Máté Hegyháti

Veszprém

DOI: 10.18136/PE.2015.585

Bath Proess Sheduling:

Extensions of the S-graph Framework

Máté Hegyháti

Supervisor: Feren Friedler, DS

Dotoral Shool of Information Siene and Tehnology

University of Pannonia

Veszprém

BATCH PROCESS SCHEDULING:

EXTENSIONS OF THE S-GRAPH FRAMEWORK

Értekezés doktori (PhD) fokozat elnyerése érdekében

Írta:

Hegyháti Máté

Készülta Pannon Egyetem InformatikaiTudományok Doktori Iskolája keretében

Témavezet®: Dr. Friedler Feren

Elfogadásrajavaslom (igen /nem)

(aláírás)

A jelölta doktoriszigorlaton % -otért el.

Veszprém,

a SzigorlatiBizottság elnöke

Az értekezést bírálóként elfogadásrajavaslom:

Bíráló neve: (igen /nem)

(aláírás)

Bíráló neve: (igen /nem)

(aláírás)

A jelöltazértekezés nyilvános vitáján % - otért el.

Veszprém,

a BírálóBizottság elnöke

A doktori (PhD)oklevélmin®sítése

Az EDT elnöke

Inbathproesses,aunitan beusedforvariousstepsofthe produtionofseveraldierent

produts. This leads to several advantages over ontinuous systems, e.g., quik adaption

to the hanging market environment. This exibility of bath proesses, however, requires

additionalonsiderationinoperationalplanning,asthe equipment unitsmustbesheduled

with aution to satisfy all the pratial onstraints of the problem. Finding the most ad-

vantageous shedule is generally a omplex problem,nevertheless it is a key omponent of

the protabilityof suh systems. As a result, the sheduling of bath proesses is awidely

researhed topi,with many dierentapproahes published.

The goalof my PhDworkwastoextendthe apabilitiesof theS-graphframeworktobe

able toaddress awider range of shedulingproblems. Unlike othermathematial program-

ming based tehniques, the S-graph framework guarantees a feasible and globally optimal

solution. There are, however, several pratial features, that ould not be takled with

the former S-graph based algorithms. In this thesis, extensions of the S-graph framework

are presented to address limited-wait storage poliies, throughput maximization-, and ex-

petedprotmaximizationproblems. Thedevelopedalgorithmsare disussedindetail,and

empiriallytested on various ase studies and literature examples.

Szakaszosüzem¶termel®rendszerekberendezéseitöbbkülönböz®termék gyártásánaklépé-

seinélisfelhasználhatók,aminekköszönhet®en azilyenrendszerekkönnyebbenalkalmazkod-

nak például a változópiai igényekhez, s további számos el®nnyel rendelkeznek afolytonos

rendszerekm¶ködésévelszemben. Ezenszabadságifoknakköszönhet®enugyanakkorkülönös

odagyelés szükséges a tervezés során, hogy a berendezések ütemezése minden gyakorlati

korlátozásnak eleget tegyen. A legel®nyösebbütemezés megtalálásaáltalában egyösszetett

feladat, mely kulsfontosságú a hasonló rendszerek nyereséges m¶ködéséhez, így a téma

széles körben kutatott, s számosmódszer látott napvilágotakapsolódószakirodalomban.

DoktorimunkáméljaazS-gráfmódszertankiterjesztésevolt,megteremtveannak széle-

sebb kör¶ alkalmazási lehet®ségeit szakaszos üzem¶ rendszerek ütemezéséhez. A mate-

matikai programozáson alapuló módszerekkel ellentétben az S-gráf módszertan korábban

kidolgozott algoritmusai garantálják az optimális megvalósítható megoldást, azonban nin-

senek felkészítve néhány fontos ipari korlátozás gyelembe vételére. Dolgozatomban az

S-gráf módszertan több kiegészítése kerül bemutatásra, melyek alkalmazásával kezelhet®k

például az id®korlátos tárolások, vagy a prot valamint várható prot maximalizálását

megélzó feladatok. A kifejlesztett algoritmusokrészletes ismertetésétkövet®en azok össze-

hasonlítása kerül bemutatásra esettanulmányokon ésirodalmipéldákon keresztül.

