BAKING TECHNOLOGY

Dr. Szabó P. Balázs PhD., associate professor Zakupszki Zita Boglárka, professional service provider

University of Szeged, Faculty of Engineering Institute of Food Engineering

2018.

BAKING TECHNOLOGY

Written by:

Dr. Szabó P. Balázs Zakupszki Zita Boglárka

Proofread by:

Prof. Dr. Véha Antal CSc.

ISBN 978-963-306-627-0

1

TABLE OF CONTENTS

1 INTRODUCTION ... 5

2 MATERIALS ... 7

2.1 Raw materials ... 7

2.1.1 Flour ... 7

2.1.2 Water ... 19

2.2 Auxiliary materials ... 20

2.2.1 Yeast ... 21

2.2.2 Salt ... 23

2.2.3 Indispensable auxiliary materials ... 24

2.3 Ancillary materials ... 25

2.3.1 Enrichment materials ... 25

2.3.2 Fillings ... 28

2.3.3 Flavouring agents ... 28

2.3.4 Other materials ... 28

2.4 Control issues ... 29

3 PRODUCTS ... 30

3.1 Breads ... 30

3.2 Pastries ... 32

3.2.1 Pastries made of kneaded dough ... 32

3.2.2 Pastries made of specialty dough ... 33

3.3 Crumbs ... 35

3.4 Quick-frozen bakery products ... 35

3.5 Control issues ... 36

4 BAKING TECHNOLOGY ... 37

4.1 Preparation ... 37

2

4.2 Dough making ... 38

4.2.1 Kneading ... 38

4.2.2 Fermentation ... 43

4.3 Dough make-up/shaping ... 45

4.4 Proofing ... 47

4.5 Baking ... 50

4.6 Product treatment ... 56

4.6.1 Cooling ... 57

4.6.2 Packaging, storing ... 58

4.6.3 Transport ... 59

4.7 Control issues ... 60

5 DEVELOPMENT TRENDS ... 61

5.1 Development trends in the baking industry ... 61

5.2 Allergen-free products ... 61

5.3 Enriched products ... 62

5.3.1 Vitamin-enriched products ... 62

5.3.2 Products enriched with minerals ... 63

5.3.3 Protein-enriched products ... 64

5.3.4 Carbohydrate-enriched products ... 65

5.3.5 Fiber-enriched products ... 66

5.4 Products with reduced content ... 66

5.4.1 Carbohydrate-reduced products ... 66

5.4.2 Salt-reduced products ... 67

5.4.3 Fat-reduced pastries ... 67

5.5 Control issues ... 68

REFERENCES ... 69

3 According to the Hungarian Learning Outcomes:

a) Knowledge of

They are familiar with the most important physical, chemical, biological processes in their food production, their basic laws and methods of testing. They know and understand the basic concepts, contexts and processes of food chain security.

They are familiar with the basic concepts, facts, theories, key features and contexts of food production and management, relevant food business operators, their functions and industry-related processes. They have the most important theoretical, methodological basics and practical knowledge required for this purpose.

They are familiar with the main products of the food industry, their raw materials and their manufacturing technologies. They are familiar with the factors that determine the quality and safety of foodstuffs for health-conscious nutrition.

They know and understand the principles, machines, equipment and instruments of widely-used food operations as well as their operation in practice.

b) Capabilities

They are able to assess the food chain safety risks of food raw materials and store their value. They can product and preserve safe food from these raw materials by using value-adding production. They are able to market food according to the related professional and administrative aspects.

They are able to perform part tasks in the development and design of technological systems, in new processes, in the development of products.

They are capable of organizing, controlling food quality processes, applying their quality system, distributing resources, and developing proposals that base their professional choices.

4 c) Attitude

They are capable of organizing, controlling food quality processes, applying their quality system, distributing resources. They are capable of developing proposals that base their professional choices.

They are committed to environmentally friendly solutions to food quality and safety, as well as to individuals and society.

They are receptive to the knowledge necessary for the operation of tools and equipment related to food processes.

d) Autonomy and Responsibility

Their sense of responsibility reflects the professional, legal, ethical norms and rules of their work and behaviour.

Solving professional problems in the food industry, working alone or with others, with the individual commitment of responsibility and the ethical standards of the profession.

They are responsible for the work of their own employees and those under their control. They are responsible for their statements and the consequences of their opinion.

5 1 INTRODUCTION

Bakery products are one of the most important food sources of the population [1].

Their protein, carbohydrate and vitamin content make their consumption an energy supplement in everyday life. In addition, these products contain incomplete proteins as well as minor amounts of fats, minerals, and vitamin B. The consumed foods help to maintain health, provide good physical and mental strength.

In the past the simplest baking products were made from flour and water. Today all baked products are made from a few main ingredients, which are the flour and water.

Materials used in the baking industry can be classified into the following categories:

main ingredients, auxiliary materials, ancillary materials, technology assistants, and packaging materials [Fig. 1]. The classification is based on the amount of ingredients. In addition to the main ingredients, all the materials used in the baking industry are generally referred to as additives.

Figure 1.Categories of materials used in the baking industry

Baking products can be divided into categories [5]. In Hungary we distinguish between bread and pastry based on the quality of their dough. We distinguish between products made of kneaded dough and special dough within pastries. There are separate categories of crumbs and quick-frozen goods. The difference is the combination and amount of the ingredients and the production (different mixing, different baking).

6

The diversity of the technology is determined by the type and quantity of the enrichment materials and the specifics of the particular product. The short technology is the following: scaling the ingredients; mixing and kneading the dough;

fermentation; punching down the dough; portioning the dough; rounding the portions; make-up: shaping the portions; proofing; baking; cooling; storing [Fig. 2].

Figure 2.General flow chart of the baking technology

7 2 MATERIALS

2.1 Raw materials

Any ingredient that is essential and necessary in the production of the product is considered as a raw material. In the baking industry we include various cereal grains and water.

2.1.1 Flour

Flour is the main and most important ingredient, every baked product contains it. It determines the dough and the end of products texture, flavour, nutrition, and binding all ingredients. The quality and technological properties of the product are determined by the flour’s water absorption capacity, the rheological properties of dough and the proper enzymatic state of the dough. All these properties are determined by the chemical composition, microflora and enzyme content of the flour [7].

The flour types are separated by three distinct differences: grain, ash content and grain size. We can talk about wheat flour, and non-wheat flour. The non wheat flour types, for example the soy flour, which has a higher protein content (high lysine content); triticale flour, which is a hybrid of wheat and rye; rye flour; buckwheat flour, etc. The typical gluten free flour is the rice flour, maize flour, potato flour (cooked and dried potatoes). Ash content is determined by the content of the flour kernel. The ash content of the flour is directly proportional to the kernel content of the flour. Grain size is a data dependent on the particle size of the grist. These properties have a significant influence on the baking properties of the flour, thus also on the properties and quality of the product produced. The millers work together with bakers to produce the right flour for the baker’s products.

