Fuzzyfied Robust Fixed Point Transformations

Ter´ez A. V´arkonyi

Doctoral School of Applied Informatics, John von Neumann Faculty of Informatics Obuda University´

96/B B´ecsi street, Budapest, H-1034, Hungary varkonyi.teri@phd.uni-obuda.hu

Abstract—Nowadays Fuzzy Logic Controllers (FLC) are get- ting more and more prevalent because of their friendly formalism and capability of using heuristic information. In many cases, traditional controllers are replaced with fuzzy techniques because they can handle systems with highly nonlinear or partly unknown models. The family of Robust Fixed Point Transformations (RFPT) has been partly developed to solve control tasks without knowing the exact parameters of the used model. This makes RFPT suitable to combine with Fuzzy Controllers resulting in the improvement of the performance of FLC. In this paper, a new RFPT-based Fuzzy Logic Controller is introduced on a cart- pendulum system. The simulations show that the more extreme situations we pick the more significantly the built-in RFPT can improve the Fuzzy Logic Controller’s results.

I. INTRODUCTION

In the 19th century stability of dynamical systems was a problematic subject for the scientists. It was sometimes very elaborate to determine whether a system was stable or not and only a few results were at hand to answer these questions. One of the first breakthroughs was made by Aleksandr Lyapunov in 1892. In his PhD dissertation [1] he introduced an approach, called Lyapunov’s “direct” method, in which on the basis of relatively simple estimations, stability (either global or local, common, exponential, or asymptotic) could be determined without obtaining and studying the solutions of the equations of motion.

Since that many controllers have been designed based on his idea because Lyapunov’s method substantiated the area of control. Still, other research directions have appeared, for example adaptive control with local convergence, like Robust Fixed Point Transformations, or neural networks and fuzzy techniques. Some of them still use Lyapunov’s results for controlling a system, but some of them do not.

Robust Fixed Point Transformation (RFPT) is a method which was invented to improve well behaving controllers’

results when a model approximation blocks the controller to give better results. This improvement can be advantageous because in real life when for example a company is no longer satisfied with a controller, it has to buy or make a new one to get more accurate products or results. On the other hand, if this company can achieve the good results without throwing away the older controller, just with building in simple modifications, then RFPT is an effective money-saving method on the market.

Fuzzy control methodologies have emerged in recent years as promising tools to solve nonlinear control problems. The Fuzzy approach was first proposed by Lotfi A. Zadeh, in 1965

when he presented his seminal paper on fuzzy sets [2]. Zadeh showed that fuzzy logic unlike classical logic can handle and interpret values between false (0) and true (1). One of the most successful application areas of Fuzzy Logic proved to be Fuzzy Logic Control, because FLC systems can replace humans for performing certain tasks for example control of a power plant [3].

The other reason for applying fuzzy techniques in control is their simple approach which provides to use heuristic knowl- edge for nonlinear control problem. In very difficult situations, where the plant parameters are disturbed or when the the systems is too complex to be described by exact mathematical models, adaptive schemes have to be used to gather data and adjust the control parameters automatically. Based on the universal approximation theorem and by incorporating fuzzy logic systems into adaptive control schemes, a stable fuzzy adaptive controller is suggested in [4] which was the first controller being able to control unknown nonlinear systems.

Later, many adaptive fuzzy control approaches have been developed for the nonlinear systems [5], [6].

In this paper a new RFPT-based Fuzzy Logic Controller is introduced. The proposed new controller is applied to supervise the balancing of an inverted pendulum on the top of a cart. FLC has successfully been used in the inverted pendulum-problem (see [7]). For comparison, we use the same FLC. According to our simulation results the RFPT-based FLC over performances simple Fuzzy Logic Controllers and significantly reduces the necessary balancing time. The more extreme situation we choose (e.g. if the initial angle of the pendulum is very high and we assume that there is no friction) the bigger difference we get between the balancing times of an RFPT-based and a simple Fuzzy Logic Controller.

