Doktori (PhD) értekezés

$V]XSUDYH]HW NHUiPLiNpVNHUiPLDL

ko m p o zito k fizika i tu la jd o n s á ga in a k ja vítá s a

Készítette:

Eniszné dr. Bódogh Margit

7pPDYH]HW

Dr. Kotsis Leventéné egyetemi docens

Készült a Veszprémi Egyetem

Anyagtudományok és Technológiák Doktori Iskolája keretében Veszprém

2003

Tartalomjegyzék

Kivonat; Abstract; Auszug

(O ]PpQ\HNpVFpONLW ]pVHN%DFNJURXQGDQGREMHFWLYHV

Alkalmazott vizsgálati eszközök; Investigation techniques used

Új tudományos eredmények, tézisek; Novel scientific achievements and theses Az értekezéssel kapcsolatos publikációk jegyzéke; Publications related to the Theses BEVEZETÉS

1. IRODALMI ÖSSZEFOGLALÓ 1.1.2[LGV]XSUDYH]HW NV]HUNH]HWH

1.1.1. O[LGV]XSUDYH]HW NWtSXVDL

1.1.1.1. SSLQHOOV]HUNH]HW V]XSUDYH]HW N

1.1.1.2. Volfrám-EURQ]V]HUNH]HW V]XSUDYH]HW N

1.1.1.3.3HURYV]NLWV]HUNH]HW V]XSUDYH]HW N

1.1.1.4. Y2O3-BaO-CuO rendszer fázisdiagramja

1.2. Kémiai helyettesítések hatása az YBa2Cu3OyV]XSUDYH]HW WXODMGRQViJDLUD

1.2.1. Ittrium eurySLXPPDOW|UWpQ KHO\HWWHVtWpVH

1.2.2. Bárium alkáliionokkal való helyettesítése 1.2)OXRUWDUWDOP~V]XSUDYH]HW N

1.2.4. Réz-ionok helyettesítése

1.2.4.1. A réz kREDOWWDOW|UWpQ KHO\HWWHVtWpVH

1.2.4.2. A rézFLQNNHOW|UWpQ KHO\HWWHVtWpVH

1.2.4.3. A rézyORPPDOW|UWpQ KHO\HWWHVtWpVH

1.2.4.4. A réz H]VWWHOW|UWpQ KHO\HWWHVtWpVH

1.3. 6]XSUDYH]HW H]VWNRPSR]LWRN

1.4. KeriPLDLV]XSUDYH]HW NHO iOOtWiVD

1.4.1. Orientált szerkH]HW V]XSUDYH]HW NHO iOOtWiVD

2. KÍSÉRLETI RÉSZ

2.1. Helyettesítések hatása az YBa2Cu3OyV]XSUDYH]HW NWXODMGRQViJDLUD

2.1.1. YBa2Cu3OyV]XSUDYH]HW NQpODEiULXPLRQDONiOLIpPLRQRNNDOW|UWpQ

részleges helyettesítése

2.1.2. Alkálifluorid adalékok hatásának vizsgálata 2.1.3. BaF2 adalék hatásának vizsgálata

2.1.4.YBa1,95K0,05Cu3OyV]XSUDYH]HW NQpODUp]NREDOWWDOpVFLQNNHOW|UWpQ

részleges helyettesítése

$]LWWULXPHXUySLXPPDOW|UWpQ KHO\HWWHVtWpVHD]<%D2Cu3Oy

V]XSUDYH]HW NQpO

2.1.5.1. A bárium káliummal való részleges helyettesítése az EuBa2Cu3Oy

V]XSUDYH]HW NQpO

2.1.5.2. A réz kREDOWWDOpVFLQNNHOW|UWpQ UpV]OHJHVKHO\HWWHVtWpVHD](X%D2Cu3Oy

V]XSUDYH]HW NQpO

2.1.5.3. A réz ólommal t|UWpQ UpV]OHJHVKHO\HWWHVtWpVH

2.1.5.4. A réz ezüsttel t|UWpQ UpV]OHJHVKHO\HWWHVtWpVH

2.2. SzupravezeW H]VWNRPSR]LWRNHO iOOtWiVa

0HJQ|YHOWPHQQ\LVpJ Ii]LVWWDUWDOPD]yNHUiPLDLV]XSUDYH]HW N

HO iOOtWiVD

2.3.1. Pt és Cr adalék kristálynövekedésre gyakorolt hatása az Y-Ba-Cu-O bázisú

V]XSUDYH]HW NQpO

NRPSR]LWRNNO|QE|] Pódszerekkel történ HO iOOtWiVD

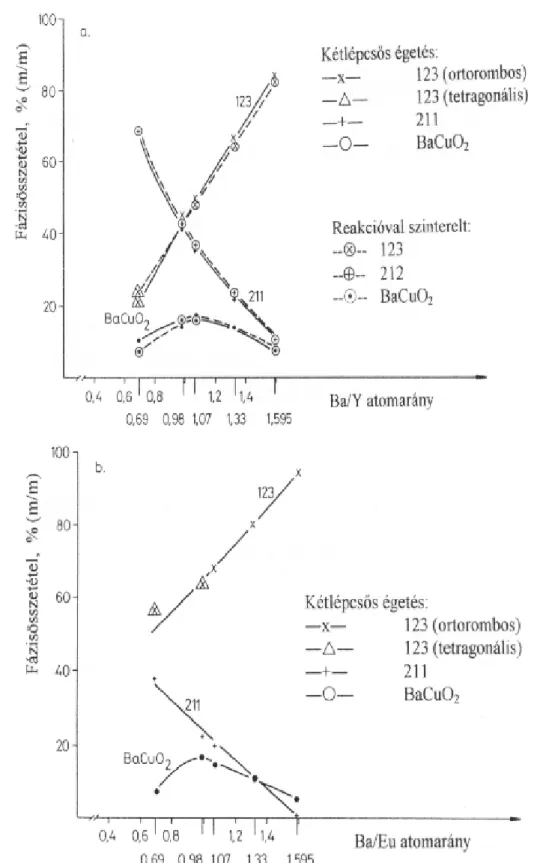

2.3.2.1. Y-Ba-Cu-O és Eu-Ba-Cu-2Ei]LV~NRPSR]LWRNNpWOpSFV V pJHWpVHVHOMiUiVVDOW|UWpQ HO iOOítása

.pV3EDGDOpNRWWDUWDOPD]yNRPSR]LWRNNpWOpSFV VpV KiURPOpSFV VpJHWpVVHOW|UWpQ HO illítása

<<NRPSR]LWRNL]RWHUPSHULWHNWLNXVUHDNFLyYDOW|UWpQ HO iOOtWisa

2.3.2.4. Y-Ba-Cu-O és Eu-Ba-Cu-2Ei]LV~V]XSUDYH]HW NROYDGpNIi]LV~

sziQWHUHOpVVHOW|UWpQ HO iOOtWiVD

2.3.2.4.1. Y-Ba-Cu-O bázisú szuprave]HW NROYDGpNIi]LV~V]LQWHUHOpVHNRU

lejátszódó folyamatok hevítéses röntgenkamrás felvételek alapján W|UWpQ YL]VJiODWD

.O|QE|] |VV]HWpWHO &-RQHO V]LQWHUHOWPLQWiNEDQROYDGpN- fázisú szintereléskor lejátszódó fázisváltozások sztatikus

módszerrel való vizsgálata

$]HO V]LQWHUHOWPLQWD|VV]HWpWHOpQHNpVSRUR]LWiViQDNKDWiVDD]

olvadékfázisú szinterelésnél lejátszódó fázisátalakulásokra 2.3.2.42OYDGpNIi]LV~V]LQWHUHOpVVHOHO iOOtWRWW(X-Ba-Cu-O bázisú V]XSUDYH]HW NYL]VJiODWD

2.3.2.5. Y-Ba-Cu-O és Eu-Ba-Cu-2Ei]LV~V]XSUDYH]HW NROYDV]WiVRV

tecKQROyJLiYDOW|UWpQ HO iOOtWiVD

2.3.2.5.1. Y-Ba-Cu-O bázisú szuprave]HW NROYDV]WiVRVWHFKQROyJLiYDOW|UWpQ HO iOOtWiVDNRUOHMiWV]yGyIi]LViWDODNXOiVRNKHYtWpVHVU|QWJHQNDPUiV

vizsgálata

.HUiPLDLV]XSUDYH]HW NIRUPi]ása

.HUiPLDLV]XSUDYH]HW NPHOHJSUpVHOpVVHOW|UWpQ IRUPi]isa 2.4.2. SzupravH]HW YDVWDJUpWHJHNHO iOOtWiVD

.HUiPLDLV]XSUDYH]HW NUREEDQWiVRVWHFKQROyJLiYDOW|UWpQ IRUPi]iVD 6]XSUDYH]HW YDVWDJUpWHJHNSODWWtUR]iVVDOW|UWpQ W|P|UtWpVH

.O|QE|] |VV]HWpWHO V]XSUDYH]HW NpVV]XSUDYH]HW Hzüst kompozitok tengelyszimmetrikus robbantásos tömörítése 2.4.3.3. Reakcióval szinterelt YBa1,95K0,05Cu3OyF0,05/Ag kompozit és Y1,8Ba2,34K0,06Cu3,4Oy3WV]XSUDYH]HW SRURNIpPOHPH]HN

közötti robbantásos tömörítése

2.4.3.3.1. Robbantással tömörített szXSUDYH]HW NXWyODJRVK NH]HOpVH

5REEDQWiVRVHOMiUiVVDOW|P|UtWHWWV]XSUDYH]HW NXWyODJRVK NH]HOpVHNRU

lejátszódó folyamatok hevítéses röntgenkamrás felvételek alapján W|UWpQ WDQXOPiQ\R]iVD

