Supporting Information

The dissolution kinetics of raw and mechanochemically treated kaolinites in industrial spent liquor – The effect of the physico-

chemical properties of the solids

Eszter Kása

a,b, Márton Szabados

a,b, Kornélia Baán

c, Zoltán Kónya

c,d, Ákos Kukovecz

c, Bence Kutus

b,e, István Pálinkó

a,b, Pál Sipos

b,f*aDepartment of Organic Chemistry, University of Szeged, Dóm tér 8, Szeged, H-6720 Hungary

bMaterial and Solution Structure Research Group, Institute of Chemistry, University of Szeged, Aradi Vértanúk tere 1, Szeged, H-6720 Hungary

cDepartment of Applied and Environmental Chemistry, University of Szeged, Rerrich B. tér 1, Szeged, H-6720 Hungary

dMTA-SZTE Reaction Kinetics and Surface Chemistry Research Group, University of Szeged, Rerrich B. tér 1, Szeged, H-6720 Hungary

eDepartment of Molecular Spectroscopy, Max Planck Institute for Polymer Research, 55128 Mainz, Ackermannweg 10, Germany

fDepartment of Inorganic and Analytical Chemistry, University of Szeged, Dóm tér 7, Szeged, H-6720 Hungary

*Correponding author.

E-mail address: sipos@chem.u-szeged.hu (P. Sipos)

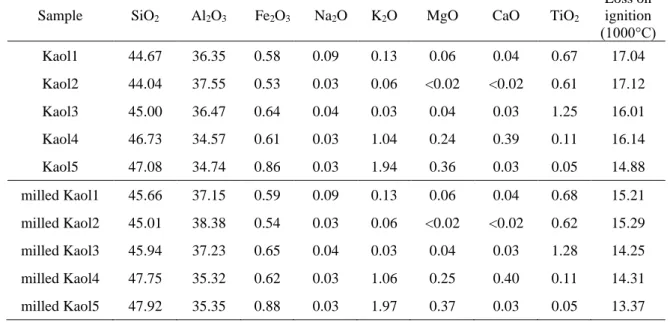

Table S1 Chemical compositions of the raw and 60 min milled kaolinites in mass%.

Sample SiO2 Al2O3 Fe2O3 Na2O K2O MgO CaO TiO2

Loss on ignition (1000°C)

Kaol1 44.67 36.35 0.58 0.09 0.13 0.06 0.04 0.67 17.04

Kaol2 44.04 37.55 0.53 0.03 0.06 <0.02 <0.02 0.61 17.12

Kaol3 45.00 36.47 0.64 0.04 0.03 0.04 0.03 1.25 16.01

Kaol4 46.73 34.57 0.61 0.03 1.04 0.24 0.39 0.11 16.14

Kaol5 47.08 34.74 0.86 0.03 1.94 0.36 0.03 0.05 14.88

milled Kaol1 45.66 37.15 0.59 0.09 0.13 0.06 0.04 0.68 15.21 milled Kaol2 45.01 38.38 0.54 0.03 0.06 <0.02 <0.02 0.62 15.29 milled Kaol3 45.94 37.23 0.65 0.04 0.03 0.04 0.03 1.28 14.25 milled Kaol4 47.75 35.32 0.62 0.03 1.06 0.25 0.40 0.11 14.31 milled Kaol5 47.92 35.35 0.88 0.03 1.97 0.37 0.03 0.05 13.37

4000 3600 3200 28001800 1600 1400 1200 1000 800 600

1640 975

915

Kaol1 Kaol2 Kaol3 Kaol4 Kaol5

Absorbance (a.u.)

Wavenumber (cm−1)

530 3695

3620 690

1005 1115

1030 1390

1140

3400 660

615

Fig. S1 FT-IR spectra of the solid products (mixtures of kaolinite and DSP phase) of the dissolution tests obtained by using various raw kaolinite samples and separated at the end of the kinetic runs from the reaction mixtures.