The paper is prepared as follows. Section II is devoted to the cart-pendulum system. In Section III the RFPT-based FLC is explained in details, first the Fuzzy Logic Controller, then its extension. Section IV shows the simulation results and finally in Section V the conclusions are summarized.

II. THE NONLINEAR DYNAMIC MODEL OF THE INVERTED PENDULUM SYSTEM

The cart-pendulum systems are standard problems in the area of control systems. They are often used to demonstrate methods in linear control such as the stabilization of unstable systems. Since these systems are nonlinear, they have also been useful in presenting some of the ideas in nonlinear control.

Fig. 1. The cart-pendulum system

The basic of the model is an inverted pendulum attached to a cart which is moved by a motor. The user is able to set the position and velocity of the cart through this motor and the track restricts the cart to move in one horizontal line. Sensors are attached to the cart and the pivots in order to measure the cart position and the joint angle of the pendulum, respectively.

Fig 1 describes how the model is built.

The system’s state propagation can be described by two equations where the following parameters (marked on Fig 1) are used respectively: in this system M denotes the weight of the cart, whilem andL are related to the weight and the length of the pendulum.xis responsible for the linear position of the cart andθdenotes the angular rotation of the hinge. The b parameter is responsible for the friction of the cart.

The Euler-Lagrange equations (got from [7]) of motion describing this system and the applied torques (F on the cart andFp on the pendulum) are as follows

(M+m) ¨x+bx˙+mLθ¨cosθ−mLθ˙2sinθ=F (1) mL

cosθx¨+Lθ¨−gsinθ

=Fp= 0 (2) From 1 and 2 the second derivatives can be easily calcu- lated:

θ¨= ((M+m)gsinθ+µcosθ)/KL (3)

¨

x=−(mgsinθcosθ+µ)/K (4) where

K=mcos2θ−(M+m) (5) µ=F+mLθ˙2sinθ−bx˙ (6) In [7] a Fuzzy Logic approach is presented for the control of the above model. In the following a new RFPT-based FLC is presented for the same problem. To make easier the comparison, the Fuzzy Logic Controller part is the same in our approach as in [7].

FIS Variables

theta

thetadot F

-40 -30 -20 -10 0 10 20 30 40

0 0.5 1

Membership function plots

input variable "theta"

NH NM NL ZR PL PM PH

FIS Variables

theta

thetadot F

-25 -20 -15 -10 -5 0 5 10 15 20 25

0 0.5 1

Membership function plots

input variable "thetadot"

NH NM NL ZR PL PM PH

FIS Variables

theta

thetadot F

-2 -1.5 -1 -0.5 0 0.5 1 1.5 2

0 0.5 1

Membership function plots

output variable "F"

NH NM NL ZR PL PM PH

Fig. 2. Membership functions forθ,θ˙andF

III. THERFPT-BASEDFUZZYLOGICCONTROLLER

The RFPT-based FLC introduced in this section consists of an FLC part and a RFPT part which modifies the output of the Fuzzy Logic Controller deteriorated by the used approximate model.

A. The Fuzzy Logic Controller

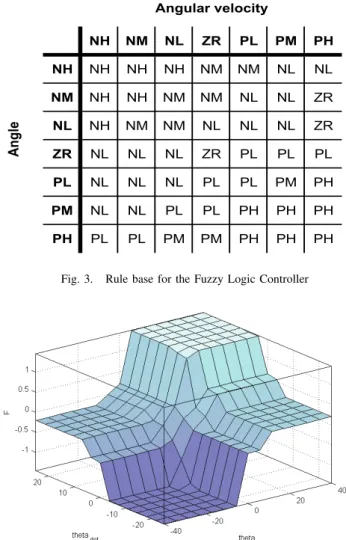

The details of the applied FLC can be found in [7]. The controller has two inputs, the angle and the angular velocity of the pendulum. From these values it calculates the desired torque (F) for the cart. Fig 2 shows the membership functions of the inputs and the output, while in Figs 3 and 4 the rule base and the rule surface can be seen.