ÖSSZEFOGLALÁS IRODALOMJEGYZÉK FÜGGELÉK

Kivonat

A dolgozat célja az YBa2Cu3Oy |VV]HWpWHO QDJ\ iWPHQHWL K PpUVpNOHW SROLNULVWiO\RV NHUiPLD V]XSUDYH]HW N iUDPYH]HWpVL pV PiJQHVHV WXODMGRQViJDLQDN MDYtWiVD D J\DNRUODWL

felhaszniOiVL LJpQ\HNQHN MREEDQ PHJIHOHO V]XSUDYH]HW N HO iOOtWiVD D V]XSUDYH]HW NULVWiO\UiFViEDQ D NO|QE|] UiFVSR]LFLyNEDQ W|UWpQ ionhelyettesítések, a fázisösszetétel változtatása, valamint NO|QE|] HO iOOtWiVL pV IRUPi]iVL HOMiUiVRN HJ\LGHM

alkalmazásávDOHOpUKHW V]|YHWV]HUNH]HWPyGRVtWiVUpYpQ

Az YBa2Cu3Oy V]XSUDYH]HW PLQG D QpJ\ DONRWy HOHPpQHN részleges vagy teljes helyettesítésével RO\DQ V]XSUDYH]HW V]LOiUG ROGDWRN 0%D2-xAxCu3-zDzOy(Fx), ahol M=Y3+

vagy Eu3+, A=K+ vagy Na+, D=Co3+ vagy Zn2+ vagy Pb2+ vagy Ag+HO iOOtWiVDW|UWpQWDKRO D] LRQKHO\HWWHVtWpVHN QHP EHIRO\iVROWiN D V]XSUDYH]HW Ii]LV LQNRQJUXHQV ROYDGiVL YLVHONHGpVpWXJ\DQDNNRUKDWiVVDOYROWDND]HXWHNWLNXVpVDSHULWHNWLNXVK PpUVpNOHWpUWpNpUH

ezáltal az olvadék fázis megjelenpVpQHN K PpUVpNOHWpUH D NHOHWNH] ROYDGpN PHQQ\LVpJpUH YDODPLQW D V]XSUDYH]HW NULVWiO\RN Q|YHNHGpVL VHEHVVpJpUH V PLQGH] D V]XSUDYH]HW

szemcsék közti kapcsolat , ezáltal a szupravezetési tulajdonságok változását eredményezte.

Az alkalmazott helyettesíWpVHN N|]O D V]XSUDYH]HW NULVWiO\RN Q|YHNHGpVH V]HPSRQWMiEyO D OHJNHGYH] EEQHN D Up] yORPPDO V D EiULXP NiOLXPPDO YDOy UpV]OHJHV KHO\HWWHVtWpVH

bizonyult, mivel ekkor az a-b VtNEDQ HU VHQ DQL]RWUyS Q|YHNHGpVW PXWDWy OHPH]HV

orientációra hajlamos szupraYH]HW NULVWiO\RN NpS] GWHN PLQG D] <-, mind pedig az Eu- tartalmú rendszereknél.

$ V]XSUDYH]HW Nfázisösszetételének változtatásával HJ\UpV]W D V]XSUDYH]HW N PiJQHVHV HU WHUpQHN Q|YHOpVH YROW D FpO DPL D V]XSUDYH]HW V]LOiUG ROGDW NULVWiO\RN N|]|WW ILQRP

eloszlású M2BaCuO5 Ii]LV PHJIHOHO PHQQ\LVpJEHQ YDOy NLDODNtWiViYDO W|UWpQW PiVUpV]WDV]XSUDYH]HW V]LOiUGROGDWRNKR]RSWLPiOLVPHQQ\LVpJ $J123 adagolásával olyan

V]XSUDYH]HW V]LOiUG ROGDWH]VW NRPSR]LWRN NpV]OWHN PHO\HN MREE PHJPXQNiOKDWyViggal rendelkeztek.

Az HO iOOtWiVL WHFKQROyJLiN N|]O D KDJ\RPiQ\RV UHDNFLyYDO W|UWpQ V]LQWHUHOpV PHOOHWW D NO|QE|] ROYDGpNIi]LV~KHWHURJpQQXNOHiFLyQDODSXOyHOMiUiVRNNHUOWHNDONDOPD]iVUDDKRO D OHJHO Q\|VHEE K NH]HOpVL SDUDPpWHUHN PHJKDWiUR]iVD D V]LOiUG ROGDWRN HO ]HWHV KHYtW PLNURV]NySLpVKHYtWpVHVU|QWJHQNDPUiVYL]VJiODWDVHJtWVpJpYHOW|UWpQW(]HQHO iOOtWiVL

eljárások alkalmazásakor részben az olvadék fázis mennyiségének, részben a nukleusz

PLQ VpJpQHN pV PHQQ\LVpJpQHN YiOWR]WDWiViYDO QDJ\PpUHW V]XSUDYH]HW NULVWiO\RNDW WDUWDOPD]yHU VHQWH[W~UiOWV]HUNH]HWNLDODNtWiViYDOVLNHUOWDV]XSUDYH]HW V]LOiUGROGDWRNLOO V]XSUDYH]HW V]LOiUGROGDWH]VWNRPSR]LWRNWXODMGRQViJDLQDNWRYiEELMDYtWiVD

$ OHJQDJ\REE PiJQHVHV HU WpUUHO UHQGHONH] V]XSUDYH]HW NHW ROYDGpN Ii]LV~ KHWHURJpQ QXNOHiFLyYDO VLNHUOW HO iOOtWDQL D %D . LOO &X 3E LRQKHO\HWWHVtWpVW WDUWDOPD]y PHJQ|YHOW

211 fázistartalmú Y1,8Ba2,34K0,06Cu3,4Oy+0,44%Pt, Y1,8Ba2,34K0,06Cu3,4Oy és Y1,8Ba2,4Cu3,29Pb0,11Oy PLQWiNQiO PDJNpS] NpQW ill. Y2O3 kristályokat alkalmazva. Ez

HVHWEHQ D] LRQKHO\HWWHVtWpVW WDUWDOPD]y PLQWiN PiJQHVHV OHEHJWHW HUHMH W|EE PLQW |WV]|U|VH

az adalék nélküli, azonos technológiával készített mintákénak.

$ NO|QE|] V]XSUDYH]HW V]LOiUG ROGDWRNEyO HJ\UpV]W KDJ\RPiQ\Rs kerámiai eljárásokkal

IyOLDK~]iVVDO KLGHJ L]RV]WDWLNXV SUpVHOpVVHO PHOHJSUpVHOpVVHO I NpQW SHGLJ D NHUiPLDLSDUEDQ NHYpVEp HOWHUMHGW GLQDPLNXV SRUW|P|UtWpVVHO IpPFV EHQ W|UWpQ

tengelyszimmetrikus tömörítéssel és fémlemezek közötti plattírozással) változatos alakkal

UHQGHONH] V]XSUDYH]HW NIRUPi]KDWyN

Bebizonyosodott, hogy dinamikus portömörítésre a reakcióval szinterelt 40 P DODWWL V]HPFVHPpUHW UH SRUtWRWW <%D1,95K0,05Cu3OyF0,05$J |VV]HWpWHO NRPSR]LWRN D

legalkalmasabbak, s az így formázott WHVWHN XWyODJRV K NH]HOpVpYHO D V]XSUDYH]HWpVL

tulajdonságok tovább javíthatók.

Abstract

Production of ceramic superconductors and composites with improved properties

The aim of present work was to improve the transport current capacity and the magnetic field strength of high temperature polycrystalline YBa2Cu3Oy ceramic superconductors by chemical substitutions in the different positions of the crystal structure, by changing the phase composition and by using of different processing and forming techniques to modify the microstructure.

In the superconducting solid solutions (MBa2-xAxCu3-zDzOy(Fx), where M=Y3+ or Eu3+, A=K+ or Na+, D=Co3+ or Zn2+ or Pb2+ or Ag+) obtained by partial or complete replacement of every element in YBa2Cu3Oy the substitutions did not effect on the incongruent melting of the superconducting phase, but the values of the eutectic and peritectic temperatures, hereby the appearance temperature and the amount of the liquid phases as well as the growth rate of superconducting grains were influenced, leading to the change of the coupling between the 123 grains and the superconducting properties.

The partial substitution of Cu by Pb and Ba by K proved to be the most favourable regarding the growth of the superconducting crystals, which showed extremely anisotropic growth in the a-b direction.

The phase composition was changed partly to improve the magnetic field strength producing M2BaCuO5 (211) grains with fine distribution in the superconducting matrix and partly to obtain superconducting solid solution/silver composites with better workability.

For preparing superconducting solid solutions reaction sintering and different melt processing techniques based on heterogeneous nucleation were used.

In order to improve the superconducting properties the amount and the quality of the liquid phase were changed causing highly oriented structure of large platelike superconducting grains.

The highest magnetic levitation forces were obtained at the samples Y1.8Ba2.34K0.06Cu3.4Oy+0.44wt% Pt, Y1.8Ba2.34K0.06Cu3.4Oy and Y1.8Ba2.4Cu3.29Pb0.11Oy, which were produced by melt processing technique using 211 or Y2O3 particles as nucleus.