Abstrat v

Abstrat in Hungarian vii

Ahnowledgements xvi

Prefae 1

1 Sheduling problems 3

1.1 Basi shedulingproblems . . . 4

1.1.1 Problem lasses . . . 4

1.1.2 Classiation of solutionsof shedulingproblems . . . 7

1.1.3 Approahes and omplexity . . . 7

1.2 Shedulingproblems of hemialbathproesses . . . 8

1.2.1 Reipesand example problems . . . 9

1.2.2 Storagepoliies . . . 13

1.2.3 Objetive funtions . . . 15

1.2.4 Common additionalparameters . . . 16

1.2.5 Representation of ashedule . . . 17

2 Mathematial tools for bath sheduling 19 2.1 MILP formulations . . . 21

2.1.1 Time disretizationbased formulations . . . 22

2.1.2 Preedene based formulations . . . 24

2.2 Analysisbased tools . . . 25

2.3 S-graph . . . 26

2.3.1 S-graphrepresentation . . . 26

2.3.2 Algorithmfor makespan minimization . . . 28

2.3.3 Extensions and developments of the S-graphframework . . . 31

3 Critial modeling issues 37 3.1 Minimal suient numberof time points . . . 39

3.2 Cross transfer . . . 41

3.3 Other issues . . . 48

3.3.1 Long tasks . . . 49

3.3.2 Time point synhronization . . . 50

Summary and onluding remarks . . . 50

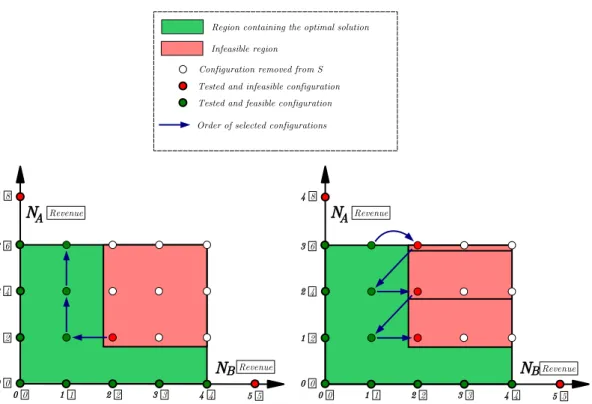

4 Throughput maximization with S-graph 53 4.1 Mainalgorithmfor revenue maximization. . . 53

4.2 Subroutines forthe algorithm . . . 55

4.2.1 The selet_remove method . . . 55

4.2.2 The update method . . . 57

4.2.3 The feasible method . . . 59

4.3 Flexiblebath sizes . . . 61

4.4 Empirialtests . . . 63

4.4.1 Pharmaeutialase study . . . 65

4.4.2 Agrohemial example . . . 67

4.4.3 Literature example . . . 68

Summary and onluding remarks . . . 68

5 LW and ZW poliies in the S-graph framework 71 5.1 Auxilary LPmodel . . . 72

5.2 Combinatorialapproah with negativeweighted ars. . . 73

5.3 Combinatorialapproah withoutnegative weights . . . 75

5.3.1 Reursivesearh . . . 75

5.3.2 Auxilary graph . . . 79

5.3.3 Model-level onversion of LW problems to ZW . . . 81

5.4 Comparison of approahes . . . 82

Summary and onluding remarks . . . 84

6 Maximizing expeted prot 87 6.1 Problemdenition . . . 88

6.2 S-gaphbased approahes . . . 89

6.2.1 Preventive shedulingwith xed bath sizes . . . 90

6.2.2 Preventive shedulingwith variable bath sizes . . . 91

6.2.3 Two stage approah . . . 92

6.3 Extended approahes for reipes with multiple produts . . . 93

6.3.1 Preventive shedulingwith xed bath sizes . . . 93

6.3.2 Deterministisheduling forvariablebathsizes . . . 94

6.3.3 Preventive shedulingwith variable bath sizes . . . 94

6.3.4 Two stage approah . . . 95

6.4 Continuous probabilitydistribution . . . 96

6.4.1 Preventive ase with xed bathsizes . . . 96

Summary and onluding remarks . . . 101

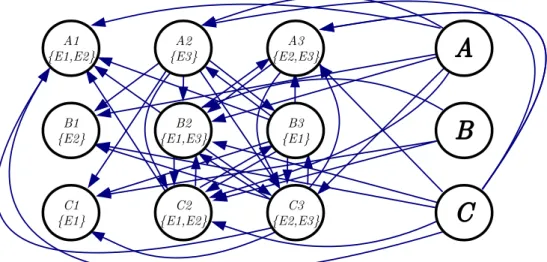

7 Generalized S-graph model: the Event S-graph 103 7.1 Modeling diulties with the originalframework . . . 104

7.1.1 Transfer times . . . 104

7.1.2 Waitingbeforeprodution . . . 106

7.1.3 Continuous proesses and multiple resoures . . . 108

7.2 Sheme of optimizationwith the S-graph framework . . . 108

7.3 Mathematial desriptionof the

e

S-graphmodel . . . . . . . . . . . . . . . . 1137.3.1 Analysis ofthe originalS-graphmodel . . . 114

7.3.2 Generalonept of the

e

S-graph model . . . . . . . . . . . . . . . . . 1157.3.3 Formal denitions . . . 116

7.4 Modeling shedulingproblems with the

e

S-graph. . . . . . . . . . . . . . . . 1207.5 Makespan minimizerfor the

e

S-graph . . . . . . . . . . . . . . . . . . . . . . 125Summary and onluding remarks . . . 128

A Environment for omparisons 131 B Nomenlature 133 C Full tables of test results 137 C.1 Throughputmaximization . . . 137

C.1.1 Pharmaeutialase study . . . 138

C.1.2 Agrohemial example . . . 139

C.1.3 Literature example . . . 139

C.2 Zero-waittest results . . . 140

C.3 Stohasti test results. . . 140

Referenes 147 Index 158 List of Figures 1.1 Dependeny between the possible entries in the

α

eld . . . . . . . . . . . . 61.2 Multiprodutexample represented in ablok diagram . . . 12

1.3 Multipurpose example represented in ablok diagram . . . 12

1.4 Preedentialexample represented in agraph . . . 13

1.5 STN representation of a generalnetwork reipe . . . 14

1.6 Example Gantthart for8 produts . . . 17

1.7 Example Gantthart withtransfer and leaning times . . . 18

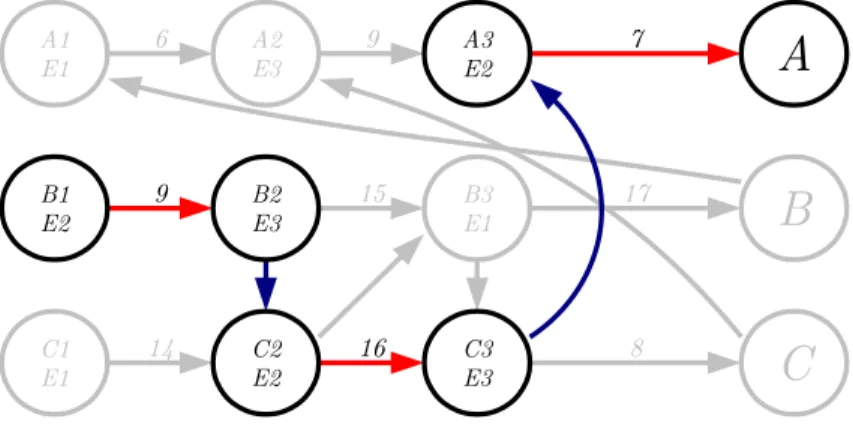

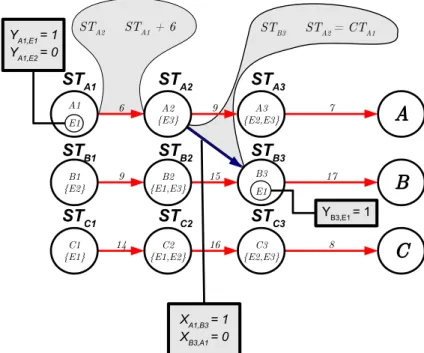

2.1 Example reipe graph. . . 26

2.2 Example shedule graphfor the reipe graphin Figure2.1 . . . 27

2.3 Sequene of tasksassignedto unit

E2

. . . . . . . . . . . . . . . . . . . . . . 272.4 Ganttdiagramgenerated from the shedule inFigure 2.2 . . . 28

2.5 Connetionbetween preedene based models and the S-graph framework . . 34

3.1 Simpleexample reipefor illustratingthe Cross Transfer issue . . . 41

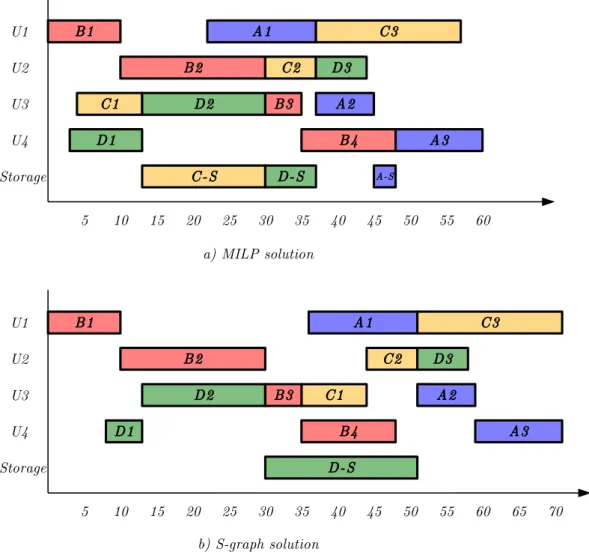

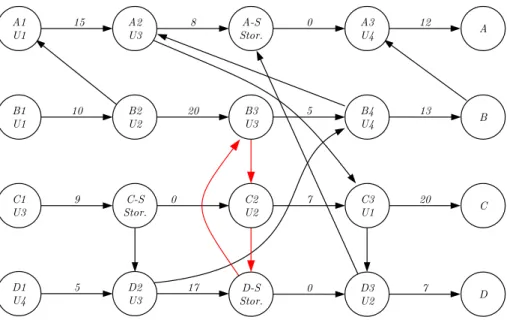

3.2 Provided Gantt harts for the example inFigure3.1 . . . 42

3.3 Literature example for ross-transfer illustration . . . 42

3.4 Solutionsprovided for the literature example . . . 43

3.5 Cyle in the S-graphrepresentation of the MILP solution . . . 46

3.6 The S-graphontaining allthe possibleshedule ars . . . 49

4.1 Findingthe initialregion for revenue maximization . . . 56

4.2 Signiane of ongurationseletiononthe number of iterations . . . 56

4.3 Reduing the searh spae basedon the best feasible solution . . . 58

4.4 Evaluationof ongurations with revenue updates on

S

. . . . . . . . . . . . 584.5 The orresponding reipe graphs forthe 6ases in Table 4.3 . . . 64