B. Extending FLC with RFPS tuning

RFPT is a method which can be applied advantageously when we try to estimate the behavior of a system using an approximate model. In the following the above FLC is extended with an RFPT part improving the performance of the Fuzzy Logic Controller. Fig 5 shows the block diagram of the proposed controller. The operation of the extended controller is the following.

Assume that on purely kinematical basis we prescribe a trajectory tracking policy which is in our caseq¨D=h

¨ xD θ¨Di given by the Fuzzy Logic Controller and some calculations.

From the desired state variables we can calculate the desired control torquesQD= [F Fp]with the help of the approximate model. Since the real system’s physical behavior differs from

NH NM NL ZR PL PM PH NH NH NH NH NM NM NL NL NM NH NH NM NM NL NL ZR NL NH NM NM NL NL NL ZR ZR NL NL NL ZR PL PL PL PL NL NL NL PL PL PM PH PM NL NL PL PL PH PH PH PH PL PL PM PM PH PH PH

Angle

Angular velocity

Fig. 3. Rule base for the Fuzzy Logic Controller

Fig. 4. Surface of the Fuzzy Logic Controller

the approximate model’s, the direct application of this QD on the real system is not suggested because in this case the realizedq¨will differ from the desiredq¨D. First we have to find the properQReq applied on the real system we get a realized

¨

q much closer to the desired q¨D (the main advantage of the RFPT is that it can give a betterQReq value without knowing the real system). SoQReqapplied on the actual system results in the realized responseq. From that the realized¨ QR can be easily calculated by the approximate model. To summarize, our aim is to find the proper deformation betweenq¨andq¨D by the application of which QR well approaches QD, that is at which the controlled system is forced to behave as the approximate model. The proper deformation may be found by the application of the iteration as follows. Consider the iteration generated by some functionGas

QReq(n+ 1) =G(QReq(n), QR(n), QD(n+ 1)) (7) in whichnis the index of the control cycle. If the desired value QDslowly varies, then it can be considered to be constant. In this case the iteration is reduced to

RFPT System

Delay

FLC Approximate Model

Approximate Model Delay

QD QReq

D

q q

QR q

Fig. 5. The block scheme of the RFPT-based Fuzzy Logic Controller

QReq(n+ 1) =G(QReq(n), QR(n)) (8) that must converge to QD.Gwill take the form of

G Q, Qd

= (Q+KCT RL)×

eBCT RLtanh(ACT RL[f(Q)−Qd])−KCT RL (9) whereACT RL,BCT RL, andKCT RLare free parameters. The derivation of G and the proof, that application of Gensures that QReq converges to QD, can be found in [8].

IV. SIMULATION RESULTS

The simulations are made by the Matlab-Simulink package.

The initial values are set to the followings:M = 1.5kg,m= 0.5kg, L = 0.1m, g = 9.8m/s2, b = 0.2kg/s. The initial values for the state variables are x= 0 and θ= 15◦. In the simulations we assume that we cannot determine the model parameters exactly, so we have to approximate them by e.g.:

Mˆ = 1.2kg, mˆ = 0.8kg, Lˆ = 0.09m, gˆ = 10m/s2 and ˆb= 0.1kg/s.

In the first step the nonadaptive case (with a simple Fuzzy Logic Controller), and the adaptive (RFPT-based) case are investigated without noise in Figs 6 and 7, respectively. The parameters for the RFPT’s function are BCT RL = −1, ACT RL= 9×106, andKCT RL=−105. As the results show the RFPT-based controller can stabilize the pendulum twice quicker.

In the second step, we assume some kind of measuring noise which is represented by two sinusoid waves added to the real system. These waves have the amplitude of 0.4m and 0.5m and frequency of 4Hz and 2.7Hz respectively. Comparing Figs 8 and 10 it can be seen that the adaptive controller is twice better again and while the adaptive controller is able to slowly stabilize the position of the cart, the nonadaptive cannot.