Compared with the undoped samples, the magnetic levitation force was about five times higher if the given substitutions were used. These superconducting solid solutions can be formed both by conventional ceramic forming techniques (i.e. tape casting, cold isostatic pressing, hot pressing) and by unconventional dynamic powder compaction (i.e. explosive axisymmetric process and explosive cladding technology) to get different shapes.

It has been shown that the YBa1.95K0.05Cu3OyF0.05+7.5wt% Ag composite powders produced by reaction sintering are the most suitable to be formed by explosive compaction at 14GPa pressure. In this case the explosive cladding technology allows to achieve a better densification, without decomposition of the superconducting phase and the superconductive properties can be improved by a subsequent heat treatment.

Auszug

Die Herstellung keramischer Hochtemperatur-Supraleitern und Kompositen mit günstigeren Eigenschaften

Der zukünftige Einsatz keramischer Hochtemperatur-Supraleitern erfordert die Verbesserung der Stromtragfähigkeit und der magnetischen Eigenschaften dieser polykristallinen Materialen.

Die für praktische Zwecke geforderten hohen kritischen Stromdichten und magnetischen Suszeptibilitäten sind durch den vollständigen oder teilweisen Ersatz sämtlicher Ionen von YBa2Cu3Oy

(123) bei gleichzeitiger Anwendung modifizierter Phasenzusammensetzung bzw. verschiedener Herstellungs- und Formungsverfahren erreichbar.

Die angewandten teilweisen oder vollständigen Substitutionen (MBa 2-xAxCu3-zDzOy(Fx), wo M=Y3+

oder Eu3+, A=K+ oder Na+, D=Co3+ oder Pb2+ oder Ag+) zeigten keinen wesentlichen Einfluss auf die inkongruente Schmelzung der supraleitenden Phase, aber sie werden die eutektischen und peritektischen Temperaturen und dadurch die Temperatur der Erscheinung und die Menge der Schmelzphase beeinflusst.

Alles diese hatte die Veränderung der Kontakte zwischen den supraleitenden Teilchen und dadurch die Veränderung der supraleitenden Eigenschaften zur Folge. Das Wachstum der supraleitenden Kristallen, bei den die ausreichende Orientierung der supraleitenden Kristallinen erfolgt wird durch den partiellen Substitutionen des Cu durch Pb und des Ba durch K am höchsten Maß beeinflusst.

Die Ursache der Zusammensetzungsoptimierung war das, durch M2BaCuO5 (211) Phasenausscheidung fein verteilte Pinning-Zentren zur Fixierung der magnetischen Flusslinien zu erzeugen. Damit können die magnetischen Levitationskräfte weiter erhöht werden.

Um bessere Bearbeitungsfähigkeit zu erhalten, wurden Supraleiter-Mischkristallen/Silber Kompositen erzeugt.

Außerdem der konventionellen Festkörpersinterung wurden verschiedene Schmelztextur-Verfahren angewandt. Der Reaktionsverlauf, die Bildung von 123 Phase und die am vorteilhafsten Parametern beim Kalzinieren wurden mit Hilfe der von Erhitzungsmikroskop und Heitzkammerröntgenograph durchgeführten Untersuchungen bestimmt. Die Herstellungsverfahren haben einen großen Einfluss auf die supraleitenden Eigenschaften. Um Supraleitern mit noch günstigeren Eigenschaften zu erhalten, wurden die Menge der Schmelzphase bzw. die Qualität und Menge von Keimkristallen (211 oder Y2O3) verändert.

Mit Schmelztextur-Verfahren können Hochtemperatur-Supraleitern (Y1,8Ba2,34K0,06Cu3,4Oy +0,44 % Pt, Y1.8Ba2.34K0.06Cu3.4Oy Y1,8Ba2,4Cu3,29Pb0,11Oy) mit den größten magnetischen Suszeptibilitäten hergestellt werden. In diesem Fall wird die Substitution des Ba durch K bzw. des Cu durch Pb durchgeführt und 211 Phasengehalt erhöht.

Die Levitationskräfte der Proben, die mit Ionsubstitutionen hergestellt wurden, hatten 5-mal größer als die der Proben ohne Zusatz.

Aus den Supraleitenden-Mischkristall-Pulvern können verschiedene Formteile und Dickschichten durch die üblichen keramischen Fertigungsprozessen (Foliengießen, kaltisostatische Pressen, Warmpressen) und durch die weniger verbreiteten dynamischen Pulver-Kompaktirung hergestellt werden.

Es wurde bestätigt, daß die gesinterten Kompositen von YBa1,95K0,05Cu3OyF0,05+7,5 % Ag durch dynamische Pulver-Kompaktirung am besten geformt werden können. Durch eine nachträgliche Erhitzung können die supraleitenden Eigenschaften der kompakten Keramiken verbessert werden.

,(O ]PpQ\HNpVFpONLW ]pVHN

$ QDJ\ iWPHQHWL K PpUVpNOHW SROLNULVWiO\RV V]XSUDYH]HW N V]iPRV J\DNRUODWL IHOKDV]QiOiViQiO SO iUDPNRUOiWR]yN HQHUJLDWiUROyN OHEHJWHWpVHV FVDSiJ\DN D PHJIHOHO DODN D QDJ\ NULWLNXV iUDPV U VpJ pV PiJQHVHV OHEHJWHW HU DODSYHW N|YHWHOPpQ\ $ KDJ\RPiQ\RV V]LOiUGIi]LV~ UHDNFLyYDO HO iOOtWRWW SROLNULVWiO\RV <%D2Cu3Oy V]XSUDYH]HW N W|EEQ\LUH NLV PpUHW V]XSUDYH]HW NULVWiO\RNDW WDUWDOPD]y KHWHURJpQ UHQGV]HUHN PHO\HNUH J\HQJH V]HPFVHKDWiU NDSFVRODW MHOOHP] DPL NRUOiWR]]D az áramszállításukat és gyengíti a

PiJQHVHV HU WHUNHW $ V]XSUDYH]HW NULVWiO\RN PpUHWpQHN Q|YHOpVpYHO WH[W~UiOW V]HUNH]HW NLDODNtWiViYDO D V]HPFVpN N|]WL NDSFVRODW Q|YHOKHW PtJ D V]XSUDYH]HW NULVWiO\RN N|]|WW ILQRP HORV]OiV~ IOX[XVU|J]tW FHQWUXPRN ( pl. Y2BaCuO5 ) kialakításával a mágneses tulajdonságok javíthatók.

Az irodalomban nagyon sok cikk taglalja a szupravezetési tulajdonságok javítására irányuló kísérleteket. Ezek egy részénél ionhelyettesítéssel, másik részénél tervezett fázisösszetétellel,

PtJ D SXEOLNiFLyN KDUPDGLN FVRSRUWMiEDQ NO|QE|] WHFKQROyJLiNNDO D V]|YHWV]HUNH]HW PyGRVtWiVD UpYpQ pULN HO D NHGYH] HUHGPpQ\HNHW -HOHQ PXQNiEDQ D KiURP ÄXWDW´

|VV]HNDSFVROYD W|UWpQLN D V]XSUDYH]HW N IL]LNDL WXODMGRQViJDLQDN MDYtWiVD D]]DO D

kiegészítéssel, hogy annak magyarázatával is találkozik az olvasó.

Dolgozatomban a reakcióval szinterelt YBa2Cu3Oy esetén a négy alkotó elem részleges vagy

WHOMHV KHO\HWWHVtWpVpYHO RO\DQ UpV]EHQ QDJ\ Ii]LVWLV]WDViJ~ UpV]EHQ D V]XSUDYH]HW PiWUL[EDQ

finom eloszlású Y2BaCuO5 Ii]LVW WDUWDOPD]y V]XSUDYH]HW V]LOiUG ROGDWRNDW 0%D2-xAxCu3- zDzOy(Fx), ahol M=Y3+, Eu3+, A=K+, Na+, D=Co3+, Zn2+, Pb2+, Ag+ NtYiQWDP HO iOOtWDQL DKRODV]XSUDYH]HW NULVWiO\RNQDND]a-bVtNEDQYDOyIRNR]RWWDQL]RWUySQ|YHNHGpVHNHGYH]

szHPFVHKDWiUNDSFVRODWRNNDOUHQGHONH] WH[W~UiOWV]HUNH]HWHWHUHGPpQ\H]VH]DV]XSUDYH]HW IL]LNDLWXODMGRQViJDLQDNiUDPYH]HWpVPiJQHVHVOHEHJWHW HU MDYXOiViKR]YH]HW

$ OHJNHGYH] EE WXODMGRQViJRNNDO UHQGHONH] V]LOiUG ROGDW |VV]HWpWHOHNQpO 0%D2-xAxCu3- zDzOy(Fx), M1,8Ba2,4-pApCu3-qDqOy(Fp), ahol M=Y3+, Eu3+, A=K+, D=Pb2+, x=0,05, z=0,1,

S T D K NH]HOpV VRUiQ OHMiWV]yGy Ii]LViWDODNXOiVRN V]WDWLNXV PyGV]HUUHO pV KHYtWpVHVU|QWJHQNDPUiVYL]VJiODWRNNDOW|UWpQ PHJILJ\HOpVHDODSMiQNO|QE|] HO iOOtWiVLpV IRUPi]iVL HOMiUiVRNDW DONDOPD]YD D] HO iOOtWiVL pV IRUPi]iVL SDUDPpWHUHNHW YiOWR]WDWYD SUyEiOWDP PpJ NHGYH] EE Ii]LV|VV]HWpWHOW pV V]|YHWV]HUNH]HWHW HOpUYH D V]XSUDYH]HWpVL

tulajdonságokat tovább javítani.

