CHAPTER 13

G O N I O M E T R Y O F FLOW A N D RUPTURE A. Jobling and J. E. Roberts

I. I n t r o d u c t i o n 503 I I . G o n i o m e t r y of C o n t i n u o u s L a m i n a r Shear 506

1. Unidirectional M o t i o n 506 2. Oscillatory M o t i o n . 518 3. N o r m a l Pressure Effects 522 4. Future D e v e l o p m e n t s 525 I I I . G o n i o m e t r y of the T r a n s i t i o n R e g i o n between C o n t i n u o u s F l o w and R u p -

ture 526 1. I n t r o d u c t i o n 526

2. Principles of the m e t h o d 527 a. Irrotational M o v e m e n t s 528 b. R o t a t i o n a l M o v e m e n t s 529 3. Experimental T e c h n i q u e 530 4. Preliminary R e s u l t s and D i s c u s s i o n 531

N o m e n c l a t u r e 535

I. Introduction

In m a n y stages of industrial processes and in the subsequent use of their products, the flow of materials is of paramount importance. B y gaining control of the phenomena governing flow, efficiency can b e achieved in the planning of the process, the design of the necessary machinery, and the suitability of the final p r o d u c t for its purpose. T h e first step in obtaining this control is the d e v e l o p m e n t of exact methods for the measurement of all the features in the flow of the material under various types of mechani- cal action. It is then desirable t o be able t o correlate these b y an adequate t h e o r y which can be used t o predict the subsequent behavior of the ma- terial in a n y t y p e of instrument and in a n y desired practical application.

B o t h theoretical and experimental progress in this direction have resulted from the realization of the necessity for goniometry of flow, which is the measurement of the distribution of stresses and strains within the flowing material at e v e r y instant in time and at e v e r y point in space around the full solid angle of directions.

It is clear that goniometric measurements will be required whenever the physical quantity t o be measured is anisotropic, that is, that it has a differ- ent value in different directions. Stresses and strains are b y definition

503

anisotropic whenever there is a shearing c o m p o n e n t in the deformation and, since almost all rheological problems involve the consideration of sheared states, it follows that goniometric measurements are essential, at least in principle, even when the material under examination is isotropic in its rest state. This stress-strain anisotropy is important in:

(i) the definition of the flow phenomena. Prior t o the d e v e l o p m e n t of the principles and methods of rheogoniometry, it had been customary t o con- sider the relation between the forces and displacements only in the (tan- gential) direction of flow. It is n o w generally agreed that in the flow of viscoelastic fluids additional forces m a y be generated in other directions and manifest themselves in a number of w a y s ("normal pressure effects"

or "Weissenberg effects"). These general flow phenomena were not clearly shown b y the early experimental techniques although they m a y appear.

(For example, in flow through a capillary tube, viscoelastic properties are manifested in a nonparabolic velocity distribution across the tube and an increase in the radius of the jet at the exit.) N e w techniques for the meas- urement in a flowing liquid of the pressure distribution around the full solid angle in space have enabled research workers t o obtain a m u c h clearer insight into the origin of these effects.

(it) the measurement of the mechanical properties. A k n o w l e d g e of the mechanical properties of a material m a y be required for one of t w o pur- poses. T h e chemist requires a knowledge of the properties in the natural or rest state in the hope that he will b e able t o relate this t o the structure of the material and so control its behavior b y adjusting its chemical con- stitution. T h e physicist and engineer require t o k n o w the properties of the material in its flowing state for use in the calculation of transport and handling problems. These mechanical properties are defined generally as the parameters relating the stresses, p, and their time derivatives p, p, t o the strains, e, and their time derivatives, é, ë · · · . Particular cases are Hooke's elasticity, G(= p/e) and the Newtonian viscosity, η(= p/e).

In the natural state, if the material t o be examined is already aniso- tropic (e.g. crystals, oriented fibres, drawn wires), the need t o measure the mechanical properties in different directions is self-evident. F o r a material which is isotropic in this state, although the stresses and strains i m p o s e d b y the mechanical action can be made sufficiently small so as not t o dis- turb this state, they are still anisotropic though the relation between t h e m is isotropic. This means geometrically that their main axes of stress are parallel t o those of the strain (and similarly for the time derivatives) and in this case the testing procedure can be simplified. T h e testing of "natural"

states with small strain-amplitude vibrations can b e regarded as g o n i o m e t r y in space-time coordinates, as the phase differences between the stresses and

G O N I O M E T R Y O F F L O W A N D R U P T U R E 505 strains appear as phase-angles in the complex plane in which the time- d e v e l o p m e n t of the m o t i o n is represented.

In the sheared state, it has already been stated that the distribution of stresses and strains and their time derivatives is such that they are always anisotropic and, at least in principle, g o n i o m e t r y is always needed for their quantitative measurement. In the special case of the N e w t o n i a n liquid, al- though the stress and strain velocities are themselves anisotropic, the rela- tion between t h e m is isotropic and characterized b y a scalar constant, the viscosity. H o w e v e r , in a sheared general material, whether isotropic or anisotropic in its rest state, the relations between the stresses and strains and their time derivatives m a y be spatially complex and can o n l y be d e - termined b y a complete goniometric investigation.

R e c e n t l y , goniometric m e t h o d s have been developed for the testing of materials in the transition region between steady flow and rupture. T h e m o v e m e n t of the material is controlled b y placing it on a deformable sub- strate and measuring the distribution in space and time of the stresses, strains, and flow disturbances in the material. T h e principle of the m e t h o d , illustrated b y some preliminary results, is described in Section I I I .

A theoretical approach t o a given p r o b l e m requires the application of the three fundamental principles of :

(i) the d y n a m i c equilibrium of forces at every point in the flowing m a - terial,

(ii) the maintenance of continuity, and (Hi) the stress-strain relation,

and g o n i o m e t r y is of importance in relation t o each of these. It is the ap- plication of the first principle that has m a d e possible the measurement of the forces in a flowing material across three mutually perpendicular planes without disturbing the m o t i o n at the point where the measurements are taken (see Section I I ) . A consideration of the second principle had led t o an appreciation of the significance of the directions of lines of zero elonga- tion and planes of zero normal extension in the continuous flow and in the cracking-up patterns that occur in the transition from continuous flow t o rupture (see Section I I I ) . Finally, g o n i o m e t r y has p r o v e d of particular interest in connection with the third principle because it is here that dif- ferences of opinion occur as each theorist has m a d e what is, in his view, the simplest assumptions compatible with the physics of the material so that the practical mathematics can b e mastered. T h o u g h it appears d o u b t - ful whether a n y one theory is y e t exact for all materials and all mechanical actions, considerable progress has recently been m a d e . T h i s is discussed in greater detail in the next section, where it is shown that goniometric meas- urements in certain laminar shearing m o t i o n s m a k e it possible t o determine what theory is most applicable t o the real substances so far examined.

(α) (6l M

FIG. 1. T h e strain ellipse in laminar shear.

II. G o n i o m e t r y o f Continuous Laminar S h e a r

L UN I D I R E C T I O N A L MO T I O N

A number of attempts have been m a d e t o derive theoretically the pres- sure distribution in a flowing liquid. Whereas the predictions of some of these theories are compatible with the behavior of materials which h a v e already been examined others are not, b u t represent extremely interesting ideas for which practical examples m a y y e t be found.