Some of the flour properties determine whether the flour is suitable for human consumption and food production. Such properties are the taste, the odour, the purity and the number of germs. These properties are checked for sensory examination.

During the investigation, they make a judgment on the colour, the smell, the taste and

8

the state of the granular set. The colour of the flour sample is examined with the Pekar test in its original dry state, wet state and its dried state [Fig.3.].

Figure 3.Pekar test in dry and wet state for different flours

Another feature of the properties is to determine technological suitability, such as colour, particle size, water absorption capacity, gluten and dough properties. The technological importance of flour is largely influenced by the carbohydrate, water, protein, enzyme, mineral and fat content of the flour.

Chemical ingredients of flour:

Starch: 70%

Moisture: 14%

Protein: 11.5%

Mineral (ash): 0.4%

Sugar: 1%

Fat (liquid): 1%

Others: 2.1%

Starch is the greater part of the wheat flour, which is broken down by enzymes. It’s degradation product, the source of the main nutrient of maltose, yeast and lactic acid bacteria. When the temperature of the dough increases, the starch absorbs water, and it is called gelatinize. This is an important compound in flour that strengthens the baked products through the starch gelatinization. It determines the crumb, and the

9

products interior. Starch’s quantity is influenced by the genus of grain, its variety, production conditions and weather. The breakdown of starch is influenced by the activity of amylase enzymes. By the amilolite state is meant the interaction between the amylases of the flour and the flour's own starch as a substrate. The following instruments are used to test the amilolite state:

Amylograph

Falling Number Test Apparatus.

Amylograph [Fig. 4.] is a rotational viscosity meter measuring the viscosity in dependence of time and temperature, designed for testing the gelatinization properties especially of starch containing cereal products and the α-amylase liquefying effect on the starch. The results obtained by the instrument give information on the expected crumb structure of baked products. The viscosigraph is drawn by pen-recorder.

Figure 4.Amylograph machine (Brabender)

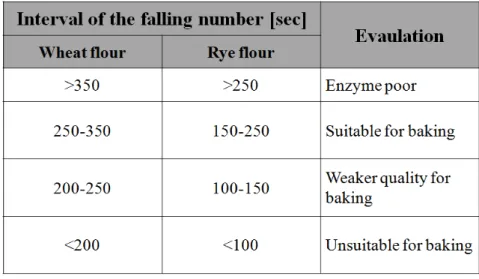

During the Falling Number Test, the enzyme content of the flours and their activity can be characterized, and the baking usability of flours [Tab. 1]. Results can be applied to monitoring the ripening process of the grain, to segregation of grain into good quality for bread making, to determine the quality of the flour supplied and to optimize flour blends.

10

Table 1.Evaulation of the falling number in wheat flour and rye flour

The method is for the rapid determination of -amylase in starch containing products (wheat, rice). The method is based up the rapid gelatinization of a suspension of flour in a boiling water-bath and the subsequent measurement of the liquefaction by - amylase of starch contained in the sample [Fig. 5.]. Falling number results are recorded as an index of enzyme activity in a wheat or flour sample and the results are expressed in time as seconds.

Figure 5.FallingNumber1500 machine (Perten)

11

In the largest quantities, about 72-75%, carbohydrates are included in the flour. As simple as glucose and fructose, and as complex as maltose and sucrose, carbohydrates in only a small amount, approx. 0.5%, are present, typically starting materials for microbiological processes of pasta, nutrients for yeast and lactic bacteria [6]. The end products of these processes partly determine the taste of the bakery product, the structure and shelf life of the dough.

The water content of the grains ranges from 8 to 20% in wide ranges, but typically 12-14% water content is available for the flours to be placed in the industry. The moisture content of the cereal grain may be influenced by the moisture content of the cereal, the grinding technology used and the storage area. The moisture content of the flour has got great economic importance in the baking industry, since the wetter flour has a lower dry matter content, which can be processed with a bad yield indicator. To determine the moisture content, the flour to be examined is dried at 130-133 °C in air oven for 60 minutes and the sample weight loss is determined.

Determining moisture content is an essential first step in analyzing wheat or flour quality since this data is used for other tests. Moisture content of 14 percent is commonly used as a conversion factor for other tests in which the results are affected by moisture content.

The most important role in the processing of flour is its protein content, which is the most important ingredient in dough design. The flour proteins have two groups:

soluble and insoluble protein. The insoluble protein is the most important, because these proteins absorb the water in the dough. It causes the elasticity and extensibility of the dough. The insoluble proteins give the gluten network, the gluten structure, which holds the carbon dioxide gas back. These proteins are the gliadin and glutenin.

The wheat flour contains insoluble proteins (this is gluten), which determine the texture of a baked product (elastic characteristic), and the volume of the products [Fig. 5.].

12

Figure 5.Gluten structure [19]

Their proportion in wheat flour is usually 1: 1, but it may also be 1: 1.5, but the flour is not able to produce a gluten structure, if gliadin and glutenin ratio of 1: 2. Gliadin itself becomes a sticky, subtle mass by binding large volumes of water. By contrast, glutenin by itself absorbs significantly less water to form an elastic, rubbery material.

We can qualify these proteins with the Automatic Gluten Test Apparatus [Fig. 6.].

During the test we determined the Gluten-index and the water absorption capacity of gluten protein from flours. By defining the Gluten-index, we can qualify the gluten proteins of the examined flours, thus determining the structure and physical properties of the dough and the degree of its gas retention, and the baking usability.

Wet gluten reflects protein content and it is a common flour specification required by end-users in the food industry. The dough is made (and the gluten) by the Glutomatic unit. The gluten is separated from excess water in Centrifuge and then it is dried in Glutork unit.

13

Figure 6.Glutomatic-Gluten Index System

Functional proteins of flour, enzymes, play an important role. The proteolytic activity of the protease enzyme degrades the ability of the dough to absorb water and make a form. During peptidase activity, amino acids are formed which serve as nutrients for microorganisms, thus enhancing yeast activity and gas production [6].

During starch degradation, β-amylase produce maltose and α-amylase produce dextrin, which is also nutrition of microorganisms. α-amylase is present in the flour in an inactive form but activates by heat. During its activity, it cleaves the starch molecule into dextrins, which play a role in the structure of bakery products. β - amylases are present in the flour in the active form against α-amylases. During their activity, the starch molecule is broken down into maltose. Maltose is of significance in the production of gas and acid production and the taste, colour, and crust properties. Increasing the lipase activity increases the free fatty acid content in the dough as well. Oxidation of unsaturated fatty acids is carried out by lipoxidases, forming peroxide compounds that play a role in rancidity and discoloring.