Az alkalmazott, heterogén nukleiFLyQDODSXOyHO iOOtWiVLWHFKQROyJLiNQiOUpV]EHQD]ROYDGpN Ii]LV PHQQ\LVpJpQHN UpV]EHQ D QXNOHXV] PLQ VpJpQHN pV PHQQ\LVpJpQHN V]HUHSpW YL]VJiOWDPËJ\DK NH]HOpVHNFV~FVK PpUVpNOHWHHJ\UpV]WD]Ii]LVLQNRQJUXHQVROYDGiVL K PpUVpNOHWH pV D Ii]LV ERPOiVL K PpUVpNOHWH N|]|WW KHO\H]NHGHWW HO DPLNRU D NULVWiO\RN V]ROJiOWDN PDJNpS] NpQW PiVUpV]W pJHWpVL FV~FVK PpUVpNOHWQHN D Ii]LV ERPOiVLK PpUVpNOHWHIHOHWWLpUWpNHWYiODV]WRWWDPDKRO<2O3MiWV]RWWDDPDJNpS] V]HUHSpW$

megnövelt ritkaföldfém-WDUWDORPPDO H]iOWDO QDJ\REE PHQQ\LVpJ PDJNpS] YHO UHQGHONH]

PLQWiNQiO NO|QE|] DGDOpNRNQDN 3W&O2, Cr2O3) a 211 kristályok növekedésére gyakorolt hatását vizsgáltam.

$ OHJNHGYH] EE WXODMGRQViJRNNDO UHQGHONH] UHDNFLyYDO V]LQWHUHOW LOO NULVWiO\osítási

HOMiUiVVDO NpV]tWHWW V]XSUDYH]HW V]LOiUG ROGDWRNEyO LOO V]XSUDYH]HW V]LOiUG ROGDWH]VW

kompozitokból részben hagyományos kerámiai eljárásokkal (fóliahúzás, hideg izosztatikus formázás, melegpréselés), részben a kerámiaiparban kevésbé használatos robbantásos

SRUW|P|UtWpVVHO NO|QE|] DODN~UD YDVWDJUpWHJ KHQJHU KDViE J\ U IRUPi]RWW V]XSUDYH]HW N HVHWpQ YL]VJiOWDP D] DGRWW IRUPi]iVL HOMiUiV D IRUPi]iVL SDUDPpWHUHN

változtatásának szupravezetési tulajdonságokra gyakorolt hatását. Részletesebben a

UREEDQWiVRV SRUW|P|UtWpV D]RQ EHOO D IpPFV EHQ W|UWpQ WHQJHO\V]LPPHWULNXV W|P|UtWpV

valamint a fémlemezek közötti plattírozás formázásra való alkalmazhatóságát vizsgáltam.

II. Alkalmazott vizsgálati eszközök

A por alakú alapanyagok fajlagos felületét ATLAS-típusú BETOGRAPH-fal, szemcseméret-eloszlását FRITSCH Analysette-22 típusú lézeres szemcseanalizátorral határoztam meg QPKXOOámhosszúságú lézersugárzás alkalmazásával.

A nyerskeverékek olvadási folyamatait MHO-2 Zeiss-gyártmányú hevíW PLNURV]NySSDO

vizsgáltam, míg a hevítés közben lejátszódó fázisátalakulásokat Philips PW 3710 típusú diffraktométerhez csatolt HTK 16 Anton-Paar hevítéses röntgenkamrával készített felvételek alapján határoztam meg. A fázisösszetétel meghatározásokat ugyancsak Philips PW 3710

WtSXV~ U|QWJHQGLIIUDNWRPpWHUUHO NpV]tWHWW IHOYpWHOHN DODSMiQ YpJH]WHP P$ FV iUDP N9 FV IHV]OWVpJ &X. sugárzás és grafit egykristály monokromátor alkalmazásával. A rácsparaméterek kiszámítása Philips Appleman Refinement programmal történt.

A mikroszerkezet vizsgálatokat Jeol JSM 50A típusú pásztázó elektronmikroszkóppal, az elemanalízist a hozzácsatolt RÖNTEC EDR228 energiadiszperzív analizátorral végeztem.

$ V]XSUDYH]HW DQ\DJRN 7c onset értékének meghatározása Faraday elveQ P N|G %UXFNHU- féle berendezéssel mért mágneses szuszceptibilitás értékek alapján történt.

$ V]XSUDYH]HW DQ\DJRN NULWLNXV iUDPV U VpJpW pV 0HLVVQHU-effektusát a Szilikát- és Anyagmérnöki Tanszéken kifejlesztett berendezésekkel mértem.

III. Új tudományos eredmények, tézisek

1. Az YBa2Cu3Oy V]XSUDYH]HW NQpO D] LWWULXP HXUySLXPPDO <3+

||Eu3+ W|UWpQ WHOMHV D

bárium káliummal vagy nátriummal (Ba2+||K+ vagy Na+ W|UWpQ UpV]OHJHV

helyettesítése, ezzel párhuzamosan az oxigén fluorral (O2-||F-) való pótlása, a réz kobalttal (Cu2+||Co3+), cinkkel (Cu2+||Zn2+) és ezüsttel (Cu2+||Ag+) való részleges

KHO\HWWHVtWpVH QHP EHIRO\iVROMD D] V]XSUDYH]HW Ii]LV LQNRQJUXHQV ROYDGiVL YLVHONHGpVpWFVXSiQD]HXWHNWLNXVpVSHULWHNWLNXVK PpUVpNOHWHWYiOWR]WDWMDPHJ

2. Az ionKHO\HWWHVtWpVHNKDWiViUDDV]XSUDYH]HW V]LOiUGROGDWRNDW WDUWDOPD]yUHQGV]HUHN

fázisösszetétele változik, az ortorombos 123 fázis mennyiségének növekedése nem áll kapcsolatban a Tc értékével.

3. $] LRQKHO\HWWHVtWpVHN KDWiViUD D V]XSUDYH]HW V]LOiUG ROGDWEDQ D V]XSUDYH]HW NULVWiO\RNQ|YHNHGpVLVHEHVVpJHQDJ\RQHU VHQYiOWR]LN

3.1. Az YBa2-xAxCu3-zDzOy (ahol A=K+ vagy Na+, D=Co3+ vagy Zn2+ vagy Pb2+)

|VV]HWpWHO V]LOiUG ROGDWRN HVHWpQ D V]XSUDYH]HW NULVWiO\RN Q|YHNHGpVpW D]

alábbi ionok a megadott sorrend szerint gyorsítják: Pb2+ (z=0,1) > K+ (x=0,05) >

Na+ (x=0,05) > Zn2+ (z=0,03). A Co3+ ] D V]XSUDYH]HW NULVWiO\RN

növekedését nem befolyásolja. Az YBa2-xAxCu3OyFx (ahol A=K+ vagy Na+, x ≤

0,15) szilárd oldatoknál a F- (x ≤ JiWROMD D V]XSUDYH]HW Nristályok növekedését.

3.2. Az EuBa2-xAxCu3-zDzOy (ahol A=K+, D=Co3+ vagy Zn2+ vagy Ag+ |VV]HWpWHO V]LOiUG ROGDWRN HVHWpQ D V]XSUDYH]HW NULVWiO\RN Q|YHNHGpVpW D] DOiEEL LRQRN D

megadott sorrendben gyorsítják:

Pb2+ (z=0,1) > K+ (x=0,05).

A Co3+ (z ≤ 0,2) a V]XSUDYH]HW NULVWiO\RNQ|YHNHGpVpWQHPEHIRO\iVROMD

A Zn2+ (z ≤ 0,05) és az Ag+ (z ≤ JiWROMD D V]XSUDYH]HW NULVWiO\RN

növekedését.

4. $ V]XSUDYH]HW NULVWiO\RN Q|YHNHGpVL VHEHVVpJpQHN YiOWR]iVD D V]XSUDYH]HW V]LOiUG

oldatban a réz ólommal, a bárium NiOLXPPDO YDJ\ QiWULXPPDO W|UWpQ UpV]OHJHV KHO\HWWHVtWpVHNRU NpWGLPHQ]LyV PtJ D Up] FLQNNHO W|UWpQ UpV]OHJHV KHO\HWWHVtWpVHNRU

háromdimenziós.

5. $ OHJQDJ\REE PiJQHVHV OHEHJWHW HU D] <-Ba-Cu-O és Eu-Ba-Cu-O bázisú szilárd oldatokban az 123 és 211 fázis W|PHJDUiQ\iQiO DODNXO NL $ OHEHJWHW HU

nagyságát az 123 kristályok mérete, a 211 kristályok mérete és eloszlása is befolyásolja.

6. $ V]XSUDYH]HW V]LOiUG ROGDW H]VW NRPSR]LWRNQiO PP $J-tartalom esetén alakul ki a legtömörebb szövetszerkezet, s ezzel párhuzamosan a legnagyobb kritikus

iUDPV U VpJ

7. Olvadékfázisú heterogén nukleációva -nukleuszként a 211 kristályokat vagy 211 kristályokat és platinát alkalmazva- D] LRQKHO\HWWHVtWHWW V]XSUDYH]HW V]LOiUGROGDWRN RULHQWiOW V]HUNH]HW HN pV %D||K vagy Cu||3E LRQKHO\HWWHVtWpVHN HVHWpQ V]XSUDYH]HW WXODMGRQViJDLNEDQ IHOOP~OMiN D] LRQKHO\HWWHVtWpV QpONOL V]XSUDYH]HW N IL]LNDL

tulajdonságait.

