0139–3006 © 2020 Akadémiai Kiadó, Budapest DOI: 10.1556/066.2020.49.3.14

EFFECT OF GENOTYPE, SEED DEVELOPMENT STAGES, AND PROCESSING TREATMENTS ON BOWMAN–BIRK INHIBITOR IN

SOYBEAN AND ITS LEVEL IN COMMERCIAL SOY PRODUCTS

P. M , V. K * and A. R

ICAR-Indian Institute of Soybean Research, Khandwa Road, Indore, 452001. India (Received: 24 March 2020; accepted: 21 April 2020)

Bowman–Birk inhibitor (BBI) is a protease inhibitor that aff ects protein digestibility; however, it is increasingly being recognised as anutraceutical and cosmeceutical molecule. In the present study, BBI concentration during soybean seed development, its loss during processing treatments, and the level in commercial soy products were determined. Signifi cant diff erences for BBI concentration were observed across the genotypes and seed development stages. Genotype × seed development stage interaction was also found to be signifi cant (P<0.05) for BBI concentration. Boiling, autoclaving, microwave irradiation, and sprouting resulted in signifi cant (P<0.05) loss of BBI. Minimum loss was observed in sprouting, while autoclaving for 5 min completely deactivated BBI. Microwave irradiation of the soaked seeds resulted in higher BBI loss than of dry seeds. Among the commercial soy products, BBI concentration was high in soy fl our brands, minuscule in ready-to-cook miso soup and undetectable in extruded soy products and roasted soy nuts.

Keywords: Bowman–Birk inhibitor, soybean, reproductive stage, processing, commercial products

Being the potential contributor of protein in vegetarian/vegan diet, soy products are gaining the attention of consumers across the globe. Beside minerals, vitamins, omega-3 fatty acids, and fi bre, soybean is a rich source of biomolecules, namely isofl avones, tocopherols, and lecithin, which have been demonstrated to reduce the risk of onset of several killer diseases (K et al., 2010; M , 2016). These active ingredients of nutraceutical importance are commercially available in several countries. One of the protease inhibitors present in soybean, namely Bowman–Birk inhibitor, a 8 kDa polypeptide comprising of 71 amino acids, which aff ects the digestibility of proteins, is even increasingly being recognised as an anticancer and cosmeceutical molecule. In 1992, the Food and Drug Administration gave soybean BBI concentrate (BBIC) the status of Investigational New Drug. A plethora of studies suggesting the anticancer activity of BBI in both in vitro and in vivo models are available (K , 2005; C et al., 2010). This biomolecule was demonstrated for its effi cacy against oral leukoplakia (A et al., 2013), prostatic hyperplasia (M et al., 2001), and colorectal cancer (C A , 2014). BBI has also been reported to suppress multiple sclerosis and attenuate muscular atrophy (D et al., 2011).

Further, BBI in soybean is a potential cosmeceutical molecule, known for its role in skin health, weight loss, and prevention of hair loss (L , 2010; S et al., 2012; K et al., 2017). Therefore, the retention of BBI during processing of soy products is desirable in contrast to Kunitz trypsin inhibitor (KTI), which aff ects protein digestibility and causes pancreatic hypertrophy in its active form and is sought to be completely inactivated in soy products.

* To whom correspondence should be addressed.