Table S2 The phase distribution of the raw kaolinites before and those of the DSP containing solids after the dissolution tests.

Crystal phase distribution (mass%)

Sample Kaolinite TiO2 SiO2 Muscovite DSP Before dissolution

Kaol1 88.4 <1 9.5 <1 − Kaol2 92.3 <1 4.6 <1 −

Kaol3 90.7 1.4 6.5 <1 −

Kaol4 84.2 <1 11.6 2.1 − Kaol5 84.5 <1 10.5 3.4 −

After dissolution

Kaol1 5.3 1.2 2.7 3.2 86.0

Kaol2 7.1 1.2 1.3 3.1 85.6

Kaol3 9.9 3.9 1.4 2.7 80.4

Kaol4 22.8 <1 7.2 9.4 58.3 Kaol5 47.1 <1 9.5 12.3 29.1

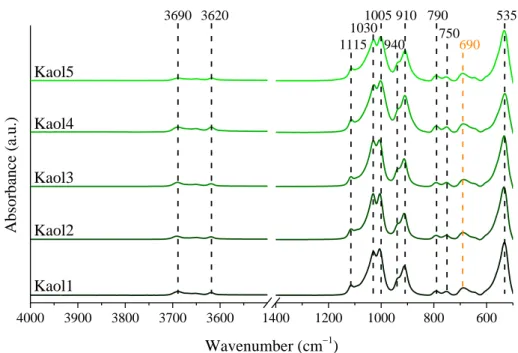

4000 3900 3800 3700 3600 1400 1200 1000 800 600 750

Kaol1 Kaol2 Kaol3 Kaol4

Absorbance (a.u.)

Wavenumber (cm−1) Kaol5

910 535

3690 3620 790

690 1005

1115 1030

940

Fig. S2 The FT-IR spectra of the raw kaolinite samples.

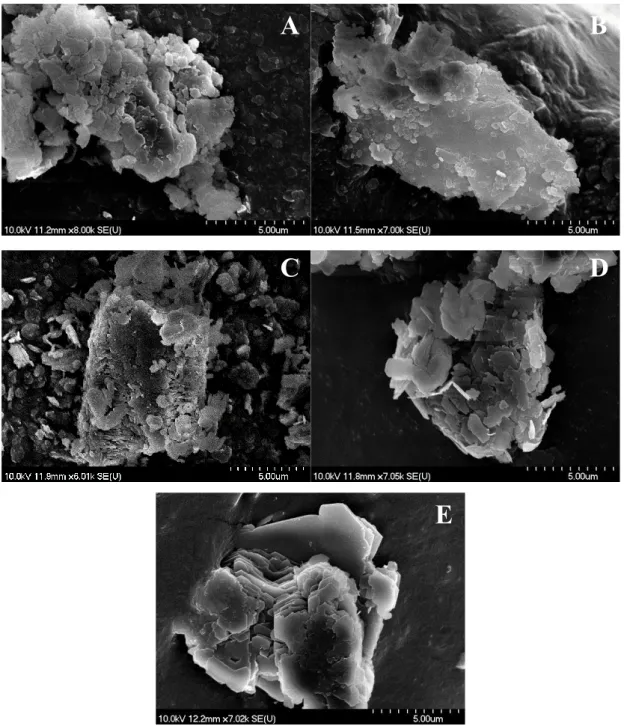

Fig. S3 SEM photos of the raw kaolinite solids: Kaol1 (A); Kaol2 (B); Kaol3 (C); Kaol4 (D);

Kaol5 (E).