8. Az M1,8Ba2,4-xAxCu3,4-zDzOy (ahol M=Y3+, vagy Eu3+, A=K+, D=Pb2+, x=0,06, z=0,11)

|VV]HWpWHO V]XSUDYH]HW N ROYDV]WiVRV WHFKQROyJLiYDO W|UWpQ HO iOOtWiVDNRU D V]XSUDYH]HW NULVWiO\RN Q|YHNHGpVpW D ULWNDI|OGIpP PLQ VpJH MHOHQW VHQ

meghatározza. M=Y3+ setén z a – b –VtNEDQHU WHOMHVHEEHQQ|YHNHGHWWNULVWiO\RN

orientált szerkezetet alkotnak, ezáltal közel háromszRU QDJ\REE OHEHJWHW HU YHO

rendelkeznek, mint az Eu–ot tartalmazók.

9. Az Y-Ba,K-Cu-O,F és Eu-Ba,K-Cu-2) Ei]LV~ V]XSUDYH]HW N 7c onset értékét az

HO iOOtWiVLWHFKQROyJLDLVEHIRO\iVROMD$UHDNFLyYDOV]LQWHUHOWV]XSUDYH]HW N-5 K-nel magasabb Tc onset értpNNHO UHQGHONH]QHN PLQW D] D]RQRV |VV]HWpWHO ROYDGpNIi]LV~

szintereléssel vagy olvasztásos eljárással készítettek.

10. $ UHDNFLyYDO V]LQWHUHOW NLV Ii]LV WDUWDOP~ V]XSUDYH]HW SRUEyO UREEDQWiVRV W|P|UtWpVVHO IRUPi]RWW V]XSUDYH]HW N pV V]XSUDYH]HW H]VW kompozitok

iUDPYH]HWpVH pV PiJQHVHV OHEHJWHW HUHMH XWyODJRV K NH]HOpVVHO Q|YHOKHW /HEHJWHWpVHV FVDSiJ\DNKR] DONDOPD]KDWy UREEDQWiVVDO W|P|UtWHWW V]XSUDYH]HW N HO iOOtWiViKR] D UHDNFLyYDO V]LQWHUHOW <%D1,95K0,05Cu3OyF0,05 $J |VV]HWpWHO

(szupravH]HW V]LOiUGROGDWH]VWNRPSR]LWRNDOHJPHJIHOHO EEHN

IV.Az értekezéssel kapcsolatos publikációk jegyzéke

Közlemények:

Kotsis, I.; Enisz, M.; Oravetz, D.; Szalay, A.: Effect of porosity on explosively compacted high-Tc superconductors, Hungarian Journal of Industrial Chemistry, 23, 1 (1994) 69-74 Enisz, M.; Kotsis, I.; Oravetz, D.; Szalay, A.: Production of Y-Ba-Cu-O based thick layer ceramic superconductors, Proceedings "High-Tc" of the European Ceramic Society 4th Conference, Riccione, 2 (1995) 305-311

Enisz,M., Kotsis, I.: Investigation of YBa2Cu3O7-/Y2BaCuO5 and EuBa2Cu3O7-/Eu2BaCuO5

composites, Key Engineering Materials Vols. 132-136 (1997) 1277-1280 Trans Tech.Publications, Switzerland

Kotsis, I., Enisz, M., Vértes, A., Homonnay, Z.: Change of phase composition and morphology of YBa1.95K0.05Cu3Oy superconductor during doping with CoCl2, Superlattice and Microstructures 21, 3 (1997) 447-450

Kotsis, I., Enisz, M., Korim, T.: Hot pressing of YBCO type superconductors, Superlattice and Microstructures 21, 3 (1997) 435-446

Kotsis, I., Enisz, M.: Processing techniques of ceramic superconductors, Development of high-temperature superconducting alternators combining rotating and levitating principles (Edited by Chubraeva, L. I.) Russian Academy of Sciences, Saint-Petersburg (2002) 52-65 Kotsis, I., Enisz, M., Szalay, A., Vajda, I., Mamalis, A. G.: Effect of explosive compaction on microstructure and physical properties of ceramic superconducting materials produced by different techniques, Materials Science Forum (in press)

Poszterek:

Enisz, M.; Kotsis, I.; Korim, T.; Oravetz, D.; Kristóf, É.: Relation between the physical properties and microstructure of the high-Tc YBa2Cu3Ox-based ceramic superconductors containing K+ and Na+-ions. 7th CIMTEC Satellite Symposia, Triest, 2-5 July 1990, 135.

Enisz, M.; KotVLV , 6]DOD\ $ %pUFHV , 9DMGD ,.HUiPLDL V]XSUDYH]HW N 0 V]DNL

Kémiai Napok '93, Veszprém 27-29 Ápr. (1993) 66

Enisz, M .RWVLV , 2UDYHW] ' .HUiPLDL V]XSUDYH]HW YDVWDJUpWHJHN HO iOOtWiVL OHKHW VpJHL0 V]DNL.pPLDL1DSRN9HV]SUpPÈSU 4-6 (1995) 120-121

Kotsis, I., Enisz, M., Korim, T.: Effect of Zn and Co additions on peritectic temperature of YBCO superconductors, Proceedings of EUROFORUM’96, Veszprém, 4-6 Sept (1996) 60 Enisz, M.,Kotsis, I.: Investigation of YBa2Cu3O7-/Y2BaCuO5 and EuBa2Cu3O7-/Eu2BaCuO5

composites, 5th ECERS Conference and Exhibition of the European Ceramic Society, Versailles, 22-26 June (1997)

Enisz, M.,Kotsis, I., Szalay, A.: Study of the magnetic interaction force of EuBa2Cu3Ox/Eu2BaCuO5 superconductive thick layers compacted by explosion, The 4th IUMRS International Conference in Asia, OVTA, Makuhavi, Chiba, Japan, 12-16 Sept (1997) Enisz, M.,Kotsis. I., Mamalis, A. G., Csetényi, L., Oravetz, D.: Bulk Eu-Ba-Cu-O superconductors produced by melt-powder-melt-growth (MPMG) technique, Proceedings of the 4th Multinational Congress on Electron Microscopy, Veszprém, 5-8 September (1999) 311-312

Enisz, M., Kotsis,I.: Influence of KF doping and heat treating conditions on the microstructure and phase composition of Y-Ba-Cu-O based superconductors, 14th International Symposium on the Reactivity of Solids, Budapest, 27-31 August (2000)

Kotsis, I., Enisz, M., Szalay, A., Vajda, I., Mamalis, A. G.: Effect of explosive compaction on microstructure and physical properties of ceramic superconducting materials produced by different techniques, Hungarian Conference and Exhibition on Materials Science, Testing and Information, Balatonfüred, 14-17 Oct (2001)

(O DGiVRN

Eniszné, B.M6]XSUDYH]HW DQ\DJRNNXWDWiVDD9HV]SUpPL9HJ\LSDUL(J\HWHPHQ2UV]iJRV 3HGDJyJLDL 7RYiEENpS] ,QWp]HW V]HUYH]pVpEHQ WDUWRWW HO DGiV N|]pSLVNRODL IL]LND WDQiURN

számára. 1990.április 18.

Eniszné, B. M.; Kotsis,L-né: Adalékok hatása az Y-Ba-Cu-2 V]XSUDYH]HW N PRUIROyJLiMiUD

XXI. Szilikátkémiai Ankét és Különleges Aluminium-oxid Konferencia, Zamárdi, 1990.május 3-4.

Eniszné Bódogh, M., Kotsis, L-Qp2ULHQWiOWV]HUNH]HW NHUiPLDLV]XSUDYH]HW N6]LOLNiWLSDUL

Tudományos Egyesület, Finomkerámiai Nap Konferencia, Herend, Szept. 20 (2000)

Az értekezés témájához kapcsolódó tudományos és publikációs tevékenység:

Közlemények:

Mamalis, A. G., Kotsis, I., Enisz, M., Szalay. A., Pantelis, D. J., Pantazopoulos, G.: Eximer laser surface treatment of high-Tc superconductive ceramic layered plasma sprayed silver plates, Supercond. Sci. Technol. 8 (1995) 470-475

Mamalis, A. G., Szalay, A., Vajda, I., Enisz, M., Palotás, B.: A novel monolith for electrical applications: Silver sheathed bulk ceramic superconductor with silver contacts, Proceedings

"High-Tc" of the European Ceramic Society 4th Conference, Riccione, 7 (1995) 217-224 Mamalis, A. G., Kotsis, I., Enisz, M., Szalay, A., Pantelis, D. J., Pantazopoulos, G.:

Fabrication of multilayered steel/superconductive ceramic (Y-Ba-K-Cu-O) silver rods by explosive powder compaction and extrusion, Journal of Materials Processing Technology 57 (1996) 155-163

Mamalis, A. G., Kotsis, I.,Pantazopoulos, G., Enisz, M., Szalay, A., Manolakos, D. E.: The effect of heat treatment on explosively compacted YBaKCuO superconductive powders, Physica C 280 (1997) 289

Klencsár, Z., Kuzmann, E., Vértes, A., Bánkuti, J., Rácz, T., Bódogh, M., Kotsis, I.:

Mössbauer study of substitution of Pr in Eu-containing high temperature superconductor, Physica C 273 (1997) 323—327

Kotsis, I., Enisz, M., Rácz, T.: Preparation of HTS composition, Textbook of the 3rd ISSHTS, Eger (1997) 255-285