E-mail: vineetksahni@yahoo.com

Several processing methods like heating, extrusion, sprouting, or combinations of these treatments are employed by soy food industry to inactivate KTI (D et al., 2012; C et al., 2014). BBI has relatively better thermo-stability than KTI due to the presence of 5 more disulfi de linkages in its structure than KTI, however, these inactivation methods result in the collateral loss of BBI. Commercial soy food products undergo diff erent types of processing treatments during manufacturing, which may aff ect BBI concentration. However, the reports pertaining to genotypic variation and loss of BBI due to processing treatments are scarce (F et al., 1991). K and co-workers (2018) investigated BBI concentration in 7 soybean varieties, which exhibited 3.2-fold variation for the trait. Further, in several countries, consumption of green soybean at immature stage, known as edamame, is becoming increasingly popular compared to soy products processed from mature grains. Better acceptability of edamame among masses is attributed to reduced off /beany fl avour and negligible fl atulence-inducing oligosaccharides content compared to soy products processed from mature soybean grains. Therefore, it is worthwhile to assess BBI concentration at diff erent soybean seed development stages to understand its level at the picking stage of edamame. Reports concerning the concentration of BBI even in the commercial soy products are limited (H -L et al., 2009). In the present investigation, 2 soybean varieties of India were assessed for BBI concentration at diff erent reproductive stages to investigate the dynamics of BBI accumulation. Mature seeds of one variety were subjected to boiling, microwave, autoclaving, and sprouting to assess BBI loss due to these processing methods. In several countries, a wide array of soy-based products has appeared in market to meet consumer needs. Diff erent types of these commercially available soy products undergo diff erent processing methods or combination of them, which would impact BBI concentration diff erently. Besides, diff erent types of soy products, such as soy fl our, soy chunks, soy granules, ready-to-cook miso soup, roasted soy nuts, were also analysed for BBI concentration.

1. Materials and methods

1.1. Soy products

Soy fl our, soy chunks, soy granules, roasted soy nuts, and ready-to-cook miso soup were commercial products and purchased from the market.

1.2. Picking at diff erent growth stages

Three soybean genotypes, namely NRC127, DS228, and JS97-52, were raised in the fi eld in single row plot of 3 meter length with plant-to-plant and row-to-row distance of 5 and 45 cm, respectively, in triplicate in randomised block design. These 3 genotypes are soybean varieties released for cultivation in India. Green pods of 2 genotypes, namely NRC127 and DS228, were picked at R5, R6, and R7 stage as described by F and co-workers (1971). Fresh tender seeds were shelled from these green pods and recorded for moisture content and 100 green seed fresh weight. A fi xed weight of green seeds picked at each of the reproductive stages was taken for BBI estimation and the data were converted on dry weight basis.

1.3. Processing treatments

Seeds of soybean variety JS 97-52 were subjected to boiling, autoclaving, microwave irradiation, and sprouting. Dry seeds were boiled in distilled water at 100 °C for 5, 10, and 15

min. Autoclaving of soybean seeds was carried out at 121 °C and 15 psi for 15 min. For microwave treatment, both dry and pre-soaked seeds (immersed in distilled water for 30 min) were irradiated in microwave oven (Samsung Model-MC28H5015VB, 0.6 KW power set at 2450 MHz frequency) for 1 and 2 min. For sprouting, soybean seeds were sprouted in germination paper at 28 °C, and the seedlings were drawn for analysis after every 24 h till 4 days.

1.4. Extraction and estimation of BBI through ELISA

Defatted soy fl our (50 mg) was suspended in 1 ml of 50 mM Tris buff er (pH 8.2) and homogenised using Polytron homogeniser (Kinematica, Model PT2100, Switzerland) followed by ultra-sonication (PCI Analytics) for 1 h. The suspension was centrifuged at 20 000 g for 35 min at 4 °C. The resultant supernatant was diluted 25 000 times using phosphate buff er saline. A standard curve (y=0.03x+0.3146, R2=0.996) was generated using varying BBI standard concentration. BBI concentration in samples was quantifi ed using indirect ELISA method as described elsewhere (K et al. 2018).

1.5. Statistical analysis

All steps and assays were performed in triplicate with satisfactory repetition of values. Data presented in Table 1 and 2 are mean ± standard deviation of 3 independent replicates. All statistical analyses were carried out through SAS 9.3 with signifi cance at P˂0.05.