The mineral and ash content of the flour is generally between 0.4 and 2.0%, which is influenced by the content of the kernel in the flour. Potassium and phosphorus, which are potassium phosphate present in grain, are outstanding minerals in the development of dough. Mineral salts enhance the hydrophilicity of the flour particles, i.e. the amount of water absorption by the particles. Significant mineral salts in flour

14

are magnesium, iron, manganese, zinc and copper. The ash content is determined by milling the sample of exactly the weighed mass after sintering in an oxidizing atmosphere at 550-600 °C in an ash oven until the total amount of the residue becomes a white (or light grey) ash [Fig.7.].When a sample is incinerated in an ash oven, the high temperature drives out the moisture and burns away all the organic materials (starch, protein, and oil), leaving only the ash. The residue (ash) is composed of the non-combustible, inorganic minerals that are concentrated in the bran layer. The mass of material residue obtained after cremation is based on the dry matter content of the sample weighed and expressed as a percentage by weight. Ash in flour can affect colour, imparting a darker colour to finished products. Some specialty products requiring particularly white flour call for low ash content while other products, such as whole wheat flour, have high ash content.

Figure 7. Ash oven while working

Fat does not contain significant amounts of fats such as phospholipids and triglycerides. During the aging of the flour, the coloring agents degrade through the presence of fatty substances during oxidation. This process will make the flour lighter during storage. Its characteristic colorants are carotenoids and xantofill for wheat flour, so it will be yellowish, but rye flours will contain chlorophyll, which will make them greyish.

In determining the appearance and loosening properties of bakery products, the physical properties of dough play an important role. Based on the structure of the

15

wheat dough, it can be classified as pseudoplastic. Dough as opposed to the forces occurring during technological processes such as stretching, bending, shearing, and compression force exert some resistance while deforming. The physical properties of pasta, such as consistency, extensibility and flexibility, indicate the changes in the state of dough by the effect of forces. All of these properties have an impact on the processability, shape ability, water and gas capacity of the dough. Ideally, the dough's texture is suitable for machining, it is easy to make, while it is sufficiently solid, moldy. Several methods are used to test the dough's physical properties. When using the dynamic method, the physical properties of the dough are determined by the kneading method. Instruments suitable for such testing:

Valorigraph

Do-Corder

The Valorigraph test is one of the most commonly used flour quality tests in the world. During the Valorigraph using, the water absorption capacity and physical properties of the examined flour can be quantified and flours can be qualified [Tab.

2]. These properties are arrival time, stability time, peak time, departure time, and mixing tolerance index. The results are also used to predict processing effects, including mixing requirements for dough development, tolerance to over-mixing, and dough consistency during production. The Valorigraph determines dough and gluten properties of a flour sample by measuring the resistance of dough against the mixing action of paddles (blades) [Fig. 8.]. Valorigraph results are also useful for predicting finished product texture characteristics.

16

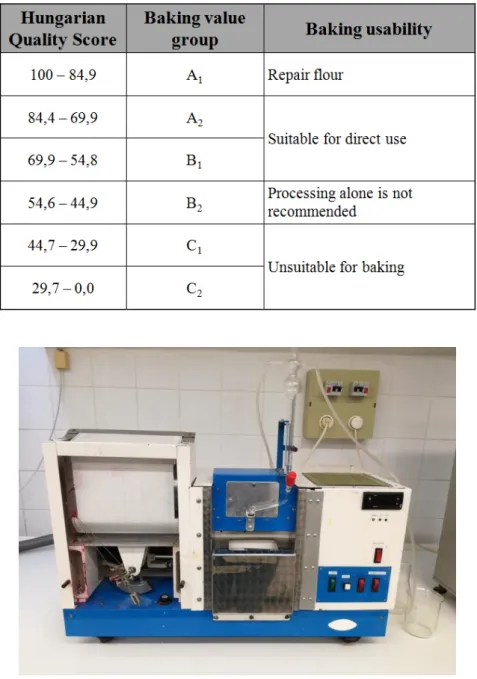

Table 2.Certification of flours based on the Hungarian quality score

Figure 8.Valorigraph machine

Not only the quality of flour can be tested by the Do-Corder and developer kneader and measure system [Fig. 9.], but also the processing behavior of dough and large variety of recipes may be examined. With the stepless variable speed (5-250 rpm) of the Do-Corder any desired mixing intensity and energy input into the dough can be simulated. The dough-cup can be tempered. The pen-recorder records the torque /time relationship.

17

Figure 9. Do-Corder machine

When using the static method, the physical properties of the dough are determined by breaking method. Instruments suitable for such testing:

Extensograph

Promylograph

Alveograph.

The alveograph consists of four main components: the mixer, the actual dough- bubble blowing apparatus, the recording manometer and the dough sheeting assembly [Fig. 10.]. The instrument allows measuring the stretching capabilities of the flour-water dough quickly, precisely and reproducible resistance to extension and extensibility. The alveograph determines the gluten strength of dough by measuring the force required to blow and break a bubble of dough. The test provides results that are common specifications used by flour millers and processors to ensure a more consistent process and product.

18

Figure 10.Alveograph (Chopin)

The extensograph and promylograph determine the resistance and extensibility of the dough by measuring the force required to stretch the dough with a hook until it breaks [Fig. 11.]. Extensograph and promylograph results include resistance to extension, extensibility, and area under the curve. Results from the test are useful in determining the gluten strength and bread-making characteristics of flour. The effect of fermentation time and additives on dough performance can also be evaluated.

Figure 11.Promylograph system

19

The classification of flour is closer to the practical conditions when the dough is examined in the state of fermentation. This type of test is suitable for studying gas- induced processes such as gas production and gas retention in the yeast dough and the damping of the dough by gases. Based on the results, it is possible to decide on the optimum fermentation time. Rheofermentometer is suitable for this testing.

Rheofermentometer measure the quality of the flour, the fermentation potential, and the protein network strength [Fig. 12.]. The instrument measures simultaneously the CO2 production, CO2 retention in dough, the % dough permeability and the increase of the volume of dough, tracking of volume evolution during the time of fermentation. It has temperature control to 45 °C. Test duration can be varied between 10-180 minutes. The analyses are computerized with spreadsheet.

Figure 12.Rheofermentometer (Chopin) 2.1.2 Water

The water has several sources, the sea water is from oceans and seas, the deep water is from geysers and volcanoes, and the third type of water is from rain and snow, this is the natural water. The other classification will be the hard water and the soft water.

The hard water contains a lot of dissolved minerals; the soft water contains loss minerals.

20

The water is the best to control the temperature of the dough (warming or cooling of dough) and the water controls the consistency of dough (elasticity, plasticity, stability).

The main task of the water to solve the dry ingredients (dissolve salt, suspend and distribute the non-flour ingredients) and allow gluten to be formed (flour proteins are hydrated). The water is required to hydrate the flour, activate the yeast and gelatinize the starch (wets and swells starch). The water contains minerals and natural impurities. In the baking process it provides steam for leaving and in the bread baking process we need to use steam in the first part of the baking.

When baking soda or baking powder is used, the water reacts with them and produces carbon dioxide gas.

