P R O B L E M S ASSOCIATED WITH THE D E V E L O P M E N T OF A THERMIONIC CONVERSION R E A C T O R *

R. L . HirschT and J. W. H o l l a n d t A t o m i c s I n t e r n a t i o n a l

A Division of N o r t h A m e r i c a n Aviation, Inc.

Canoga P a r k , California A b s t r a c t

T h e r m i o n i c c o n v e r s i o n of n u c l e a r r e a c t o r power is p a r - t i c u l a r l y a t t r a c t i v e for space applications b e c a u s e of the potentially high c o n v e r s i o n efficiencies obtainable, and high heat rejection t e m p e r a t u r e s . This r e s u l t s in a t t r a c t i v e low specific weight e l e c t r i c a l g e n e r a t i n g s y s t e m s . This p a p e r d e s c r i b e s a conceptual design of a 300 kwe t h e r m i o n i c space power r e a c t o r with a subsequent d i s c u s s i o n of a s s o c i a t e d development r e q u i r e m e n t s .

I. 300 kwe Conceptual Design A. The T h e r m i o n i c F u e l E l e m e n t

One method of employing the t h e r m i o n i c c o n v e r t e r is to i n t e g r a t e it in a n u c l e a r r e a c t o r c o r e in such a m a n n e r that the fuel m a t e r i a l a l s o s e r v e s as the cathode of the c o n v e r t e r . A typical t h e r m i o n i c c o n v e r s i o n fuel e l e m e n t is i l l u s t r a t e d in F i g . 1, w h e r e a n u m b e r of t h e r m i o n i c c o n v e r t e r cells a r e

shown connected in s e r i e s . Since each cell is capable of p r o - ducing a potential of a p p r o x i m a t e l y one volt, m a n y cells m u s t be connected in s e r i e s to p r o d u c e useful high voltage. E a c h cell c o n s i s t s of a cathode, an anode, an i n t e r e l e c t r o d e space containing c e s i u m vapor, insulation to p r o v i d e the p r o p e r e l e c t r i c a l configuration, and an outer sleeve to i s o l a t e the e n t i r e e l e m e n t from its e x t e r n a l s u r r o u n d i n g s and p r o v i d e the s t r u c t u r a l integrity for the a s s e m b l y .

The cathodes a r e solid c y l i n d e r s of fuel m a t e r i a l which a r e held in place by the insulation s e p a r a t o r s and the e l e c - t r i c a l l e a d s in the m a n n e r of a filament in a light bulb. N u c l e a r

* P r e s e n t e d at the Space P o w e r S y s t e m s Conference, Santa M onica, California, S e p t e m b e r 27-30, I960.

Work done u n d e r AEC C o n t r a c t : AT(11-1 ) - G E N - 8 t C o m p a c t P o w e r S y s t e m s D e p a r t m e n t

heat supplies the t h e r m a l e n e r g y to 'lift' free e l e c t r o n s at the cathode surface to an e n e r g y level at which they a r e

emitted into the i n t e r e l e c t r o d e s p a c e . This e l e c t r o n r e m o v a l of heat from the cathode is a c c o m p a n i e d by other cooling p r o - c e s s e s including radiation to the anode, and conduction of heat through the e l e c t r i c a l l e a d s connecting the anodes to the cathodes. T h e s e l a t t e r two p r o c e s s e s a r e heat l o s s e s and m u s t be accounted for in cell o p t i m i z a t i o n s . It m a y be that the cathodes will have to be clad to p r e v e n t d e l e t e r i o u s effects caused by the r e l e a s e of the fission p r o d u c t s from the fuel.

F o r this conceptual design, however, cladding is not con- s i d e r e d .

