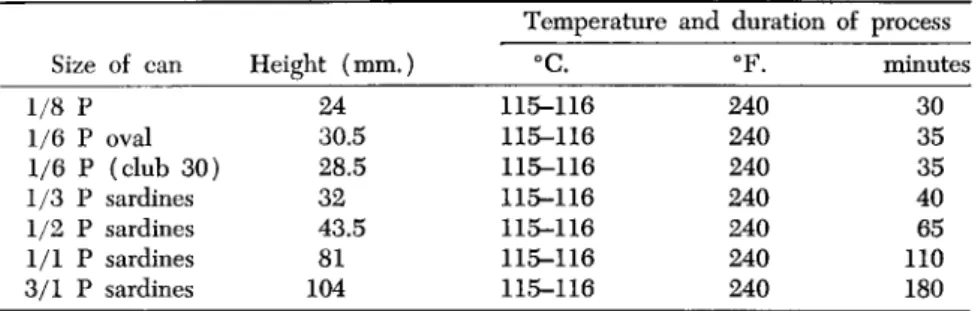

TABLE II

RECOMMENDED PROCESSES FOR CANNED SARDINES

Temperature and duration of process Size of can Height (mm.) °C. °F. minutes

1/8 Ρ 24 115-116 240 30

1/6 Ρ oval 30.5 115-116 240 35 1/6 Ρ (club 30) 28.5 115-116 240 35 1/3 Ρ sardines 32 115-116 240 40 1/2 Ρ sardines 43.5 115-116 240 65 1/1 Ρ sardines 81 115-116 240 110 3/1 Ρ sardines 104 115-116 240 180

cans. At that time, however, c a n n e d sardines in oil w e r e always held in the factory warehouse for at least one year b e f o r e b e i n g sold, a n d this procedure permitted removal and destruction of all cans w h i c h eventually swelled.

Nowadays, since bacteriological studies on the canning of fish in b o t h California and F r a n c e have demonstrated the danger inherent in proces

sing in boiling w a t e r even of a product like oil-fried sardines p a c k e d in oil, all cans of sardines are processed in retorts at 1 1 5 ° C . ( 2 4 0 ° F . ) . Retorts are of the still, vertical, or horizontal types. No continuous type of pressure cooker seems ever to have b e e n used for sardine cans.

5. CANNING T H E SARDINE Clupea pilchardus W A L B A U M 2 6 1

A d e q u a t e processes h a v e b e e n published b y t h e Institut Appert for most c a n n e d foods ( 1 9 5 7 ) , a n d some o f those applying to sardines are given in T a b l e I I .

X. Cooling of the Cans

T h e traditional w a y was to leave t h e cans in t h e retort ( o r rather w a t e r b a t h ) crate and let t h e m stand until cold. T h i s slow cooling no doubt increased the effect of the process. T h e cans w e r e t h e n dried b y running t h e m through rotating steel or w o o d e n horizontal drums partly filled with sawdust, a barbarous procedure w h i c h d a m a g e d the lithogra

p h y and jeopardized the seams.

At present t h e cans a r e generally c o o l e d in water, or u n d e r w a t e r sprays; a n d the large ones are pressure-cooled in the retorts, as is done with other c a n n e d products.

XI. Casing; Types of Cases; Warehousing

I n this instance the traditional m e t h o d is still a d h e r e d to in m a n y fish canneries, mainly b e c a u s e it is a n off-season j o b w h i c h helps to k e e p part of the factory labor on a yearly basis. E a c h c a n is w i p e d clean of sawdust with a towel, inspected, t h e n t a p p e d against another c a n ( a hollow sound would indicate slack filling or a l e a k ) and p l a c e d in the case.

E v e n w h e r e t h e cans are water-cooled, casing is done b y hand.

W o o d e n cases to 1 0 0 cans are still in w i d e use for small-size cans, b u t cartons are also employed.

As already pointed out, c a n n e d sardines in oil as a rule are k e p t a certain t i m e in the factory warehouse b e f o r e shipping. Previous to W o r l d W a r I, t h e b e s t quality p a c k s in olive oil w e r e thus k e p t in storage for two to three years, a n d connoisseurs still today store cans of sardines in their cellars like bottles o f vintage wines. A g i n g improves t h e texture a n d the flavor, since it allows t h e oil to fully i m p r e g n a t e t h e fish a n d slowly dispels t h e "cooked taste" w h i c h is apparent in r e c e n t l y p a c k e d sardines.