W e i s s e n b e r g13 has considered initially an ideally elastic material which is isotropic in its ground state but b e c o m e s increasingly anisotropic with increasing shear strain. T h e main axes of strain are parallel t o those of the stress, irrespective of the magnitude of the strain v e l o c i t y . T h i s also applies t o viscoelastic media if the elastically recoverable part of the strain is c o n - sidered. In the laminar shear of b o t h elastic and viscoelastic materials, the orientations of the main axes of the stress m a y deviate from those of the strain velocity. T h i s is illustrated in Fig. 1, which shows the change in orientation of the strain ellipse. A circle is marked out t o denote the un- strained state ( a ) . A small m o v e m e n t changes this into an ellipse with its axes at 45 deg. t o the direction of shear (6) b u t as the recoverable strain increases, the major axis turns more and more into the direction of shear ( c ) . If a circle is marked out in the strained state, an additional small shear re- sults in its transformation into another ellipse at 45 deg. t o the direction of shear. H e n c e the strain velocity is always represented b y an ellipse at 45

1 K . Weissenberg, Abkandl. preuss. Akad. Wiss. Math, naturw. Kl. No. 2 (1931).

2 K . Weissenberg, Arch. sei. phys. et nat. [5] 17, 1 (1934).

3 K . Weissenberg, Rept. General Conf. Brit. Rheologists' Club p . 36 (1946).

G O N I O M E T R Y O F F L O W A N D R U P T U R E 507

deg. T h i s angular deviation should increase with the rate of shear as the recoverable strain increases and should p r o d u c e b o t h normal and tangential stress c o m p o n e n t s .

Reiner4 and R i v l i n5 7 h a v e assumed a nonlinear relation between stress and strain v e l o c i t y and n o storage of elastically recoverable energy. Garner et al.s attribute pressure differences entirely t o differences in the rate of shear in different parts of the flowing system. D e W i t t9 and F r o m m10 h a v e developed mechanical equations of state which are summarized below.

L o d g e /1 , l la from a consideration of a p o l y m e r solution as a network with transient junctions, predicts a simple relation between the stress and refrac- tive index ellipsoids in the flowing material1 l b and a pressure distribution similar t o that of Weissenberg (see a b o v e ) . O l d r o y d1 2 , 13 obtained a v e r y general equation which allows for the production of normal stresses and contains a sufficient number of empirical constants which can be adjusted t o the experimental results and t o the theories of M o o n e y , Weissenberg, and Reiner and Rivlin. M o o n e y ,1 4"16 b y an extension of his theory of rubber- like elasticity, has introduced an elasticity law containing t w o material characteristics, one the shear modulus, (?, and another modulus, H, w h i c h allows for normal pressures.

T o consider these theories in greater detail, a system of coordinates is required. T h e trirectangular system used is described in F i g . 2. In this sys- tem, the strain v e l o c i t y tensor is given b y

4 M . Reiner, Am. J. Math. 67, 350 (1945).

5 R . S. R i v l i n , Proc. Roy. Soc. (London) A193, 260 (1948).

6R . S. R i v l i n , Proc. Roy. Soc. (London) A200, 168 (1950).

7 R . S. R i v l i n , Trans. Faraday Soc. 45, 739 (1949).

8 F. H . Garner, A . H . Nissan, and G . F . W o o d , Phil. Trans. Roy. Soc. A243, 37 (1950).

9 F. J. Padden and T . W . D e W i t t , J. Appl. Phys. 25, 1086 (1954).

1 0 H . F r o m m , Ζ. angew. Math. u. Mechanik 28, 43 (1948).

1 1 Α . S. Lodge, Trans. Faraday Soc. 52, 120 (1956)

l la A . S. L o d g e , Paper read at 9th Intern. Congr. Appl. Mech. Brussels (1956).

l lb L o d g e ' s prediction that in a flowing viscoelastic material the stress tensor and and the refractive index tensor have the same principal directions and anisotropies in p r o p o r t i o n has been confirmed experimentally b y PhilippofT.1 1 0- l ld

l lc W . Philippoff, J. Appl. Phys. 27, 984 (1956).

l ld W . Philippoff, Nature 178, 811 (1956).

1 2 J. G . O l d r o y d , Proc. Roy. Soc. (London) A200, 523 (1950).

1 3 J. G . O l d r o y d , Quart. J. Mech. Appl. Math. 4, 271 (1951).

1 4 M . M o o n e y , J. Colloid Sei. 6, 96 (1951).

M . M o o n e y , J. Appl. Phys. 24, 675 (1953).

1 6 M . M o o n e y , private communication.

e =

0 6 ! CIS 0 0 0

€12 0 0 0 0 0

( 1 )

Shear

Shear

with p1 2 = p2 1

No. 1 plane No. 2 plane No. 3 plane FIG. 2 . R e s o l u t i o n o f pressures a t a p o i n t i n l a m i n a r s h e a r .

w h e r e έι2 i s t h e rate of s h e a r a s u s u a l l y defined.

T h e stress, p ,1 6a a t a n y p o i n t i n t h e l i q u i d c a n b e r e s o l v e d i n t o 9 c o m - p o n e n t s , pji , t h u s :

V =

Pu ?>i2 Pu

P21 P22 pn Pn Pn Pu

(2)

T h e t e r m s i n w h i c h j = k a r e n o r m a l stresses a n d d o n o t c o n t r i b u t e t o t h e w o r k d o n e o n t h e l i q u i d . T h e t e r m s i n w h i c h j 9^ k a r e s h e a r i n g stresses.

T h i s e x p r e s s i o n c a n b e s i m p l i f i e d since pjk h a s t o s a t i s f y certain c o n d i t i o n s of e q u i l i b r i u m a n d s y m m e t r y s u c h t h a t pk = pkj . F u r t h e r , i n a t o r s i o n a l s h e a r i n g a c t i o n a s e m p l o y e d i n t h e r h e o g o n i o m e t e r ( d e s c r i b e d b e l o w ) , there is a d i g o n a l s y m m e t r y a b o u t t h e N o . 3 a x i s s o t h a t ρ2ζ = p-& = 0. E q u a t i o n

(2) t h e n r e d u c e s t o

ρ = Pn P12

UPu P22

00 0

(3)

L a t e r W e i s s e n b e r g1 7 i n t r o d u c e d a n a s s u m p t i o n t h a t , a t least a s a first a p p r o x i m a t i o n , there s h o u l d b e a s i m i l i t u d e i n t h e a n i s o t r o p y of t h e stress a n d of t h e r e c o v e r a b l e s t r a i n . F o r p l a n e s of a n y o r i e n t a t i o n i n a n y flow s t a t e , t h e s h e a r i n g forces a n d t h e e l a s t i c a l l y r e c o v e r a b l e p a r t of t h e s h e a r

i6a Tn e n o t a t i o n a d o p t e d h e r e , i n c o n t r a s t t o t h a t p r e v i o u s l y u s e d b y R o b e r t s , is t h e m o r e u s u a l o n e i n t h a t a p u l l i n t h e l i q u i d h a s a p o s i t i v e s i g n a n d a p u s h a n e g a - t i v e s i g n . T h i s c o n v e n t i o n h a s t h e a d v a n t a g e t h a t i t leads t o p o s i t i v e v a l u e s f o r t h e e l a s t i c i t y a n d v i s c o s i t y b u t t h e d i s a d v a n t a g e t h a t i t r e p r e s e n t s r e a l pressures ( e . g . , t h o s e b a l a n c e d b y t h e l i q u i d h e a d i n t h e c a p i l l a r y gages) as negative p r e s s u r e s .