2. Results and discussion

2.1. Genotypic and seed development stages diff erences

In general, mature soybean seeds are used as raw material for processing diff erent soy products. However, soybean is picked at immature stage, i.e. R5, R6, or between R6-R7 stages for consumption as vegetable. Figure 1 depicts BBI concentration in 2 soybean varieties picked at 3 seed development stages, namely R5, R6, and R7 stages of reproductive phase. These seed development stages, i.e. R5, R6, and R7 in soybean have been defi ned by F and co-workers (1971). Fresh green seed weight of these 2 genotypes increased as reproductive stage transitioned from R5 to R6 and thereafter from R6 to R7 stage. BBI concentrations in mature seeds of NRC127 and DS228 were found to be 11.4 and 3.7 mg g–1 dry matter, respectively, exhibiting about 4 fold genotypic variation. Further, it may be noted that NRC127 is a KTI free soybean variety released for cultivation in India, and is essentially derived from variety JS97-52, as the former constitutes 96.2% genome of the latter (AICRPS, 2018). BBI concentration in NRC127 continuously increased as the seed development progressed from R5 to R8 stage. At R5 stage, BBI concentration in NRC127 was 4.83 mg g–1 dry matter, which spiked to 11.4 mg g–1 dry matter at maturity. The variety registered maximum increase of 52.0% in BBI accumulation between R5 to R6 stages, 21.4% increase between R6 and R7 stages and 27.9% increase between R7 and R8 stages. In case of DS228, at R5 stage, BBI concentration was 1.89 mg g–1 dry matter, which at R8 stage increased to 3.7 mg g–1 dry matter. Like NRC127, DS228 registered about 52% increase in BBI between R5 and R6 stages, however, both between R6 and R7, and R7 and R8 stages, the percent increase in BBI concentration was about half of NRC127. These results showed that the eff ects of genotype, seed development stage, and genotype × seed development stage interaction were

signifi cant (P<0.05) on the accumulation of BBI concentration in soybean. The data showed that soybean at R5 stage may possess half the concentration of BBI at full maturity. To compare our results, we could not come across any previous studies wherein accumulation pattern of BBI during soybean seed development has been reported in the literature.

1.89

4.83 2.88

7.34

3.2

8.91

3.7

11.4

0 2 4 6 8 10 12 14

7 2 1 C R N 8

2 2 S D BBI,mg g–1 dry matter

Genotype

Fig. 1. BBI concentration of soybean genotypes DS228 and NRC127 at diff erent seed development stages (R5, R6, R7, and R8). Numerical value given on the top of the bar corresponds to BBI concentration mg g–1 dry matter

at the particular seed development stage of genotype : R5; : R6; : R7; : R6

2.2. Eff ect of processing treatments

Variety JS97-52 was chosen for investigating the eff ect of processing treatment. BBI concentration in the untreated sample of JS97-52 (7.4 mg g–1) was also found to be much lower than observed in NRC127 (11.4 mg g–1). The data pertaining to the loss of BBI due to 4 processing treatments, i.e. boiling, autoclaving, microwave irradiation, and sprouting, are presented in Table 1. Boiling of seeds for 5, 10, and 15 min reduced BBI from 7.4 to 3.4, 1.5, and 1.2 mg g–1, thereby causing 52, 79.7, and 83.8% loss, respectively. The results of our previous study (K et al., 2019) showed that boiling of soybean seeds for 5 and 10 min caused a loss of KTI, the major protease inhibitor in soybean, to the magnitude of 68.8 (from 11.2 to 3.5 mg g–1) and 75.9% (from 11.2 to 2.7 mg g–1), respectively. Autoclaving (at 121°C and 15 psi) of soybean seeds for 15 min completely deactivated BBI. Complete inactivation of KTI as a result of autoclaving for 15 min has also been reported in our previous study (K et al., 2019). F and co-workers (1991) investigated the eff ect of autoclaving of soy fl our on BBI content, and reported 78.0 and 98.8% loss of BBI in soy fl our on autoclaving at 121°C for 10 and 20 min, respectively, which is comparable to the extent of BBI loss due to autoclaving for 15 min in the present study.