4.6 Summaryof results for the pharmaeutial ase study . . . 66

4.7 Flowsheet of the agrohemialproess for herbiide prodution . . . 67

4.8 S-graphof the two xed reipesfor the agrohemial proess . . . 67

5.1 Modeling LW poliy with negative weighted ars . . . 74

5.2 Feasible UW shedule. . . 76

5.3 Infeasible ZW shedule . . . 76

5.4 Aelerationby insertingadditionalars in the graph . . . 79

5.5 Example for the graph of ZWlasses onstruted fromthe reipe . . . 80

5.6 Example for the extended graph of ZW lasses based ona shedule . . . 81

5.7 Example for modeltransformationof LW stages . . . 82

5.8 Example for the omparison of LW/ZWapproahes . . . 82

5.9 CPU time ofZW/LW approahes for the smaller ases . . . 83

5.10 Qualityof reported solutionsof ZW/LW approahes . . . 84

6.1 Classiationof approahes dealingwith unertainty . . . 87

6.2 Optimalpreventive solutionfor the example . . . 100

7.3 Modied S-graphto addresstransfer time . . . 105

7.4 Addressing transfer time with several subsequent tasks. . . 106

7.5 Addressing transfer time with additionalnodes. . . 106

7.6 Example for produtwith task of multiple inputs . . . 107

7.7 Solutionsprovided by the S-graphalgorithmfor the example . . . 107

7.8 Solutionwith better makespan if storage if allowed beforeproessing . . . . 108

7.9 Generalsheme of the S-graphbased optimizationproedure . . . 109

7.10 Optimizationproedure with modeltransformation . . . 111

7.11 Optimizationproedure with algorithmiextension . . . 112

7.12 Optimizationproedure with modelbased extension . . . 112

7.13 Simplieddependenynotations for the

e

S-graph . . . . . . . . . . . . . . . 1207.14

e

S-graphmodelof asimple task . . . . . . . . . . . . . . . . . . . . . . . . . 1217.15

e

S-graphmodelof atask with input and outputtransfers. . . . . . . . . . . 1217.16

e

Sgraphmodel of atask and transfers . . . . . . . . . . . . . . . . . . . . . . 1227.17

e

Sgraphmodel of part of aomplex reipe . . . . . . . . . . . . . . . . . . . 1237.18

e

Sgraphequivalent of anS-graph model . . . . . . . . . . . . . . . . . . . . 126List of Tables 1.1 Example data for asingle stage problem . . . 11

1.2 Multiprodutexample represented in atable . . . 11

3.1 Illustrationof the iterative approahfor MILP formulations . . . 40

3.2 Proessing times forthe single stageexample . . . 40

3.3 Illustrationof the time pointissue . . . 40

4.1 27dierent"xed reipes" forthe exampleby Kondili etal.[66℄ . . . 62

4.2 Non-dominatedases for the example by Kondiliet al.[66℄ . . . 63

4.3 Merged non-dominated ases for the example by Kondili etal.[66℄ . . . 63

4.4 Proessing times and revenue data forthe pharmaeutialase study . . . . 66

4.5 Test results for the agrohemial example. . . 68

4.6 Test results for the example of Setion4.3 . . . 68

6.1 Senarios for the illustrativeexample . . . 99

6.2 Polarity of the S-graph basedapproah . . . 100

List of Algorithms 2.1 Makespan minimization with the S-graphframework . . . 29

3.1 Algorithmto generate onstraintsavoiding ross transfer . . . 47

3.2 Reursivesubroutine for Algorithm3.1 . . . 48

4.1 Throughputminimization with the S-graphframework . . . 54

4.2 Feasibilitytester subroutine for revenue maximization . . . 60

5.1 Findingnon-negativepath between twoverties . . . 78

7.1 Makespan minimization with the S-graphframework . . . 127

First of all,I would like to thank tomy supervisor and all members of the Sheduling Re-

searh Group atthe Department of Computer Siene and Systems Tehnology, Faulty of

Information Tehnology, University of Pannonia, for helping me making my own ontribu-

tion to the eld of bath proess sheduling. Prof. Feren Friedler, my supervisor aided

my researh with many suggestions, orretions, and ontinuous guidane thourough our

eveningmeetingsdespiteallthe strains Hebeard asthe retorof our University. Dr. Tibor

Holzinger,my seniorolleagueattheresearh groupprovidedmewithmanygreatinsights

and suggestions, and showed always innite patiene towards me, though I often meant a

hindrane inour jointworks. Iamexeptionally thankful toallthe students I had theluk

towork with: Ákos Orosz,András Szoldatis,András Éles, BalázsKovás, BenjáminTóth,

Olivérsz,and ZsoltNemes,asthey wereveryative,resoureful,reative,andstimulative

olleagues during this last5 years.

For providing a supportive aura and workplae for my researh I am thankful to my

friends,family,andallthesta(inludingleturers,researhers,administrativeandleaning

personnel, et.) oftheDepartmentand theUniversity, aswellastheity ofVeszpremitself.

SpeialthanksisinorderforGergelyVakulya,whosharedthesameoewithmethorough

thislastoupleofyears,andprovedtobeasupportingroommate,withwhomIsharedmany

sientially inspiringdisussions.

The PaulErdosTalentCareProgramandDr. FerenPinter played akeyroleshepherd-

ingmetowards theaademi areer,forwhihIamnowutmostgrateful. Overmy 21years

of beingastudent, many peopleontributed indevelopingskillsneessary forgraduatingas

aPhDstudent,inludingallmyteahers,students,orhestramembers, powerhikingfellows,

and rivalsinompetitions.

This researh has been supported by the European Unionand Hungary and o-naned

by the European SoialFund through the projet TÁMOP-4.2.2.C-11/1/KONV-2012-0004

- National Researh Center for Development and Market Introdution of Advaned Infor-

mation and Communiation Tehnologies.

Bath proesses are beomingmore and more importantinthe produtionindustry due to

their exibility. This advantage,however, alsoomesasashortoming,asthe units needto

be sheduled, whih resultsinanadditionalomplexity forthe planningofoperations. The

industrygeneratesawiderangeofbathshedulingproblems,wherethegoalingeneralisto

alloatethe tasksof theproess tothe availableequipmentunits inthemost favorableway.

Thus, sheduling is an important and unavoidable problem of bath proesses, for whih

many approahes has been published in the literature overthe past two deades.

Chapter1rstpresentsthetheoretialfoundationsofmahinesheduling,whihprovides

the basis for the pratial, industrialproblems desribed in the seond part of the hapter.

The approahes developed and published in the literature for bath sheduling problems

are summarized in Chapter 2. The MILP programming based approahes presenting the

majority of publiations are disussed in detail. The model and algorithmsof the S-graph

framework and its past developments are detailed thoroughly in the seond part of the

Chapter, as it provides the basis for the new developments presented inthis thesis.

In thenext vehapters, the newresultsofthethesis aredetailed. First,somemodeling

issues are addressed inChapter 3,that appear inthe literature approahes. Thenext three

haptersprovideextensionsoftheS-graphframeworkforthroughputmaximization(Chapter

4, limited-waitstoragepoliy (Chapter 5),and stohasti prot maximization(Chapter 6),

respetively. InChapter7,ageneralizedmodelingframeworkispresentedinordertoextend

the expressiveness of the S-graphframework.

Sheduling problems

Shedulingproblems appear inalmostevery partof life,e.g., ndingthe shortest path with

a shopping list in a mall, seleting the best order of airplanes to land during a rush hour,

orprovidinga robustexeution planfor aonstrution projet. Theproblems that arise at

dierent parts of life often dier in many aspets, however, the underlying basis are the

same: the goal is to assign tasks to some kind of available resoures and time

intervals in the most favorable way for a ertain objetive, while satisfying the

onstraints of the problem denition. Just like the aforementioned onstraints and

objetives vary, the terminologyfor the basi elements of the problem are alsodierent at

dierent elds of siene. Tasks to be performed are often alled jobs, ativities, et. The

availableresouresinmanyasesare somekindofmahinesthat areoftenalledequipment

or units as well. The main eld of the present work is the sheduling of bath proesses of

hemial industries, thus the terms task and unit are used almost everywhere, whih are

the most aepted inthis eld.