For the effective comparison we include a third simulation with very extreme initial conditions:b= ˆb= 0and the initial state variables are x = 0 and θ = 72◦. Fig 9 illustrates the nonadaptive case where the improvement of θ is only 2◦ in 100 seconds. In contrast with this, the adaptive controller can completely stabilize the pendulum in less than 90 seconds as shown in Fig 11.

0 5 10 15 20 25 30 35 40 45 50 -15

-10 -5 0 5 10 15

t

0 5 10 15 20 25 30 35 40 45 50

-0.9 -0.8 -0.7 -0.6 -0.5 -0.4 -0.3 -0.2 -0.1 0

t

x

Fig. 6. The angle of the pendulum and the position of the cart, nonadaptive (simple FLC) case, without noise

V. CONCLUSIONS

Fuzzy Logic Controller is a widely used, very popular controller type. In this paper authors offer an extended FLC scheme, which offers an opportunity how an existing and well set controller’s results can be ameliorated. The presented new Robust Fixed Point Transformation-based Fuzzy Logic Controller is applied to balance a cart-pendulum system. The simulations show that in simple cases the RFPT can bisect the balancing time of the FLC and the more extreme situation we choose the bigger difference we get between the balancing times of an RFPT-based and a simple Fuzzy Logic Controller.

ACKNOWLEDGMENT

The authors gratefully acknowledge the grant provided by the project T ´AMOP-4.2.2/B-10/1-2010-0020, support of the scientific training, workshops, and establishing talent manage- ment system at ´Obuda University.

REFERENCES

[1] A.M. Lyapunov,A general task about the stability of motion(in Russian), PhD Thesis, 1892

[2] L.A. Zadeh, Fuzzy Sets. Information Control, vol. 8, pp. 338–353, 1965 [3] S.N. Pant and K. E. Holbert. Fuzzy Logic in Decision Making and Signal Processing, http://scholarchio.wordpress.com/fuzzy-logic/about/, March 2004.

0 5 10 15 20 25 30 35 40 45 50

-15 -10 -5 0 5 10 15

t

0 5 10 15 20 25 30 35 40 45 50

-1.2 -1 -0.8 -0.6 -0.4 -0.2 0 0.2

t

x

Fig. 7. The angle of the pendulum and the position of the cart, adaptive (RFPT-based FLC) case, without noise

[4] Procyk, T. and Mandami, E. (1979), ’A Linguistic Self-organizing Process Controller’ Automatica, 15(1), 15-30.

[5] Layne, J.R., Passino K. M. and Yurkovich, S (1993) ’Fuzzy Learning Control for Anti-skid Braking Systems’, IEEE Trans. Control Systems Tech., 1(2) 122-129

[6] Layne, J.R. and Passino K.M. (1993) ’Fuzzy Model Reference Learning Control for Cargo Ship Steering’, IEEE Control Systems Magazine, 13(6), 23-34

[7] David Kadjo: “A Fuzzy Classifier for an Inverted Pendulum”, http://faculty.utep.edu/Portals/1255/david.pdf, 2006

[8] J.K. Tar, I.J. Rudas, J.F. Bit´o, T.A. V´arkonyi, Chaos Synchronization by Model Reference Adaptive Control Using Fixed Point Transformations, Proc. of the 13thIASTED International Conference on Intelligent Systems and Control (ISC 2011), Cambridge, United Kingdom, pp. 23–28, 2011 [9] Liu Li HE Hua-Can (School of Computer Science, Northwestern Poly-

technical University, Xi’an 710072);Overview of the Stable Control of the Inverted Pendulum System[J];Computer Science;2006-05

[10] J.K. Tar, Towards Replacing Lyapunov’s “Direct” Method in Adaptive Control of Nonlinear Systems, (invited plenary lecture), Proc. of the 3rd Conference in Mathematical Methods in Engineering, 21–24 October 2010, Coimbra, Portugal, Paper 11 (CD issue) 2010

[11] J. Lam, “Control of an inverted pendulum,” http://www- ccec.ece.ucsb.edu/people/smith/student projects/Johnny Lam report 238.pdf [12] Saflida , Mohd Nor (2006) Fuzzy logic controller simulation for

water tank level control. EngD thesis, Universiti Malaysia Pahang, http://umpir.ump.edu.my/383/ 2010

[13] G. Feng, R. Lozano, Adaptive Control Systems, Newnes - Reed Educ.