The anode is a thin c y l i n d r i c a l shell of m e t a l l i c con- ductor s u r r o u n d i n g the cathode. The e l e c t r o n s which t r a v e l to the anode from the cathode a r e a b s o r b e d with the c o n v e r -

sion of t h e i r kinetic e n e r g y into s e n s i b l e heat. T h i s heat m u s t be r e m o v e d from the anode to m a i n t a i n the e l e c t r o d e t e m p e r a t u r e difference. F o r good heat t r a n s f e r the anode m u s t be in t h e r m a l contact with the outer m e t a l l i c sleeve, which is cooled by a liquid m e t a l as is d i s c u s s e d l a t e r . In o r d e r that the anode of the adjacent cells a r e not e l e c t r i c a l l y shorted, a l a y e r of e l e c t r i c a l insulation m u s t be i n t e r p o s e d .

The annular space between the e l e c t r o d e s contains c e s i u m vapor which is ionized by the high t e m p e r a t u r e e n v i r o n - m e n t and s e r v e s to n e u t r a l i z e the space c h a r g e which is p r o - duced by the high e l e c t r o n flux in the i n t e r e l e c t r o d e s p a c e . B. T h e r m i o n i c R e a c t o r

The t h e r m i o n i c fuel e l e m e n t s a r e a s s e m b l e d into a close spaced hexagonal lattice to f o r m a 9 inch d i a m e t e r by 1 0 inch long cylindrical r e a c t o r c o r e . F i g u r e 2 p r e s e n t s the e n t i r e r e a c t o r a s s e m b l y which c o n s i s t s of the c o r e c o m p o s e d of c o n v e r t e r fuel e l e m e n t s located by an upper and a lower grid plate, a r e f l e c t o r with m o v a b l e sections for n u c l e a r control, e l e c t r i c a l t e r m i n a l s for power output, and a c e s i u m c i r c u l a - tion s y s t e m .

T h e r e a r e two e l e c t r i c a l s e r i e s of the c o n v e r s i o n fuel e l e m e n t s in the c o r e ; one for the m a i n power output and a s e r i e s of special e l e m e n t s for supplying the power r e q u i r e d by an e l e c t r o m a g n e t i c pump used to c i r c u l a t e a coolant b e - tween the r e a c t o r and w a s t e heat r a d i a t o r . T h e r e a r e two c e s i u m r e s e r v o i r s to s e r v e the two sets of c o n v e r t e r fuel e l e m e n t s . T h e s e r e s e r v o i r s a r e externally located to the r e a c t o r so t h e i r t e m p e r a t u r e can be m o r e easily controlled.

The r e s e r v o i r s a r e connected to one end of each s e r i e s of

e l e m e n t s and the other end is a bleed-off nozzle which is used to continuously r e l e a s e a s m a l l amount of the vapor in o r d e r to m i n i m i z e the c o n c e n t r a t i o n s of g a s e o u s fission p r o d u c t s .

The r e f l e c t o r completely s u r r o u n d s the c o r e , and can be used for n u c l e a r control b e c a u s e of the high n e u t r o n leakage a s s o c i a t e d with a s m a l l fast c o r e . Reflector control is e s p e - cially useful since this type of control c a u s e s only s m a l l power p e r t u r b a t i o n s within the c o r e . The r e f l e c t o r c o n s i s t s of t h r e e p a r t s : control d r u m s which r o t a t e away from the c o r e to p r o v i d e continuous control; t h r e e safety shutdown slabs which a r e spring loaded to fall away f r o m the c o r e s i d e s ; and a s t a t i o n a r y portion which c o n s t i t u t e s the end r e f l e c t o r s .

The r e a c t o r coolant is the liquid m e t a l , NaK eutectic which is selected b e c a u s e of its good heat t r a n s f e r p r o p e r t i e s , high t e m p e r a t u r e c a p a b i l i t i e s , and the ability to employ an e l e c t r o m a g n e t i c p u m p . The u s e of an EM p u m p p r o v i d e s operation of a completely sealed s y s t e m . The r e a c t i o n v e s s e l has p l e n u m c h a m b e r s at both ends of the c o r e for p r o p e r flow d i s t r i b u t i o n through the channels f o r m e d by the c o n v e r t e r fuel e l e m e n t s .