0.0 0.2 0.4 0.6 0.8 1.0

0 20 40 60 80

Quantity adsorbed gas (cm3 /g STP)

Relative pressure (p/p0)

Adsorption

Desorption Kaol1

0.0 0.2 0.4 0.6 0.8 1.0

0 10 20 30 40 50 60 70

Quantity adsorbed gas (cm3 /g STP)

Relative pressure (p/p0) Kaol2

Adsorption Desorption

A B

C D

E

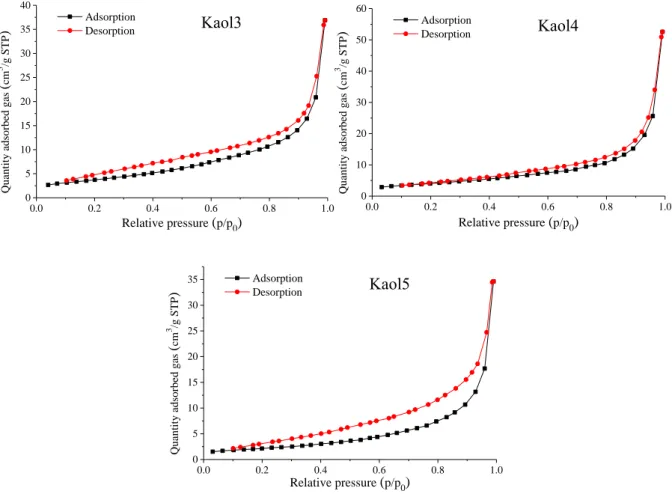

0.0 0.2 0.4 0.6 0.8 1.0 0

5 10 15 20 25 30 35 40

Quantity adsorbed gas (cm3 /g STP)

Relative pressure (p/p0) Kaol3

Adsorption Desorption

0.0 0.2 0.4 0.6 0.8 1.0

0 10 20 30 40 50 60

Quantity adsorbed gas (cm3 /g STP)

Relative pressure (p/p0) Kaol4

Adsorption Desorption

0.0 0.2 0.4 0.6 0.8 1.0

0 5 10 15 20 25 30 35

Quantity adsorbed gas (cm3 /g STP)

Relative pressure (p/p0) Kaol5

Adsorption Desorption

Fig. S4 The N2 adsorption-desorption isotherms of the various raw kaolinite samples.

100 1000

0 10 20 30 40

Intensity (%)

Hydrodynamic diameter (nm)

Kaol1 Kaol2 Kaol3 Kaol4 Kaol5 310

310

480 580

730

Fig. S5 The intensity-weighed size distribution curves of the raw kaolinite samples obtained from DLS measurements.

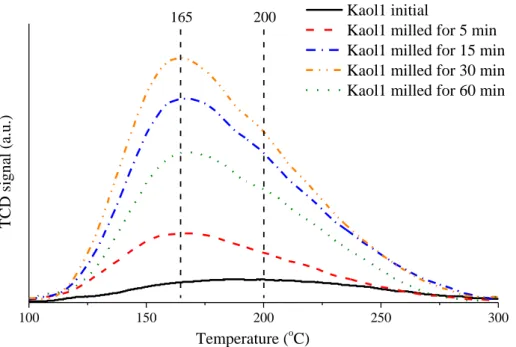

100 150 200 250 300

Temperature (oC)

TCD signal (a.u.)

Kaol1 initial

Kaol1 milled for 5 min Kaol1 milled for 15 min Kaol1 milled for 30 min Kaol1 milled for 60 min

165 200

Fig. S6 The NH3 temperature-programmed desorption curves of the raw and mechanically treated Kaol1.

100 150 200 250 300

TCD signal (a.u.)

Temperature (oC)

Kaol2 initial

Kaol2 milled for 60 min Kaol3 initial

Kaol3 milled for 60 min Kaol4 initial

Kaol4 milled for 60 min Kaol5 initial

Kaol5 milled for 60 min 170

Fig. S7 The TPD-NH3 patterns of the different raw and mechanochemically treated kaolinites.