We can talk about the contributing water (in the milk, other ingredients), which determines the texture, the crumb and the crust.

2.2 Auxiliary materials

Auxiliary materials can be divided into two large groups as:

Essential auxiliary materials

Indispensable auxiliary materials.

Any additive that necessary for the product but necessarily in small quantities is considered as essential auxiliary materials. In the baking industry, these materials are typically salt and yeast.

The materials, which, with a small amount of addition, improve the quality of the flour, the properties of the final product and accelerate the preparation of the formulations, are the indispensable auxiliary materials [9]. This category includes improving flour properties agents, consumable time-increasing agents, and substances that simplify technological processes.

21 2.2.1 Yeast

Yeast is a raising agent in a baking technology. It is a Baker’s yeast, Saccharomyces cerevisiae. They are facultative anaerobes and a single cell plant fungus.

Yeasts have a high protein content that improves the nutritional value of baking products [8]. Beside protein, the carbohydrate content is significant in yeasts, and also contains fats, minerals, enzymes, vitamins B and E. The enzymes play an important role in the enzymes of maltase and saccharose, as well as the zimase enzyme system that catalyzes alcoholic fermentation. Zimase enzymes in the process produce ethyl alcohol, carbon dioxide and heat by breaking down the glucose and fructose molecules, which, while loosening the dough structure and increasing volume, still give the product a distinctive flavour. This gas-producing effect also has a beneficial effect on maturation, fermentation and baking.

In the food industries, they are classified the yeast on their activity: baker’s yeast;

brewer’s yeast; dried brewer’s yeast, etc. In the bakehouse there are three types:

Fresh yeast (compressed yeast) [Fig. 13.]

Dry yeast

Instant yeast (powered dried yeast) [Fig. 13.]

Figure 13.Fresh (on the left side) and instant (on the right side) yeast

22

The fresh yeast is better, but we have to keep in cold place (it must be kept refrigerated). It is firm, moist, cream-colored, and a mixture of yeast and starch with approximately 70% moisture content. The yeast is a small granular form of yeast (it needs water to rehydrate before we use). It can be stored without refrigeration for months. The instant yeast is a dry ingredient in a bread formula without rehydrating (the other name is rapid rise or quick rise yeast. If we use too much instant yeast, it will cause the dough to rise too quickly, but it is easy to use, because we sprinkle straight into a bowl of flour [9].

The added sugar, malt, starch repellent formulations, and various nutrients stimulate but salt, fats, oxidants and acids, such as lactic acid and acetic acid, which are present in higher concentrations, inhibit the activity of the baker's yeast. The baking pot's relaxation effect is influenced by the temperature in addition to the various materials because while the 40-45 °C temperature activates the yeast cells, yeast cells are destroyed at 60 °C or above, and the buoyancy is eliminated [Tab. 3.].

Table 3.The temperature effects to the yeast activity

During the mixing (hydration) the yeast is activated in warm water.

Yeast + carbohydrates = alcohol + CO2

The carbon dioxide gas is trapped in the dough, while the alcohol evaporates. So the carbon dioxide generated by growing yeast makes dough rise.

23

The Saccharomyces cerevisiae has close “wild” relatives, the natural yeast starters (sourdough is a type of natural yeast) used prior to the development of commercial yeast.

The other leavening agents are the baking soda and the baking powder.

2.2.2 Salt

Salt is the oldest preservative, widely used in the food preparation. Due to salts drainage, hygroscopic properties it slows down the microbal growth. Salt is a mineral composed of sodium chloride (NaCl), which has different types:

Solar mining salt, sea salt (the sun evaporate the sea water),

Rock mining salt (from the underground),

Solution mining,

Vacuum salt, refining (this is the table salt, which is evaporated, it has chemical and sulfuric acid treatment).

In the bakehouse the main type which used is the table salt (it is made up of sodium and chloride). But we know that there is little difference in these salt types, so we can also use the other types. The sodium is a mineral, and used by the human body. The chloride is another important nutrient.

HCl + NaOH NaCl + H2O

The table salt is the best, because it is completely soluble in water and it has a clear solution. This salt is free from biting taste and lumps and it is pure.

The salt determines the flavouring of the products, volume, texture, shelf-life and the evenness of the cell structure. The salt regulates the yeast activity (inhibits the yeast action – the enzymes) and the yeast fermentation, so determines the aroma, the colour and the texture of the products (without salt the dough is hard to handle).

The future is finding the substitute for salt, it can be the potassium chloride. It has a salty flavour, but it has bitter aftertaste.

24 2.2.3 Indispensable auxiliary materials

The additives which are improve flour properties are increase the water retention and gas development capabilities of flours. For complex development of water absorption, gas development and retention ability, ascorbic acid, dried gluten, soy flour or milk protein are blended into the dough during the technology.

Ascorbic acid (as vitamin C) is an essential nutrient found in citrus fruits [Fig. 14].

It’s used as a bread improver. It causes an increase in loaf volume and an improvement in crumb structure in bread dough. It is used as an oxidizing agent for dough mixing.

Figure 14. Ascorbic acid

Dried gluten helps to improve the dough's ability to increase in volume. It is increases the structural stability and chewiness of bread. It increases the protein content of the final products.

Soy flour proteins can increase white colouring in the crumb of baked goods. The protein in milk creates strong dough, the rising is higher. The soy and the milk are allergen materials.

Calcium propionate is an effective growth inhibitor of most molds and some bacteria.

This preservative is widely employed in bread and other bakery products. It is good to prevent mold and rope formation and it extends the bakery products normal shelf life.

25

When describing the consumable time-increasing agents, we distinguish between anti-mold agents and anti-aging agents. Anti-mold agents, also known as preservatives, acetic acid, lactic acid, calcium propionate, potassium sorbate and ascorbic acid, which are a kind of anti-microbial agent [9]. To delay aging, mono- or diglycerides of fatty acids or diacetyl tartaric acid are used [10].

By using materials simplifying technological processes, we aim to provide time and device savings, continuous, permanent dough consistency, which makes machine processing easy. To this end, pre-mixes are often added to the pastry during bakery technology. Pre-mixes are multi-component, combined agents containing both enzymatic agents, gluten-stabilizing additives and emulsifiers [9].

2.3 Ancillary materials

As ancillary materials, all additives are substances that influence the nature of the product, which influence the nutritional value and enjoyment of the product. These materials are:

Enrichment materials

Fillings

Flavoring agents 2.3.1 Enrichment materials

Enrichment agents greatly influence the properties of bakery products' dough, adding dough to more durable, more formable, enabling a diverse product form. Such main materials include fat, sugar, milk and milk powder, and egg and egg powder [9].