With regard to microwave irradiation, this treatment for 1 min in dry seeds plummeted BBI from 7.4 to 5.4 mg g–1, causing 27% loss, however, exposure of soaked seed to microwave radiation for the same duration reduced this biomolecule concentration from 7.4 to 0.5 mg g–1, resulting in 93.4% loss, i.e. about 3-fold higher loss than in dry seeds. Higher percentage of

loss for BBI was registered in both dry and soaked seeds with 2 min exposure to microwave irradiation compared to the lesser duration of 1 min, i.e. microwave irradiation induced loss of BBI was proportionate to exposure time, whether the seeds were soaked or dried. Our results also showed that microwave irradiation for 2 min also caused signifi cantly higher BBI loss in soaked seeds than in dry seeds. Similar observations were reported for KTI reduction due to microwave irradiation in an earlier study (K et al., 2019), which reported the reduction of the KTI due to microwave irradiation as a function of exposure time and the moisture percent in seed, and the higher reduction observed in soaked compared to dried seeds on microwave irradiation may be because of the higher electric dipole forms due to water molecules in the former case, which may result in intense heat energy transfer to proteins. In literature, the studies demonstrating the eff ect of microwave irradiation on total trypsin inhibitor activity (TIA) on soybean and other beans are available. S and co-workers (2010) reported 15.0 and 26.84% reduction in TIA of dry Polish bean fl our on exposure to microwave irradiation for 1 and 2 min, respectively.

Table 1. Changes in BBI concentration in soybean due to diff erent processing treatments

Treatment BBI concentration

mg g–1 dry matter

Percent reduction compared to the control

Control 7.4±0.37a

Boiling

5 min 3.4±0.19d 54.1

10 min 1.5±0.10e 79.7

15 min 1.2±0.10e 83.8

Autoclaving (15 min) n.d. 100

Microwave irradiation (dry seeds)

1 min 5.4±0.18c 27.0

2 min 1.2±0.09e 83.8

Microwave irradiation (pre-soaked seeds)

1 min 0.5±0.07f 93.2

2 min. 0.4±0.03f 94.6

Sprouting

1 day 7.6±0.48a 0

2 days 7.1±0.45a 4.1

3 days 6.6±0.41b 10.8

4 days 6.2±0.35b 16.2

Values given are means of triplicate ± standard deviation and expressed on dry weight basis. Values superscripted with diff erent letters are signifi cantly (P<0.05) diff erent from each other. n.d.: not detected

The data presented in Table 1 also show that sprouting caused only 10.8 and 16.2% loss in BBI concentration in soybean on 3rd and 4th day, which is comparable to 13% loss reported for this molecule after 3 days of sprouting in soybean in an earlier study (D et al., 2012).

BBI loss occurring after 4 days of sprouting was about one fi fth of the reduction (66.1%) for KTI concentration reported in our previous study (K et al., 2019). D and co-workers

(2012) investigated the eff ect of germination on BBI in soybean seeds sprouted for 72 h (3 days) at 25 °C and reported non-signifi cant changes in both KTI and BBI due to sprouting.

A 10.8% reduction in BBI after 72 h in our results may be attributed to higher temperature at which sprouting was carried out in the present investigation. The decline in BBI due to sprouting may be because of the de novo synthesis of proteases during sprouting as suggested in an earlier study (P W , 1991).