The lassiation of sheduling problems is dierent for eah eld. However, there are

somebasiaspetsthatanbethebasisoftheategorizationinalmostanyase. Regardless

oftheeldspeiattributesofashedulingproblem,itanbelassiedaseitheranonline,

oine, or semi-oine problem. In the ase of oine problems, all the neessary input

dataisavailableatthe timeoftheoptimization,whentheshedulingdeisionsaremade. In

ontrast,foranonlineshedulingproblem,the deisionshavetobemadebeforesomeofthe

problemparametersarerevealed. Inthesemi-oinease,somebutnotallinformationabout

the problem parameters is available in advane before making the deisions. In general, it

is impossible to provide an approah generating the optimal solution if the problem is not

oine. In the online and semi-oine ase the proposed methods in the literature an only

guarantee aompetitiveratio,that isthemaximum deviationofthe provided solutionfrom

the optimalone. Foroine problems,the optimal solutionisusually theoretiallyndable.

Nevertheless, most ofthe oineproblems are NP-hard, thusndingthe optimalsolutionin

a reasonable time isin many ases not possible orat least hallenging.

An other dimension for lassiation is the unertainty. A sheduling problem is alled

stohasti ifsome of theproblemparameters takevalues onlyatthe time ofthe exeution

oftheprovidedshedule,andtheproblemisalleddeterministi otherwise. Forstohasti

problems the deisionsto be made an be ategorizedintotwogroups: the ones that must

take values before the stohasti parameters take values, and the ones that an alter their

value afterthat.

The two mentioned ategorization aspets are only loosely dened, and thus they also

havekindofanoverlap. Asanexample,stohastiproblems anbe onsideredsemi-oine,

as some of the deisions has to be made before knowing the exat values of some problem

parameters, and usually some additionalinformation is available, e.g., the probability dis-

tribution funtion of them. Nevertheless, both of the aspets are addressed independently,

as the most ommon attributes of a stohasti and a semi-oine problem are dierent, as

well asthe objetives and the developed approahes for solving them.

In this work, mostly deterministi and oine problems are onsidered if not stated

otherwise. Chapter 6 fouses on a lass of stohasti sheduling problems. The domain of

theproblemsandthedevelopedapproahesistheshedulingofthebathhemialproesses

althoughmanyofthealgorithmsmaybeappliedforsimilarproblemsofotherelds. Setion

1.1providesabriefreviewofthebasishedulingproblemsintheliteratureofombinatorial

optimization,assomeoftheseproblemsaretherootsfortheshedulingproblemsthatappear

in the hemial industries. The introdution of the speial features of bath sheduling

problems is given inSetion 1.2.

1.1 Basi sheduling problems

In this setion some of the most simple sheduling problems are disussed. Simple refers

here tothe desriptionofthe problem,not the mathematialomplexityof solvingit. Asit

willbepresented, some of these problems are already very diulttotakle tobegin with.

Shedulingproblemsinhemialindustriesusuallyinvolvemoreproblemparametersand

onstraints than the problems presented in this setion. These problems, however, are the

basis for the more detailed pratial problems, and they provide a lower bound for their

omplexity.

1.1.1 Problem lasses

In the literature[101℄ of these problems, the terms job,operation, and mahine are used

insteadof produts,tasks, and units,respetively. Theproblemlasses areformulatedwith

a triple,

α|β|γ

, wheretheα

eld desribesthe jobsand the available infrastrutureβ

eld provides additionalparameters of the problemif anyγ

eld denes the objetiveThe

α

eld desribes the number of mahines, whether they are idential or not, andalso the type of the jobs to be ompleted on those units. Without attempting to be om-

prehensive, some of the possibleentries of the

α

eld are given here:Single stage problems

1

- Single mahine A single mahine is available, eah job onsists of asingle steptobeperformedonthatmahine. Theprodutsmay (and

usually do) have dierentproessing times.

P m

- Idential parallel mahinesm

idential mahines are available,with single step jobs, that an be ompleted onany of the mahines.

Qm

- Parallel mahines with dierent speed are similar to theP m

ase with the dierene that eah mahine has an assigned speed

fator.

Rm

- Unrelated mahines in parallel Generalizationofthesinglestage ase, when theproessing timeof ajob onamahineis dened asaninput parameter.

Shop problems

F m

- Flow shop The jobshavem

stepsthathavetobeperformedonthem

mahines in the same order for eah job.F F c

- Flexible ow shop GeneralizationoftheF m

andP m

ases,whereeah job has togo through

c

stages in the same order, where severalparallel mahinesare available.

Jm

- Job shop Generalization of theF m

ase, where the jobs an havedierent order for the mahines, moreover, it is not mandatory for a

job tovisit allof the mahines.

F Jc

- Flexible job shop GeneralizationoftheJm

andF F c

ases, whenthe jobs have to go through some of the stages in a job-dependent

order, and ateah stage, some idential units are available.

Om

- Open shop Eah job has to go through all of the mahines. How-ever, their order is not given by the problem denition.

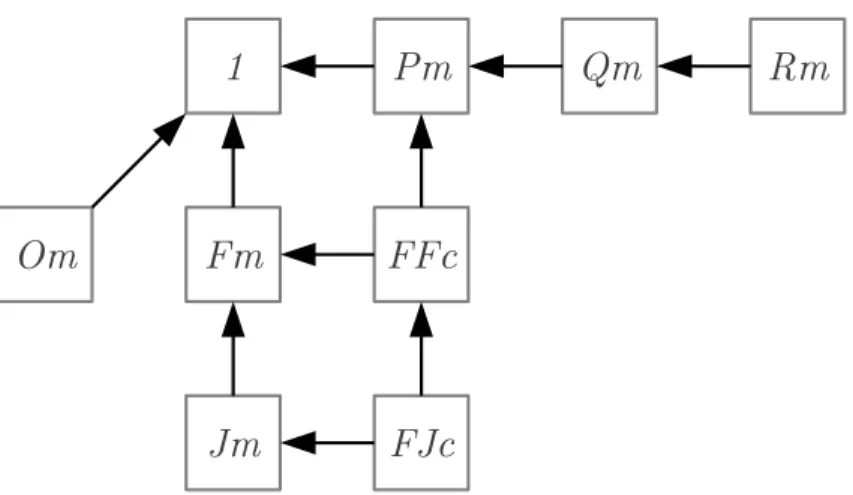

As it is already highlighted in the desription, some of the ases are speial ases of

others, e.g.,

P m

is a speial ase ofF F c

whenc = 1

. These dependenies between the dierentα

eldvaluesareshown inFigure1.1,whereanarleadingfromA

toB

representsthat

B

is a speial ase ofA

.Unlike the

α

andγ

elds, theβ

eld that provides additionalonstraints, may ontain several orno entries atall. Someof the most ommonentries are:Figure1.1: Dependeny between the possible entries in the

α

eldr j

- release dates For eah job, its proessing annot start earlier than its releasedate.

prmp

- preemptions The proessing of a job on amahine an be interrupted, and ontinued later on any suitablemahine.s jk

- sequene dependent setup times After ompleting jobk

on a mahine, itneeds

s jk

time tobe adjusted for the jobj

.batch(b)

- bath proessing The mahines an perform at mostb

jobs simultane-ously, however, thejobs has towaitforeahother whenstartingornishingthe

task.

brkdwn

- breakdowns The mahines are available onlyin given timeintervals.M j

- mahine eligibilityrestritions Intheaseofparallelmahines,eahjobhas a subset of mahines that an beused toproess it.prmu

- permutation In ase of ow shop problems, the order of the jobs at eah stage must be the same.nwt

- no wait The jobsan notwaitbetween the dierentmahines inase ofow-,job-, oropen shop problems.

In the ase of the

α

eld, all of the entries were generalizations of the1

ase. Similarly,the empty

β

eld is a speial ase of many other. From the above listr j

,s jk

,brkdwn

,M j

,and their ombination are suh entries, however, the preemptions, for example, hange the

problemin itsore.