C. A u x i l i a r y E q u i p m e n t

The a u x i l i a r y equipment to c o m p l e t e and i n t e g r a t e the s y s t e m includes the w a s t e heat r a d i a t o r , pump, control s y s t e m , payload shielding (if r e q u i r e d ) , and s t r u c t u r e a s shown s c h e m a t i c a l l y in F i g . 3. The NaK p u m p is of the d i r e c t c u r r e n t conduction v a r i e t y . It w a s selected b e c a u s e of the convenient s o u r c e of low voltage high c u r r e n t e l e c t r i c a l power is easily supplied by t h e r m i o n i c c o n v e r t e r s . This p u m p is used to c i r c u l a t e the NaK through the r e a c t o r and out to the r a d i a t o r w h e r e the cycle w a s t e heat is r a d i a t e d to s p a c e . D. A s s u m p t i o n s for the Conceptual Design

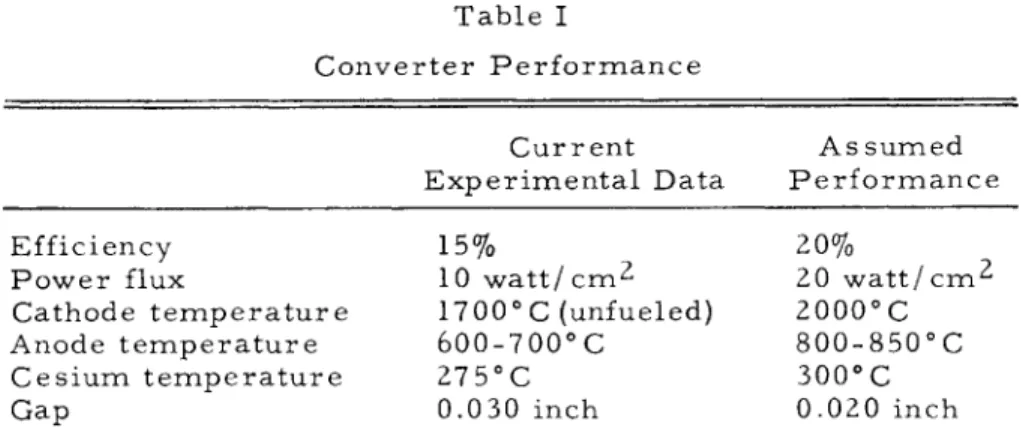

A s s u m p t i o n s of the c o n v e r t e r p e r f o r m a n c e a r e b a s e d on a r e a s o n a b l e extrapolation of c u r r e n t e x p e r i m e n t a l data.

Table I c o m p a r e s the e x p e r i m e n t a l data with the a s s u m e d p e r f o r m a n c e .

In the light of the r e c e n t r e s e a r c h a c c o m p l i s h m e n t s in approaching the e m i s s i o n l i m i t e d diode p e r f o r m a n c e , the a s s u m e d p e r f o r m a n c e values do not a p p e a r to be u n r e a s o n - able. Work at A t o m i c s I n t e r n a t i o n a l h a s r e s u l t e d in achieving power d e n s i t i e s a s high as 18.5 w a t t s / c m ^ at a cathode t e m - p e r a t u r e of 1800°C when the spacing of m o l y b d e n u m e l e c - t r o d e s is 0.005 inch.

Table I

C o n v e r t e r P e r f o r m a n c e C u r r e n t

E x p e r i m e n t a l Data A s s u m e d P e r f o r m a n c e Efficiency

P o w e r flux

Cathode t e m p e r a t u r e Anode t e m p e r a t u r e C e s i u m t e m p e r a t u r e Gap

15% 10 watt/ cm2 , 1700°C(unfueled) 600-700°C

Z75°C 0.030 inch

20 w a t t / c m20% 2 2000°C 800-850°C 300°C 0.020 inch The r e a c t o r c r i t i c a l i t y calculations a r e b a s e d on a fast one group c r i t i c a l i t y equation and r e f l e c t o r w o r t h s and ex- t r a p o l a t i o n lengths a r e b a s e d on the L o s A l a m o s Godiva and Topsy e x p e r i m e n t s .