Different fats are often used to improve the structure of the dough. Butter is a dairy product; it is the fat of the milk. The fine bakery products contain a lot of butter and in the baking process we use sweet or sour cream to fill the products. The butter must contain more than 80 % of milk fat. It has some different types, for example sweet butter (this is the traditional butter, we use it every day); cultured butter, which contains bacterial culture; flavoured butter with different spices and herbs; whipped butter is softer and easier to spread, because it contains innert gas (air). Margarine is the other dairy product, which is a mixture of vegetable oils (hardened vegetable oil),

26

animal fats (for example fish) and water/milk. The margarine has a similar appearance to butter, so it is used as a butter substitute (and the margarine is cheaper). It determines the volume of the products, because it coats the flour and prevents the gluten. The margarine has an effect on the strength of crumb. The product, which contains margarine, is richer, tenderer and tastier. In the bakery products we can use the traditional, regular margarine, not the whipped and liquid types. During dough design, fats improve their mechanical properties so that the more flexible, denser dough becomes suitable for machine machining, as well as inhibits the activities of enzymes, especially amylases and yeast cells, so the dough will be more compact. In addition, it reduces flour water absorption capability and delays the aging of the product.

The sugars have a lot of function in the baking technology. The main function is the sweetening. The sugars with proteins make dark compounds called melanoidins during heating. The sugars help in the yeast fermentation, from glucose, fructose, sucrose and maltose are fermented by yeast. This is the alcohol fermentation, where the yeast produces carbon dioxide and alcohol from the sugar. Sugars are hygroscope materials, so they absorb and retain the moisture. The solubility of the sugars controls the crystallization of the products. The sugars have hydrolysis properties, when the maltose and the sucrose are hydrolyzed by the enzyme (the yeast has this enzyme). This is an important reaction in the dough before the sugars are fermented.

The sugar has a heat sensitivity (the pH determines these properties – low pH, less sensitive), it is the caramelization. Fructose, maltose and dextrose are the most sensitive and lactose and sucrose are the least. In the baking technology, the sugars help to brown the crust (the crust color is darkened by adding sugar), increases the volume (source of energy of yeast activity) and the moistness (moisture retention and the tenderness (the texture become smoother and finer).

27 Types of sugars:

table sugar

sanding sugar

molasses

corn syrups

brown sugar

granulated

honey

malt syrup

The sugars are the following: monosaccharides; glucose, fructose; disaccharides;

Lactose (glucose and galactose) –milk; maltose (glucose and glucose); sucrose (glucose and fructose –table sugar; reducing sugars.

Milk is a very important ingredient in the fine bakery products. The main nutritions are the water (87%) and the solids (13%). The solids are: carbohydrates, protein, water-soluble vitamins and minerals, fat and fat-soluble vitamins. The carbohydrates, the fats provide energy, the protein builds muscle. The calcium builds strong teeth and bones and regulates the muscle. The phosphorus strengthens the body cells. The milk contains vitamin A, B and D, the vitamin D helps the calcium and the phosphorus to build strong teeth and bones. Evaporated milk is produced from whole milk, is made by removing ~ 60% water from whole milk. After the evaporation, this milk is homogenized, and fortified with vitamin D and vitamin A (it is optional).It has two types, which depends on the fat content, the fat free evaporated milk content (maximum 0.5% fat), the sweetened condensed milk content (maximum 8% fat) (it has been sugar added, which is sucrose). And we can talk about the mixing of the two types, this is the sweetened condensed fat free milk, it contains the same fat content like evaporated fat free milk and it contains sweetener. The liquid milk needs refrigerator, and when we once open we can use in a week. Dry milk has longer shelf life and it doesn’t need refrigerator. This is powder, made from dried milk solids and we can reconstitute it with water. The bakers like it to use.

The malt is made by barley grain germination (by soaking grains in water). The temperature of water is between 10-15 °C. The water enters the grain and 24 hours

28

later, we can sign the germination. During this process the enzyme activates the embrio developing. We can talk about green malt in 5 days. After the germinating we dry and ground the barley seed into malt powder. This malt powder is used in the baking technology. The brittle malt rootlet is used in the animal feeds. These products contain amylase enzymes, which help to break down the starch. We use malt extracts in the bakehouse.

2.3.2 Fillings

The main purpose of filling applications is to increase the enjoyment and nutritional value of the bakery product. They use plant material such as fresh and preserved fruits, fruit preparations as a mixed fruit jam, but use oilseeds such as walnut, poppy, cocoa and pudding. Products are often enriched with substances of animal origin such as meat products, such as frankfurter, ham, bacon, as well as meat and liver creams, but also dairy products such as cottage cheese and cheese.

2.3.3 Flavouring agents

Flavourings are called spices made from materials derived from plants, fungi, animals, minerals, which are used to flavour baking pies. Spices enrich the bake product with flavour, colour, fragrance and preservative. For sweet products, vanilla, cinnamon, clove, lemon, anise, ginger, cardamom and cocoa are used. When preparing salt-flavoured products, they use cumin, black and white pepper, coriander, spice paprika and garlic.

2.3.4 Other materials

Technology assistant materials only aid the production of the product and are not included in the product. Such materials include baking paper, edible oil, roasted flour, and starch powder.

Packaging materials, such as technology-assistants, are not included in the product, but the sole purpose of these materials is to protect the product and its environment from each other. The type of packaging material is affected by the shelf life of the product. Based on the shelf-life of the product, we can talk about short-life products

29

with water vapor permeable packaging material and long shelf life products for which water vapor sealant is used.

The good packaging material is keeping air out and flavors in, the material is highly transparent and weather resistant. Other characteristics are oil and solvent resistant, flexible, moldable, recyclable, and even printable.

2.4 Control issues

1. Describe the chemical composition of flour!

2. List the flour properties that determine the suitability for human consumption and food production!

3. Which factors influence the moisture content of the flour?

4. What limits can the moisture content of flour range between?

5. What is the ash content?

6. What does the term amilolite state mean? What methods do you know to test this?

7. List and describe the gluten proteins!

8. What methods do you know about the physical properties of dough?

9. What is the difference between the essential and indispensable auxiliary materials?

10. List enrichment materials! How does enrichment affect the technological properties of dough?

30 3 PRODUCTS

Baking products are foods made from flour with water or milk, as well as loosened doughs made with various ancillary and auxiliary materials [11]. Baking products typically have high carbohydrate content, which is a major part of starch and a smaller proportion of sugar and fiber. In addition, these products contain incomplete proteins as well as minor amounts of fats, minerals, and vitamin B.

Baking products can be divided into categories in Hungary according to the quality of their dough [5]:

Breads

Pastries, two subclasses of which are manufactured from kneaded dough and fine bakery products

Crumbs

Quick-frozen goods.

3.1 Breads

The type of bread is mainly influenced by the quality of the flour, but also by its additional ingredients. Famous bread types are:

Baguette (France)

Balady (Egypt, Syria)

Chapatti (India)

Man-tu (China)

Tannouri (Iran)

Pan (Japan)

White bread (Hungary) [Fig. 15.].

In Hungary, mainly wheat flour is used to make bread, but with the advancement of healthy nutrition, wheat bran or rye flour rich in mineral salts is increasingly used.