Klencsár, Z., Kuzmann, E., Homonnay, Z., Vértes, A., Vad, K., Bánkuti, J., Rácz, T., Bódogh, M., Kotsis, I.: The effect of Pr substituted in Eu1-xPrxBa2Cu3O7- and EuBa2- xPrxCu3O7- perovskites, Physica C 304 (1998) 124-132

Klencsár, Z., Kuzmann, E., Vértes, A., Gubbens, P.C. M., van der Kraan, A. M., Bódogh, M., Kotsis, I.: Evidence for Pr3+ in EuBa1.3Pr0.7Cu3O7- by 141Pr Mössbauer spectroscopy, Physica C 329 (2000) 1-4

Poszterek:

Kotsis, I.;Enisz, M.; Kristóf, J.: Preparation of an YBa2-xKxCu3Oy- type superconductor with a single firing process. 32nd IUPAC Congress, Stockholm, (1989) 107

Kotsis, I., Enisz, M., Szalay, A., Szász, A., Korim, T.: Relation between the physical properties and microstructure of Y-Ba-Cu-O based ceramic superconductors compacted with explosion technique, 7th CIMTEC Satellite Symposia, Triest, 2-5 July 1990

Kotsis, I.; Enisz, M.; Szalay, A.; Vajda, I.:How to make a modell of a HTSC rotating electrical machine, SIEMENS Symposia Budapest 14 Nov 1991

Kotsis, I.; Enisz, M.; Korim, T.; Szalay, A.; Bérces, I.; Vajda, I,: Explosive powder compaction of superconductive materials for the development of electrical machines. 5th Symposium on Particle Size Analysis and Powder Technology, Sopron, 14-16 Sept 1992 Kotsis, I.; Enisz, M.: Effect of alkali fluoride additives on properties of superconductors of the system Y-Ba-Cu-O. Proceedings of 8th SIMCER Rimini,10-12 Nov 1992, 186

Kotsis, I.; Enisz, M.; Korim, T.; Szalay, A.; Bérces, I.; Vajda, I.; Nabil, M. Ghoneim:

Application of ceramic superconductors compacted with explosion technique. International Symposium on High-Tc Superconductivity and its Applications, Cairo, Egypt 5-15 April 1993

Kotsis, I., Enisz, M., Vértes, A., Kuzmann. E., Homonnay, Z., Rácz, T.: Szilárdfázisú reakciók vizsgálata az Y(Ba,K)2(Cu,Co)3O7-y és az Eu(Ba,K)2(Cu,Co)3O7-z rendszerekben,

0 V]DNL.pPLDL1DSRN9HV]SUpPÈpr. 4-6 (1995) 113-114

Rácz, T., Kotsis, I., Enisz, M., Klencsár, Z., Kuzmann, E., Vértes, A.: Is the Pr-Ba-Cu-O exception or not? Proceedings of EUROFORUM’96, Veszprém, 4-6 Sept (1996) 21

Kotsis, I., Enisz, M., Oravetz, D., Szalay, A., Vajda, I.: Investigation of Y(Ba,K,Na)2Cu3Ox/Fy+Ag based superconductive solid solutions and composites compacted by explosion, 2nd Japan-Central Europe Joint Workshop on Modelling of Materials and Combustion, Budapest 7-9 November (1996) 22

(O DGiVRN

Kotsis, I.; Enisz, M.: Ceramic Superconductors, 10. Int. Baustoff- und Silikattagung, Weimar, 9-13.05. 1988.

Kotsis, I.; Enisz, M.; Korim, T.; Székely, S.; Kristóf, J.;Szabó, S.; Oravetz, D.:Superconducting Ceramics. XV.Szilikátipari és Tudományi Konferencia Budapest, (1989) 297

Kotsis, I.; Enisz, M.; Oravetz, D.; Szalay, A.: Effect of size and particle size distribution on physical characteristcs, morphology and crystal structure of explosive compacted high-Tc

surerconductors. Proceedings of 4th International Conference and Exhibition of World Congress on Superconductivity, USA Orlando, Florida, 1994, 125

Rácz, T., Kotsis, I., Enisz, M.: Az Y/Eu,Pt és Cu/Co, Zn helyettesítések hatásának vizsgálata az YBa2Cu3O7 UHQGV]HUEHQ 07$ 0 V]DNL $Q\DJWXGRPiQ\L 0XQNDEL]RWWViJL pV 07$

Szilikátkémiai Munkabizottsági Ülés, Veszprém, Okt.24 (1995)

Kotsis, I., Enisz, M.: The most important results in HTSC research carried out in the Department of Silicate Chemistry and -Technology at Veszprém University, Internationale Committee Meeting on Superconductors, Budapest, 19-22 Oct (1994)

Kotsis, I., Enisz, M.: Novel results in HTSC research, 12th Meeting on Silicate Chemistry, Budapest, 24 Oct (1994)

Az értekezés témájához szorosan nem kapcsolódó, de az anyagtudománnyal kapcsolatos publikációs tevékenység:

Közlemények:

Bódogh M.; Kotsis L-né; Balogh K-né; Bálint Gy-né; Diskai J-né: Korundtartalmú

V]LJHWHO SRUFHOiQRNpJHWpVLWHFKQROyJLiMiQDNPyGRVtWiVD6]LOLNiWWHFKQLND-126.

Bódogh M.; Egyházi T-né; Kotsis L-né: A modern információs rendszerek felhasználási

OHKHW VpJei, Szilikáttechnika 6 (1983) 144-145.

Bódogh M0i]IHOHWWLSRUFHOiQIHVWpNHNV]tQLQJHUMHOOHP] LQHNYL]VJiODWDeStW DQ\DJ 36,1 (1984) 12-17.

Kotsis L-né; Bódogh M.: Porcelánfestékek Pb2+ oldódásának vizsgálati módszerei. Az égetési atmoszféra, az égetéVL K PpUVpNOHW pV D K QWDUWiVL LG V]HUHSH D SRUFHOiQIHVWpNHN HFHWVDYDV ROGKDWyViJiEDQeStW DQ\DJ-352.

Kotsis I.; Bartháné, B.Á.; Eniszné, Bódogh M.; Kutasiné, G.J.; Csiszár, J.; Vargáné, L. R.;

+ J\pV]L - (QHUJLDWDNDUpNRV HOMiUiV V]intetikus béta-wollastonit és béta- és/vagy alfa-

ZROODVWRQLWHO iOOtWiViUDV]V]DEDGDORP

Enisz, M; Kotsis, I.:Change of phase composition and physical properties in hydrocarbon- containing Fuller's earth waste under heat treatment. Proceedings of 6th Conference on Colloid Chemistry, Balatonszéplak, 16-19 Sept 1992, 82-87.

Kotsis, I.; Enisz, M.; Dudás, I.: A MOL Rt.-QpO NHOHWNH] KXOODGpNDQ\DJ IHOKDV]QiOiViYDO NpV]OWNHUiPLDLEXUNROyODSRNeStW DQ\DJ-34

Kotsis, I., Enisz, M., Korim, T.: Modelling of deparaffination of injection moulded Y-PSZ specimens, Proceedings „Basic Science” of the European Ceramic Society 4th Conference, Riccione, 1 (1995) 456-472

Kotsis, I., Korim, T., Enisz, M.: Comparison of preparation mechanism of Al2TiO5 during various heat treatment techniques, Key Engineering Materials Vols. 132-136 (1997) 840-843 Trans. Tech. Publications, Switzerland

Kotsis,I., Enisz, M., Korim, T., Lenkei, M., Lendvay, L., Zimány, P.: Characterization of plasma sprayed coatings, Hungarian Journal of Industrial Chemistry Veszprém, 26 (1998) 37- 42

Kotsis, I., Korim, T., Enisz, M.: Comparative study of Al2TiO5 formation during atmospheric sintering and hot pressing , Advanced in Technology of Materials and Materials Processing Journal (ATM) 1, 2 (1999) 142-149

Poszterek:

Bódogh M.; Oravetz D.: Determination of the optimum thickness of surface-improving ceramic coatings by X-ray microanalysis, EUREM 8th European Congress on Electron Microscopy, Budapest, 1984.

Eniszné, Bódogh M.:ZrSiO4-bázisú Cd(SxSe1-x) zárványszíntestek szilárdfázísú reakcióval

W|UWpQ HO iOOtWiVD;,;6]LOLNiWNpPLDL$QNpW=DPiUGL

Enisz, M.; Kotsis, I.; Bóta, J.; Bódogh, Zs.: Quantitative study of metal ions dissolved from overglaze colours in the function of the colour thickness and the firing temperature. 24th Conference on Porcelain and Technical Ceramics, Karlovy Vary, 12-14.June 1990.

Enisz, M; Kotsis, I.:Change of phase composition and physical properties in hydrocarbon- containing Fuller's earth waste under heat treatment. Proceedings of 6th Conference on Colloid Chemistry, Balatonszéplak, 16-19 Sept 1992, 82-87.

Kotsis, I.; Enisz, M.; Dudás, I.: Veszélyes hulladékanyag felhasználásával készült kerámiai burkolólapok. III. Másodnyersanyag-hasznosító Konferencia, Sopron, 1992. 116

Kotsis, I.; Enisz, M.; Korim, T.; Balogh, Á.: A SiO2IVW NRPSOH[IHOKDV]QiOiVLOHKHW VpJHL

Környezetvédelmi Kiállítás és Konferencia, Veszprém 2-10 Márc. 1993.

Kotsis, I.; Enisz, M.; Korim, T.: A ferroszilicium-gyártás hulladékának hasznosítása a szilikátiparban, CERECO '94 Nemzetközi Konferencia, Ungvár, Ukrajna 30 Máj.-1 Jun.