The

γ

eld denes the objetive of the optimization. Similarly to theα

eld, exatlyone entry is allowed (and required) here. The most ommonentries are:

C max

- makespan Minimizationof the maximum ompletion time.P w j C j

- weighted ompletion time Minimization of the total weighted omple- tion time of jobs.L max

- maximum lateness Minimizingthemaximalviolationofduedates. Latenessan take anegativevalue, whena job isnished earlier thanits due date.

P w j T j

- total weighted tardiness Minimizationoftheweightedsumofnon-negative lateness values of the jobs.P w j U j

- total weighted number of tardy jobs Minimizationoftheweightednum- ber of jobs that are not ompleted within the given deadline.Similarly to the other two elds,

C max

is a speial ase ofL max

when all the due datesare 0,and

P w j C j

is the speial ase ofP w j T j

.Obviously,ifaproblemlassisthesameorspeialaseofanotherinallofthethreeelds,

its solution an be redued to the solution of the less restrited one. Sine the algorithms

for the latter are appliable for the former one, the former an not be more omplex than

the latter one.

1.1.2 Classiation of solutions of sheduling problems

The term shedule refers to an assignment of eah task to units and time intervals in

most of the ases. There exist, of ourse, innitely many assignment funtions for a given

sheduling problem,and the termsolution is alsooftenused whenreferring toa shedule.

The shedules that do not satisfy atleast one of the onstraints of the problemdesription

are alled infeasible, and the others are termed feasible. Among the feasible shedules,

one is alled non-delay if no unit is kept idle while a task is waiting for proessing. It

is obvious that any feasible shedule an easily be onverted to a non-delay shedule, by

shifting eah taskas earlyas possible inthe solution.

A shedule for a problem is alled ative if there exists no other feasible shedule in

whih some of the tasks start earlier, and none of them starts later. Obviously, all of the

ative shedules must be non-delay shedules aswell.

Ative and non-delay shedules play an important role in the ase of makespan mini-

mizationobjetive, wherethe optimal solutionorsolutions must be non-delay, and at least

one of the optimalsolutionsan befound amongthe ative shedules.

1.1.3 Approahes and omplexity

Some lasses of the aforementioned problems an be solved to guaranteed optimality by

simple,polynomialalgorithms. Mostofthese problems,however, areproven tobeNP-hard,

thus eient algorithmsare not expeted for them.

1

1

Note, that there are polynomialalgorithms developedforsomeNP-hard problems, whihan provide

optimal solutionforthe majority ofthe instanesof theproblem lass, and asuboptimalsolution forthe

rest.

A simplestrategyouldbetoassignthejobstothe mahinesbasedontheinreasingor-

der ofproessingtimes. This, so-alledSPT (ShortestProessingTime)algorithmprovides

optimal solution for a ouple of problem lasses if the objetive is

P C j

. If the objetiveis

C max

, the opposite strategy, i.e., prioritizingjobs with the longestproessing time, often provides good ompetitive ratio forF F

problems.Among the easy to solve problems, the 2-stage ow- and job-shop sheduling problems

are probably the losest ones to industrial sheduling problems disussed later. In this

ase there are two mahines for either one or two stage jobs, and the objetive is

C max

,i.e., the minimization of the makespan. Johnson's[61 ℄ and Jakson's[58℄ algorithmprovide

an optimal solution for the sheduling problems in this lasses. However, inreasing the

numberofmahinesandstagesperjobmakestheproblemmuhmoreomplex,andeient

algorithmsare not expeted.

Also, in many ases, the problem denition of a real industrial ase study involves ad-

ditional parameters that need to be addressed. In suh ases, even oine problems with

parallel idential units beomeNP omplete[110℄.

1.2 Sheduling problems of hemial bath proesses

Shedulingproblems that arise inthe hemialindustry are more omplex intheir desrip-

tion, though they show many similarities to the basi problems desribed in the previous

setion.

Bathhemialsheduling problems are mostly given by their

1. reipe

2. storage poliy

3. objetive, and relatedparameters

4. additionalparameters

These parameters are desribed in the following subsetions in detail, however, some

words must be addressed to the assumptions and onventions of this eld.

Assumptions

If not stated otherwise, the followingassumptions are onsidered:

Unique alloation Ataskisassignedtoasingle unitinthe shedule,even if several

appliable ones are available.

Non-preemptivity The exeutionof a task must not beinterrupted

Bath proesses Eah task behaves in a bath-like favor. If atask is ontinuous, it

has suiently largedediated storages toonsider itas abath proess.

Fixed bath sizes The amount of material proessed in eah task is xed by the

produtionreipe.

Conventions

Thenotationusedamongsientistisnotstandardized. However, several onventionsareap-

plied, whihmayhangebasedontheatualexample. Toavoidfurtheronfusion,the most

ommonnotations are summarizedhere briey,as they willbeused alternatelythroughout

the whole doument in problemdesriptions, diagrams,et.

In ase studies, produts, tasks, units are usually assigneda realname. However, ifthis

is not the ase (frequent for literature examples), or the notations need to be shorter, the

followingonventions are used to labelthe elementsof the system.

Produts are oftendenoted by the rst apital lettersof the alphabet, i. e.,

A, B, C, . . .

,or by

P 1, P 2, P 3, . . .

.Tasks are often labeled after their produt, espeially in sequential reipes, like

A1

,A2

,A3

,. . .

. Insome papers, labelslikeT 1

orT 1

are applied. In mathematialformulationsthe dummy indexi

isused fortasks, thussometimes labels likei1

,i 1

,ori A1

are used.Units are similarlydenoted by

U 1, U2, . . .

, and sometimes labeled asEq.1

,E1

,orE 1

torefer to equipment units. In ase of the mathematial formulations, the applied dummy

index is

j

, thus sometimesj1

orj 1

is used as well.1.2.1 Reipes and example problems

The word "reipe" itself is an ambiguous term, as the ISA SP88 standard denes four

levels of reipes: generalreipe, site reipe, master reipe, and ontrolreipe[52℄, however,

none of these are entirelysatisfyingour requirementstowards areipe. Thus, thorough the

doument the term reipe willreferto the olletionof the followingparameters:

•

listof produts•

listof tasks, that are to be performedin order toprodue the produts•

produtional preedenes amongtasks 2•

availableunits•

proessing times forsuitable task-unit pairs2

Thisisoftenindiretlygivenbyprovidingtheinputsandoutputsof tasks.

Thereipeofaprodutreferstotheinformationinthereiperelatedtothatspeiprodut.

Based onthe preedene struture among tasks, the reipesare usually ategorizedinto

the followinggroupsstartingfromthe simplestone tothe most generalone. Eahlass isa

spei ase of the next one.

Single stage Eah produt is produed via a single step. Similar to the

P m

ase,but the available units are not neessarily idential or uniformlyappliable.

Simple Multiprodut Similarto an

F F c

layout, i.e,eah produt is produed lin-early through a xed number of stages. The dierene is the same as in the

previous ase: theunits atastage are usually notidential and annot perform

the same subset of tasks.

General Multiprodut Often referred to as Multiprodut reipe, the generaliza-

tion to the simple ase allows for a prodution plan toskip several stages.

Multipurpose Unlikeinthe Multiprodutase, thestagesannotbeorderedinsuh

a way along a line that the prodution of eah produt goes from left to right.

Thenumberofstagesandtheirorderisarbitrary. Moreover,astagemayreour

several times inthe sameprodution. This isthemost generalsequential reipe.

Preedential The tasks in the prodution of a produt are not assigned to stages,

and the preedene between them is given apiee. The key dierene between

the multipurpose and preedential reipes isthat the prodution of aprodut is

not neessarilylinear, i.e., therean bejuntions init,but inthe ase of several

prerequisites for a task,all of them must be ompleted before startingit.