T h e t e r m p r e s s u r e is u s e d t h r o u g h o u t as a n a b b r e v i a t i o n f o r p r e s s u r e d e n s i t y a t a p o i n t p e r u n i t a r e a across a d e f i n i t e p l a n e .

17 K . W e i s s e n b e r g , Nature 159, 3 1 0 ( 1 9 4 7 ) .

G O N I O M E T R Y O F F L O W A N D R U P T U R E 509

strain should have their m a x i m a along the same directions. F r o m this he d e d u c e d that for elastic and viscoelastic materials

Pi — Vi _ Vi — V% _ Vi — Vi

λι2 - λ22 λ22 - λ32 λ32 - λχ2 = G ( 4 ) where pk are the main values of the stress, λι the main elongation ratios of the recoverable strain, and G a kind of elasticity modulus which m a y depend on any or all of the invariants of the stresses, strains, and their time deriva- tives. A special case of this law has been derived b y T r e l o a r18 from a molecu- lar m o d e l of rubber.

F o r a laminar shearing m o t i o n equation (4) can be written

( 5 )

where ye is the shear c o m p o n e n t of the recoverable strain and is related t o λ b y

pn - P22 pn

0

T e 2 T e0

Vl2 0 0

= G T e0 0

0 0 0 0 0 0

- 1 = (6)

Weissenberg has also s h o w n19 that the same equations m a y be deduced from an alternative assumption that planes will exhibit the same normal forces per unit area if t h e y have undergone the same normal displacements per unit area from their parallel neighboring planes. T h i s applies approxi- mately t o the total m o v e m e n t as well as t o the recoverable part of it.

F o r the determination of the shearing c o m p o n e n t of stress in a viscoelastic fluid in laminar flow, almost a n y of the conventional viscometric m e t h o d s can be adapted since the shear stress at a point in a flowing material is de- termined already b y the m o t i o n in the immediate vicinity. It is proposed t o consider here only those experimental m e t h o d s w h i c h a t t e m p t t o deter- mine some or all of the other c o m p o n e n t s of stress, and t o this end compara- tively little w o r k has so far been d o n e .

Early quantitative measurements of normal stresses were those of Russell and W e i s s e n b e r g20 w h o measured b o t h the total normal force acting on a plate which formed one b o u n d a r y of the gap containing the material under test and also the distribution of pressures across this plate b y the introduc- tion of a series of capillary gages. A t a b o u t the same time, Garner et al.s'21

18 L . R . G . T r e l o a r , " T h e Physics of R u b b e r E l a s t i c i t y . " Oxford U n i v . Press, N e w Y o r k , 1949.

1 9 K . Weissenberg, Proc. 1st Intern. Rheol. Congr., Scheveningen p . 1-29 (1948).

2 0 R . J. Russell, P h . D . thesis, L o n d o n University (1946).

2 1 F . H . Garner and A . H . Nissan, Nature 158, 634 (1946).

were using a new arrangement consisting of a flat-bottomed cup driven in rotation a b o u t its axis with a stationary, centrally m o u n t e d circular plate a short distance a b o v e the b o t t o m of the beaker. T h e normal stress on this plate was measured b y means of a series of manometer tubes connecting with small portholes at various radial distances. In order t o measure the normal pressure in all directions, certain of these gages projected into the gap containing the material and must certainly have p r o d u c e d unsatis- factory disturbances of the flow. These authors also used a series of Couette- t y p e instruments in which the inner m e m b e r t o o k various forms. Pressures at a series of points on the surface of the inner m e m b e r were measured, and it was claimed that normal pressure differences were observed only when differences in the rates of shear at various points were also present.

A similar arrangement constructed with greater precision has been de- scribed b y R i v l i n and G r e e n s m i t h .2 2 , 23 T h e temperature was controlled t o within ± 0 . 1 ° C . and the g e o m e t r y of the gap could be varied, but the use of a parallel gap in which the rate of shear varied from point t o point in- troduced an additional complication. It is considered that the b o u n d a r y conditions in the last t w o sets of experiments were such that n o clear c o n - clusions can be drawn from the experimental results.

Rivlin and Greensmith considered their observations t o p r o v i d e an ex- perimental check on R i v l i n ' s theory. Subsequent experiments b y R o b e r t s2 4 , 25 with the same materials in the better defined conditions of the rheogoniome- ter are in agreement with the theoretical predictions of Weissenberg and L o d g e and against those of R i v l i n . In particular the negative pressures de- manded b y R i v l i n ' s theory were not o b s e r v e d2 5" (see Plate I ) .

W a r d and L o r d2 6 have investigated the w a y in which the g e o m e t r y of the system affects a secondary normal pressure effect, the climbing of a viscoelastic fluid up a central rod or cylinder immersed in it when the outer container is rotated. T h e y measured b o t h the t o r q u e and the vertical thrust on the inner cylinder, but here again the b o u n d a r y conditions were varying continuously so that there is n o simple m e t h o d of evaluating the stress distribution from these measurements.

P a d d e n and D e W i t t9 have described a semiquantitative apparatus in which the height a b o v e the free surface t o which a liquid rises in a hollow rotating central cylinder is measured as a function of the rate of shear.

2 2 R . S. Rivlin and H . W . Greensmith, Nature 168, 664 (1951).

2 3 H . W . Greensmith and R . S. R i v l i n , Phil. Trans. Roy Soc. A245, 399 (1953).

2 4 J. E . R o b e r t s , unpublished Ministry of Supply report.

2 5 J. E . R o b e r t s , Proc. 2nd Intern. Rheol. Congr. Oxford, p . 91 (1953).

25a T h e experiments have been fully discussed with Greensmith. H e is of the opin- ion that the discrepancy between the foregoing experiments and those of Greensmith and Rivlin m a y be due t o extraneous edge effects in the latter case.

2 6 A . F . H . Ward and P. Lord, Proc. 2nd Intern. Rheol. Congr., Oxford, p . 214 (1953).

G O N I O M E T R Y O F F L O W A N D R U P T U R E 511

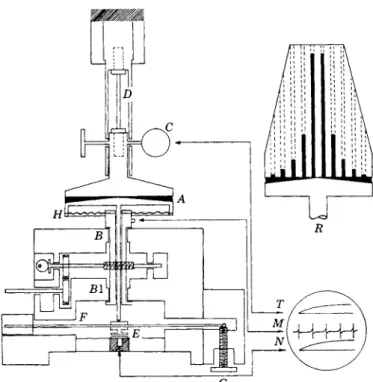

G

FIG. 3. T h e Roberts-Weissenberg R 8 rheogoniometer.