1994

Kotsis, I., Enisz, M., Korim, T.: Modelling of deparaffination of injection moulded Y-PSZ specimens, Proceedings „Basic Science” of the European Ceramic Society 4th Conference, Riccione, 1 (1995) 456-472

Kotsis, I., Enisz, M., Bartha, L., Laczkó, L., Oravetz, D., Porat, R.: Rapid phase transformations in nanocrystalline WC/Co system, Proceedings of the 4th Multinational Congress on Electron Microscopy, Veszprém, 5-8 September (1999) 177-178

(O DGiVRN

Kotsis, I.; Bódogh M.: Der Bildungsmechanismus von Farbkörper auf Zirconsilikatbasis, 9.Internationale Baustoff und Silikattagung Weimar,1985.

Bódogh, M.; Kotsis L-né: Kordieritbázisú kerámiai anyagok. MTA VEAB Szilikáttechnológiai Munkabizottsági ülés, Budapest, november. 1988.

I. Background and objectives

Many applications (e.g. fault current limiters, energy storage devices, levitated bearings for rotating machines) of high-Tc superconductors require the fabrication of bulk polycrystalline ceramics with different shapes, high critical current densities and magnetic levitation forces.

The bulk YBa2Cu3Oy (123) superconductors prepared by conventional solid-state sintering are generally heterogeneous materials with small superconducting crystals, which are characterized by weak links between the 123 grain boundaries, reduced transport current density and magnetic field. The formation of the weak links can be avoided by increase of the grain size of the superconducting phase and by the a-b plane alignment of these grains, while the presence of flux pinning centers (e.g. Y2BaCuO5 (211)) dispersed finally in the 123 matrix can improve the magnetic properties.

In numerous publications the improvement of the superconducting properties is studied.

These investigations cover the following typical areas: chemical substitutions in the superconducting crystal structure, the systematic change of the phase composition and the modification of the microstructure.

In the present work these areas are connected and completed by the explanations of the processes.

Superconducting solid solutions (MBa2-xAxCu3-zDzOy(Fx), where M=Y3+, Eu3+, A=K+, Na+, D=Co3+, Zn2+, Pb2+, Ag+) were prepared by the partial or complete substitution of every element of YBa2Cu3Oy obtained by reaction sintering to yield superconductors with high phase purity or with a given 211 phase content, where the anisotropic growth and alignment of the 123 grains within the a-b plane resulted in better grain boundary connection and so improved physical properties (e.g. transport current density, magnetic levitation force).

Among superconducting solid solutions (MBa2-xAxCu3-zDzOy(Fx), M1.8Ba2.4-pApCu3- qDqOy(Fp), where M=Y3+, Eu3+, A=K+, D=Pb2+, x=0.05, z=0.1, p=0.06, q=0.11) showing the best properties investigations have been carried out on the phase transformation during the heat treatment using static method and high temperature X-ray diffraction, and according to these results the processing parameters were determined. The role of the amount and the quality of the liquid phase and the effect of the nucleus in the melt processing techniques based on heterogeneous nucleation was also studied.

The peak temperature of the heat treatment was chosen partly between the incongruent melting temperature of 123 phase and the decomposition temperature of 211 phase, so in this case Y2O3 can be regarded as nucleus.

The effect of different (PtCl2, Cr2O3) on the growth mechanism of 211 particles In samples with increased rare-earth content and in this way with 211 excess was also investigated.

The superconducting solid solutions and superconducting solid solution / silver composites prepared by reaction sintering and melt processing technique were formed partly by conventional ceramic methods (tape casting, cold isostatic pressing, hot pressing),and partly by dynamic (explosive) powder compaction, which is a less common technique in the ceramic industries. The effect of the change of the forming parameters on the superconducting properties was thoroughly investigated, especially to clarify details of dynamic compaction, namely the axisymmetric and the cladding type compaction.

II. Investigation techniques used

The specific surface area of the starting powders were measured by an BETOGRAPH Model ATLAS and their grain size distributions were determined by a Fritsch particle sizer Model

$1$/<6(77(XVLQJODVHUEHDPZLWK QP

The melting behavior of the powder mixtures was observed by a Zeiss heating microscope Model MHO-2, while the crystallization process during the heat treatment was examined by high temperature X-ray diffraction using an Anton-Paar High-Temperature Camera Model HTK 16 type connected to a Philips Model PW 3710 X-ray diffractometer.

The phase compositions of the samples were determined by room temperature X-ray diffraction with CuK radiation, 50kV generator tension, 40mA generator current and graphite monochromator, using an X-ray diffractometer as described above. The lattice parameters were calculated by a Philips Appleman Refinement Program.

The pore volume of the samples was measured by a Carlo Erba mercury porosimeter.

The microstructural and the microchemical analysis was carried out using a JEOL scanning electron microscope Model JSM 50A equipped with an energy dispersive X-ray spectrometer (RÖNTEC EDR 228).

The magnetic susceptibility was measured by a Brukers susceptibility microbalance according to Faraday’s principle.

The critical current density and the Meissner-effect were measured by test equipment developed at the Department of Silicate and Materials Engineering, University of Veszprém.

III. Novel scientific achievements and theses

1. In the YBa2Cu3Oy (123) superconductors the complete substitution of yttrium by europium (Y3+ (X3+

), the partial substitution of barium by potassium or sodium (Ba2+ .+

or Na+), collaterally with the substitution of oxygen by fluorine (O2- )-

), and the partial substitution of copper by cobalt (Cu2+ &R3+), zinc (Cu2+ =Q2+) and silver (Cu2+ $J+

) have no influence on the incongruent melting behavior of the superconducting 123 phase, only the eutectic and peritectic temperatures are changed by these substitutions.

2. The phase compositions of the superconducting solid solutions are changed by the chemical substitutions, but the increase of the orthorhombic 123 phase content is not related to the Tc value.

3. The Tc onset values of the Y-Ba,K-Cu-O,F and Eu-Ba,K-Cu-O,F base superconductors are also affected by the processing technology. The Tc onset values of the superconductors produced by reaction sintering are 3-5K higher than that of the superconductors, which have the same chemical compositions, but were produced by melt processing technique.

4. The chemical substitutions affect significantly the growth rate of the superconducting crystals in the solid solutions.

4.1. In the solid solutions with the composition of YBa2-xAxCu3-zDzOy (where A=K+ or Na+, D=Co3+ or Zn2+ or Pb2+) the growth rate of the superconducting crystals is accelerated by the following ions in the given succession: Pb2+ (z=0.1) > K+ (x=0.05) > Na+ (x=0.05) > Zn2+ (z=0.03). The Co3+ (z=0.03) has no effect on the growth rate of the superconducting crystals. In the solid solutions with the composition of YBa2-xAxCu3OyFx (where A=K+ or Na+, x WKH JURZWK RI WKH

superconducting crystals is inhibited by the presence of F- ions (x

4.2. In the solid solutions with the composition of EuBa2-xAxCu3-zDzOy (where A=K+, D=Co3+ or Zn2+ or Ag+) the growth rate of the superconducting crystals is accelerated by the following ions in the given succession: Pb2+ (z=0.1) > K+ (x=0.05). The Co3+ addition (zhas no effect on the growth rate of the superconducting crystals. Their growth is inhibited by the addition of Zn2+ (z

and Ag+ (z

5. The change of the growth rate of the superconducting crystals is two-dimensional in the solid solutions obtained by partial substitution of Ba2+ by K+ or Na+, while in the case of partial substitution of copper by Zn2+ the change of the growth rate is three-dimensional.

6. In the superconducting solid solutions, which contained chemical substitutions and were produced by liquid phase heterogeneous nucleation using 211 crystals or 211 crystals and platinum as nucleus a microstructure with a high degree of grain orientation was developed and in the case of substitutions Ba .RU&X 3EWKHVXSHUFRQGXFWLQJSURSHUWLHV

exceed that of the samples without substitution.

7. In the M1.8Ba2.4-xAxCu3.4-zDzOy (where M=Y3+ or Eu3+, A=K+, D=Pb2+, x=0.06, z=0.11) superconductors produced by melting technique the growth rate of the superconducting crystals is significantly determined by the quality of the rare-earth metal. In the case of M=Y3+ the 123 grains with the maximum growth rate within the a-b plane showed oriented microstructure leading to about three times higher magnetic levitation force than that of the Eu-containing samples.

8. The maximum magnetic levitation force can be obtained at 123:211=8:1 mass ratio in the solid solutions based on Y-Ba-Cu-O and Eu-Ba-Cu-O systems.

9. In the case of the superconducting solid solutions /silver composites the microstructure with the highest density and at the same time the highest critical current density can be obtained at a silver content of about 7 wt%.

10. The transport current density and the magnetic levitation force of the superconducting solid solution/silver composites and bulk superconductors formed by explosive cladding compaction from the sintered powders with low 211 phase content can further be improved by a subsequent heat treatment. The composite with the composition of YBa1.95K0.05Cu3OyF0.05+7.5wt% Ag was found to be the most suitable to form by explosive powder compaction.