A g i n g is, however, a financially expensive process, and nowadays even fancy packs are not k e p t over a y e a r b e f o r e marketing; a storage period of three to six months is, nevertheless, still c o m m o n p r a c t i c e for all packs of sardines in oil.

XII. Regulations

F r e n c h regulations c o n c e r n i n g c a n n e d fish are on two levels: official rules ( d e c r e e s and "arretes") taken u n d e r t h e authority o f t h e funda

mental l a w of August 1, 1 9 0 5 , and decisions issued b y t h e Confederation

des Industries de T r a i t e m e n t des Produits des P e c h e s Maritimes, which has b e e n given authority to define the various products, to prescribe sanitary rules and to organize the inspection of the fish at landing and of the canneries. B o t h sets of regulations have official force, b u t infringe

ments are not prosecuted in the same way.

All regulations pertaining to c a n n e d foods have b e e n assembled and discussed in a book b y Fourgoux and Cheftel ( 1 9 5 6 , 1 9 6 3 ) , and the reader is referred to it for detailed information.

As regards canned sardines, the main points m a y b e summed up as follows:

No other fish but Clupea pilchardus W a l . m a y b e called sardine.

"Sardines in oil" means in any edible oil, b u t usually only olive or peanut oil is used. I f the oil is stated to b e "pure," the fish, w h e n cooked b y frying, shall have b e e n fried in the same kind of oil as the one added to the fish in the cans.

T h e acidity of the oil shall not exceed 1% ( a s oleic a c i d ) .

T h e amount of free water in the can shall not exceed 2.5 to 3 % of the drained weight, for sardines labeled " E x t r a " ( f a n c y ) quality.

Net weights, condition of the fish, and other quality factors are also defined. And it goes without saying that sardine canneries and their produce have to comply with all regulations pertaining to foodstuffs in general and to c a n n e d foods in particular.

R E F E R E N C E S

Beard, H. R. (1927). Preparation of fish for canning as sardines. U. S. Bur. Fish

eries Document No. 1020, 223 pp.

Beauvais, M. (1954). Le nouveau cuisseur a poisson I.M.C. Rev. tech. inds. Ali

ment. 2.

Cheftel, H. (1950). French sardine canners keep accent on taste. Food Inds. 22, 84-87.

Cheftel, H., and Mocquard, J. (1939). Recherches sur la friture des sardines pour la mise en conserve. Ann. fab. et fraudes 32, 25-36.

Cheftel, H., and Panouse-Pigeaud, M.-L. (1938). "A propos de la presence de plomb dans les conserves de sardines," Ets. J. J. Carnaud et Forges de Basse- Indre, Bull. No. 6. Gauthier-Villars, Paris.

Fourgoux, J.-C, and Cheftel, H. (1956 and 1963). "La fabrication et la vente des produits alimentaires conserves—Statut juridique." Revue de la Conserve, Paris.

Institut Appert. (1957). "Baremes de sterilisation des conserves alimentaires en boites metalliques," 46 pp. Paris.

Lampitt, H. L., and Rooke, H. S. (1933). Occurrence and origin of lead in canned sardines. Analyst 58, 733-738.

Lang, O. W. (1935). Thermal processes for canned marine products. Univ. Calif.

(Berkeley) Pubis. Public Health 2 ( 1 ) , 1.

Lopez Capont, F. (1957). Methods of cooking sardines. Rept. Intern. Permanent Committee on Canned Foods, Paris, 17 pp.

5 . CANNING T H E SARDINE Clupea pilchardus W A L B A U M

263

MacCallum, W. Α., Dyer, W. J., Curi, S., Simoncic, J. J., Kovacevic, M., Hörne, D. C , McNeill, R. J., Krvaric, M., and Lisac, H. (1956). Quality of sardines (Clupea pilchardus WALB.) held unfrozen and frozen prior to canning. Food Technol.

10, 432-438.

Meesemaecker, R., and Sohier, Y. (1957). Rept. Intern. Permanent Committee on Canned Foods, Paris, 34 pp.

Meesemaecker, R., and Sohier, Y. (1959). Food Manufacture 34, 148-153, 158;

193-196, 204.

Mouchet, R. (1956). Reveil de la conserverie de poisson. Rev. tech. inds. Ali

ment. 3 ( 2 8 ) , 26-39, 71; ( 2 9 ) , 26-35.

Roskis, G. (1950). La ligne I.M.C. pour la fabrication des conserves de sardines.

Offic. de Ζα Conserve No. 22, 22-28.