II. Development R e q u i r e m e n t s

The development of a t h e r m i o n i c r e a c t o r is complicated by e x t r e m e l y high operating t e m p e r a t u r e s and a need to s a t - isfy both the n u c l e a r and e l e c t r i c a l r e q u i r e m e n t s . T h e r e a r e a n u m b e r of v e r y s e v e r e p r o b l e m s in the technology which will r e q u i r e significant a d v a n c e s , but none a p p e a r to r e q u i r e a m a j o r b r e a k - t h r o u g h . The scope of this d i s c u s s i o n is limited to the t h e r m i o n i c r e a c t o r .

A. M a t e r i a l s and F a b r i c a t i o n R e q u i r e m e n t s

Several r e q u i r e m e n t s exist which apply to all of the m a t e - r i a l s within the t h e r m i o n i c c e l l s . T h e s e a r e high t e m p e r a - t u r e capability (see t e m p e r a t u r e s in T a b l e I), physical and c h e m i c a l compatibility, fabricability and joinability, and ability to withstand t h e r m a l cycling and a high radiation en- v i r o n m e n t . S e v e r a l inter compatibility p r o b l e m s will exist and a r e due to the e x t r e m e l y high t e m p e r a t u r e s w h e r e vapor p r e s s u r e s of o r d i n a r y solids b e c o m e a p p r e c i a b l e and r e a c t i o n r a t e s between the cell m a t e r i a l s m a y be unusually r a p i d . Also since insulating m a t e r i a l s a r e involved, which a r e usually oxides, the p r o b l e m of d i s a s s o c i a t i o n m a y p r o v e quite i m - portant in the p r e s e n c e of c e s i u m . Some of the r e q u i r e m e n t s for each m a t e r i a l a r e e n u m e r a t e d below.

1. C a t h o d e - F u e l M a t e r i a l

The fuel m u s t have a high u r a n i u m density in o r d e r to r e s u l t in a compact fast r e a c t o r . This is r e q u i r e d b e c a o s e

of the unusually l a r g e a m o u n t s of n o n - f i s s i o n a b l e m a t e r i a l s in the c o r e r e q u i r e d for p r o p e r e l e c t r i c a l configuration. Long t e r m e n d u r a n c e is usually a specification for s p a c e power, so high b u r n u p s will be r e q u i r e d on the o r d e r of 1 to Z m e t a l atom p e r c e n t . The d i m e n s i o n s of the fuel c y l i n d e r s m u s t r e m a i n p r a c t i c a l l y t i m e i n v a r i a n t b e c a u s e of the r a t h e r high t o l e r a n c e r e q u i r e d on the d i m e n s i o n s of the i n t e r e l e c t r o d e s p a c e . Should fuel swelling occur short c i r c u i t s would r e s u l t . In o r d e r for the cathode not to c r a c k a s a r e s u l t of t h e r m a l s t r e s s e s , the fuel should have a high t h e r m a l con- ductivity and have good s t r e n g t h c h a r a c t e r i s t i c s at operating t e m p e r a t u r e s .

A d e s i r a b l e p r o p e r t y of the fuel is that it have an optimum w o r k function or a surface capable of being coated with a m a t e r i a l with an optimum w o r k function. A p a r t i c u - l a r l y i n t e r e s t i n g fuel m a t e r i a l which m a y fill m a n y of the specifications is U C - Z r C . The addition of z i r c o n i u m carbide to UC is found to add s t r e n g t h and thus r e d u c e the swelling p r o b l e m , and to i n c r e a s e the melting point of the fuel.

2. Anode

The anode m a t e r i a l should have a high t h e r m a l con- ductivity, low surface e m i s s i v i t y , and a low e l e c t r i c a l r e s i s - tivity. The l a t t e r p r o p e r t y is i m p o r t a n t to s y s t e m weight if t h e r e is a high c u r r e n t power output r e q u i r e m e n t . Anode t e m p e r a t u r e s in the o r d e r of 800°C m u s t be endured for ex- tended p e r i o d s of t i m e . Nickel plated copper m a y be able to fulfill the anode r e q u i r e m e n t .