Weissenberg has formulated the principles of a testing instrument which he has termed the ' ' r h e o g o n i o m e t e r ' ' since, in its ideal form, it w o u l d yield a complete specification of rheological data b y measuring at every point in the flowing material the d e v e l o p m e n t in time of the stresses and strains round the full solid angle in space. T h e preliminary d e v e l o p m e n t of this instrument has been reported b y Russell20 and F r e e m a n28 and a modified form for the study of molten plastics has been described b y Pollett and C r o s s .29 Further substantial i m p r o v e m e n t s have been m a d e b y R o b e r t s and there are n o w in existence several instruments of the basic design illustrated in Fig. 3 . A number of these have been built b y Farol Scientific Instruments, Ltd., B o g n o r Regis, England.

T h e basis of the instrument is a slide (not shown) m o u n t e d vertically on a steel base. T h e material under test is held in the gap, A, whose form can be varied. T h e form illustrated is one of the cone-and-plate t y p e introduced b y M o o n e y ,3 0 in which the rate of shear across the gap is constant t o within

27 K . Weissenberg, Proc. 1st Intern. Rheol. Congr., Scheveningen p p . 11-114 (1948).

28 S. M . Freeman, Rept. General Conf. British Rheologists' Club p . 68 (1946).

2 9 W . F. O . Pollett and A . H . Cross, Sei. Instr. 27, 209 (1950).

so M . M o o n e y and R . H . Ewart, Physics 5, 350 (1934).

± 2 % . T h e lower cone can be either rotated continuously, or given an os- cillatory m o t i o n of variable amplitude, or the oscillatory m o t i o n can b e superimposed on the continuous rotation so that the material m a y be examined b y vibrational methods in any state of shear. B o t h rate of rotation and frequency can be varied continuously over a wide range b y gearbox and m o t o r controls. In the earliest experiments, the upper b o u n d a r y of the gap was formed b y the capillary head, R. T h i s consists of t w o glass plates fused very accurately in the form of an inverted Τ and pierced through the up- right of the Τ with a series of holes. T h e lower plate is machined t o optical limits. T h e hydrostatic head of the liquid in each tube is taken as a measure of the normal pressure at that point. T h e capillary head is also p i v o t e d a b o u t its vertical axis so that the tangential stress, pi2, can be measured b y balancing it against a calibrated spring.

Using an apparatus of this t y p e , R o b e r t s2 4 , 25 has described an experi- mental investigation into the stress distribution in a series of flowing visco- elastic materials (solutions of rubber in xylene, aluminum laurate in petrol, and polyisobutylene in o-dichlorobenzene) in which all the pressure c o m - ponents were measured. T h e materials were sheared in gaps of various shapes. p22 pressures were determined b y balancing them against the height of liquid in the capillary gages. pzz pressures were measured b y balancing them against pressures exerted b y standard N e w t o n i a n liquids and, b y making these observations at various radii, r ( = 0 at the center and R at the free b o u n d a r y ) δρ^/δ In (r/R) was determined. pn pressures were then determined b y applying the principle of the equilibrium of forces, according t o which they must be in balance (for negligible forces of gravity and iner- tia) with the experimentally determined quantities, p22, Pw , and δρ^/δ In (r/R) b y the equation

P n = n^R) + 2 P 33 - P 22 ) ( 7 R o b e r t s found that in all the systems he investigated

P22

= pzz

(8)Vu -

pn = pn - Pn

=J^J^

(9)T h e gap must be sufficiently small that the velocity gradient across it is linear; this was checked within the liquid b y observing through the glass head, R, with a depth microscope the velocities of small included particles.

Cinephotographs were also taken of the m o v e m e n t of aluminum particles in the edge of Couette-type gaps.

Plate I illustrates the pressure distribution in a tetralin solution of a

G O N I O M E T R Y O F F L O W A N D R U P T U R E 513

PLATE I. N o r m a l pressure distribution in an 8% solution of p o l y i s o b u t y l e n e ( O p - panol B200) in tetralin.

polyisobutylene sheared in a conical gap and d y e d for ease of p h o t o g r a p h y . T h e equivalence of p22 and pu at the free boundary, after correction for surface tension effects, is observed directly and is confirmed b y extrapola- tion t o the rim of the measured distribution.

These experimental findings are predicted b y the theories of Weissen- berg1"3 and L o d g e1 1 but are not compatible with the theories of Garner et al.,s

F r o m m ,1 0 Padden and D e W i t t ,9 or Reiner4 and Rivlin5"7 except in the trivial case where δρ^/δ In r/R —» 0 when all the theories b e c o m e indistinguish- able. F o r all values of δρ^/δ In r/R > 102 d y n e s / c m .2, the disagreement is b e y o n d the limits of experimental error. There is n o indication that, for these liquids, the agreement is i m p r o v e d between experiment and Weissen- berg's or L o d g e ' s theory b y the introduction of an additional constant as suggested b y the theory of M o o n e y .1 4"1 6 Certain special cases of the theories of M o o n e y and O l d r o y d1 2, 13 are consistent with these results.

W i t h a standardized notation, the predictions of these various theories can be summarized as follows:

Weissenberg: pn — P22 = ρ 11 — = g fa ^ / f i ) = P le 2 7

(where ye is the shearing c o m p o n e n t of recoverable strain) Garner, Nissan, and W o o d : pn — p^ = p^ — P22

(i.e., pn == p22 = 7>33 = 0 ) ΔΡ33 Reiner and R i v l i n : 2 ( p22 — Pn) = 2(pu — P 3 3 )

Δ I N (r/R)

M o o n e y : Jf^Tg ^ n " = JT~~Q ^2 2 "~V ^ = ^ ^ " V^

Δ I N ( R / Ä ) (Η and G are constants)

F r o m m : pn > p22 9E Vu P a d d e n and D e W i t t : pu > p2 2 7^ Pu

L o d g e : pn = pn = 0, p22 — p™ = 0, pn — P22 Œ .2

A n investigation of the variation with the rate of shear of the normal and tangential stresses in polyethylene has been reported b y Pollett.3 1' 32

He also observed that p22 = Pw in this system within the limits of experi- mental error.

It follows from equation (5) that

G =

P'

2 (10)Pu - P22

le = Pn - P22 P12

The apparent viscosity, 77, is defined in the usual manner b y the ratio of the experimentally measured quantities, pi2 and ei2, and in most visco- elastic materials it is observed to fall with increasing rate of shear, έί 2. This drop is normally attributed to the onset of a structural breakdown under

3 1 W . F. O. Pollett, Brit. J. Appl. Phys. 6, 199 (1955).