3

General network Thisis themost generalreipelass, wherethetasksare given by

their inputs andoutputs, whih indiretlydene theirpreedenes. Here, unlike

the Preedentialase, thesame materialmaybe produed by several alternative

tasks making them optionaland not mandatory prerequisites. Moreover, yles

may our inthe dependenies.

It is important to note that although some papers have attempted to provide a las-

siation of sheduling problems[32, 93℄, the terminology is not standardized. Terms like

"multiprodut" may refer to (slightly or signiantly) dierent reipe lasses in dierent

papers.

4

The above lassiation is the proposition of the author, that satises the following

importantriteria: mostof the publishedapproahes an unambiguouslyassignedtoone of

the dened problemlasses.

3

Obviously,thedependeniesmustnotreateayle.

4

Thesedenitions aremostlyindiretbytheproblemlassesoveredbythepresentedapproah. Many

artiles state that the proposed approah or formulation solves e.g., multiprodut sheduling problems.

However,theproblemlassoveredbytheseapproahesvaryforeahpaper,makingtheindiretdenition

ofthemultipurpuseproblemlassinonsistent.

Reipe representations and example problems

Single stage reipes are usually simply given by a table, where the rows orrespond to

jobs,theolumnstounits,andeahellontainstheproessingtimeiftheunitisappliable

forthatprodut. Kopanosetal.[67℄presentedsuhaasestudy,whosedataisgiveninTable

1.1.

5

Proessing times (h)

U1 U2 U3 U 4

P 1

1.538 1.194P 2

1.500 0.789P 3

1.607 0.818P 4

1.564 2.143P 5

0.736 1.107P 6

5.263 3.200P 7

4.865 3.025 3.214P 8

1.500 1.440P 9

1.869 2.459P 10

1.282P 11

3.750 3.000P 12

6.796 7.000 5.600P 13

11.25 6.716P 14

2.632 1.527P 15

5.000 2.985Table 1.1: Example data for asingle stage problem

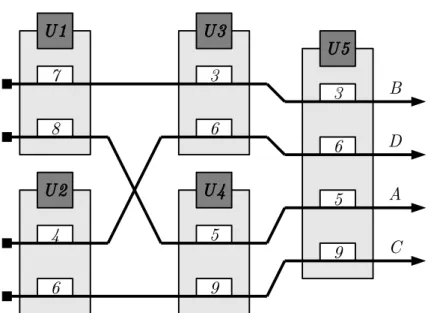

Multiprodut reipes an still be represented by tables. However, inmany ases blok

diagrams are simpler to desribe the problem. The problem from Voudouris et al.[126℄ is

presented in Table 1.2and asa blok diagramin Figure1.2. Note, that the blok diagram

is onlysuitable if eahtask an be performed by exatly one unit ata stage.

Proessing times (h)

Stage 1 Stage 2 Stage 3

U 1 U2 U 3 U4 U 5

A

7 3 4B

8 5 3C

4 6 4D

6 9 3Table 1.2: Multiprodut examplerepresented ina table

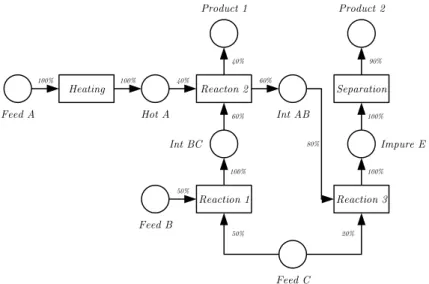

Multipurpose reipes are diult to represent in a table, as the order of the stages

are arbitrary. If eah task an be performed only by a single unit, the blok diagram is a

suitable hoie, asrepresented in Figure1.3 foran example by Ferrer-Nadal et al.[31℄.

5

Theproblempresentedinthepaperontainedadditionaldataforhangeoversaswell.

Figure1.2: Multiprodut example represented ina blok diagram

Figure1.3: Multipurpose example represented ina blok diagram

Preedentialreipes areusuallyrepresentedbysomekindofgraphs,wherethetasksare

assignedtothe verties,and the arsrepresent theprodutional dependenies. Anexample

by Holzinger[52℄is illustrated in Figure1.4. The proessing time and the appliable units

areindiatedateahvertex,anditisassumed thattheproessingtimeisthesameifseveral

units are suitable.

Figure1.4: Preedentialexample represented in agraph

Generalnetworkreipes aremostoftenrepresentedbyState-Task-Networks(STN[66℄)

or Resoure-Task-Networks (RTN [100℄). The original example for introduing the STN

representationfromKondilietal.[66℄isgiven inFigure1.5. Cirleshaped vertiesrepresent

materials, while retangles represents tasks. This graphialrepresentation sometimes does

not ontain proessing times, it is provided in an additional table. The representation is

idential to that of the P-graph mathematialmodelintrodued by Friedler et al.[33℄, that

wasdevelopedfortheoptimaldesignofontinuousproesses.[34,36,35℄Thekeydierenein

anRTNrepresentationisthatunitsarealsorepresentedasresouresandtasksaredupliated

if several units an perform them. Some papers use the so-alled State-Sequene-Network

representation[84℄, where dediated states (mostly materials) give the verties, and ars

represent tasks.

1.2.2 Storage poliies

The term,storage poliy refers tothe onstraintsforthe storageofintermediateproduts

between onseutive tasks of a reipe. For eah material there are two fators that an

indue onstraintson itsstorage:

1. Chemial and physial properties of the material

2. Infrastrutural opportunities for storage inthe given plant

Thus, storagepoliyisatwodimensionalpropertythatandierforalloftheintermediates

in the reipe. In the majority of the ases, however, the poliy is uniform for all of the

intermediate materials.

Figure1.5: STN representation of a generalnetwork reipe

The hemialand physialproperties of the materialprovidebounds onthe time ofthe

storage, based onwhih the followingategories are usually identied:

UW - Unlimited Wait isthesimplestand mostommonpoliy,when thematerial

doesnotloseanyofitsimportanthemialorphysialpropertiesbytime,thusit

anwaitanyamountoftimebeforegoingtotheupomingtaskoftheprodution.

LW - Limited Wait storage poliy is applied to the intermediate materials that

must not wait longer than a ertain amount of time before the next task in

order not to lose a ertainproperty, e.g., ooling out.

ZW - Zero Wait poliy isstritly speaking the speial ase of the LW poliy, when

the limiton the storage time equals to0.

Theinfrastruturalapabilitiesofthegivenplantimposelimitsontheamountofmaterial

that an bestored, and onthe way of storing it:

UIS - Unlimited Intermediate Storage poliy is applied when there is enough

storage plae available tostore any amountof intermediates.

FIS - Finite Intermediate Storage poliy is onsidered when there are storage

units availableto store the intermediate, but it islimited.

NIS - No Intermediate Storage poliy refers to the ase when dediated storage

unitsare notavailableforthestorageofanintermediatematerial,butitstillan

wait inthe proessing unit of the previous task.

In many papers, the storage poliy is not dened by a pair, as UW poliy is assumed

for UIS, FIS, and NIS if not stated otherwise. In the ase of ZW poliy, the limit for the

storage spae isirrelevant,thus it isoften used initself asit is, and this is the reason,why

it isnot takled as aspeial ase of LW.

Although,theombinationoftheabovementionedpoliiesoversmostoftheases,there

are always pratial problems whih require speial denition. One of the most ommon

examples is the Common Intermediate Storage poliy (CIS), where there is (typially

nite)storageavailablethatissharedamongseveral intermediates,andatmostoneofthem

an use the storage ata time.

Storagepoliyisanimportantparameterofthe problemdenition,hangingthestorage

poliy ofthe probleman hange the optimalsolution,the set of feasible solutions,and the

appliable approahes as well.

1.2.3 Objetive funtions

Industry provides a wide range of objetives resulting from pratialonsiderations. How-

ever, thetwomost ommonobjetivesarethe minimization of makespan andthe max-

imization of throughput.