Profes. Publishing Ltd, New York, 1999.

[14] A.M. Lyapunov, Stability of motion, Academic Press, New-York and London, 1966

[15] Tanaka, K., Wang, H.O, Fuzzy Control Systems Design and Analysis.

New York: John Wiley & Sons, Inc., 2001

0 5 10 15 20 25 30 35 40 45 50 -15

-10 -5 0 5 10 15

t

0 5 10 15 20 25 30 35 40 45 50

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

t

x

Fig. 8. The angle of the pendulum and the position of the cart, nonadaptive (simple FLC) case, with noise

0 5 10 15 20 25 30 35 40 45 50

-80 -60 -40 -20 0 20 40 60 80

t

0 5 10 15 20 25 30 35 40 45 50

0 0.005 0.01 0.015 0.02 0.025 0.03 0.035 0.04 0.045

t

x

Fig. 9. The angle of the pendulum and the position of the cart, nonadaptive (simple FLC) case, without noise, with very wide angle

0 5 10 15 20 25 30 35 40 45 50

-15 -10 -5 0 5 10 15

t

0 5 10 15 20 25 30 35 40 45 50

-1 -0.8 -0.6 -0.4 -0.2 0

t

x

Fig. 10. The angle of the pendulum and the position of the cart, adaptive (RFPT-based FLC) case, with noise

0 10 20 30 40 50 60 70 80 90 100

-80 -60 -40 -20 0 20 40 60 80

t

0 10 20 30 40 50 60 70 80 90 100

-4 -3.5 -3 -2.5 -2 -1.5 -1 -0.5 0 0.5

t

x

Fig. 11. The angle of the pendulum and the position of the cart, adaptive (RFPT-based FLC) case, without noise, with very wide angle

[16] V´arkonyi-K´oczy, A.R., State Dependant Anytime Control Methodology for Non-linear Systems, International Journal of Advanced Computational Intelligence and Intelligent Informatics (JACIII), Vol. 12, No. 2, pp. 198–

205, March 2008

[17] R. Isermann, K.H. Lachmann, and D. Matko,Adaptive Control Systems, Prentice-Hall, New York DC, USA, 1992

[18] Jean-Jacques E. Slotine, W. Li,Applied Nonlinear Control, Prentice Hall International, Inc., Englewood Cliffs, New Jersey 1991

[19] Charles C. Nguyen, Sami S. Antrazi, Zhen-Lei Zhou, Charles E.

Campbell Jr.: Adaptive control of a stewart platform-based manipulator, Journal of Robotic Systems, Volume 10, Number 5, 1993, pp. 657–687

[20] R.M. Murray, Z. Li, S.S. Sastry: A mathematical introduction to robotic manipulation, CRC Press, New York, 1994.

[21] R. Kamnik, D. Matko and T. Bajd: Application of Model Reference Adaptive Control to Industrial Robot Impedance Control, Journal of Intelligent and Robotic Systems, vol. 22, pp. 153–163, 1998.

[22] J. Soml´o, B. Lantos, P.T. C´at, Advanced Robot Control, Akad´emiai Kiad´o, Budapest, Hungary, 2002

[23] K. Hosseini–Suny, H. Momeni, and F. Janabi-Sharifi, Model Reference Adaptive Control Design for a Teleoperation System with Output Predic- tion,J Intell Robot Syst, DOI 10.1007/s10846-010-9400-4, pp. 1–21, 2010.