32 W . F. O. Pollett, Proc. 2nd Intern. Rheol. Congr. Oxford, p . 85 (1953).

G O N I O M E T R Y O F F L O W A N D R U P T U R E 515

the action of the shearing m o t i o n but m a y in fact be partly or wholly a geometrical effect resulting from a gradual divergence with increasing re- coverable strain of the main directions of stress and strain v e l o c i t y . W h e n this occurs, only a part of the stress is effective in o v e r c o m i n g the viscous resistance. In order t o determine whether or n o t a true structural break- d o w n is occurring, it is necessary t o compensate for this angular deviation and t o calculate an idealized viscosity coefficient, 7 7M AX , which w o u l d be obtained if the whole of the stress were effective in overcoming viscous re- sistance, that is, if the stress and the strain velocity still had the same main directions. It can be shown that the angle, a, between the major axes of stress and strain v e l o c i t y is given b y cotan 2a = 2 / 7 e whence

= ' ιΛ+? = ' iA + Cn^f

2)

2 (12)T h i s correction depends only on the directions of the main axes of the stress ellipsoid and n o t on their magnitudes so that it is independent of the choice of stress quadric. r ;m ax could, at least in theory, be determined directly b y subjecting the material t o an irrotational shear (such as that described in Section I I I ) .

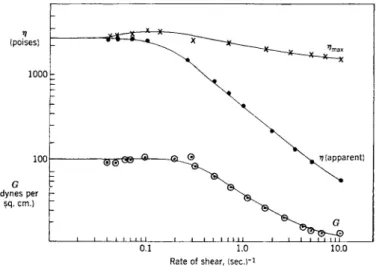

Figure 4 provides a striking illustration of the importance of this correc- tion in certain cases. T h e material is a solution of aluminum laurate in petrol peptized with ethoxyethyl alcohol, and the graphs are obtained b y recalculation of the data of Russell.20 Over the initial part of the graph, the geometrical correction fully compensates for the observed d r o p in 77, and

0.1 1.0 10.0 R A TE OF S H E A R, ( S E C . )-1

FI G . 4. 77, 7 7 m ax , and G as functions of the rate of shear ( 7 % A I . laurate in petrol peptized with e t h o x y e t h y l a l c o h o l ) .

there m a y even be a slight increase in the true resistance t o deformation.

T h e subsequent falling-off of b o t h 7 7m ax and G m a y indicate the onset of a true structural breakdown. T h u s , if only the tangential stress is measured, not only is some of the available information not collected but that which is obtained cannot be correctly interpreted.

N o such angular correction t o G is required as b o t h the stress and the recoverable strain have the same main directions at all times.

T h e definition of η as the constant governing the proportionality of stress and strain velocity is not v e r y satisfactory since, in the general case, this proportionality will be different in different directions in space, η is better regarded as a constant governing the dissipation of energy during flow (energy dissipated per second per unit v o l u m e = pn/η)· F r o m a knowledge of η and G at a n y given rate of shear, relaxation times, τ ( = η/G) and rm ax ( = 7 7m a x/ 6 r ) can be calculated. P i l p e l3 3'3 3a has studied the varia- tion of these parameters with chemical composition in a series of aqueous soap gels.

F o r a given material, the logarithmic distribution of normal pressures across the t o p plate of a conical gap and the equality of p22 and p3 3 at the free b o u n d a r y have first t o be established for extreme conditions of flow.

For intermediate experiments, it then suffices t o measure the total normal pressure o n the plate. It can be shown that the relation between this total normal pressure, p, and pn — p22 is given b y

opw àp22 2p ( .

Pn - P i2 = pn - = =

^^j^

= ^ (13)For this purpose, the arrangement on the left-hand side of Fig. 3 is used.

The upper plate is constrained from moving vertically and the lower cone is rotated through a special diaphragm, H, which allows a rigid rotational movement t o be imparted t o the cone but leaves it free t o m o v e for a very small distance along the vertical axis. T h e total normal force, N, is trans- mitted b y a rod t o the spring condenser gage, E, F, where it can either be recorded or, if static, measured b y a null method using the micrometer screw, G. Tangential stresses, T, are measured b y recording the displace- ment of the condenser gage, C, against the torsion bar, D. In addition t o their virtually instantaneous operation, condenser gages have the further advantage that the actual physical displacements m a y be made very small.

This is an approach t o the ideal of a null method of measurement. T h e sensitivities of both condenser gages, C and E, can be varied over wide limits b y the use of interchangeable springs, F, and torsion bars, D. T h e

33 N . Pilpel, Trans. Faraday Soc. 50, 1369 (1954).

3 3a N . Pilpel, Trans. Faraday Soc. 51, 1307 (1955).

G O N I O M E T R Y O F F L O W A N D R U P T U R E 517

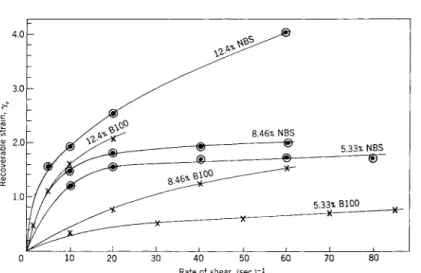

- J

1

I L_10 20 30 4 0

5.33% B 1 0 0 X '

5.33% N B S

®r

ο 50 60 70 80

Rate of shear, (sec.)-1

FIG. 5. R e c o v e r a b l e strain as a function of the rate of shear (m-xylene solutions of p o l y i s o b u t y l e n e s ) .

proximity meter incorporates an additional sensitivity control. T h e v e r y small capacity changes i n v o l v e d are measured b y modified Fielden M o d e l P M 4 proximity meters (differential capacity bridges). B y coupling these t o a double b e a m cathode-ray oscilloscope with photographic recording, Jobling and R o b e r t s have m a d e an extensive series of measurements of the flow properties of solutions of polyisobutylene in m-xylene of varying con- centration and molecular weight. Figure 5 shows the variation of the re- coverable strain with the rate of shear in some of these systems. T h e N . B . S . sample is that distributed b y D r . R . S. M a r v i n of the National Bureau of Standards for a cooperative study and the Β 1 0 0 is an unfractionated commercial product ( O p p a n o l ) . Their viscosity average molecular weights are, respectively, 1.35 Χ 1 06 and 1.3 Χ 1 06. Concentrations are in s o l u t e / solution percentages.

The addition of an electromagnetic clutch enables observations t o b e m a d e of the build-up and d e c a y of the normal and tangential stresses at various predetermined accelerations. These observations are in qualitative agreement with a theoretical prediction of L o d g e11 that, in general, the nor- mal stress will d e c a y more slowly than the tangential one. A n additional advantage of a clutch and a " h a r d " t y p e of measurement is that materials w h i c h are particularly sensitive t o temperature variation m a y be rapidly and accurately tested since the duration of the experiment m a y be cut d o w n t o 0.1 sec. T h i s m e t h o d is particularly suited t o the testing of some printing inks with which, even in narrow gaps, it is difficult t o dissipate the viscous heat at the required rate of shear.

2. OS C I L L A T O R Y MO T I O N

If a material is subjected to an oscillatory laminar shear of sufficiently small strain amplitude, information is obtained about the material in its natural or ground state.

It can be shown both experimentally and theoretically that the normal stress components vary with the even powers of the strain velocity, έ, whereas the tangential component of stress varies with the odd powers. In the region of the natural state, second and higher terms can be neglected and the normal stresses approximate to zero, whereas the tangential stress becomes linearly related to e. Within this region, a large field of investiga- tion has been covered b y applying harmonically varying small strains at a series of frequencies and studying the resulting harmonic variation of the tangential and only component of the stress.