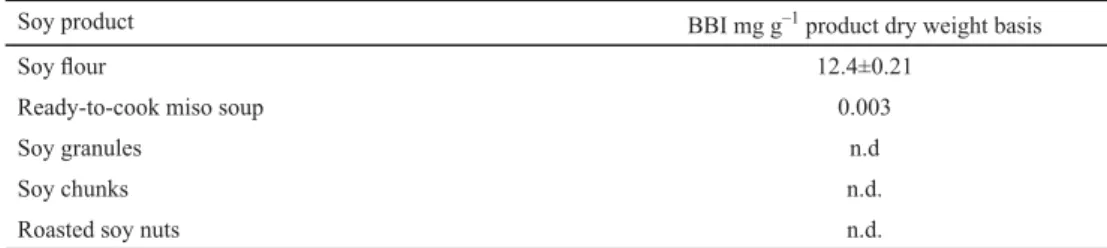

2.3. Concentration in commercial products

Table 2 presents BBI concentration in diff erent types of soy products analysed. Soy fl our showed very high BBI concentration, which was as high as reported in soybean varieties (K et al., 2018). This shows that no heat treatment has been applied during soy-fl our manufacturing of these brands. However, in the rest of the soy-products, such as soy granules, soy chunks, and roasted soy nuts, BBI concentration was non-detectable. Soy granules and soy chunks both are extruded products. C and W (2007) investigated the eff ect of extrusion conditions on TIA of full fat soybean, and reported negligible value of 1.6 mg g–1, which could be due to BBI only, as extrusion completely destroys KTI. BBI was not detectable in roasted soybean nuts either. B and S (2005) reported that 2 min of microwave roasting led to about 88% reduction of total TIA and the residual activity in this study may be attributed to BBI. In the present study, though both modes of roasting and the duration of roasting in roasted soy nuts packets were not mentioned, however, non-detectable values of BBI may be due to exhaustive roasting treatment given to this soy-product rather than microwave roasting applied for only 2 min in the above mentioned study. Further, minuscule BBI concentration observed in ready-to-cook soy miso soup may be because of the presence of benefi cial fungi culture in this product, which release proteases to degrade BBI.

Table 2. BBI concentration in diff erent soy products

Soy product BBI mg g–1 product dry weight basis

Soy fl our 12.4±0.21

Ready-to-cook miso soup 0.003

Soy granules n.d

Soy chunks n.d.

Roasted soy nuts n.d.

Values given are mean of triplicate ± standard deviation and expressed on dry weight basis. n.d corresponds to non- detectable.

3. Conclusions

In the backdrop of recent reports demonstrating the nutraceutical value of BBI, the accumulation pattern of BBI during seed development as a function of genotype was investigated and the loss of BBI due to diff erent processing treatments was assessed. Most of the studies conducted so far concerning the eff ects of processing treatments focused on total TIA, which does not distinguish KTI from BBI. In the present study, eff ect of genotype, seed development stage, and genotype ×seed development stage interaction on BBI concentration

was found to be signifi cant (P<0.05). Among all the processing treatments employed in the study, sprouting caused minimum BBI loss. Among diff erent types of the commercial soy products investigated, extruded and roasted soy products were found to be devoid of BBI.

*

The authors acknowledge the support provided by ICAR - Indian Institute of Soybean Research, where this investigation was carried out.

Ethical approval

This article does not contain any studies involving human participants or animals performed by any of the authors.

Declaration of interest

The authors report no confl ict of interest. The authors alone are responsible for the content and writing of the paper.

References

A , W.B., T , T.H., K , A.R., M , R.J., M , D.V. … M , F.L. (2013):

Bowman–Birk inhibitor concentrate and oral leukoplakia: A random phase IIb trial. Cancer Prev. Res., 6(5), 410–418.

AICRPS (2018): Proceedings of varietal identifi cation committee meeting held on 15th March during 48th Annual Group meeting of the All India Coordinated Research Project on Soybean (AICRPS) held from March 15th to March 18th, 2018 at Raipur. p. 40.

B , M.B. S , S. (2005): The eff ect of microwave roasting on soybean protein composition and components with trypsin inhibitor activity. Acta Alimentaria, 34, 23–31.

C , Y., X Z., Z , C., K , X. H , Y. (2014): Heat induced inactivation mechanism of Kunitz trypsin inhibitor and Bowman–Birk inhibitor in soymilk processing. Food Chem., 15, 108–116.

C , E. W , J. (2007): Eff ects of extrusion conditions on trypsin inhibitor activity of full fat soybeans subsequent eff ects on their nutritional value for young broilers. Brit. Poultry Sci., 48, 703–712.