3. E l e c t r i c a l Connections Between Adjoining Anodes and Cathodes

In addition to conducting the e l e c t r i c a l c u r r e n t , the connections support the c a t h o d e s . The m a t e r i a l m u s t have strength and low e l e c t r i c a l r e s i s t i v i t y at elevated t e m p e r a - t u r e s . Likely candidates for the c o n n e c t o r s a r e molybdenum, tantalum, tungsten, and p o s s i b l y r h e n i u m . Connection to the anode will be far l e s s difficult due to the p r o b a b l e m e t a l l i c n a t u r e of the anode and m u c h lower t e m p e r a t u r e s involved.

4. E l e c t r i c a l Insulation

The insulation between the anode and the cladding m u s t satisfy the operating r e q u i r e m e n t s of: good t h e r m a l conduc- tivity; high d i e l e c t r i c strength; fabricability in thin l a y e r s ; ability to contact anode and cladding s u r f a c e s without high t h e r m a l r e s i s t a n c e ; and have a compatible t h e r m a l coefficient

of expansion with the contacting m a t e r i a l s .

P o s s i b l e candidates for this insulation include a l u m i - num oxide, b e r y l l i u m oxide, and boron n i t r i d e . P r o b a b l y none of t h e s e m a t e r i a l s p o s s e s s all the d e s i r e d c h a r a c t e r - i s t i c s , so that some c o m p r o m i s e m u s t be m a d e i n t r o d u c i n g a device which h a s the r e q u i r e d lifetime and p e r f o r m a n c e . It a p p e a r s that one of the m o s t difficult p r o b l e m s lies in the fabrication of the a n o d e - i n s u l a t i o n - c l a d d i n g sandwich since e l e c t r i c a l s h o r t s a r e i n t o l e r a b l e and t h e r m a l contact r e s i s t - a n c e s m u s t not v a r y with t i m e . If s e p a r a t i o n s occur between the l a y e r s , melting of the anode could o c c u r .

Insulation between the adjacent cells m u s t have high t e m p e r a t u r e s t r e n g t h since it m u s t d i r e c t l y face the c a t h o d e s . D i e l e c t r i c s t r e n g t h is m u c h l e s s significant for this a p p l i c a - tion since the potential between adjacent cells is of the o r d e r of one volt.

5. Cladding M a t e r i a l s

The cladding m u s t have high s t r e n g t h and c h e m i c a l r e s i s t a n c e to both the i n t e r n a l and e x t e r n a l environment, in o r d e r to m a i n t a i n s t r u c t u r a l integrity and i s o l a t e the cells from the liquid m e t a l coolant. F a b r i c a t i o n of the cladding in the end a r e a s w h e r e the e l e c t r i c a l l e a d s and the c e s i u m ducts e m e r g e will undoubtedly be a difficult t a s k .

B. Design R e q u i r e m e n t s

The specific r e a c t o r p r o b l e m of power flattening is unique to this type of r e a c t o r . In a s m a l l r e a c t o r with a fast s p e c - t r u m the peak to a v e r a g e power can be as high as 1.8. A s e r i e s of uniformly fueled t h e r m i o n i c c o n v e r t e r s in such a flux field would p r o d u c e e l e c t r i c a l power at significantly l e s s than m a x i m u m efficiency. S e v e r a l m e t h o d s can be employed to r e m e d y t h i s . E l e c t r i c a l power production can be flattened by n u c l e a r m e a n s or c e r t a i n c o n v e r t e r c h a r a c t e r i s t i c s can be a l t e r e d to i m p r o v e o v e r a l l p e r f o r m a n c e s . The significant c h a r a c t e r i s t i c of n u c l e a r power flattening is to i n c r e a s e c o r e volume and weight. F o r this r e a s o n , its u s e m u s t be m i n i - m i z e d in t h e r m i o n i c r e a c t o r s which a r e c r i t i c a l i t y l i m i t e d .