T h e question of what constitutes a sufficiently small strain can be settled experimentally, and has been found t o vary with a number of factors in- cluding frequency. T h e t w o criteria available are (a) the absence of any normal component of stress and (b) the independence of both the measured phase difference between stress and strain, and of the ratio of their ampli- tudes with respect t o the imposed strain amplitude. Mathematically the strain is defined as small if its square is negligible compared with the ex- perimental accuracy. This definition m a y rule out strains which the t w o above criteria would admit.

In vibrational tests on viscoelastic materials at large strain amplitudes, the anisotropy of the sheared state shows up in time as well as in space.

According to Weissenberg's theory, the normal components of stress should vibrate with twice the frequency of the shear components, and this has been verified experimentally b y Weissenberg and Freeman.34

M a n y authors have assumed that, in the region of the natural state, the stress and its time derivatives are linearly related to the strain and its time derivatives b y an equation of the general form (cf. ref. 35)

π0ρ + ττφ + 7Γ2ρ · · · = σ0β + σιέ + σ2έ' · · · (14)

where ρ = pn and e = ei2 but the subscripts are generally dropped since there are now no spatial complications. T h e coefficients are constants char- acteristic of the material and for a material which is predominantly liquid, σ0 = 0.

Equation (14) contains, as special cases, the mechanical equations of state of the

34 K . Weissenberg and S. M . Freeman, Nature 161, 324 (1948).

3 5 T . Alfrey, "Mechanical Behaviour of High P o l y m e r s . " Interscience, N e w Y o r k , 1948.

G O N I O M E T R Y O F F L O W A N D R U P T U R E 519 Hookean solid: π0ρ = a0e

Newtonian liquid: π0ρ = σιέ And a Maxwell b o d y : π0ρ + πγρ = σιέ

A four-term equation which may be written πορ + πιΡ = σιέ + σ2έ has been proposed b y Oldroyd1 2' 13 for certain materials.

If a series of stationary vibrational states is now set up in the material, equation (14) may be written

ρ(πο + (—ίω)πι + ( — ίωγπ2 + · · · + ( — ϊω)ηπη)

= β(σο + ( — ΐω)σι + ( — ίωγσ2 + · · · ( — ΐω)ηση) (15)

since ρ = ρΑβ~ί(ω'~Ρφ) (16)

ρ = (-τω)ρΑβ-ϊ{ωί-^ = ( - ί ω ) ρ (17)

ρ = ( - i „ ) >i le -, ( w i"p*) = ( - ζ ω ) > (18) and similarly for e (where pA and are the amplitudes and ρφ and €φ the

phases of the stress and strain, respectively).

Equation (15) can be written

ρ = T ( c o ) e (19) where

r f ) = (°"o + ( —^ω)σι + { — ίωγσ2 + · · · + ( — ΐω)ηση) ,

Κ ω (πο + ( - ά ο ) τ ι + ( - a o ) V2 + · · · + ( - ώ ΰ ) νη) 1 Ψ

Γ (ω) is termed the complex modulus of elasticity and is a function of the frequency and the angular velocity, ω. F r o m the knowledge of Γ as a func- tion of ω gained from vibrational experiments a series of harmonic solutions to equation (14) can be obtained, but Weissenberg has pointed out that vibrational experiments alone cannot uniquely determine the π and σ con- stants, since Γ (ω) defines only the ratio of the t w o characteristic functions (20) and not the functions themselves.

It is possible to write down equations of the form of (14) for materials having different π and σ values, but all having the same Γ (ω). These ma- terials would behave identically in vibrational tests but would differ in their behavior in stress relaxation and strain retardation. T h e ideal relaxation experiment is regarded as one in which e, é, έ · · · are all put equal to zero and the resulting changes of the stress with time are observed (and simi- larly for the strain retardation with stress and strain transposed in the fore- going) . Satisfactory methods for doing either of these experiments have not yet been found, the chief difficulty being that, for example, a rapid m o v e - ment to bring e to zero is equivalent to a large έ term.

W i t h this view it can be seen that the complete characterization of a material in terms of 7r's and σ'β requires a knowledge of the results of at least t w o of the three types of experiment: vibrational, stress-relaxation, and strain-retardation.

This concept is in conflict with the idea that the rheological behavior of a material can be completely described b y the mechanical spectrum of re- laxation or retardation times derived from either vibrational or stress- relaxation tests only. T h e fact that mechanical spectra obtained b y these t w o methods d o agree fairly well should be regarded as a phycial fact rather than a confirmation of the mathematical theory. It is probable that the generalized M a x w e l l and V o i g t models on which this theory is based are not adequate t o describe all types of rheological behavior.

F o r materials whose behavior is predominantly liquid, it is advantageous t o express the stress-strain relationship in terms of the reciprocal complex modulus, Λ, where

pA = e (21) and

U \ tto + ( —ΐω)πι + ( — ίω)2π2 + · · · + ( — ίω)ηπη , .

Α{ω) = , , . ν — τ ^ ; ΓΊ · \η ^

σ0 + (ΐω)σι + ( — τω)ζσ2 + · · · + ( — ΐω)ηση

Λ can be determined experimentally from the equality

Λ = A„e'A* = = - - ^ ( 2 3 )

where

A , =

1

= ^ (24)TA PA and

Αφ = — Τφ = €φ — ρφ (25)

A t any given frequency, the experimentally determined quantities are the amplitude ratio of strain and stress, €A/PA and the phase difference be- tween them, €φ — ρφ .

Additional restrictions on the experimental technique are that the gap size should be small compared with the wavelength of the mechanical w a v e propagated through the material and that the m o v e m e n t from which pA is determined should be very small compared with eA . (In theory it should be zero.)

F o r a physicochemical interpretation and for comparison with the results of continuous flow tests, it is convenient t o express the results in the form of dynamical moduli of viscosity and elasticity as functions of frequency.

G O N I O M E T R Y O F F L O W A N D R U P T U R E 521

T h e definition of these m o d u l i can be d e d u c e d from a calculation of the w o r k done per second and per unit v o l u m e and a division of the w o r k into free energy, φ, according t o an elastic potential and the w o r k of the dis- sipated energy, H, given out as heat t o an isothermal bath. T h a t is,

P. . é = f t +H (26)

In harmonic shear, the work of the free energy as well as of the dissi- pated energy will, in general, be different from zero, whereas in the station- ary states of continuous unidirectional flow, the work of the free energy, though not necessarily the free energy itself, is always equal to zero, as the whole of the external work done on the material is dissipated as heat. If these energies are expressed in terms of stress (since strain has little meaning in liquid), then

where

and

1_

G

1

COS Αφ (28)

= AA sin Λφ (29)

ωη

A t sufficiently l o w frequencies η and G approach constant values, a n d in this region, a n y viscoelastic material approximates t o a M a x w e l l b o d y char- acterized b y a single shear elasticity and a single viscosity. F o r those m a - terials which h a v e been tested b y b o t h vibrational and continuous-flow techniques, these limiting values agree with those obtained from continuous flow measurements extrapolated t o zero rate of shear.