IV. Publications related to the Theses

Communications:

Kotsis, I.; Enisz, M.; Oravetz, D.; Szalay, A.: Effect of porosity on explosively compacted high-Tc superconductors, Hungarian Journal of Industrial Chemistry, 23, 1 (1994) 69-74 Enisz, M.; Kotsis, I.; Oravetz, D.; Szalay, A.: Production of Y-Ba-Cu-O based thick layer ceramic superconductors, Proceedings "High-Tc" of the European Ceramic Society 4th Conference, Riccione, 2 (1995) 305-311

Enisz,M., Kotsis, I.: Investigation of YBa2Cu3O7-/Y2BaCuO5 and EuBa2Cu3O7-/Eu2BaCuO5

composites, Key Engineering Materials Vols. 132-136 (1997) 1277-1280 Trans Tech.Publications, Switzerland

Kotsis, I., Enisz, M., Vértes, A., Homonnay, Z.: Change of phase composition and morphology of YBa1.95K0.05Cu3Oy superconductor during doping with CoCl2, Superlattice and Microstructures 21, 3 (1997) 447-450

Kotsis, I., Enisz, M., Korim, T.: Hot pressing of YBCO type superconductors, Superlattice and Microstructures 21, 3 (1997) 435-446

Kotsis, I., Enisz, M.: Processing techniques of ceramic superconductors, Development of high-temperature superconducting alternators combining rotating and levitating principles (Edited by Chubraeva, L. I.) Russian Academy of Sciences, Saint-Petersburg (2002) 52-65 Kotsis, I., Enisz, M., Szalay, A., Vajda, I., Mamalis, A. G.: Effect of explosive compaction on microstructure and physical properties of ceramic superconducting materials produced by different techniques, Materials Science Forum (in press)

Poster presentations:

Enisz, M.; Kotsis, I.; Korim, T.; Oravetz, D.; Kristóf, É.: Relation between the physical properties and microstructure of the high-Tc YBa2Cu3Ox-based ceramic superconductors containing K+ and Na+-ions. 7th CIMTEC Satellite Symposia, Triest, 2-5 July 1990, 135.

Enisz, M., Kotsis, I., Szalay, A., Bérces, I., Vajda, I.:Ceramic superconductors, Meeting on Industrial Chemistry ’93, Veszprém 27-29 April (1993) 66

Enisz, M.,Kotsis, I., Oravetz, D.: Production of ceramic superconductive thick layers, Meeting on Industrial Chemistry, Veszprém, 4-6 April (1995) 120-121

Kotsis, I., Enisz, M., Korim, T.: Effect of Zn and Co additions on peritectic temperature of YBCO superconductors, Proceedings of EUROFORUM’96, Veszprém, 4-6 Sept (1996) 60 Enisz, M.,Kotsis, I.: Investigation of YBa2Cu3O7-/Y2BaCuO5 and EuBa2Cu3O7-/Eu2BaCuO5

composites, 5th ECERS Conference and Exhibition of the European Ceramic Society, Versailles, 22-26 June (1997)

Enisz, M.,Kotsis, I., Szalay, A.: Study of the magnetic interaction force of EuBa2Cu3Ox/Eu2BaCuO5 superconductive thick layers compacted by explosion, The 4th IUMRS International Conference in Asia, OVTA, Makuhavi, Chiba, Japan, 12-16 Sept (1997) Enisz, M.,Kotsis. I., Mamalis, A. G., Csetényi, L., Oravetz, D.: Bulk Eu-Ba-Cu-O superconductors produced by melt-powder-melt-growth (MPMG) technique, Proceedings of the 4th Multinational Congress on Electron Microscopy, Veszprém, 5-8 September (1999) 311-312

Enisz, M., Kotsis,I.: Influence of KF doping and heat treating conditions on the microstructure and phase composition of Y-Ba-Cu-O based superconductors, 14th International Symposium on the Reactivity of Solids, Budapest, 27-31 August (2000)

Kotsis, I., Enisz, M., Szalay, A., Vajda, I., Mamalis, A. G.: Effect of explosive compaction on microstructure and physical properties of ceramic superconducting materials produced by different techniques, Hungarian Conference and Exhibition on Materials Science, Testing and Information, Balatonfüred, 14-17 Oct (2001)

Lectures:

Enisz-Bódogh, M.: Research of superconducting materials at the University of Veszprém, Lecture for teachers of physics organized by National Pedagogical Continuing Education Institute, 18 April 1990

Enisz-Bódogh, M., Kotsis, I.:Effect of additions on the morphology of Y-Ba-Cu-O superconductors, 21st Conferance on Silicate Chemistry and Special Alumina, Zamárdi, 3-4 May 1990

Enisz, M., Kotsis, I.: Ceramic superconductors with oriented microstructure, Conference on Fine Ceramics (organized by Scientific Society of Silicate Industry) Herend, 20 September (2000)

Scientific outputs and publications related to the subject:

Communications:

Mamalis, A. G., Kotsis, I., Enisz, M., Szalay. A., Pantelis, D. J., Pantazopoulos, G.: Eximer laser surface treatment of high-Tc superconductive ceramic layered plasma sprayed silver plates, Supercond. Sci. Technol. 8 (1995) 470-475

Mamalis, A. G., Szalay, A., Vajda, I., Enisz, M., Palotás, B.: A novel monolith for electrical applications: Silver sheathed bulk ceramic superconductor with silver contacts, Proceedings

"High-Tc" of the European Ceramic Society 4th Conference, Riccione, 7 (1995) 217-224 Mamalis, A. G., Kotsis, I., Enisz, M., Szalay, A., Pantelis, D. J., Pantazopoulos, G.:

Fabrication of multilayered steel/superconductive ceramic (Y-Ba-K-Cu-O) silver rods by explosive powder compaction and extrusion, Journal of Materials Processing Technology 57 (1996)

155-163

Mamalis, A. G., Kotsis, I.,Pantazopoulos, G., Enisz, M., Szalay, A., Manolakos, D. E.: The effect of heat treatment on explosively compacted YBaKCuO superconductive powders, Physica C 280 (1997) 289

Klencsár, Z., Kuzmann, E., Vértes, A., Bánkuti, J., Rácz, T., Bódogh, M., Kotsis, I.:

Mössbauer study of substitution of Pr in Eu-containing high temperature superconductor, Physica C 273 (1997) 323—327

Kotsis, I., Enisz, M., Rácz, T.: Preparation of HTS composition, Textbook of the 3rd ISSHTS, Eger (1997) 255-285

Klencsár, Z., Kuzmann, E., Homonnay, Z., Vértes, A., Vad, K., Bánkuti, J., Rácz, T., Bódogh, M., Kotsis, I.: The effect of Pr substituted in Eu1-xPrxBa2Cu3O7- and EuBa2- xPrxCu3O7- perovskites, Physica C 304 (1998) 124-132

Klencsár, Z., Kuzmann, E., Vértes, A., Gubbens, P.C. M., van der Kraan, A. M., Bódogh, M., Kotsis, I.: Evidence for Pr3+ in EuBa1.3Pr0.7Cu3O7- by 141Pr Mössbauer spectroscopy, Physica C 329 (2000) 1-4

Poster presentations:

Kotsis, I.;Enisz, M.; Kristóf, J.: Preparation of an YBa2-xKxCu3Oy- type superconductor with a single firing process. 32nd IUPAC Congress, Stockholm, (1989) 107

![3. ábra. A LiTi 2 O 4 VSLQHOOV]HUNH]HW V]XSUDYH]HW NULVWiO\V]HUNH]HWH>@](https://thumb-eu.123doks.com/thumbv2/9dokorg/875100.47103/28.918.140.750.232.882/ábra-liti-vslqhoov-hunh-xsudyh-nulvwio-hunh-hwh.webp)

![4. ábra. BaBiO 3 kristályszerkezete (O:Ba, oBi) [8]](https://thumb-eu.123doks.com/thumbv2/9dokorg/875100.47103/29.918.295.625.573.946/ábra-babio-kristályszerkezete-o-ba-obi.webp)

![11. ábra. Az Y 2 O 3 -BaO-CuO x WHUQHUUHQGV]HUELQHUUHQGV]HUHLOHYHJ DWPRV]IpUDHVHWpQ>@](https://thumb-eu.123doks.com/thumbv2/9dokorg/875100.47103/38.918.270.645.101.539/ábra-bao-cuo-whuqhuuhqgv-huelqhuuhqgv-huhlohyhj-dwprv-ipudhvhwpq.webp)

![13. ábra. BaO-CuO x UHQGV]HUOHYHJ DWPRV]IpUiEDQNpV]tWHWWIi]LVGLDJUDPMD>@](https://thumb-eu.123doks.com/thumbv2/9dokorg/875100.47103/39.918.301.616.482.887/ábra-bao-uhqgv-huohyhj-dwprv-ipuiedqnpv-twhwwii-lvgldjudpmd.webp)

![15. ábra. ½ Y 2 O 3 -BaO-CuO x rendszer fázisdiagramja 950 °C – 1010 °C között [62]](https://thumb-eu.123doks.com/thumbv2/9dokorg/875100.47103/41.918.277.636.106.442/ábra-y-o-bao-cuo-rendszer-fázisdiagramja-c.webp)

![17. ábra. YCuO 2,5 -BaCuO 2 , YCuO 2,5 -CuO és BaCuO 2 -CuO oxigén atmoszférában felvett pszeudobiner fázisdiagramok [68]](https://thumb-eu.123doks.com/thumbv2/9dokorg/875100.47103/42.918.202.705.188.604/ábra-bacuo-bacuo-oxigén-atmoszférában-felvett-pszeudobiner-fázisdiagramok.webp)

![20. ábra. A &XLRQN|UOLOLJDQGXPRNNRRUGLQiFLyMDNO|QE|] Ii]LVRNHVHWpQ [ 102 ]](https://thumb-eu.123doks.com/thumbv2/9dokorg/875100.47103/48.918.209.708.521.818/ábra-a-amp-xlrqn-ololjdqgxprnnrruglqiflymdn-qe-ii-lvrnhvhwpq.webp)