The breads made of rye flour are typically smooth, brown in colour and have a more concise texture, more acidic than bread made of wheat flour. The white and semi- brown breads, on the other hand, have a shiny, crunchy crust and their structure soft

31

and elastic. The use of higher-grade flour-containing flour increases the content of the product's bran, fiber and vitamin B content.

Figure 15.White bread

The shelf life of long-lasting breads is longer than the shelf life of any other bread.

Their storage capacity is due to the fact that they contain rye flour, margarine and various additives such as sorbic acid and calcium propionate preservatives. These additives protect the product from molding. The product packaging locks the water vapor and it delays aging and dehydration [12]. We are categorized into this category:

Sliced sandwich bread

Sliced toast bread

Rusk.

Rusk has the longest shelf life of long-lasting breads. After baking, they are immediately sliced and dried to 8-9% water content to ensure long shelf life, which is usually 6 days after baking.

32 3.2 Pastries

Pastry products are made using wheat flour, yeast or other structuring agents, flavoring agents and enrichment materials [Tab. 4]. Depending on the use of additives and the dough design, we can divide the pastries into two large groups:

Kneaded dough

Specialty dough.

Table 4.Additional material content of pastries

3.2.1 Pastries made of kneaded dough

Pastry made from dough, which made with water made from cereal grains, yeast, salt, water and, where appropriate, food additives and other ingredients. This type of dough does not contain any additive that is why a loose structure characterizes the products made from this dough.

The pastries made from dough, which made with milk, are made from cereal grains, yeasts, salt, at least 3% skimmed milk powder or equivalent type of milk powder, and milk, edible fat, sugar, water and, where appropriate, food additives and other ingredients.

33

The definition of pastry made from enriched dough is the same as the definition of pastry made dough, which made with milk. In enriched dough, more sugar and fat are typically used than dough made with milk, so these products will have a darker crust colour due to the higher carbohydrate content.

Pastries made from egg-enriched dough are made from cereal grains, yeast, salt, milk powder or milk, edible fat, sugar, water and egg or egg preparation, if necessary using food additives and other ingredients. As a result of the use of eggs and larger quantities of sugar and fat, the product will be luscious and sweet. Figure 16 shows an example of a typical Hungarian pastry from egg-enriched dough.

Figure 16. Hungarian fine braided milk-loaf 3.2.2 Pastries made of specialty dough

Pastries made from friable dough are made from cereal grains, yeast, salt, edible fat, water, as needed, using enrichment and food additives and other ingredients, using a distinctive technology. These products are typically solid, inflexible, friable breaking fine bakery products. Figure 17 shows an example of a typical Hungarian pastry from friable dough.

34

Figure 17. Bratislava crescent roll with poppy seed (on the left side) and walnut (on the right side) fillings

Fine bakery products made from layered dough are produced by using grain cereals, salt, edible fat, and enrichment and food additives as needed. These products have typically loose and layered structure. Products made of layered dough may be salty or sweet depending on their filling. Figure 18 shows an example of sweet pastry from layered dough.

Figure 18. Cocoa roll

35 3.3 Crumbs

Crumbs are long-lasting baking products, the raw material of which is due to defective or possibly over-production of bread and pastry. We differentiate the crumbs from each other by their basic material:

Bread crumbs,

Mixed crumbs,

Crumbs made of pastries.

3.4 Quick-frozen bakery products

Quick-frozen bakery products are semi-finished products which are preserved by quick freezing and can only be consumed after any further technological operation such as baking.

The frozen bakery supply chain is composed of a wide range of products and companies. Famous bakery products are the pie (which are usually made of pastry dough and contains filling of various sweet or savory ingredients), the croissant (it has buttery taste), etc. The frozen products will be pre-cooked and ready-to-bake products. The pre-cooked products have already been partially baked, and it can be ready in minutes. The ready-to-bake products have not been cooked at all, and it is required complete baking. It is semi-finished baked goods. The more important technologies are the refrigerated dough (retarded dough), the frozen dough (fermented or not) and the partially baked goods (frozen or packed in modified atmosphere).

36 3.5 Control issues

1. Define the bakery products!

2. What are the characteristics of bakery products?

3. Based on the quality of the dough, which groups can be divided into bakery products?

4. List some famous bread types!

5. How does rye flour affect the sensory properties of bread?

6. What distinguishes long-lasting breads from other breads?

7. What kind of kneaded pastry you know?

8. Define crumbs as durable bakery products!

9. What kind of crumbs do you know about its basic material?

10. What do we call quick-frozen bakery products?

37 4 BAKING TECHNOLOGY

4.1 Preparation

During the preparation of the raw materials, the temperature of the substances to be used is adjusted first, which promotes the production of the right kind of dough. The temperature of the flour is only needed when its temperature is so low that the general temperature of 30-32 °C is only achieved with hot water more than 45 °C which would have a damaging effect on yeast and the technofunctional properties of the flour [13]. In the case of dough preparation by intensive mixer, it is not necessary to preheat the flour due to the heat generated during the operation.

In addition to the raw materials, the temperature of the kneading water is adjusted.

The temperature of the water determines the temperature of the dough.

They often work with blended flours during manufacture process. For small bakeries, this is accomplished by the sieving operation, however, in larger bakeries, a cell feeder, volume dispenser or bulk dispenser is used for this purpose [13].

The scaling is very important to keep the recipe and the quality of the product. All ingredients must be weighted before using. The correct weight is necessary to bake good products. We can use electric scaling to measure the amount of flour, salt, water, yeast, milk, egg, etc. [Fig. 19.]. The operation of the measurement is carried out in small bakeries by scales, in large bakeries they use an automated metering system [13].

38

Figure 19. Scaling the ingredients

4.2 Dough making 4.2.1 Kneading

The aim is to mix the fundamental ingredients (flour, water, salt, yeast, sugar, etc.) to be homogenous dough. The dough will be smooth and elastic. Some of the gluten develops during the mixing, but most of the gluten developers during the kneading.

Yeast bread is prepared by mixing the ingredients into dense, pliable dough that is kneaded, allowed to rise by fermentation.

The main ingredients determine the dough. The flour, with high protein content has more gluten potential. Liquids are hydrated the solids and are important in the gelatinization. The salt controls the yeast growth, because, without salt the fermentation will be rapid. The yeast is the biological leaving agent. The yeast is a one celled fungus, which are leavened with carbon dioxide gas.

There are some best known methods:

Straight dough method

Sponge method

Batter method

Rapid method

39

In the straight dough methods, we mix and knead the all the ingredients in one step.

First we have to soften the yeast, the compressed yeast should be activated in warm water, and it is 25 °C (the dry yeast needs more temperature). After it, the other ingredients have to be combined with the yeast. Combine with the liquid and the other dry ingredients, and mix until it reaches smooth dough. This method is a fast mixing method.

First we mix the liquid, the yeast, the sugar and the part of the flour. This is a sponge.