Vibrational m e t h o d s h a v e been v e r y w i d e l y used for the mechanical test- ing of materials because of the applicability of the technique t o the whole range of consistencies from solid t o liquid. F e r r y36 has recently given an excellent extensive review of the subject.

T h e Roberts-Weissenberg rheogoniometer can b e used for vibrational testing since the lower cone can be given a sinusoidal m o t i o n of varying frequency and amplitude. T h e resulting phase and amplitude of stress can b e followed b y the condenser gage, C (Fig. 3 ) , coupled t o the Fielden proximity meter and a cathode-ray oscilloscope as described a b o v e . T h e instrument can b e geared d o w n t o as l o w a frequency as is desired and its

36 J. D . F e r r y , Ann. Rev. Phys. Chem. 4, 345 (1953).

PLATE I I . Normal pressure phenomena (outer container r o t a t i n g ) . T h e flow p a t - terns of the general (viscoelastic) liquids in a variety of gaps are c o m p a r e d with that of a special ( N e w t o n i a n ) liquid in Fig. 6.

p r e s e n t u p p e r l i m i t i s a b o u t 5 0 c . p . s . T h e i n e r t i a o f t h e u p p e r p l a t e h a s t o b e t a k e n i n t o a c c o u n t a b o v e a b o u t 10 c . p . s . A s o u t l i n e d a b o v e , a c h e c k o n t h e a b s e n c e of a n y n o r m a l c o m p o n e n t of s t r e s s p r o v i d e s c o n f i r m a t i o n t h a t t h e a m p l i t u d e of s t r a i n i s s u f f i c i e n t l y s m a l l .

U s i n g i n s t r u m e n t s o f t h i s t y p e , R o b e r t s a n d J o b l i n g h a v e e x a m i n e d a series o f p o l y i s o b u t y l e n e s o l u t i o n s of v a r y i n g s o l u t e m o l e c u l a r w e i g h t a n d c o n c e n t r a t i o n a n d h a v e o b t a i n e d r e s u l t s i n g e n e r a l a g r e e m e n t w i t h t h o s e f o r s i m i l a r s y s t e m s r e p o r t e d b y F e r r y3 7 a n d c o w o r k e r s .

T h e e x p e r i m e n t a l o b s e r v a t i o n i n t h e s e m a t e r i a l s o f a p h a s e d i f f e r e n c e b e t w e e n s t r e s s a n d s t r a i n , v a r y i n g w i t h t h e f r e q u e n c y a t a n y c h o s e n s t r a i n a m p l i t u d e , p r o v i d e s f u r t h e r e v i d e n c e of t h e i n a p p l i c a b i l i t y t o t h e s e s y s t e m s of t h e R e i n e r - R i v l i n a s s u m p t i o n t h a t s t r e s s a n d s t r a i n v e l o c i t y a r e i n p h a s e u n d e r a l l c o n d i t i o n s .

3. NO R M A L PR E S S U R E EF F E C T S

T h e p r i m a r y c a u s e of t h e " n o r m a l - p r e s s u r e e f f e c t s " o r " W e i s s e n b e r g e f f e c t s ,7 , 1 9'3 8'3 9 o b s e r v e d i n m a n y flow e x p e r i m e n t s w i t h v i s c o e l a s t i c m a - t e r i a l s i s t h e p r e s e n c e of t h e (pn — p^) c o m p o n e n t of s t r e s s a l o n g t h e l i n e of flow. I f t h e g e o m e t r y of flow h a s a c y l i n d r i c a l s y m m e t r y , t h i s b e c o m e s a

37 J. D . Ferry, I. Jordan, W . W . E v a n s , and M . F. Johnson, J. Polymer Sei. 14, 261 (1954).

38 Κ . Weissenberg and S. M . Freeman, Proc. 1st Intern. Rheol. Congr. Scheveningen p . 11-12 (1948).

3 9 K . Weissenberg, Proc. Roy. Soc. (London) A200, 183 (1950).

G O N I O M E T R Y O F F L O W A N D R U P T U R E 523

" h o o p s t r e s s / ' with a resulting tendency for the material t o be constricted toward the cylindrical axis. Three simple experiments illustrating this effect are shown in Plate I I .

T h e climbing of a viscoelastic material up a rod rotating in it provides a simple test for the presence of elastically recoverable strain. E v e n manual rotation is often sufficient.

BOUNDARIES OF GAPS

O U T E R : C U P , r o t a t i n g a t - I N N E R : A s b e l o w

1 N O N E

2 F I X E D C Y L I N D E R ( s m a l l s i d e g a p )

3 F I X E D R O D ( l a r g e s i d e g a p )

4 F I X E D O P E N T U B E ( s m a l l b o t t o m g a p )

5 F I X E D A N N U L U S ( s m a l l b o t t o m g a p )

GENERAL LIQUIDS

Z e r o S p e e d Low S p e e d H i g h S p e e d

u u u

7 N O N - R O T A T I N G D I S K ( v a r i a b l e b o t t o m g a p )

υ

17 TT

"IT

T T u

A F I X E D D I S K W I T H G A U G E S

nlfl]

w ( s m a l l b o t t o m g a p ) 1 11

y υ

υ XT

XT

O D O

τ τ üb i L

l O j I TT TT

Ο TT

M A X I M U M S H E A R S T R A I N R E C O V E R Y I N G I V E N R A N G E O F C O N D I T I O N S

G E N E R A L

" ( a n y f i n i t e v a l u e )

S P E C I A L ( i n f i n i t e l y s m a l l v a l u e ) FIG. 6 . F l o w of liquids under actions of s t a t i o n a r y shear in various gaps.

SPECIAL LIQUIDS

A n y S p e e d

U

ο

υ y j

u

m

ITm

These effects have n o w been observed in a wide range of materials of b o t h industrial and academic interest. T h e y include m a n y p o l y m e r solutions, rubber solutions (though not gutta-percha), molten polyethylene, aqueous gelatin solution in a narrow range of temperature and concentration just a b o v e the gel point, h y d r o c a r b o n gels of aluminum soaps, certain aqueous soap gels (for example, freshly prepared a m m o n i u m oleate solution), some printing inks, and bitumen.

A n o t h e r t y p e of normal pressure effect which, b y contrast, is m o s t marked in the nonelastic, purely plastic materials has been recognized recently.

W h e n a ball or flat cylinder of a purely plastic material is rolled between parallel plates under gentle pressure, it forms an elongated cylinder and, at the same time, the ends of the cylinder are sucked in as the action proceeds.

In the most favorable case, the t w o depressions meet and a hollow tube is formed, the central hole being somewhat jagged. T h e p h e n o m e n o n was o b - served b y W i l l i a m s o n40 in a particular t y p e of Australian clay. H e was also able t o form a tube in w a r m plasticine and c o m m e n t e d on the resemblance t o the Mannesmann process in the steel industry for the production of steel tubes. ( N o r m a l l y a mandrel is used in this process but it has been shown not t o be essential.)41 Weissenberg42 concluded that the effect should be a v e r y general one and that the essential features are m a c r o s c o p i c , namely, the consistency of the material as defined b y the stress-strain relation and the distribution in time and space of the stresses and strains induced b y the rolling action. M o r e o v e r , he predicted that tube formation should occur in materials with little or n o elastic r e c o v e r y and that an annulment or even a reversion of the effect (a pressing-out of the ends of the cylinder) should be observed in materials with appreciable amounts of elastic r e c o v e r y .