The techniques of i n c r e a s i n g c o r e p e r f o r m a n c e by t h e r m - ionic c o n v e r t e r techniques a r e as follows:

1) C o n v e r t e r length can be v a r i e d so that each cell can p r o d u c e total line c u r r e n t at the optimum con- ditions c o r r e s p o n d i n g to its i n t e g r a t e d t h e r m a l power input.

2) Heat shielding techniques can be utilized not only to i n c r e a s e equivalent surface e m i s s i o n but to d e c r e a s e i n t e r n a l cathode t e m p e r a t u r e d i f f e r e n c e s . The p e r f o r m a n c e gains r e s u l t i n g from cathode length v a r i a t i o n s can be easily d e t e r m i n e d once the c h a r a c t e r i s t i c s of a c o n v e r t e r have been e s t a b l i s h e d . The gains r e s u l t i n g from heat shielding will be c o n s i d e r a b l y m o r e difficult to evaluate b e c a u s e the p r o b l e m depends on such v a r i a b l e s a s e l e c t r o d e spacing v a r i a t i o n s , groove g e o m e t r y , and t e m p e r a - t u r e d i s t r i b u t i o n .

B e c a u s e m i n i m u m weight is the u l t i m a t e goal, t h e r m i - onic space r e a c t o r s will p r o b a b l y utilize both c o n v e r t e r and n u c l e a r m e t h o d s of power flattening. In higher power s y s t e m s c r i t i c a l v o l u m e will no longer be a limiting factor, and n u c l e a r power flattening will be l e s s costly f r o m a weight standpoint.

III. Growth P o t e n t i a l

T h e r m i o n i c c o n v e r s i o n s y s t e m s have excellent growth potential, and achievable upper l i m i t s on efficiency and

specific power a r e m u c h higher than have been p r e s e n t l y d e m o n s t r a t e d . I m p r o v e m e n t s in c o n v e r t e r p e r f o r m a n c e will d e c r e a s e c o r e , pump, and r a d i a t o r size r e q u i r e m e n t s and p e r m i t lighter weight power p l a n t s . The r e a c t o r specific weight for v a r i o u s size power plants has been e s t i m a t e d and is shown in F i g . 4. T h e r m i o n i c c o n v e r s i o n r e a c t o r s a r e e s t i m a t e d to weigh l e s s than one pound p e r kilowatt for s t a t e - o f - t h e - a r t specific p o w e r s of 10 w a t t s / c m ^ and for p o w e r s g r e a t e r than 800 kwe.

VO ON

LEAD AND CATHODE SUPPORT SEPARATION INSULATION

CATHODE ANODE

CATHODE

GRID PLATE GUIDE

• SLEEVE

■ COOLANT

ELECTRICAL INSULATION

■ CESIUM VAPOR GAP

>

n

-<

</>

—I rn CO

POWER LEAD AND GAS VENT

Fig. 1. Thermionic Conversion Fuel Element

CONTROL DRUM

FISSION PRODUCT OUTLET

MAIN POWER TERMINAL VO

REFLECTOR

THERMIONIC CONVERSION FUEL ELEMENTS

*=4~**-~-~ PUMP POWER TERMINAL

— SAFETY SLAB

>

n O

Co -<

CO Co CESIUM RESERVOIR

FOR PUMP ELEMENTS CESIUM RESERVOIR

FOR MAIN POWER ELEMENTS COOLANT OUTLET

SYSTEM

REACTOR WITH CONVERTER FUEL-

ELEMENTS

• ^ - i

FISSION PRODUCT HANDLING SYSTEM

WASTE HEAT RADIATOR

^ - ^ C O O L - ^ PIU PUMP

POWER

COOLANT PUMP

PRIMARY POWER OUTPUT

F i g . 3. Schematic D i a g r a m of a High P o w e r R e a c t o r T h e r m i o n i c Space P o w e r Plant

X J MAX IMUM CATHO DE EMISSION

1 20 W

= 10 WATTS /cr

ATTS/cm2 . n2

400 600 8 0 0 1000 1200 1400 1600 REACTOR POWER OUTPUT (kw)

F i g . 4. R e a c t o r Specific Weight vs P o w e r