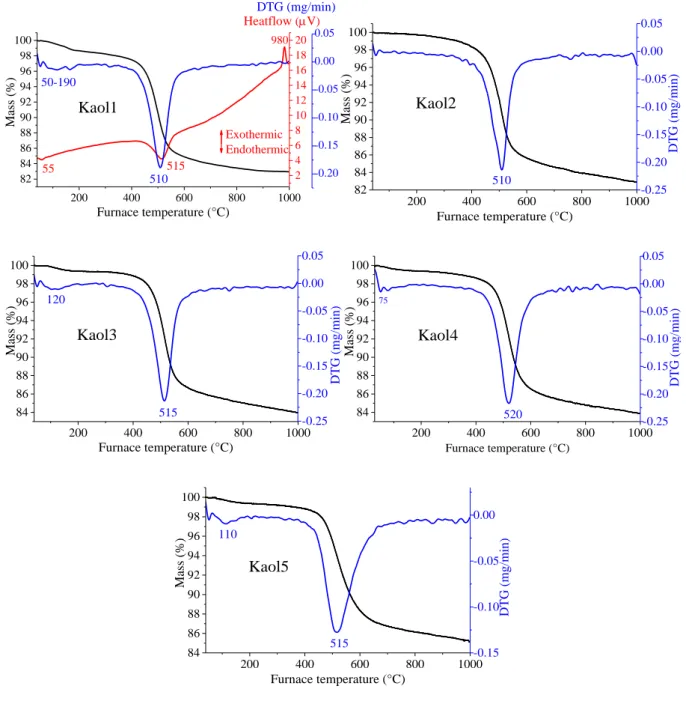

200 400 600 800 1000 82

84 86 88 90 92 94 96 98 100

Kaol1

980

55 50-190

Exothermic Endothermic

Heatflow (V)

Mass (%)

Furnace temperature (°C) 515 510

DTG (mg/min)

2 4 6 8 10 12 14 16 18 20

-0.20 -0.15 -0.10 -0.05 0.00 0.05

200 400 600 800 1000

82 84 86 88 90 92 94 96 98 100

Kaol2

DTG (mg/min)

Mass (%)

Furnace temperature (°C)

510 -0.25

-0.20 -0.15 -0.10 -0.05 0.00 0.05

200 400 600 800 1000

84 86 88 90 92 94 96 98 100

515 120

-0.25 -0.20 -0.15 -0.10 -0.05 0.00 0.05

Kaol3

Mass (%) DTG (mg/min)

Furnace temperature (°C)

200 400 600 800 1000

84 86 88 90 92 94 96 98 100

520

75

-0.25 -0.20 -0.15 -0.10 -0.05 0.00 0.05

Kaol4

DTG (mg/min)

Mass (%)

Furnace temperature (°C)

200 400 600 800 1000

84 86 88 90 92 94 96 98 100

Kaol5

515

DTG (mg/min)

Furnace temperature (°C)

Mass (%) 110

-0.15 -0.10 -0.05 0.00

Fig. S8 Thermogravimetric curves of the raw kaolinite samples.

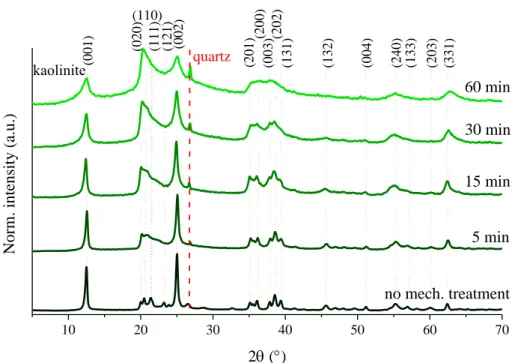

10 20 30 40 50 60 70

(331)

kaolinite (131)

(111)

Norm. intensity (a.u.)

2 ()

(110)

(201) (202) (240) (203)(003)(200)

quartz

(002)

(020)

5 min 15 min

no mech. treatment 30 min 60 min

(001) (121) (132) (004) (133)

Fig. S9 The XRD patterns of the Kaol1 samples milled for various times.