C ,A., M , F.J., M -M M , C., J , E. D , C. (2010): The cytotoxic eff ect of Bowman–Birk isoinhibitors, IBB1 and IBBD2, from soybean (Glycine max) on HT29 human colorectal cancer cells is related to their intrinsic ability to inhibit serine proteases. Mol. Food Nutr. Res.,5(3), 396–405.

C , A. A , M.C. (2014): Bowman Birk inhibitors from legumes as colorectal chemopreventive agents.

World J. Gastroentero., 20(30), 10305–10315.

D , H., C , B., Z , G.X. R , A.M. (2011): Bowman–Birk inhibitor attenuates experimental autoimmune encephalomyelitis by delaying infi ltration of infl ammatory cell into CNS. Immunol. Res., 51, 145–152.

D , V.P., G , T., V , G., B , M., C , Y.K. M , G.E. (2012): Bowman–Birk and Kunitz protease inhibitors among antinutrients and bio-actives modifi ed by germination and hydrolysis in Brazilian soybean cultivar BRS133. J. Agr. Food Chem., 60, 7886–7894.

F , W.R., C , C.E., B , D.T. P . J.S. (1971): Stage of development descriptions for soybeans, Glycine max (L.). Merrill. Crop Sci., 11, 929–931.

F , M., B , D.L., B , A.H. H , T. (1991): Comparison of a commercial soybean cultivar and an isoline lacking the Kunitz trypsin Inhibitor: Composition, nutritional value, and eff ects of heating. J.

Agr. Food Chem., 39, 327–335.

H -L , B., H , C.C. L , B.O. (2009): Lunasin and Bowman–Birk protease inhibitor (BBI) in US commercial soy foods. Food Chem., 115, 574–580.

K , A.R. (2005): The status of human trials utilizing Bowman–Birk inhibitor concentrate from soybean. -in:

S , M. (Ed.): Soy in health and disease prevention. CRC Press, Taylor & Francis, pp. 207–223.

K , J.E., K , Y.G., P , J.S., L , T.G. L , K.W. (2017): Review of soybean phytochemicals and their bioactive properties relevant for skin health. J. Food Nutr. Res., 5, 852–858.

K , V., R , A. C , G.S. (2010): Nutritional value of soybean. -in: S , G. (Ed.) Soybean: The botany, production and uses. CAB International, pp. 375–403.

K , V., R , A., M , P. S , M. (2019): Kunitz trypsin inhibitor in soybean: Contribution to total trypsin inhibitor activity as a function of genotype and fate during processing. J. Food Meas. Charact., 13, 1583–1590.

K , V., R , A., S , M. M , P. (2018): Comparative assessment of trypsin inhibitor vis-à-vis Kunitz trypsin inhibitor and Bowman–Birk inhibitor activities in soybean, Food Anal. Method., 11, 2431–2437.

L , J.N. (2010): The biochemical and functional food properties of Bowman Birk inhibitor. Crit. Rev. Food Sci., 48(1), 94–118.

M , S.B., M K , W.G., V , D.J., W , X.S., P , K.J., … K , A.R. (2001): Eff ects of Bowman–Birk inhibitor concentrate in patients with benign prostatic hyperplasia. Prostate, 48(1), 16–18.

M , M. (2016): Soy and health update: Evaluation of the clinical and epidemiological literature. Nutrition, 8, 754.

P , G. W , K.A. (1991): Initiation of the degradation of the soybean Kunitz and Bowman–Birk trypsin inhibitors by a cysteine protease. J. Plant Physiol., 96, 1086–1092.

S , R., C , S. G , V.K. (2012): Newer and upcoming therapies for melasma. Indian J. Dermatol Ve.,78(4),417–428.

S , M., W -J , M. S , M. (2010): Determination of trypsin activity of microwave heated bean seeds using bromocresole purple index (BCPI). Pol. J. Food Nutr. Sci., 60, 329–333.