Makespan minimization

Makespan minimization is equivalent to the denition of

C max

in the previous setion. Ingeneral,the minimaloverall proessing timeisto befound fora given numberof bathes of

eahprodut. In many aseshowever, thenumberofbathesisnot speiedintheproblem

denition, only the amount of produts to be produed, thus, the number of bathes an

hange if the reipe allows variable bath sizes. Larger number of bathes may lead to

better solution, when the smaller units are less loaded, or the proessing time depends on

the quantity.

Throughput maximization

Inaseof throughputorprotmaximization,theproblemdesriptionentailsatimehorizon

aswell asaertainbenet value foreahprodutthat isusually based onmass, prot, and

revenue. The goal is to maximize the umulative benet of all of the produed produts

whilekeepingtheprodutiontimebelowthetimehorizon. Thenumberofbathesoramount

of produts is usually unbounded, it is even allowed to leave out some of the produts

ompletely.

Other objetives

Although these two are the basi and most ommon objetives that provide the basis for

omparison of the sheduling approahes, there are plenty of other objetives that arise in

real life hemial prodution. Without attemptingto be omprehensive, some of themare:

•

minimizingthe ost of total earliness-tardiness•

minimizingthe lean water use, and inparallelthe wastewater euents (See e.g.,[20,28,40, 44,83℄)

•

minimizingheat utilityenergy orost (See e.g., [19, 54, 73,74,81, 130℄)•

optimization for a ombined ost funtion that may inlude utility ost, lean water osts, et. (See e.g., [43,38, 80℄)•

maximizingthe overall expeted prot•

maximizingyli prot(See e.g., [105,19, 73℄)•

minimizingthe over-or underonsumption of eletriity (See, e.g., [94℄)•

minimizingtransportationost (See e.g., [106℄)•

et.1.2.4 Common additional parameters

Sheduling problems arising in industry often entail further problem spei parameters.

Some of them may not play important role in the shedule, thusit is negleted orapproxi-

mated,e.g.,thetemperatureandoolingofamaterial,ontrolparametersoftheproess. In

manyases,however, theseparametersmustbeinludedintheproblemdenition. Without

attempting tobeomprehensive,some of the most ommon additionalparametersare:

Cleaning time Some tasks leave a unit ontaminated, making it unsuitable for any

upomingtask,thusitneedsleaning,whihisoftenomparablewithproessing

times. Seee.g.,thepaintprodutionexamplebyAdonyietal.[1℄. Thisparameter

usually depends on the task-unit pair.

Changeover time This parameterissimilartothe leaningtime,whihan be on-

sidered as a speial ase. The dierene isthat ahangeover time alsorelies on

the subsequent task that is sheduled for the unit. This happens for example

when a unit must be adjusted before undergoing a ertain task.

6

See e.g., the

examples inthe papers by Kopanos et al.[67, 68℄.

Transfer time Often, the time required for the transfer of intermediates from one

unit to an other is not negligible. See e.g., the examples by Grau et al.[41℄.

This parameter is usually dened for the triple of soure unit, material, and

destination unit. If the transfer is ontinuous, both units must be available

during the material tansfer. If the transfer is disrete like in the ase of the

6

Setup times are in this sense also a speial ase of hangeover times, as theydo notdepend on the

previoustaskofaunit.

shedulingof wet-ethstations[5,7,6,13,12,18,37,62,95,129, 128℄,the units

may beused for other purposes duringthe transfer.

7

Unit piping Ifthe intermediatesare liquid,thustheir transportbetween the unitsis

mostly done via pipes and ompressors. Although several appliable units may

be available for two subsequent stages of a prodution, the piping (or better its

absene between two units) limits the possible hoies. See e.g., Kopanos and

Puigjaner[69℄.

Cleaning the units,transferring materials,et. obviously entailsosts, energy onsump-

tion, lean water onsumption, wastewater generation, et., whih are often onsidered as

onstraints forthe shedule aswell.

Some papers onsider shedulingintegrated withproessplanning[41,70,116℄orontrol

level deisions[108, 15℄, and inlude relevant parameters from that level and a ombined

objetive.

1.2.5 Representation of a shedule

A shedule is basiallya set of quadruplets inthe form of

(i, j, t s , t f )

, where:i

is the task to beperformedj

isthe unit toperform taski

t s

,t f

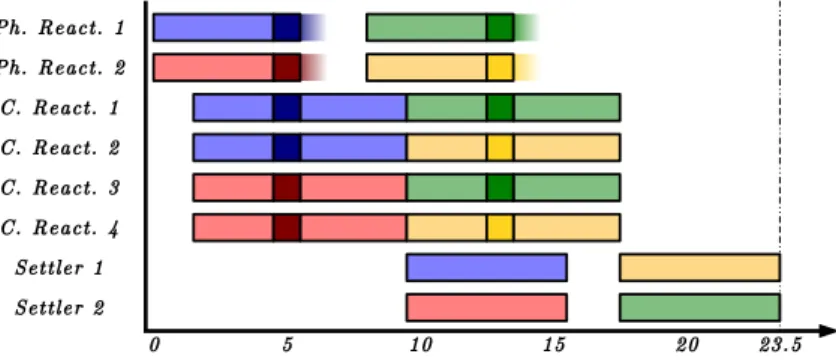

are the starting and nishingtimes respetivelyThe prevalent graphial visualization of this data is the Gantt hart, see Figure 1.6 as

anexample for 8sequential produts. The

x

axisrepresents time,while the units are listedon the

y

axis. Eah task isrepresented by a retangle in the row of the unit performing it, ranging fromitsstarting time toits nishingtime horizontally.Figure 1.6: Example Gantthart for 8 produts

7

Note,thatinaseofwet-ethstations,therobotarmperformingthetransfermustbesheduledasthe

otherunits (bathsin thisase).

To enhane visibility, the retangles of the tasks belonging to the same produt are

usually highlighted with an idential olor. In many ases, espeially if olors are not

applied todierentiate between produts, onlythe name of the produt is indiated atthe

retangles.

If the problem inludes hangeover, leaning, or transfer times, they are represented

analogously with retangles. In Figure 1.7, a shedule for produing PHBA (para-hydroxy

benzoi aid)isillustrated. Here, fourbathes ofthe same produtare produed,thuseah

bathhas itsdesignated olor. The reipe is not sequential, whilethe phenolate reationis

exeuted in therst orseondphenolate reator,marlothermis lledintoand heatedup in

twoparallelarboxylationreators. When the phenolate reationnishes, the intermediate

istransferredtothe twoseletedarboxylationreators,represented bydarkenedretangles

at all of the three reators. After the transfer nishes, the phenolate reators need to be

leaned, whih isvisualized asa fadingretangle.

Figure1.7: Example Gantthart fornon-sequentialreipewithtransfer and leaningtimes

Mathematial tools for the sheduling of

bath hemial proesses

In the lasttwodeades, manydierent approahes have been published inthe literature to

takle the problems presented in Setion1.2. They dier in both their domain of solvable

problems, and the applied mathematialtools. Overthe years, these approahes have gone

through vastdevelopment, whose goalwas dual:

1. broadening the range of solvable problems

2. aeleratingthesolutionproedures inordertobringlargerproblemstoamanageable

level

Theadvanementinbothdiretionsisremarkable. Therst,heuristisbasedapproahes

have onsideredonly simplemultiprodut examples,and ould not guarantee optimal solu-

tions for even the smaller instanes. The rst optimization based methods were extended

toa wide rangeof problems. Interms of speed, omputationaltimeswere redued by mag-

nitudes, allowing not only the solution of larger problems, but also integration with other

ontrolor designaspets.

In order toprovideareview ofthe state-of-the art toolsof theeld inthe next setions,

these approahes must be ategorized beforefurther disussion. This ategorization an be

based on various aspets. The most ommon one is to onsider the applied mathematial

tool asthe major attribute[32,93, 48℄.