This method needs more time, these breads take even longer, requiring about six – ten hours to make and fully develop their flavour. It is important, that adding too much flour to the sponge will make the dough stiff. This method is a pre- fermentation method, where the dough is mixed in two steps. When the sponge is ready, it means it becomes bubbly and light, we add the other ingredients (fat, salt, and the rest of the flour) to form a dough.

Some recipe is prepared by the batter; it means to use less flour and less yeast. This method is the other type of the straight dough that eliminates kneading (no mix method).

The aim of the mixing are:

Flour, yeast, salt, etc. mixed with water

Formed flexible dough

Stretch and elastic dough kneaded.

There are some other well-known methods, for example the frozen dough method.

The frozen dough process means, when the process is stopped after the forming/shaping. It needs to reduce the product temperature to -20 °C. The problem with it, that the yeast activity (the gas production) decreases and the gas retention of the dough is not enough. In this process we need yeast (which is good for this process), because in the water there will be ice crystals during the freezing and it can damage the cells wall of the yeast. We need to increase the yeast dosage. In this process we need low protein flour, but with higher protein quality and the water temperature should be close to 0 °C. More salt helps to strengthen the gluten (and adds flavour), the sugar quantity should be reduced to compensate for reduced

40

fermentation. The emulsifiers help the development of the gluten structure. The technology changes, the mixing has to give the maximum development for gas retention. The fermentation time must be as short as possible, the dividing must be carried out as soon as the mixing has been finished. The resting time will be short, maximum 10 minutes, it is enough for the dough to relax. For the freezing we use blast freezer, where the temperature is in between -30 to -35 °C. The requirement of the packaging:

Waterproof

Air tight

Flexible and resistance to low temperature (polyethylene)

Sealable.

The storage temperature is -20 °C. The time is maximum 6 months. It requires cold chain transportation, where the products must be kept at -20 °C.

Before using we have to thaw. It can be in a proof box, in a room temperature in a prover. For the baking we need deck oven or convection oven.

The mixing time is very important, it depends on the mixer type, the dough method, the dough volume, the dough temperature, the water absorption capacity of the flour, the amount of shortening, the amount and type of oxidizing agents and the amount of other ingredients (for example: milk, eggs, etc.). During the mixing we can talk about different stages. The first is the pickup stages, where the dough is cold and lumpy and getting smoother and drier (absorbs the water). The second step is the clean up stages, when the dough reaches the maximum stiffness and the colour change (will be whiter). The third is the final development, the gluten is ready, and the dough has good temperature.

After these stages, the dough reaches the let down and the breakdown stages. It is an overmixing period, where the dough is too warm, becomes lack elasticity and will begin to liquefy.

The remaining time is necessary to develop the gluten. Overmixed and undermixed dough have poor volume and texture. In practice we have to learn, when the dough is

41

ready (sight, feel). The dough is smooth and elastic and not sticky. Too much flour will make the dough stiff, if we add a little more flour if the dough hasn't lost its stickiness after most of the mixing time has passed. The developing depends on the mixer, slow speed at first and fast speed secondly. The knead work: mix ingredients and develop gluten. Too much pressure at the beginning of kneading can keep the dough sticky and hard to handle. Too much pressure at the end of kneading can tear or mat the gluten strands that have developed.

The mixing and kneading are determined by the mixers. There are some types, which operate like the hand mixing. The difference among these mixers is the mixer arm rotation [Tab. 5.]. The quicker mixer is practical and the dough is mechanically developed within 3 minutes.

Table 5.Types of the mixers

The low speed mixer [Fig. 20.] needs more time (20 minutes) to develop the dough.

This operates like the hand. This was the first mixer type all over the world. The rotation is 20-40 rotation per minutes, but the capacity of these mixers wherefrom 100 to 300 kg. It is a gentle mixing.

42

Figure 20. Low speed mixer

The quick mixer [Fig. 21.] is the main mixer in the bakehouse. The mixing takes 8 minutes. It has a spiral-shaped mixing hook, which rotates. It has slow and fast speed function too. The slow speed is good, when we use flour with weak gluten content, the fast speed is good, when we have flour with strong gluten content. The capacity of the bowl is ~100 – 200 kg dough and the bowl is rotated.

Figure 21. Spiral mixer

43

The high speed mixer’s [Fig. 22.] mixing time of this type is 3 minutes, but it needs high level of mechanical energy. It is required cooling, because the temperature of the dough increases rapidly. The capacity is from 50 to 300 kg dough. Here the bowl doesn’t rotate.

Figure 22. High speed mixer

After the mixing if we use the dough immediately, it will be fresh dough. It should be completely cooled before being wrapped and stored in a dry, cool place at room temperature. In the tropical regions we can find refrigerated dough and frozen dough.

The frozen dough can be frozen for two or three months.

4.2.2 Fermentation

After the mixing and kneading, we allow the dough (which contains yeast) to rest.

This is the rest time, when the yeast acts on the sugars and starches in the dough.

This is the fermentation, where alcohol (ethanol) and carbon dioxide gas are produced.

The yeast converts the sugar to carbon dioxide that enables dough volume expansion.

In the same time the pH decreases and the enzymes change the characteristics of the dough (the gluten) to allow more gas retention. If we use dried yeast, we have to hydrate it with water.

44

During this process the dough should be doubled in size. Therefore we have to control the temperature and the humidity. The humidity is about 75 %, the temperature is between 25 – 30 °C.

During the fermentation the structural and rheological properties change the dough; it will be soft and expanded. The gluten becomes smoother and more elastic.

The ingredients, the dough temperature and the room temperature control the fermentation (warm and humid environment). The other ingredients (fats, improvers) also determine it. The fermentation is in the kneading bowls, which is covered with cloth (it allows to double in size).

The underferment dough has little volume increasing and the texture is coarse. The overfermented dough is sticky, and it is hard to work with it. In this case the cell walls break and collapse [Fig. 23.]. The carbon dioxide gas goes away and it causes the low volume of the end products.

Figure 23. CO2 gas bubble

45

The good fermented dough is doubled, and if you press fingers into the dough and if indentation remains, the dough is ready, it has risen enough. A dent will remain after the hand or finger is pressed into the top of the dough.

We can talk about straight dough method and sponge dough method. In the bread making technology the traditional process is the sponge dough process.

The alcohol evaporates during the baking, the carbon dioxide gas increases the bread volume (it causes the bread rise)

To make good bread, we have to keep the following: precise measuring, good mixing and kneading, controlled fermentation temperature and humidity, correct baking temperature.

4.3 Dough make-up/shaping

The first step is the scaling with bakers scale. The aim is to divide the dough into pieces (uniform scaling, pan flows, texture). Sharp knife is used for a dough cutter to divide into pieces. There is weight loss during the baking, so the scaling weight is more, than the final weight of the products (the moisture, the alcohol will evaporate).