4000 3900 3800 3700 3600 1480 1110 740

60 min

30 min

15 min

5 min

Absorbance (a.u.)

Wavenumber (cm−1) no mech. treatment

3690 3620

750

910 790 535

690 1005

1115 1040

940

Fig. S10 The FT-IR spectra of the raw and mechanochemically treated Kaol1.

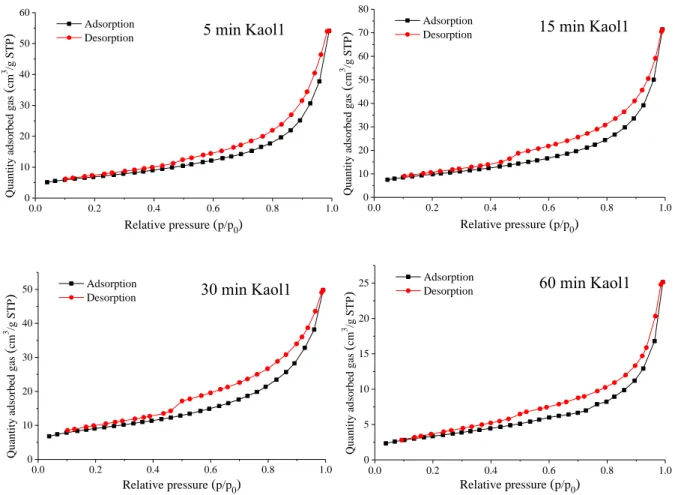

0.0 0.2 0.4 0.6 0.8 1.0 0

10 20 30 40 50 60

Adsorption Desorption

Quantity adsorbed gas (cm3 /g STP) 5 min Kaol1

Relative pressure (p/p0)

0.0 0.2 0.4 0.6 0.8 1.0

0 10 20 30 40 50 60 70 80

Adsorption Desorption

Quantity adsorbed gas (cm3 /g STP) 15 min Kaol1

Relative pressure (p/p0)

0.0 0.2 0.4 0.6 0.8 1.0

0 10 20 30 40 50

Quantity adsorbed gas (cm3 /g STP) Adsorption

Desorption 30 min Kaol1

Relative pressure (p/p0)

0.0 0.2 0.4 0.6 0.8 1.0

0 5 10 15 20 25

Quantity adsorbed gas (cm3 /g STP)

Adsorption

Desorption 60 min Kaol1

Relative pressure (p/p0)

Fig. S11 The N2 adsorption-desorption isotherms of the mechanochemically treated Kaol1.

100 1000

0 5 10 15 20 25 30

1170 760

160 200

1250 865

900 570

600 445

Intensity (%)

Hydrodynamic diameter (nm)

initial 5 min 15 min 30 min 60 min

Fig. S12 The intensity-weighed size distribution curves of the raw and mechanically treated Kaol1 obtained from DLS measurements.

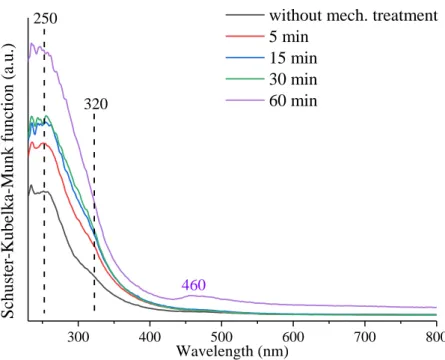

300 400 500 600 700 800 320

Schuster-Kubelka-Munk function (a.u.)

Wavelength (nm)

without mech. treatment 5 min

15 min 30 min 60 min

460 250

Fig. S13 The UV-Vis diffuse reflectance spectra of the raw and mechanochemically treated Kaol1.