The majority of the published approahes rely on mathematial programming, namely

on Mixed-Integer Linear Programming (MILP) formulations, or Mixed-Integer Non-linear

Programming (MINLP) models in rare ases[32 , 93℄. These models are usually solved by

an implementation of general purpose MILP algorithms[127℄. In ase of MINLP problems,

the authors have also developed general purpose MINLP solution proedures.[42 ℄ Another

branhof researh fouses onapplying graphtheoretial and ombinatorialtoolsand prob-

lemspei solutionproedures. Among thesethe S-graphframework[112℄, theAlternative

Graph model[98℄, and the Timed Pried Automata[99℄ or Timed Plae Petri Net[39℄ ap-

proahes are notable. A small number of papers onsiders mathematial logi [103℄ or

Constraint Programming (CP)[128℄ to takle sheduling problems. More often, these tools

are used ombined with other approahes, likeMILP formulations[87, 107℄.

These lastly introdued lass of approahes will not be disussed in more detail. The

lassiation of ombinatorial approahes based on the exat tool is enough for further

disussion. In the ase of MILP models, however, further ategorization is needed before

investigatingthem losely.

The further lassiation of MILP formulations an be best explained by the binary

variables used to address sheduling deisions. Though the variables may dier in some

detailsfordierentapproahesinthesame sublass, theseminordierenes willbedetailed

in the subsequent setions.

Preedene based formulations binary variable

X i,j,i ′

representswhethertaski ′

ispreeded by task

i

in unitj

.Time point/slot based formulations has abinary variable

y i,j,n

denotingwhetherunit

j

perform taski

at time pointn

, orin then

th slot.Start-Stop formulations 1

usevariables

Start i,j,n

andStop i,jn

torepresentthestart-ing and nishingof task

i

in unitj

at time pointn

Some formulations apply several dierent tehniques redundantly in the hope of a better

performane, and thusannot be ategorizedunambiguously[64℄.

Before disussing these approahes in detail, one other lassiationhas tobenoted by

Hegyhati and Friedler [47℄, thatonsiders the underlyingidea of addressing the problemas

the mainategorizationangle. This aspet hasvariousbenets, the approahes inthe same

main ategory

•

an usually address the same or very similar set of sheduling problems;•

have similarperformane•

an benetfrom the development of others, orimplementtheir idea of improvement;•

suer from the same diulties and shortomings The proposed main ategories are:Time disretization based tehniques onsistofthetimeslotandtimepointbased

approahes, and the Start-Stop models, whih rely on the disretization of the

time horizonthatan leadtosuboptimaloreven pratiallyinfeasiblesolutions.

On the other hand, they an address a wider range of sheduling problems,

though the implementationof sequene dependent attributes are ompliated.

1

There isno ommonlyused terminologyfor thisset of formulations,theStart-Stop term isused only

here.

Preedene based tehniques onsidertheorderoftasksassignedtothesameunit

as the key deision, rather then their exat timing. Preedene based MILP

models,theS-graphFrameworkandtheAlternativeGraphmethodsbelonghere.

Theseapproahesoftenoutperformthepreviouslymentionedonesonthe lassof

shedulingproblemsthey antakle,thoughthis domainisonsiderablysmaller.

An additionaladvantage isthe absene of suboptimalorinfeasiblesolutionsdue

modeling errors.

State spae based tehniques areperformingthe optimizationvia asophistiated

exploration of the state spae of the system. Although, similarly to the pree-

dene based methods, their model building ensures global optimality, in terms

of performane and modeling power they drop behind the aforementioned ap-

proahes. Thesigniantadvantage ofthesemethodsresidesinthe possibilityof

integration with the ontrol level, and their straightforward extension to online

problems.

2.1 MILP formulations

Asitwasalreadydisussed,theMILPmodelsplayadominantroleinsolvingbathshedul-

ing problems. In this setion the dierent branhes of MILP models are disussed. The

related modeling issues are not disussed here, only briey mentioned, as they willbe pre-

sented in detail inChapter 3.

Before thedetaileddesriptionofdierentMILPformulationbranhes, thereisanother

lassiationaspetthatneedstobementioned. Thereexistso-alledSTNandRTNmodels

forallof theformulationtypesthat willbedisussed later. ThoughSTN and RTNare only

representation tools, this terminology is widely used to indiate how proessing units are

takled in he model. In STN formulations, units are dediated elements of the model,

thusthe binary variablesusually haveanindex forunits aswell,indiatingwhether atasks

starts,nishes, orpreedes anotherinaertainunit. Ontheotherhand,RTNformulations

onsider unitsasanyotherresoures,e.g.,materials,andthetasks"onsume"and"release"

these resoures whentheir exeutionstarts and nishes. As aresult, units donot expliitly

appear inthe models, onlyaset of materialbalaneonstraints refertothem. Notethat in

RTNmodels, a taskshould be dupliatedif it an be performed by several dierent units.

2

In the followingsubsetions the examplesare given for STN models,fromwhose theirRTN

ounterpartan bederived easily).

2

Note thatevenamongRTN models, stritand lenientmodels anbedierentiated,whih anhavea

notable impat onthe performane asindiated by Eles [30℄. If several idential units are available, the

lenient RTN models onsider them separate resoures, implying a sort of redundany, while strit RTN

modelsonsider themasasingleresourewithhigheravailability.

2.1.1 Time disretization based formulations

Chronologially these types of formulations were the rst ones to appear in the literature

[66℄. Their underlyingidea is toidentify several time points ortime slots over the time

horizon. Time slotand time pointbased approahes [124℄ show a lotof resemblane,as an

interval froma time point tothe next one an be onsidered as a time slot, and vie versa

the startingtimeof atimeslotanbeonsideredasatimepoint. Althoughtimeslotbased

approahes were mainlydeveloped for sequential proesses and the time point approahes

taklegeneralnetworkproblems,thetwolassesofapproahesareaddressedsimultaneously

in this setion. If not indiated otherwise, statements for time point approahes hold for

time slotapproahes aswell.

Ateahtimepoint,binaryvariablesareassignedtotasksdenotingwhethertheexeution

ofthe taskissheduled tostartatthattimepointornot. Asaresult,the numberofbinary

variables isroughly proportionaltothe numberof timepoints,i.e., the omputationaltime

strongly depends on the number of time points. Thus, it has always been the researhers

intention to develop models that an nd the optimal solution with minimal number of

time points. However, it is not evident, how the suient number of time points an be

determined fora modeland aprobleminstane. The most ommonlyappliedmethodology

is to onsider a smallnumber of time pointsrst, and perform the optimization. Then the

numberof time points is inreased by one, and the optimization is arried out again. This

laststep is repeateduntil the same objetivevalue isfound for two onseutive steps. This

tehnique, however, does not guarantee the optimal solution, whih is disussed in detail

in Setion 3.1. Nevertheless, the vast amount of development foused on these approahes

ahieved a signiant redution in the neessary number of time points. However, the

advaned models often beame less transparent, the onstraints beame more ompliated

and modelingerrors ourred.

In general, time disretizationtoolsan address the widestrange of shedulingproblem

withgeneralnetworkreipes,reyling,exiblebathsizes,loaddependentproessingtimes,

et. An other advantage of these models is that there is no need to dene the number of

bathes a-priorithe optimization,asateah time pointthe deision ismade independently

oneah task. This feature alsoallows these models toaddress several units performingthe

same tasks inparallel, withoutany modiation.

The following subsetions present the key properties and elements of models belonging

to abranh of formulations.

Fixed time point models

In the early time disretization models, the time points was equidistantly seleted prior

to the optimization proess, resulting in the so-alled Disrete-time models[66 ℄. The

used terminology in the literature is misleading in this ase, as the later, more advaned

approahes also disretize the time, the only dierene is whether the plaing of the time