This weight loss is between 10 and 20 percent of the weight of the dough. It depends on the final weight of the bread required (generally 12 % extra dough). Dividing should be done within the shortest time in order to ensure the uniform weight.

After the scaling the next step is the rounding, when the pieces of dough is shaped into round balls. Roll the dough into 10 rectangles. The rounder is good to impart a new continuous surface skin [Fig. 24.]. The width of the dough depends on the length of the bread pan.

46

Figure 24. Rounder machine [24]

After these steps, the dough needs a rest (it is about 10 minutes). It is an intermediate proofing, the machines cause that the dough is like a rubber and it will not moulded easily. After the intermediate proofing the dough will be flexible, extensible and it tears easily. It will be easier to handle, and rise again after the scaling and rounding.

After it, the moulding will be the next one, it has three steps: sheeting, curling, scaling [Fig. 25.]. The sheeter degasses the dough, so the dough will be manipulated easily. In the curling section, the roll into a cylindrical form carries the sheeted dough.

47

Figure 25. Different bakery products form

4.4 Proofing

The purpose of the proofing is to loosen the dough pieces compacted during forming and to form a gluten structure at the end of the process. The gluten structure should be follow the increase in volume, hold back the gas and allow the product to retain its shape until it is solidified during baking [7].The duration of the proofing should be chosen so that the dough pieces have the most favourable properties at the end of the process, and their conditions have to be regulated to suit microbiological, enzymatic and colloidal processes [Fig. 26.]. It is the same process as the mixing dough fermentation, but the proofing is the final fermentation before baking.

48

Figure 26. Volume changing (increasing) during the proofing

Setting the technological parameters of the proofing is very important. In the air space of the bakehouse, the dough cannot proof under favourable conditions, so it is necessary to set up a mounted or built-in prover to ensure the proper conditions [Fig.

27.].We need prover, where the average temperature is 27°C to 35°C. This temperature is higher than fermentation temperature. The humidity is important (keep the crust moist), it is 80-85 %.

Figure 27. Mounted prover [23]

49 Among the provers, you can distinguish:

Simple latching provers

Air-driven latching provers.

Among to delay proofing, you can distinguish:

Cooling chillers

Louvers interrupter chillers.

For simpler units, there is no built-in timer since the process is used for a longer period of time, but it is possible to switch the unit on or off and read the actual temperature of the prover [22].

Factors influencing growth include enzymatic and gluten properties of flour, technological dough indexes and dough size and shape [13]. All of them determine the proofing time. The duration of the proofing may last 30-70 minutes [13].

Under the proofing the volume of the products increases, without proofing the results will be poor volume and dense texture (it is young dough) [Fig. 28.]. When you over proof the product, it will have coarse texture and there will be loss of flavour (old dough).

Figure 28. The products volume after normal proofing (left products) and without proofing (right products)

50 4.5 Baking

Baking is the most typical operation of making bakery products. Baking is a complex process under the influence of heat and moisture, during which complicated physical, colloidal, microbiological and biochemical changes occur inside the dough. During baking, the existing ingredients of the dough are transformed, resulting in the formation of distinctive new materials.

The aim is nicely browned crust and good crumb. Crumb is the cell structure, when the products are sliced [Fig. 29.]. The size, the shape, and the thickness of the cells are important parameters. The size of the cells will be large (open) and small (close), the thickness of the cell will be thin in the fine crumb and predominate in a coarse crumb.

Figure 29. The structure of the bread crumb

This process is determined by the size of the loaf and the kind of the dough. The two important parameters are the baking time and the baking temperature.

During the baking the following reaction will happen:

In the first part of the baking the dough volume will rise quickly, because the gas cell expands. It is called oven spring.

At first the yeast is very active, but when the temperature reaches the 60 °C, it is killed.

The protein coagulation.

The starches will gelatinization.

The crusts will formation and browning.

51

The beginning of the bake is the initial drying. If this happens too fast, the volume of the product cannot grow; it will disintegrate, so it is necessary to fill the baking chamber with steam. As the furnaces operate at atmospheric pressure, the dew point of the oven compartment can be up to 100 °C, i.e., the immediate dewatering of the dough on the lower temperature, giving it a large amount of heat. This effect ensures that the surface of the dough is flexible [10].

The temperature is gradually increasing in the interior of the dough. Based on the temperature rise, the processes here are divided into four parts. At 30-40 °C the yeast gas production capacity, the acid production activity of the bacteria and the speed of the enzymatic processes increase, i.e. the maturation of dough is practically continued. At 40-60 °C, the gas production capacity of yeasts suddenly slows down and disappears, the cells die, the enzyme activity decreases with the exception of α- amylase, and their detrimental effect occurs at this stage. The most significant changes occur between 60-80 °C, as gluten and starch are transformed, and the phase of the formation of the crumb starts. Gluten proteins precipitate and melt, lose their extensibility, solidify while water is added to the swelling during and after the kneading. However, the starch granules start to swell and the granules disintegrate.

Due to the stiffening of the starch gel and the proteins, the entire mass of the dough solidifies, loses its pasta-like properties and becomes a breadcrumb, the dough between the gas bubbles forms thin porous walls that can break through, enzymes cease to function and the alcohol evaporates. At 80-100 °C the water content of the hardened crumb decreases due to evaporation, its volume is no longer altered.

The bread crust is dry and the breadcrumb contains moisture up to 40 per cent after the baking. Temperature inside the product does not rise above 100 °C. On the surface, the temperature is relatively fast above 100 °C, so changes occurring above this range are examined [Fig. 30.]. At 100-120 °C the surface is dry and its colour is still doughy. Between 120-140 °C the starch gel is formed, dextrin degrades to give yellowish colorants. At 140-160 °C already light brown dextrins appear. Colour change is promoted by the caramelization of sugars and the products of the Maillard reaction between sugars and certain amino acids, along with the addition of pleasant flavour and aroma.

52

Figure 30. The temperature increasing in the loaf There are two baking techniques:

HTST (high temperature short time): if the baking is too quick, the crust will be good, but the crumb structure is not.

LTLT (low temperature long time): it causes a thicker rigid skin without browning.

The temperature depends on the types of the products. The rolls are baked at a higher temperature than the larger products. It causes, that they become browned in short time during baking. The average baking temperature of the fine bakery products is between 200°C to 245°C. The products which contain a lot of sugar, need lower temperature (175°C to 200°C), because their fat, sugar, and milk content makes the crust brown faster. The bread baking temperature is higher (250 °C to 300 °C). In the bread making process after the oven spring, we have to reduce the oven temperature, this prevents the over browning on the surface of the product. The dough is ready, we check for doneness, it means to remove the loaf from the pan and tap bottom and sides. Well baked bread sounds like the hollow.

The baking time as the baking temperature is considerably depend on the products type.

![Figure 5.Gluten structure [19]](https://thumb-eu.123doks.com/thumbv2/9dokorg/1104684.76717/14.892.277.679.106.374/figure-gluten-structure.webp)