These predictions have been confirmed b y E g a n and J o b l i n g43 in an ex- perimental investigation of a wide range of materials of varying structure and consistency. Plate I I I illustrates the different behavior of three typical materials. These are, from left t o right:

(a) A sample of polyisobutylene with a molecular weight of about 20,000.

This exhibits a high degree of elastic recovery and the ends b e c o m e convex on rolling.

(6) A paste of asbestos fiber in Nujol (liquid paraffin). T h i s is representa- tive of the fibrous pastes in which the tube is formed b y the opening up of radial cracks \vith little or n o drawing-in of the ends.

(c) A paste of icing sugar in N u j o l . This is typical of the s m o o t h pastes which form tubes b y the sucking-in of the ends.

4 0 W . O . Williamson, Am. J. Sei. 252, 129 (1954).

4 1 J. Gassen, Arch. Eisenhüttenwesen 127, (1927-8).

42 Κ . Weissenberg, Bull. Brit. Soc. Rheol. No. 43, 6 (1955).

4 3 M . J. Egan and A . Jobling, Nature 176, 689 (1955).

G O N I O M E T R Y O F F L O W A N D R U P T U R E 525

PLATE I I I . B e h a v i o r of different materials in a simple rolling a c t i o n

S o m e manifestation of this effect, such as a tendency t o suck in air, might be expected t o occur in industrial milling or rolling processes with materials of suitable consistency such as concentrated clay or pigment suspensions.

4. FU T U R E DE V E L O P M E N T S

It has been pointed out that the relation between stress and recoverable strain [equation (5)] from which the elasticity modulus, G, is determined in continuous flow experiments depends on an assumption which has n o t y e t been tested b y experiment. If, on the continuous shearing m o t i o n , an addi- tional oscillatory shear could be imposed, G could b e determined inde- pendently b y the standard vibrational technique and c o m p a r e d with the value calculated at the same rate of shear from equation ( 1 0 ) . T h i s addi- tional m o t i o n has n o w been incorporated into the drive of the latest rheo- goniometers and experiments t o this end are n o w in progress.

In addition, this m o v e m e n t appears t o be fruitful for the study of dilatant materials which tend t o flow out of the conical gap in continuous s h e a r .4 4 , 45 T h e well-known shear hardening of dilatant pastes (e.g., m a n y printing inks) has been found t o be relaxed b y the application of mechanical vibra- tion of sufficiently small amplitude, and a further study of these systems is proceeding.

T h e use of the glass capillary head (Ä in Fig. 3) is not always satisfactory for the measurement of normal pressure distributions, some materials taking an excessively long time to reach equilibrium in the tubes. A new type of head in which the normal pressure at a series of points on its surface can be measured with condenser gages has been constructed. It is hoped that this arrangement will enable the true pressure distributions to be determined in a number of materials which exhibit apparently anomalous patterns in the present apparatus.

Further improvements in the experimental method will be achieved b y the introduction of automatic null methods of stress measurement. These will simplify the mathematical analysis; for example, corrections for the inertia and movement of the measuring plate will be eliminated. These null methods are particularly advantageous in stress relaxation experiments.

III. Goniometry o f the Transition Region Between Flow a n d Rupture 1. IN T R O D U C T I O N

The study of materials in the transition between steady flow and rupture can throw light on a number of subjects of great practical importance such as the breaking and yield strength of materials, fatigue, solid friction, and boundary lubrication. A characteristic of the region is the appearance of perturbations which may range from submicroscopic dislocations of elec- trons, atoms or molecules to micro- and macroscopic irregularities, such as ridging, crazing, cracking, or twinning, and further on to complete rupture.

M a n y types of rupture tests are well known. Almost without exception these involve the use of rigid grips to impose the required mechanical action on the material with the resulting serious drawback that, at the boundary where the transmission of the action occurs, there is no deformation. This limits both the type of deformation which can be imposed and the extent to which one has control over it. Recently, Weissenberg has suggested that these objections could be overcome b y imposing the mechanical action through a deformable boundary member situated in a main plane of the de- formation, that is, on a plane in which the maximum changes in length are occurring. Elastic, viscoelastic, or purely viscous materials can be used for the boundary member, either alone or in conjunction with additional rigid

44 R . McKennell, Proc. 2nd Intern. Rheol. Congr. Oxford p. 350 (1953).

4 5 E . Bantoft, private communication.

G O N I O M E T R Y O F F L O W A N D R U P T U R E 5 2 7

members. In most of the preliminary experiments described here, this ma- terial is rubber, either natural or synthetic, in the form of plane sheets, tubes, or balloons.

A general m e t h o d has been developed b y which the chosen boundary ma- terial can be given any one of a wide variety of t w o - or three-dimensional rotational or irrotational shearing m o v e m e n t s and the resulting develop- ments in space and time of the stresses, strains, and disturbances propagated through the material under test can b e observed round the full solid angle in space.

Despite the early state of development of the necessary instruments, a number of very interesting results have already emerged from the prelim- inary experiments. In addition t o the m u c h wider range of mechanical actions which can be applied b y the new methods, it is clear from the regu- larity of the pattern of disturbances which is produced that the action is caused t o occur in a very even fashion throughout the material under test.

T h e pattern is so uniform that it should be amenable t o quantitative meas- urement of the periodicity and direction of the disturbances. It is, therefore, possible b y this m e t h o d t o obtain m u c h more information about the rupture process than has hitherto been available. B y the choice of suitable materials for the boundary members, substances as varied as dry powders, pastes of these in liquid media, p o l y m e r films, and vacuum-deposited metal films have been examined and their behavior has been found t o exhibit some un- expected c o m m o n features.

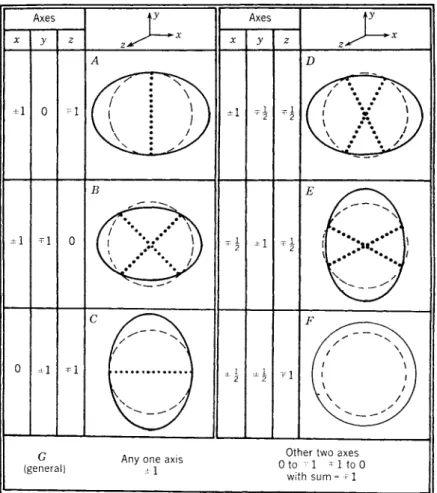

2 . PR I N C I P L E S O F T H E ME T H O D

T h e new m e t h o d described here is a kinematic test in which the m o v e - ment that the material under test is t o undergo is prescribed. One then o b - serves the development in time of the distribution round the full solid angle in space of the resulting disturbances t o flow and, in the ideal case, also of the stress. T h e complementary d y n a m i c m e t h o d in which the stress w o u l d b e prescribed and the resulting displacements and disturbances observed has not y e t been developed.

FI G . 7. F o r m of b o u n d a r y m e m b e r used in the general m e t h o d of rupture testing A

Β