200 400 600 800 1000

84 86 88 90 92 94 96 98 100

-0.20 -0.15 -0.10 -0.05 0.00

505

5 min

Mass (%) DTG (mg/min)

Furnace temperature (°C) 90

200 400 600 800 1000

86 88 90 92 94 96 98 100

15 min

Mass (%)

Furnace temperature (°C)

DTG (mg/min)

100

500

-0.15 -0.10 -0.05 0.00

200 400 600 800 1000

84 86 88 90 92 94 96 98 100

30 min

-0.15 -0.10 -0.05 0.00

Mass (%)

Furnace temperature (°C)

DTG (mg/min)

115

495

200 400 600 800 1000

84 86 88 90 92 94 96 98 100

60 min

Mass (%)

Furnace temperature (°C)

DTG (mg/min)

125

475 -0.08

-0.06 -0.04 -0.02 0.00 0.02

Fig. S14 Thermogravimetric curves of the mechanically treated Kaol1 samples.

10 20 30 40 50 60 70

2 ()

Norm. intensity (a.u.)

Kaol5 Kaol4

Kaol3 Kaol2 Kaol1 muscovite

quartz kaolinite

anatase

Fig. S15 The XRD patterns of the mechanochemically treated kaolinites (1 hour milling time).

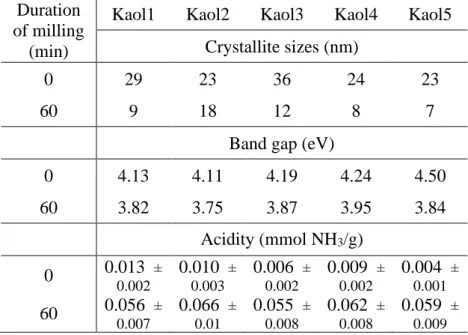

Table S3 Crystallite size, band gap and acidity values of the raw kaolinites before and after 1 hour milling.

Duration of milling

(min)

Kaol1 Kaol2 Kaol3 Kaol4 Kaol5 Crystallite sizes (nm)

0 29 23 36 24 23

60 9 18 12 8 7

Band gap (eV)

0 4.13 4.11 4.19 4.24 4.50

60 3.82 3.75 3.87 3.95 3.84

Acidity (mmol NH3/g) 0 0.013 ±

0.002

0.010 ± 0.003

0.006 ± 0.002

0.009 ± 0.002

0.004 ± 0.001

60 0.056 ± 0.007

0.066 ± 0.01

0.055 ± 0.008

0.062 ± 0.008

0.059 ± 0.009

Table S4 Chemical compositions of the obtained desilication products from the dissolution tests of raw and 60 min milled kaolinites in mass%.

Sample SiO2 Al2O3 Fe2O3 Na2O K2O MgO CaO TiO2 SO2

Loss on ignition (1000°C) Kaol1 - DSP 40.22 30.35 0.44 14.66 0.11 0.09 <0.02 0.61 4.30 8.82 Kaol2 - DSP 38.70 30.41 0.59 14.20 0.08 <0.02 0.02 0.58 3.81 11.03 Kaol3 - DSP 39.75 30.22 0.60 13.94 0.05 0.02 0.04 1.53 3.39 9.70 Kaol4 - DSP 42.92 28.77 0.57 11.51 0.23 0.21 0.34 0.19 3.15 11.34 Kaol5 - DSP 52.53 26.75 0.73 6.23 1.29 0.24 0.02 0.07 2.01 10.47 milled Kaol1 -

DSP 39.36 29.39 0.48 14.41 0.08 0.06 <0.02 0.58 3.89 11.20 milled Kaol2 -

DSP 40.04 30.59 0.64 14.38 0.03 0.03 0.02 0.64 3.93 9.41 milled Kaol3 -

DSP 39.78 30.11 0.58 14.09 0.02 0.05 0.03 1.39 3.16 10.50 milled Kaol4 -

DSP 40.15 29.39 0.46 13.97 0.19 0.15 0.28 0.17 3.78 10.95 milled Kaol5 -

DSP 40.70 30.78 0.76 13.73 0.65 0.22 0.03 0.08 2.84 9.65